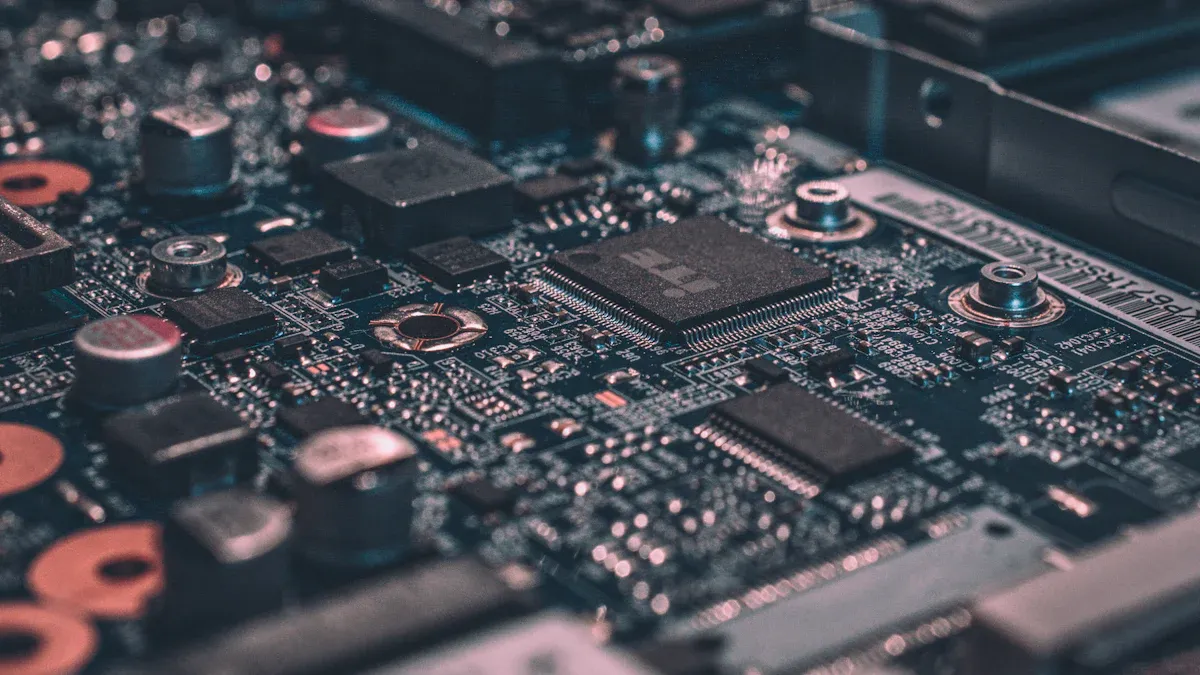

What Are IC Substrate PCBs and Their Key Functions?

IC substrate PCBs are special circuit boards for modern electronics. They link tiny chips to bigger systems for smooth data transfer. Small and fast devices need IC substrates to work well. For example:

Gadgets use IC substrates to work faster and better.

Cars need IC substrates for electric and self-driving features.

5G networks use IC substrates for quick data sharing.

These boards are very important in areas like space, military, and communication, where they must be dependable.

Key Takeaways

IC substrate PCBs link tiny chips to bigger systems. They help data move smoothly and signals stay strong.

These PCBs handle heat well by using special materials. This keeps devices cool and makes them last longer.

IC substrates are important for modern gadgets like phones, cars, and airplanes. They are also used in telecom and space tech.

Key Functions of IC Substrate PCBs

Electrical Connections and Signal Flow

IC substrate PCBs connect small chips to larger systems. They help signals move smoothly by creating exact electrical paths. Copper foil is used as the main conductor. It is layered to form complex connection patterns. Thin insulating layers separate the copper to keep signals clear. These layers reduce signal loss and stop interference.

Engineers use tools like Cadence Quantus to study noise in circuits. This tool shows noise patterns with 2D maps and 1D graphs. It helps find and fix signal problems. For RF designers, Quantus predicts noise spikes and helps avoid signal issues. This ensures signals stay strong and reliable.

Managing Heat and Cooling

IC substrate PCBs also help control heat in devices. Smaller, faster gadgets create more heat, which is hard to manage. These PCBs use special materials like phase change materials (PCMs) and heat pipes (HPs). These materials remove heat better, even in small spaces.

Unlike older cooling methods, IC substrates handle changing workloads well. They make devices last longer and work more reliably. New ideas like nanomaterials and liquid cooling may improve heat control even more in the future.

Aspect | IC Substrate Cooling Methods | Older Cooling Methods |

|---|---|---|

Heat Control | Works better in small designs | Limited by size |

Reliability | Increases device lifespan | Depends on design |

Flexibility | Handles changing workloads | Fixed performance |

Material Innovation | Uses advanced materials like PCMs and HPs | Basic materials |

Support for Chips

IC substrate PCBs give strong support to chips. Materials like BT, ABF, and FR4 are tough and resist heat. These materials keep chips steady and safe during use.

The making process adds strength to the PCBs. Layers are joined, and holes are drilled to connect them. Special finishes protect copper parts from damage. This keeps chips working well in devices like phones and cars.

Differences Between IC Substrate PCBs and Regular PCBs

Design and Structural Variations

IC substrate PCBs are very different from regular PCBs. They are smaller and more detailed. These PCBs handle many connections for modern chips. Layers of copper and insulation create tiny paths for signals.

Regular PCBs are bigger and simpler. They are used in devices where space and speed are less important. These PCBs have fewer layers and basic designs, making them good for simple gadgets like appliances.

IC substrates have special features like microvias and thin-line patterns. These help make small devices that still work fast. Regular PCBs use older designs like through-holes or surface mounts. These designs can't handle the needs of today's advanced chips.

Material Composition and Manufacturing Techniques

IC substrate PCBs use better materials than regular PCBs. They often include BT resin or ABF, which handle heat and electricity well. These materials are great for fast and high-frequency devices.

Regular PCBs usually use FR4, a cheaper material. FR4 works fine for everyday electronics but isn't as strong as IC substrate materials.

Making IC substrates needs advanced methods like laser drilling and electroplating. These steps create precise and tiny features. Regular PCBs are made with simpler, less accurate methods that cost less.

Attribute | IC Substrate PCBs | Regular PCBs |

|---|---|---|

Material | High-quality (e.g., BT resin, ABF) | Basic (e.g., FR4) |

Manufacturing | Advanced (e.g., laser drilling) | Simple methods |

Complexity | Handles many connections | Basic designs |

Applications in Advanced Electronics

IC substrate PCBs are key in high-tech devices. They are found in smartphones, laptops, and 5G systems. These PCBs allow powerful chips to fit into small gadgets, making them faster and better.

Regular PCBs are used in simpler products. These include home appliances, toys, and basic machines. While useful, they can't handle the speed and power of advanced electronics.

IC substrates are also used in cars and space tech. For example, they are in self-driving systems and satellites. Regular PCBs are not reliable enough for these critical uses.

Attribute | IC Substrate PCBs | Regular PCBs |

|---|---|---|

Applications | High-tech (e.g., 5G, satellites) | Everyday electronics |

Performance | Fast and powerful | Standard |

Reliability | Needed for important systems | Good for basic use |

IC substrate PCBs are better than regular PCBs in design, materials, and uses. They are crucial for modern chips and advanced devices, keeping them small, fast, and dependable.

Types of IC Substrate PCBs

Packaging-Based Classification (e.g., Flip-Chip, Wire Bonding)

IC substrates are grouped by how chips are attached. Common methods include Flip-Chip (FC), Wire Bonding, Ball Grid Array (BGA), and Chip Scale Packaging (CSP). Flip-Chip connects chips directly to the board with solder bumps. This allows faster signals and compact circuits. Wire Bonding uses thin wires to link chips to the board. It works well for simpler designs.

Classification Category | Examples | Description |

|---|---|---|

BGA, CSP, MCM, FC | Ways to attach chips to the board. |

Material-Based Classification (e.g., Organic, Ceramic)

IC substrates are also sorted by the materials used. Organic types, like BT resin and ABF, are light and affordable. They are great for fast and high-frequency devices. Ceramic types, such as alumina and aluminum nitride, handle heat well and are very strong. Aluminum nitride, for example, conducts heat 100 times better than FR4. This makes it ideal for devices that get very hot.

Material Type | Thermal Conductivity | Dielectric Constant |

|---|---|---|

Alumina | ~20x FR4 | 9.0 to 10.0 |

Aluminum Nitride | 8.6 to 9.0 |

Bonding Technology Classification (e.g., Solder Bump, Wire Bond)

Bonding technology shows how chips connect to the board. Solder Bump, used in Flip-Chip designs, creates strong connections and manages heat well. Wire Bonding is simpler but less effective for dense circuits. Cleaning bonding surfaces with plasma can boost pull force by up to 300%. This ensures stronger and more reliable connections.

Surface Condition | Pull Force Test Result (N) | Improvement (%) |

|---|---|---|

Contaminated Pads | Low | N/A |

Cleaned with Plasma | High | Up to 300% |

IC substrates come in many types to meet different needs. Whether you need better heat control, dense circuits, or lower costs, there’s an IC substrate for your device.

Applications of IC Substrate PCBs Across Industries

Consumer Electronics (e.g., Smartphones, Laptops)

IC substrate PCBs are key parts of gadgets like phones and laptops. These devices need to be small, fast, and cool while working. IC substrates help make this possible with tiny, powerful designs. The global market for electronics may pass USD 1 trillion by 2028. This growth shows how important IC substrates are for multitasking and staying connected in modern devices.

Automotive Electronics (e.g., ADAS, EVs)

Cars use IC substrates for systems like ADAS and electric vehicles. These systems need fast data processing and energy-saving features. IC substrates keep connections strong and manage heat well, even in tough conditions. As cars use more electronics, better substrates are needed. This demand pushes new ideas in car technology, making IC substrates vital for modern vehicles.

Telecommunications (e.g., 5G Infrastructure)

IC substrates are important for building strong 5G networks. These networks need materials that keep signals clear and save energy. Companies like Qualcomm use IC substrates to make better 5G systems. For example, Qualcomm's 5G module shows how substrates help high-speed communication. IC substrates make networks faster and more reliable, improving telecom technology.

Metric | Description |

|---|---|

Dielectric constant | Helps keep signals clear in 5G networks |

Loss tangent | Reduces energy waste in substrate materials |

Benchmarking low-loss | Compares materials for better performance |

Medical Devices and Aerospace

IC substrates are very useful in medical tools and space equipment. In medical devices, they help ensure accurate and dependable results. These substrates support powerful chips for precise operations. In aerospace, IC substrates work well in extreme conditions and stay safe. They are used in imaging tools, portable monitors, and defense systems. Their strength and reliability make them perfect for important tasks in these fields.

Why Pick LT CIRCUIT for IC Substrate PCBs?

Modern Manufacturing Methods

LT CIRCUIT uses advanced methods to make top ic substrates. They use laser drilling, electroplating, and special lamination steps. These methods create accurate designs for today’s ic pcb needs. Their focus on new ideas improves how substrates handle heat. This is very important for fast electronics. Their careful work makes LT CIRCUIT a top choice in the field.

Top Materials and Custom Options

LT CIRCUIT uses high-quality materials like BT resin and ABF. These materials help with heat control and electrical performance. They make sure devices work well in advanced systems. You can also design your ic pcb to match your needs. Choices include solder mask colors, finishes, and testing options. This lets you create substrates for your specific projects. Whether for gadgets or cars, LT CIRCUIT has you covered.

Trusted by Big Industries

Big companies in many fields trust LT CIRCUIT’s ic substrates. Telecom, car, and space industries use their products for key tasks. You can rely on their skill to make strong and efficient pcbs. Their focus on quality and new ideas keeps your devices working well, even in tough conditions.

IC substrate PCBs are crucial for today’s electronics. They link chips to systems, control heat, and keep signals clear. These abilities make them important for powerful devices.

IC substrates boost electrical performance and handle heat better.

They help advanced gadgets multitask and connect quickly.

Their heat control keeps data centers running smoothly.

LT CIRCUIT makes high-quality IC substrate PCBs. Their smart designs are perfect for modern electronics.

FAQ

How are IC substrate PCBs different from regular PCBs?

IC substrate PCBs are smaller and more detailed. They use better materials and methods to work with fast, high-tech devices. Regular PCBs are simpler and made for basic electronics.

Can IC substrate PCBs work in tough conditions?

Yes, IC substrate PCBs are made with strong materials like BT resin and ceramic. These materials can handle heat and pressure, making them great for cars, space, and medical tools.

Why pick LT CIRCUIT for IC substrate PCBs?

LT CIRCUIT uses advanced tools, top materials, and custom designs. Many big industries trust them for making reliable and efficient PCBs for modern devices.

See Also

An Overview of PCB Printed Circuit Boards and Essentials

The Components That Comprise Printed Circuit Boards

The Importance of ENEPIG in PCB Production Explained