Mastering Immersion Tin Finish Techniques for PCB Design

Making great circuit boards needs careful work at every step. Immersion tin finish is important for easy soldering and good conductivity. LT CIRCUIT uses advanced methods, like a two-step immersion tin process. This method gives even tin coating for dependable PCB performance.

Key Takeaways

Immersion tin finish gives a flat surface for better soldering. It works well for tiny and exact parts.

Store and handle immersion tin boards carefully. Use sealed bags and gloves to stop rust and harm.

Fix problems like tin whiskers by adding nickel layers. Keep manufacturing steps controlled for dependable PCB work.

Understanding Immersion Tin Finish

What Is Immersion Tin Finish

Immersion tin finish is a thin, smooth coating for circuit boards. It looks shiny and white, made using a chemical process. The tin layer is very thin, less than 1.0 microns. This makes it great for small parts like SMDs.

Tip: Immersion tin finish works well for precise and easy soldering.

The process has many steps to make the coating even. Here's how it works:

Step | Description |

|---|---|

1 | Clean the board |

2 | Rinse with water |

3 | Lightly etch the board |

4 | Rinse with clean water |

5 | Prepare the surface |

6 | Apply tin coating |

7 | Rinse after coating |

8 | Neutralize chemicals |

9 | Rinse twice with water |

10 | Dry with hot air |

11 | Final drying |

This careful process helps the tin stick evenly, improving the board's quality.

Role in Printed Circuit Board Manufacturing

Immersion tin finish is very important in making PCBs. It gives a flat, smooth surface for easy soldering of tiny parts. Many industries use it, like electronics, machines, and cars.

New rules, like RoHS, make this finish popular. It avoids harmful lead, meeting safety standards. Also, the need for strong, long-lasting electronics makes it a top choice for PCBs.

Note: Immersion tin finish is one of many PCB finishes, but its special features make it great for certain uses.

Key Features and Applications

Immersion tin finish has many benefits:

Flat Surface: Works well with small parts and press-fit pins.

Shelf Life: Can last up to a year if stored right.

Cost-Effective: Cheaper than other types of finishes.

It is used in many areas:

Consumer Electronics: Found in phones, tablets, and small gadgets.

Industrial Machinery: Handles tough conditions in machines.

Automotive Electronics: Used in systems like GPS and engine controls.

These benefits make immersion tin finish a smart choice for modern PCBs.

Benefits of Immersion Tin Finish in PCB Design

Better Soldering and Smooth Surface

Immersion tin finish helps with soldering and gives a smooth surface. It makes sure connections stay strong, even after heating many times. This is very useful for parts like BGAs and small components needing accuracy.

The table below shows why immersion tin finish is great for soldering and flatness:

Advantage | Description |

|---|---|

Smooth Surface | Keeps the board flat for tiny parts like BGAs |

Works well even after heating cycles |

A flat surface lowers the chance of soldering mistakes. This improves the quality of your circuit board.

Affordable and Safe for the Environment

Immersion tin finish costs less than other finishes like ENIG. It works well without being expensive. It also follows RoHS rules, which stop lead pollution and protect the environment.

Key points to know:

Flat surface helps with SMT processes.

Great for soldering, reducing mistakes during production.

No lead, making it safe and eco-friendly.

This finish is a smart choice for saving money while keeping high quality.

Perfect for Small, Precise Parts

Tiny parts need careful placement and soldering. Immersion tin finish gives a thin, smooth layer for these parts. It helps with accurate placement of chips and processors.

This finish is also good for crowded designs where space is tight. Choosing immersion tin finish ensures strong connections and good performance, even for tricky layouts.

Challenges of Using Immersion Tin Finish

Tin Whisker Formation

Tin whiskers are tiny, hair-like growths on tin coatings. These whiskers can cause short circuits in crowded designs. They are a problem in sensitive areas like aerospace and telecom. Whiskers form because of stress in the tin layer. Environmental factors often make this worse.

To reduce whiskers, follow good manufacturing practices. Use methods to lower stress and avoid damage. While immersion tin finish is great for soldering, whiskers need careful attention.

Limited Shelf Life

Immersion tin finish lasts only 3–6 months. For best results, use the board within 30 days. Over time, tin mixes with the copper underneath. This can hurt the board's performance.

Store boards properly to keep the finish in good shape. Air exposure can cause oxidation, making the shelf life shorter. Controlled storage helps delay damage and keeps the board reliable.

Storage and Handling Considerations

Immersion tin boards need careful handling. Moisture and air can cause oxidation over time. Store boards in sealed, dry packaging to prevent corrosion.

Avoid touching the board's surface directly. Skin oils can damage the tin layer and affect soldering. Use gloves and keep your workspace clean to protect the finish and get good results during assembly.

Best Practices for Applying Immersion Tin Finish

Getting the PCB Ready for Immersion Tin

Preparing the PCB surface is key for a good tin finish. The surface must be clean, with no dust, grease, or rust. Dirt can stop the tin from sticking well, causing weak soldering.

First, clean the board with a chemical cleaner or soft scrub. This removes leftover dirt from earlier steps. Rinse the board with pure water to wash off any chemicals. Dry it fully to keep moisture from ruining the coating.

Next, lightly roughen the copper surface with micro-etching. This step helps the tin stick better. Following these steps ensures the tin layer is smooth and even.

Tip: Use a magnifying glass to check for dirt or flaws after cleaning.

Improving the Immersion Process

The immersion process affects how strong and smooth the tin layer is. To get the best results, control the temperature, time, and chemicals.

Keep the chemical bath at 60°C to 70°C. This helps the tin spread evenly. Dip the PCB for 2–5 minutes, depending on how thick you want the tin. Don’t leave it too long, or the coating may become uneven.

Check the chemical levels often. Over time, the solution can weaken or get dirty. Add fresh chemicals when needed to keep it working well. Using machines for this step can make the process more accurate, especially for big projects.

Note: A well-done immersion process makes soldering easier and stops rust.

Storing and Handling Boards the Right Way

After coating, store and handle the boards carefully to keep them in good shape. Air, water, or dirt can damage the tin layer and shorten its life.

Follow these tips for storage:

Keep boards in a dry, cool place. Use sealed or moisture-proof bags to block humidity.

Wear clean gloves when touching boards to avoid leaving oils or dirt.

Don’t stack boards directly. Use spacers to avoid scratches or dents.

The IPC-1601 A standard gives clear rules for storing and handling PCBs. It focuses on keeping boards safe from dirt, damage, and moisture. Following these rules helps the boards last longer and work better.

By using these storage tips, you protect the tin finish and keep your PCBs in top condition.

Overcoming Common Challenges in Immersion Tin Finish

Stopping Oxidation and Tin Whiskers

Oxidation and tin whiskers are problems with immersion tin finishes. Oxidation happens when tin reacts with air, making it dull. This dull surface makes soldering harder. To stop oxidation, store PCBs in sealed, dry packaging. Keep the storage area cool and free of moisture.

Tin whiskers are tiny metal hairs that grow from tin layers. These whiskers can cause short circuits in crowded designs. Adding a nickel layer under the tin can help stop whiskers. Nickel lowers stress in the tin, which causes whiskers to grow. Checking the tin coating often helps keep it even and reduces whisker risks.

Keeping Boards Reliable Over Time

Boards stay reliable if you protect their surface finishes. Handle them carefully. Always wear gloves to keep oils and dirt off the surface. Even small dirt can make soldering worse later.

Using special treatments during manufacturing can protect the tin layer. These treatments add a shield to stop damage from air or moisture. Check stored boards often to find and fix problems early.

Avoiding Uneven Coatings

Uneven coatings can hurt how your PCBs work. To avoid this, keep the immersion process steady. Control the temperature and chemicals in the tin bath. Machines can help check these settings for better results.

Calibrate your tools regularly to keep the process consistent. This makes sure every PCB gets a smooth, high-quality finish. Following these steps helps your boards solder well and work reliably.

Why Choose LT CIRCUIT for Immersion Tin Finish PCBs

Commitment to Quality and Innovation

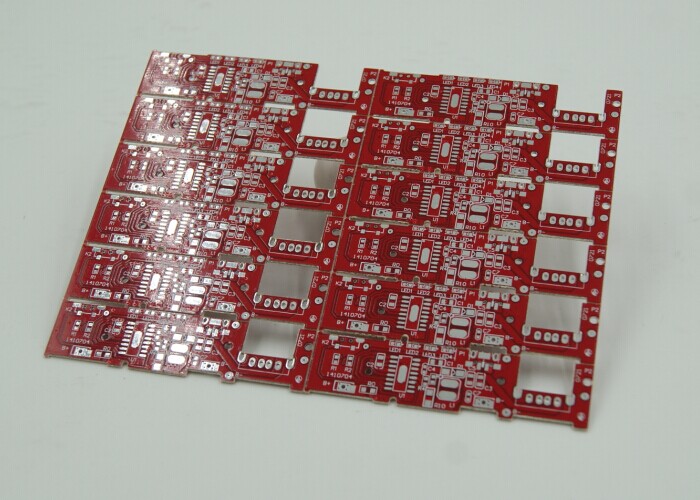

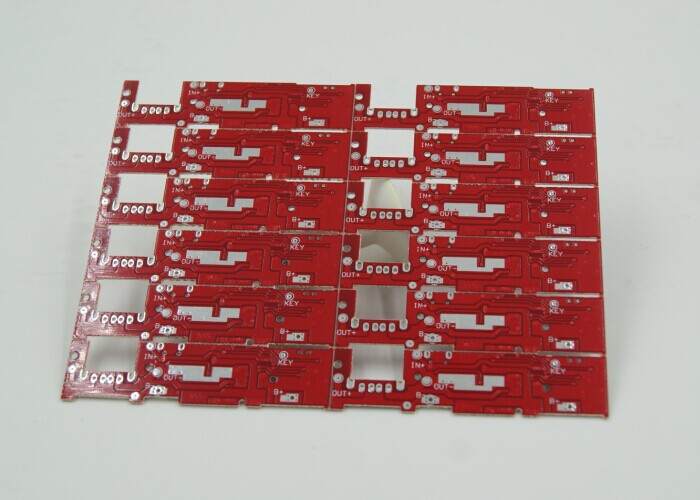

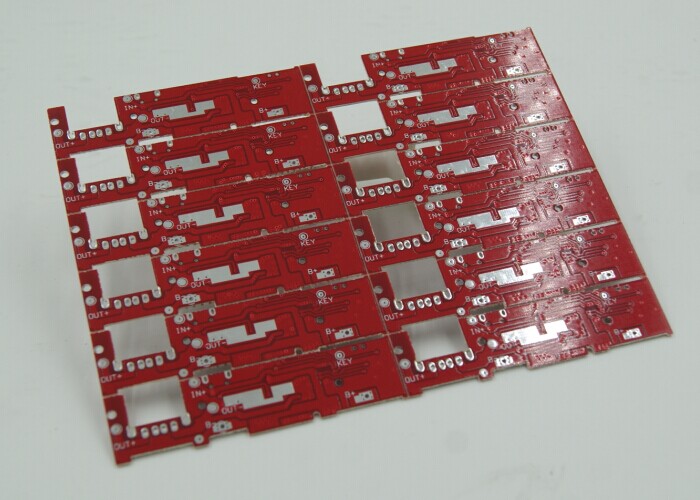

LT CIRCUIT cares about making strong and reliable PCBs. Each board is tested carefully to meet industry rules. They use modern tools and methods to create great products.

Tip: LT CIRCUIT’s new ideas make their PCBs ready for today’s electronics.

The company keeps improving its ways to stay the best in PCB design. This means you get boards that work well in many different uses.

Advanced Manufacturing Techniques

LT CIRCUIT uses smart machines to make top-quality immersion tin finish PCBs. These machines ensure the tin coating is even on every board.

What makes LT CIRCUIT special:

Precision Equipment: Tools are set up to give smooth, perfect finishes.

Controlled Environment: Clean spaces stop dirt from ruining the boards.

Quality Assurance: Boards are checked many times to ensure they work well.

These methods help your boards solder better and last longer.

Tailored Solutions for Diverse Applications

LT CIRCUIT knows every project is different. They offer custom options to fit your needs. Whether you need PCBs for gadgets, machines, or cars, LT CIRCUIT adjusts its process for the best results.

Note: You can choose things like solder mask colors and testing services.

With LT CIRCUIT, your PCBs will be made just right for your project. This ensures they work efficiently and last a long time.

Immersion tin finish is great for soldering and smooth surfaces. It is also a cheaper option for PCB finishes. Problems like tin whiskers and oxidation need proper care to avoid issues. Using good methods helps keep boards reliable and working well.

Tip: Work with LT CIRCUIT for high-quality PCBs. Their smart methods and custom options ensure the best results for your projects.

FAQ

Why is immersion tin finish better than other PCB finishes?

Immersion tin gives a smooth surface and solders easily. It costs less and works well for tiny parts. It also follows RoHS rules to avoid harmful materials.

How can tin whiskers on PCBs be stopped?

Use methods to lower stress during production. Add a nickel layer under the tin to stop whiskers. Store boards in dry, safe places to prevent damage.

Can immersion tin finish work for crowded PCB designs?

Yes! Its thin layer fits tight spaces and small parts. It helps soldering stay accurate and keeps connections strong in packed layouts.

See Also

How Tin Immersion Affects Solder Mask Stability in PCBs

Why Immersion Gold Outshines Other PCB Surface Finishes

Essential Knowledge for Designing Multi-Layer PCB Layouts