Understanding Immersion Gold Finish in PCB Manufacturing and Its Impact on Device Longevity

Immersion Gold Finish helps devices last longer. It makes strong and safe solder joints. It also keeps parts safe from rust. Studies show that the right gold thickness is important. Even gold layers help signals stay clear and strong. LT CIRCUIT uses new technology to make great PCBs. This helps electronics work well for a long time.

Key Takeaways

Immersion Gold Finish (ENIG) keeps PCBs safe from rust and oxidation. This helps devices last longer and work well in hard places.

ENIG gives a smooth, flat surface. This makes strong solder joints. It is good for small, close parts in new electronics.

LT CIRCUIT uses new technology and careful checks to make strong PCBs with ENIG. This makes sure they work well and customers are happy.

Device Longevity

Reliability Factors

How long a device lasts depends on many things. The materials in a printed circuit board (PCB) are very important. Using a good finish like Immersion Gold Finish helps protect the PCB. The nickel layer acts like a shield. It keeps the copper safe from damage and rust. The gold layer adds more protection. Gold does not rust or get dirty easily, so it keeps connections working well.

A flat and smooth surface is also important. This kind of surface helps make strong solder joints. Strong solder joints hold parts tightly to the board. They also help signals move without problems. The finish works well with fine-pitch parts. These are small parts that sit close together. This is needed for new electronics that must fit many parts in a small space.

Tip: Devices with a good finish can last longer, even in places with lots of moisture or very hot and cold weather.

Manufacturers also check if the finish stops oxidation. Oxidation can make metal parts weak. The nickel and gold layers stop this from happening. This helps the PCB work well for many years.

Real-World Impact

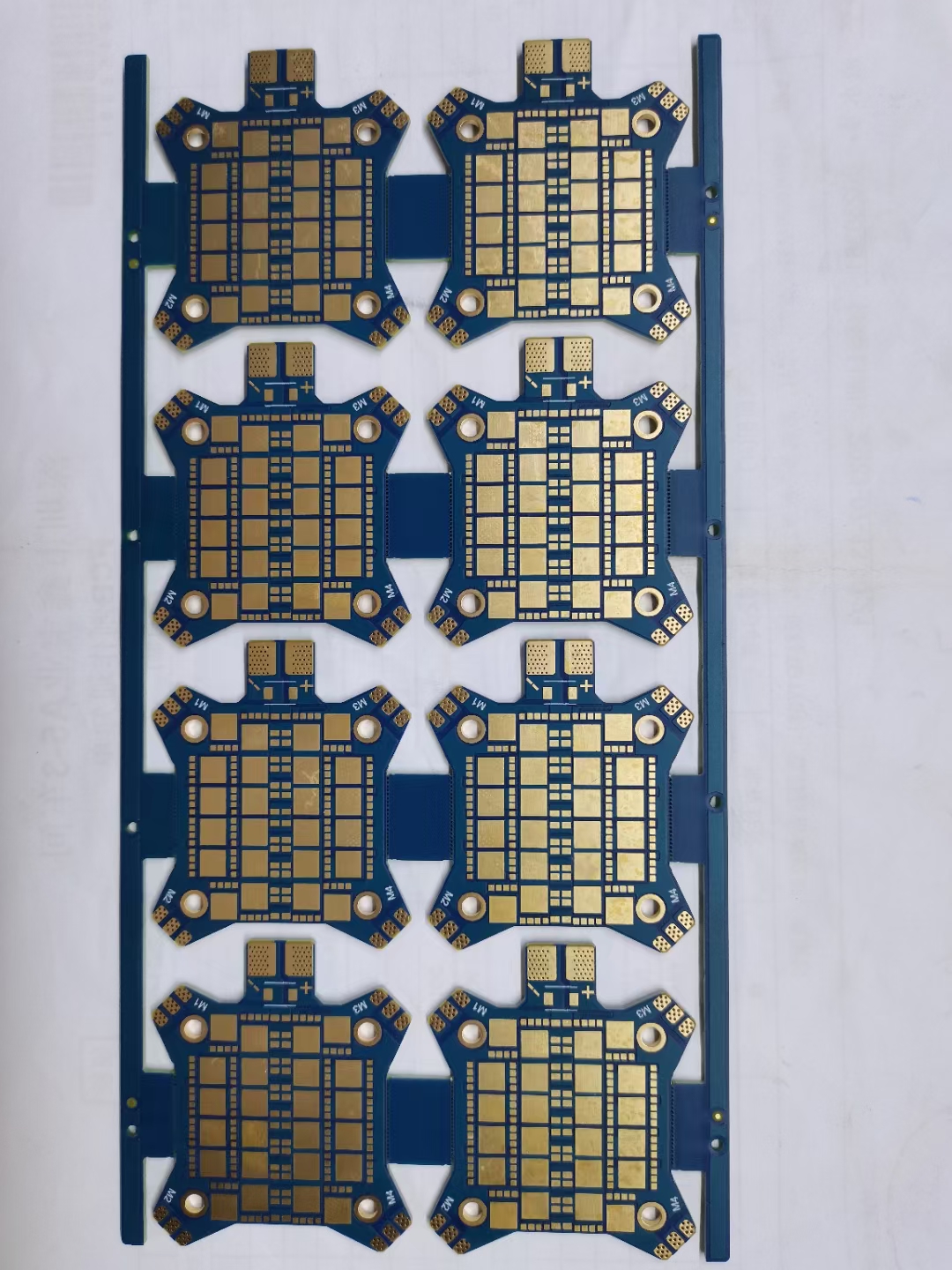

A strong PCB finish helps many types of products. Things like phones, cars, medical tools, and airplanes need PCBs that last. These devices face tough things like heat, water, or chemicals. A finish like Immersion Gold Finish protects the board from harm.

In cars, PCBs must handle shaking and changes in temperature. The nickel and gold layers stop rust and keep circuits safe.

Medical tools must always work right. The smooth gold surface helps put parts together and keeps connections strong.

In telecommunications, devices work for years without stopping. The finish keeps solder joints strong and signals clear.

Aerospace gear faces very hard conditions. The protective layers help the PCBs last and work well.

The finish also helps when storing and building the boards. PCBs with this finish stay good for a long time. This means makers can store them without worry. When it is time to build, parts stick on easily and stay in place.

A table below shows how this finish helps different industries:

Industry | Benefit of Finish |

|---|---|

Automotive | Corrosion resistance, durability |

Medical | Reliable connections, safety |

Telecommunications | Long-term performance |

Aerospace | Withstands harsh environments |

All these things help devices last longer and break less often. Devices keep working well, even in hard places.

Immersion Gold Finish

What Is ENIG

ENIG means Electroless Nickel Immersion Gold. This process puts a special coating on printed circuit boards. The coating has two layers. The first layer is nickel. It is about 2 to 7 microns thick. Nickel covers the copper pads and acts like a shield. The second layer is gold. This gold layer is much thinner, from 0.05 to 0.23 microns. Gold sits on top of the nickel. It protects the nickel from air and water.

A chemical reaction adds both layers. The nickel stops copper from mixing with other metals. The gold keeps the nickel from rusting. It also makes the surface smooth. This smooth surface helps when adding tiny parts. ENIG works with both leaded and lead-free solder. This makes it better for the environment.

ENIG gives a flat and shiny surface. It stops rust and keeps connections strong for a long time.

Why Choose ENIG

Many makers use ENIG for their PCBs because it has many good points:

It keeps copper safe from rust and damage, so devices last longer.

The finish is flat, so small parts fit close together.

ENIG helps make strong solder joints for reliable electronics.

The gold layer protects the board in storage, so it lasts longer.

ENIG does not have lead and meets RoHS rules, so it is safer and greener.

Feature | ENIG Advantage |

|---|---|

Corrosion Resistance | High |

Surface Flatness | Excellent |

Solderability | Strong, reliable joints |

Environmental Safety | Lead-free, RoHS compliant |

Shelf Life | Long |

Immersion Gold Finish is special because it is strong, safe, and works well. This is why it is a top pick for high-quality electronics.

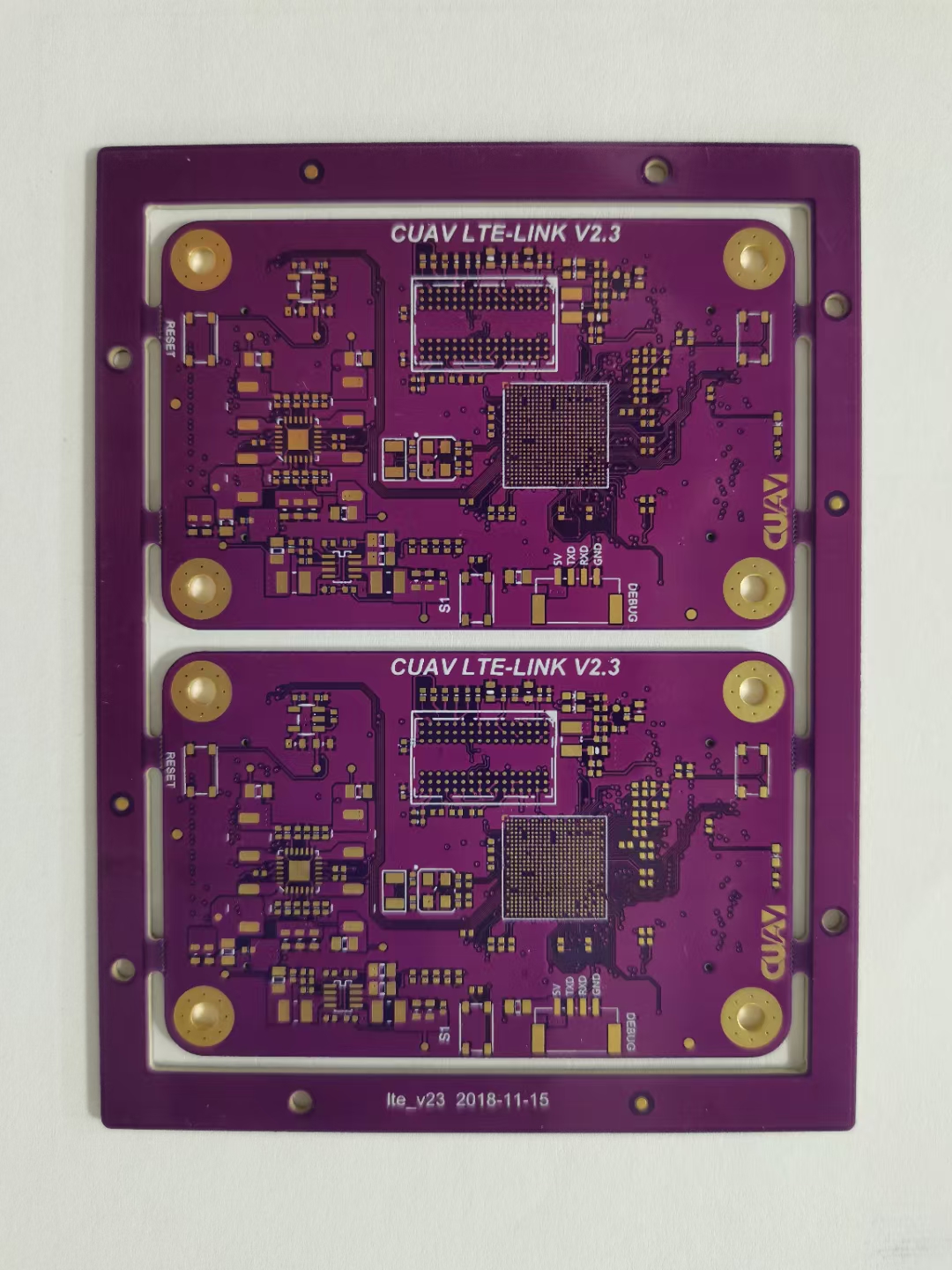

ENIG Process at LT CIRCUIT

Step Overview

LT CIRCUIT uses a careful way to add Immersion Gold Finish. First, the team cleans the PCB to get rid of dust and oil. Then, they put a nickel layer over the copper pads. This nickel keeps the copper safe and helps make strong solder joints. After that, a thin gold layer goes on top of the nickel. The gold stops the nickel from rusting and makes the surface smooth and flat.

LT CIRCUIT checks every step with special tests to make sure the boards are good. The table below shows some main ways they check the boards:

Purpose | |

|---|---|

Four-Point Probe Test | Checks if the plating is the right thickness |

Eddy Current Testing | Looks for problems and checks coating thickness |

Salt Spray Test | Sees if the board can resist rust over time |

Thermal Cycling | Checks if the plating stays strong in hot and cold |

Humidity Resistance | Tests how water affects the plating |

UV Exposure Testing | Checks if sunlight makes the board weaker |

Optical and X-ray Inspection | Makes sure holes and plating are the right size |

These steps help LT CIRCUIT make PCBs that work well in many places.

Quality Control

LT CIRCUIT uses strict rules to make sure every PCB is strong. They use special tools like XRF testing and cross-section microscopy. These tools check how thick the nickel and gold layers are. Nickel is kept at about 4 microns. Gold is kept at 0.08 microns. The team also does solder ball tests and HAST to see if the board can resist rust.

LT CIRCUIT has many world certifications like ISO 9001 and IATF 16949. Their PCBs can last up to 20 years if stored right. Tape tests and microsection checks show the coating is strong. These checks prove LT CIRCUIT works hard to make great boards for cars, medical tools, and more.

Benefits for Electronics

Corrosion Resistance

Corrosion can hurt electronics as time goes by. Immersion Gold Finish helps stop rust and oxidation on printed circuit boards. The nickel layer acts like a shield. It keeps copper safe from water and chemicals. The gold layer sits on top of the nickel. It blocks air and water from touching the metal below. Studies show this finish works well in places with lots of moisture or salt. Thicker gold gives more protection, but it costs more. Most electronics use immersion gold because it is a good balance. Devices with this finish can last longer, even in hard places.

Solderability

Good solderability means parts stick well to the board. ENIG gives a flat and smooth surface. This helps make strong solder joints. This is important for small and close parts. The gold layer stops oxidation, so the board is easy to solder. This stays true even after months in storage. Tests show ENIG works well with lead-free solder. It can handle many heating cycles during building. Medical tools and car electronics need this kind of trust. ENIG also works with gold and aluminum wire bonding. This is needed in advanced electronics.

Durability

Durability means the board can take stress and last long. The nickel under the gold makes the board strong. It keeps copper safe from harm. The gold layer stays stable and does not wear away fast. ENIG finishes help devices work for years, even in tough jobs like telecom and aerospace. The finish keeps its solderability and smooth surface over time. This makes it a top pick for products that need to last and work well.

Challenges and Solutions

Cost Factors

Immersion Gold Finish is also called ENIG. It gives many good things but costs more money. Gold and nickel are used, and both are pricey. The ENIG process needs special tools and careful steps. This makes it harder than other finishes.

A table below shows how ENIG is different from other finishes:

Surface Finish | Cost | Benefits | Drawbacks | Typical Use Cases |

|---|---|---|---|---|

Immersion Gold (ENIG) | High | Excellent solderability; long shelf life; high reliability | High cost; risk of black pad; complex process |

Even though ENIG costs more at first, it gives strong contact resistance and lasts a long time. It is great for boards with lots of small parts close together. These things help stop problems and save money later. Many makers pick ENIG when they need the best performance and trust.

Note: ENIG costs more at the start, but it can save money by stopping repairs and making devices last longer.

Black Pad Prevention

A big problem with ENIG is something called black pad. Black pad makes the nickel layer weak and easy to break. This happens if the chemical baths are not watched closely. Bad control can make solder joints weak and cause boards to fail.

To stop black pad, makers must control the process well. They check the bath temperature, pH, and chemical amounts. Cleaning and filtering the baths often keeps things safe. Getting the surface ready and checking quality, like looking at the board and testing solder, also helps. Studies show these steps lower black pad risk and make solder joints stronger.

Some new finishes, like ENEPIG, add a palladium layer. This layer blocks rust and helps stop black pad even more. These changes make PCBs work better for hard jobs.

Comparing PCB Finishes

ENIG vs. HASL

ENIG and HASL are two finishes for printed circuit boards. Each finish has good points. ENIG gives a flat and smooth surface. This helps when small parts are close together. HASL uses a solder layer that can be bumpy. The bumpy surface makes it hard to use tiny parts.

Studies show ENIG is better for fast signals. Its smooth surface keeps signals clear and strong. ENIG also stops rust and follows RoHS rules. This makes it safer for the environment. HASL costs less and is easy to check and fix. It also works well with heat during soldering.

The table below shows how ENIG and HASL are different:

Performance Aspect | ENIG (Electroless Nickel Immersion Gold) | HASL (Hot Air Solder Leveling) |

|---|---|---|

Surface Flatness | Superior flatness, great for fine-pitch PCBs | Uneven surface, less ideal for small parts |

Corrosion Resistance | Excellent | Lower |

Solderability | Excellent for small parts | Good for larger parts |

Signal Integrity | High, good for fast signals | Can cause problems with fast signals |

Environmental Compliance | Lead-free, RoHS compliant | Traditional HASL uses lead; lead-free options exist |

Cost | Higher | Lower |

Reliability Issues | Risk of black pad | Uneven surface can affect small parts |

Thermal Resistance | Good | Excellent, handles many solder cycles |

Inspection and Repair | Harder | Easier |

ENIG is best for high-tech devices. HASL is good for simple and cheap projects.

ENIG vs. OSP

ENIG and OSP both protect copper pads but work differently. ENIG uses nickel and gold layers. OSP uses a thin organic coating. Studies show ENIG lasts longer and stops rust better. ENIG works well in tough places like factories or outside. OSP does not last as long, especially with heat or water.

Tests with bending and dropping show OSP can bend more before breaking. ENIG joints can break easier, but ENIG is still better for important uses. ENIG keeps working after many heating cycles. OSP can wear out faster.

ENIG is better for devices that must last long or work in hard places. OSP is good for simple products that do not need to last long.

Key points from quality studies:

ENIG gives better rust protection and lasts longer.

OSP may bend better in some tests but does not protect as well over time.

ENIG is picked for important and high-reliability electronics.

LT CIRCUIT Advantages

Product Quality

LT CIRCUIT cares a lot about making good products. They use new machines to build and check PCBs. These machines place parts and check for mistakes. Automated Optical Inspection finds problems on the surface. Flying probe testing checks small parts. X-ray inspection looks inside for hidden issues. In-circuit and functional tests make sure each board works right.

The team also tests how strong the boards are. They use thermal cycling to see if boards handle hot and cold. Environmental stress screening puts boards in tough spots. Burn-in tests help find boards that might fail early. These steps help LT CIRCUIT make PCBs that last longer and work better.

LT CIRCUIT can make and send out test boards in just 24 hours. This fast work helps customers fix problems and build products quickly.

Customer Focus

LT CIRCUIT always thinks about what customers need. They offer many PCB choices and ways to customize. The company helps with design, testing, building, and shipping. This makes things easy for customers.

A table below shows how well LT CIRCUIT serves customers:

Customer Focus Metric | Typical Value / Benchmark |

|---|---|

90% to 98% | |

First Pass Yield (FPY) | 95% to 98% |

On-Time Delivery Rate | Up to 97% |

Customer Satisfaction Score | Over 80% |

These numbers show LT CIRCUIT works hard to deliver on time. Big companies like Signify (Philips), Normagrup, and SpaceX trust them. LT CIRCUIT uses smart tools and tests to make sure every order is right.

Immersion Gold Finish makes devices last longer and work well. ENIG gives strong safety and makes soldering simple. Many companies use this finish for important things.

LT CIRCUIT uses new ways to make the best PCBs.

Customers get boards they can trust and good help.

Think about using LT CIRCUIT for your next PCB job.

FAQ

What makes ENIG different from other PCB finishes?

ENIG uses nickel and gold layers. These layers protect copper pads. ENIG gives a flat surface and strong solder joints. Many high-tech devices use ENIG.

How does ENIG help with device reliability?

ENIG stops rust and oxidation. The finish keeps solder joints strong. Devices with ENIG often last longer and work better in tough places.

Can ENIG be used for lead-free soldering?

Yes. ENIG works well with lead-free solder. The gold layer helps make clean, strong joints. Many companies choose ENIG for safer, greener products.

See Also

Why Immersion Gold Outperforms Other PCB Surface Finishes

Essential Techniques To Perfect Immersion Tin For PCB Design

OSP Finish Advantages, Drawbacks, And Best Practices In PCB