7 Key Advantages of Rigid Flex PCBs for Space-Constrained Electronic Designs

As gadgets get smaller, better designs are more important. Rigid-flex PCBs help solve space problems in a smart way. They mix the bendiness of flex circuits with the strength of rigid boards, showcasing key advantages that make them great for tight spaces. LT CIRCUIT is a top company for rigid-flex PCBs, providing strong and creative solutions you can trust for your projects.

Key Takeaways

Rigid-flex PCBs mix stiff and bendable layers, saving room and weight in tiny gadgets.

These boards are strong and dependable, perfect for devices that deal with tough use and rough environments.

Rigid-flex PCBs make building and making devices easier, cutting costs and lowering mistakes during production.

Compact and Lightweight Design with Rigid Flex PCBs

Saving Space with Combined Layers

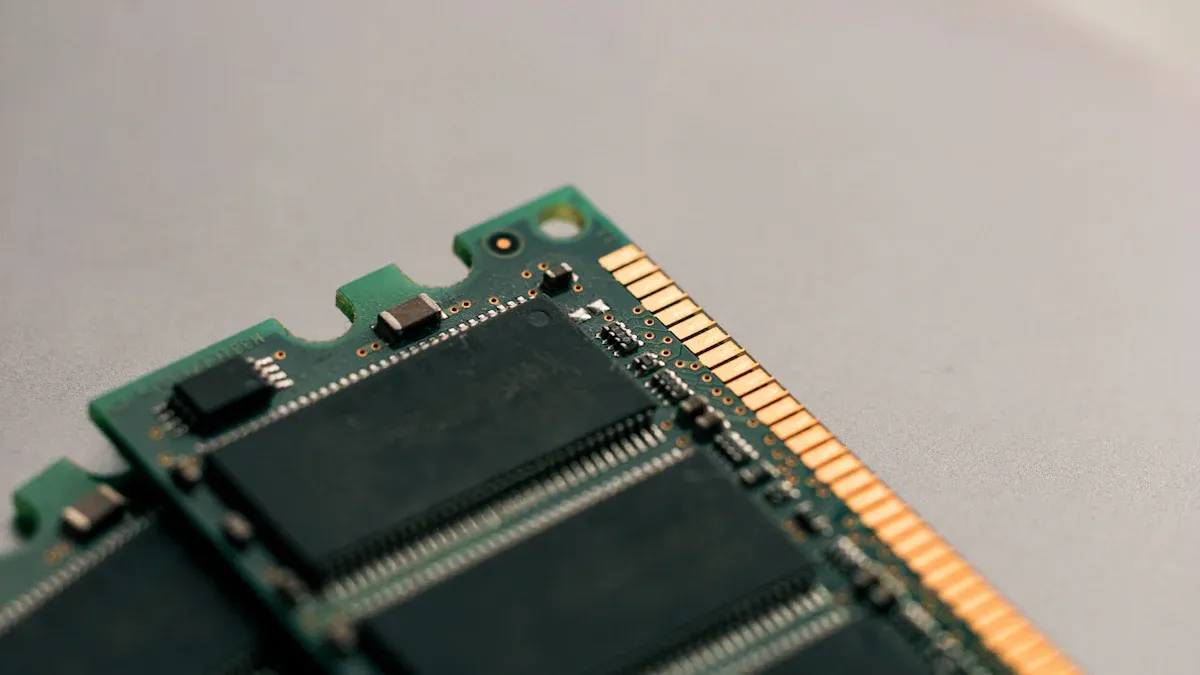

Rigid-flex PCBs mix rigid and flexible parts into one board. This makes them perfect for small designs. They remove the need for big connectors and cables. Flexible parts can bend to fit tight spots. Rigid parts give strength where needed.

Here’s a simple comparison of rigid and flexible PCBs:

Feature | Rigid PCBs | Flexible PCBs |

|---|---|---|

Heavier | Lighter | |

Space Use | Not great for small spaces | Great for small spaces |

Design Flexibility | Not very flexible | Very flexible |

Best Use | Not for tiny gadgets | Perfect for tiny gadgets |

This table shows how flexible layers save space better than rigid ones. Rigid-flex PCBs let you design cool gadgets for small, tricky spaces.

Cutting Extra Parts to Save Weight

Rigid-flex PCBs also make devices lighter. Regular PCBs need extra connectors and cables. These add weight and take up room. Rigid-flex boards connect everything directly. This saves weight and avoids weak spots.

For things like wearables, drones, and medical tools, weight matters a lot. Rigid-flex PCBs are light and small but still work great. They are the best choice when every gram and inch counts.

Enhanced Durability and Reliability in Flex PCBs

Strong Against Mechanical Stress

Rigid-flex PCBs handle stress well. They work great in tough situations. Their special design lets them bend, twist, and vibrate without breaking. Flexible layers soak up stress, stopping cracks or breaks. This makes them perfect for devices that move a lot or face strain.

Tests prove their strength, such as:

Bending Test: Checks if bending damages the board.

Vibration Test: Shows how the board handles shaking and shocks.

Pull Test: Tests how strong the solder and parts stick.

These tests show rigid-flex PCBs are tough. They work well in important gadgets like medical tools, wearables, and aerospace devices.

Good Connections in Small Spaces

Small designs need strong connections. Rigid-flex PCBs skip big cables and connectors. These can fail under stress. Flexible layers link rigid parts directly. This keeps signals flowing in tight spots. It also stops weak points from forming.

Durability tests prove their reliability:

Test Type | What It Checks |

|---|---|

Sees if circuits resist static and electromagnetic damage. | |

Moisture Resistance Testing | Checks if water harms the board. |

Vibration | Tests if parts work after shaking or moving. |

Low Pressure | Simulates high-altitude or weather pressure changes. |

Thermal Cycling Testing | Tests heat effects without causing damage. |

MTBF/MTTF | Measures how long the board lasts before failing. |

Rigid-flex PCBs are strong and reliable. They fit small spaces and keep working under tough conditions.

Easy Assembly and Setup with LT CIRCUIT Rigid-Flex PCBs

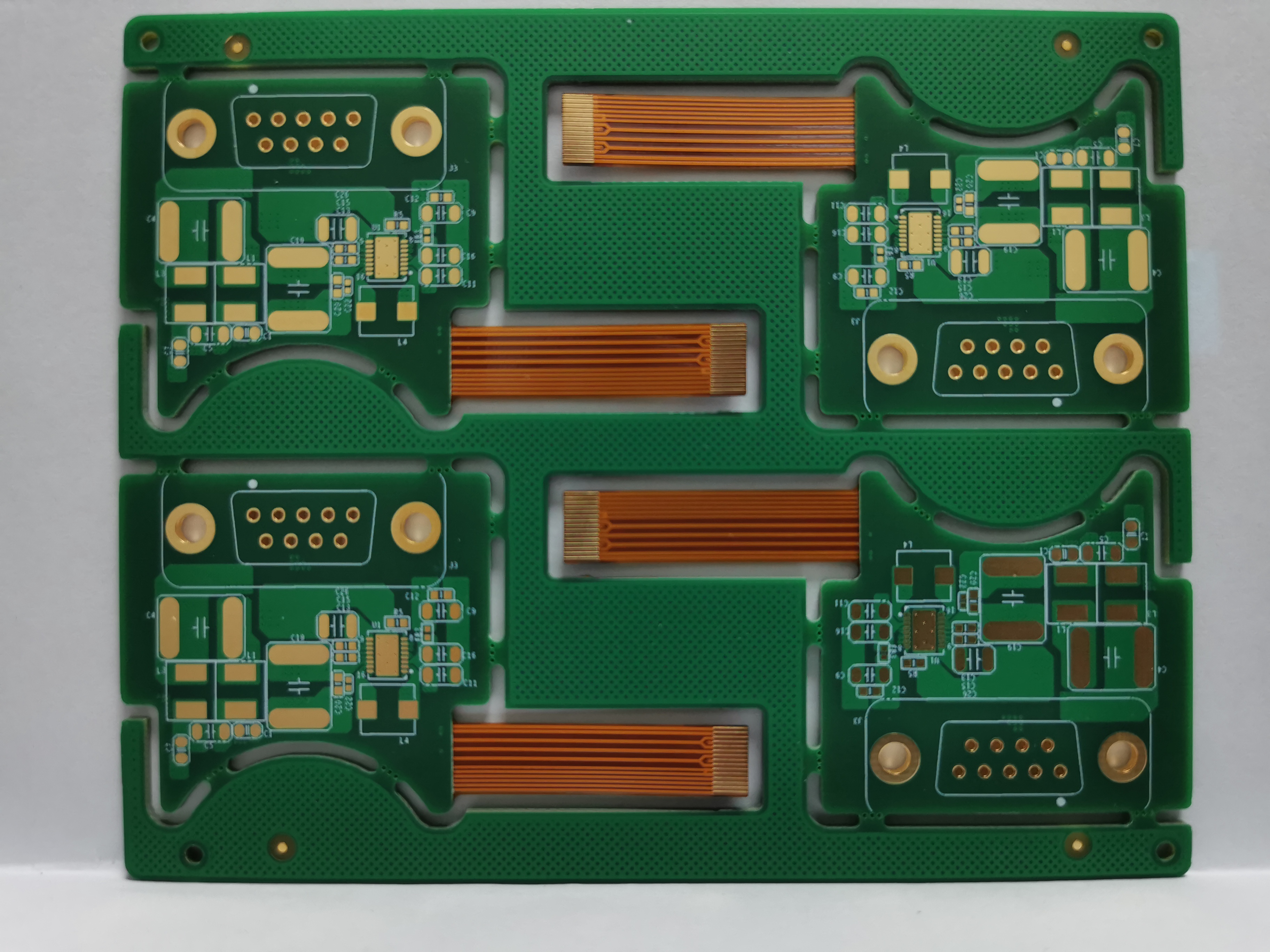

Simple Design for Complicated Projects

Rigid-flex PCBs make building complex gadgets easier. They combine stiff and bendy layers into one board. This removes the need for big connectors and cables. It saves space and makes the design stronger by reducing weak spots. LT CIRCUIT’s rigid-flex boards are made to handle tricky designs and fit them perfectly.

For example, LT CIRCUIT offers special boards like multilayer HDI/microvia rigid-flex boards. These are great for making tiny 3D designs that still work well. The table below shows some cool features and uses of LT CIRCUIT’s rigid-flex boards:

Feature/Application | Description |

|---|---|

Multilayer HDI/microvia rigid-flex circuit boards | Built for small 3D designs |

High-frequency rigid-flex HDI solutions | Uses LCP material for better performance |

Turnkey flex solutions | Made for reliable 3D miniaturized designs |

Complex mechanical features | Includes folds, cut-outs, and special shapes |

16 layer rigid flex PCB | Used in medical tools with tight spaces and vias |

These features show how rigid-flex PCBs make tough designs easier to build. They are perfect for small spaces and tricky projects.

Easier to Make and Build

Rigid-flex PCBs also make manufacturing simpler. They combine stiff and flexible parts into one board. This means fewer pieces are needed. You don’t have to add connectors or cables separately. This makes production faster and reduces mistakes.

LT CIRCUIT’s rigid-flex boards are made to be easy to produce and very reliable. Their flex technology ensures every board is high quality. These boards are great for things like medical tools, space equipment, and everyday electronics. They make building gadgets quicker and more dependable.

Choosing LT CIRCUIT’s rigid-flex boards gives you small designs that are strong and easy to make. They are a smart choice for modern electronics.

Better Signal Quality in Rigid-Flex PCB Designs

Shorter Paths for Stronger Signals

Rigid-flex PCBs improve signal quality by shortening signal paths. Shorter paths keep signals strong and reduce problems in devices. Unlike regular PCBs, rigid-flex skips long cables and connectors. This direct setup lowers issues that can weaken signals.

The way layers are arranged in rigid-flex PCBs is important. Good layer design stops signals from interfering with each other. Ground planes in these boards give signals a steady path to return. They also cut down on electromagnetic noise, making devices more reliable.

Here are key benefits of shorter signal paths:

Fewer reflections stop signals from weakening.

By focusing on these points, rigid-flex PCBs ensure great signal quality. They are perfect for small, tight designs.

Great for Fast and Reliable Systems

Rigid-flex PCBs work well in systems needing speed and dependability. They handle high-frequency signals without losing quality. Flexible layers allow compact designs, reducing signal problems. This makes them ideal for advanced tech like network tools and data systems.

For instance, a tech company improved its network using rigid-flex PCBs. This upgrade boosted data speed, cut delays, and made systems faster. These results show how rigid-flex PCBs handle tough tasks easily.

To improve performance, rigid-flex PCBs use controlled impedance and smart layer setups. These features help signals move quickly and stay strong in small spaces. Whether for space tools, medical devices, or gadgets, rigid-flex PCBs offer the strength and speed needed to succeed.

Greater Design Flexibility with Rigid-Flex PCBs

Fitting Unique Shapes and Sizes

Rigid-flex PCBs are very flexible and useful. They mix stiff parts with bendy layers to fit special shapes. These boards can fold, twist, or bend without breaking. This makes them perfect for small or odd-shaped gadgets.

Here are some reasons why rigid-flex PCBs are great:

They cut down on extra connectors, which often break.

Their design is strong and works well for electricity.

They fit easily into small spaces in devices.

Many industries use these boards to improve their products.

Industry | How They Are Used |

|---|---|

Cars | Help make electric cars smaller and manage power better. |

Planes and Defense | Work well in flight controls and tough conditions, saving fuel. |

Green Energy | Used in solar panels and smart grids to last longer and handle heat. |

This flexibility makes rigid-flex PCBs a smart choice for tight and creative designs.

Helping Build 3D Designs

Rigid-flex PCBs are great for making 3D designs. They combine stiff and bendy parts to save space and weight. These boards can be up to 75% lighter and take up 90% less room. This makes them perfect for small, advanced systems.

They are also very durable and can bend many times without breaking. For example, car sensors and military tools use these boards because they last long. Fewer connectors in these designs mean fewer chances of breaking.

Whether for cars, planes, or gadgets, rigid-flex PCBs are reliable and flexible. They fit into tight spaces and help create strong, smart designs.

Cost-Saving Choices for Tight Spaces

Lower Costs for Materials and Assembly

Rigid-flex PCBs help save money on materials and assembly. They combine stiff and bendy layers into one board. This removes the need for big connectors and extra parts. Fewer pieces mean lower costs and easier assembly. Flexible areas connect circuits directly, cutting down on parts. Fewer parts also mean fewer production steps, saving money.

Smaller rigid-flex boards use less material and weigh less. This lowers shipping costs and saves money. Simple designs make assembly faster and reduce mistakes. Fewer errors mean fewer repairs, saving even more. These boards are a smart choice for small designs that need to save space and money.

Less Need for Repairs

Rigid-flex PCBs are strong and last a long time. They handle stress, shaking, and tough conditions without breaking. This means fewer repairs and less downtime. Industries like aerospace and medical tools rely on this strength to keep working well.

These boards work in extreme conditions like heat or moisture. They don’t need to be replaced often, saving money over time. Rigid-flex PCBs are reliable and flexible, making them great for small spaces and tricky designs. They offer good performance and save money in the long run.

Rigid Flex PCBs for Tough Conditions

Working Well in Extreme Situations

Rigid-flex PCBs work great in places with tough conditions. Their mix of stiff and bendy layers makes them strong and flexible. They keep working even in high heat, quick temperature changes, or harsh environments.

To prove their toughness, they go through strict tests:

HAST checks if they can handle heat and moisture for a long time.

Temperature Cycling Testing makes sure they survive sudden temperature changes.

Salt Spray Testing tests how well they resist salty, corrosive air.

These tests show rigid-flex PCBs are perfect for hard jobs like in space. They can handle vibrations and work in vacuums, making them great for satellites. This design lets you build strong devices for tough places without losing performance.

Strong Against Vibrations and Water

Rigid-flex PCBs are built to handle shaking and wet conditions. Their bendy parts absorb shocks, keeping parts safe from damage. Unlike regular boards, they don’t need big connectors that can break easily.

Here’s why rigid-flex PCBs are special:

Feature | What It Does |

|---|---|

Handles shaking and stress for long-lasting use. | |

Moisture Protection | Shields against water, UV light, and chemicals. |

Fewer Weak Spots | Fewer connectors mean fewer chances of breaking. |

Lightweight and Flexible | Less weight helps reduce damage from shaking. |

Heat Stability | Special materials keep them steady in high heat. |

These qualities make rigid-flex PCBs great for planes, cars, and factory machines. Whether it’s wet, shaky, or very hot, these boards stay reliable. They help your devices work well, even in the hardest conditions.

Rigid-flex PCBs have seven big benefits for small gadgets. They save room, weigh less, and last longer. These boards are easy to put together and improve signals. They also fit special shapes and save money. Their strength in tough conditions makes them great for today’s devices.

LT CIRCUIT makes top-notch rigid-flex PCBs. They create high-quality designs for many industries. The table below shows how flexible PCBs help in different ways:

Application Area | Benefits of Flexible PCBs | Example Use |

|---|---|---|

Consumer Electronics | Stays connected even with lots of movement | Phones and laptops |

Automotive Sensors | Handles bending and stretching, works in changing conditions | Car sensors |

Wearable Devices | Light and bendy, perfect for health tools | Health-monitoring sensors |

Check out LT CIRCUIT’s products to make your small projects work better with strong and smart rigid-flex PCBs.

FAQ

What are flex PCBs, and how are they different from rigid PCBs?

Flex PCBs can bend and twist easily. They fit small spaces better than rigid PCBs, which are hard and cannot bend.

Can flex PCBs survive tough conditions?

Yes, flex PCBs can handle heat, water, and shaking. Their strong design makes them last in harsh places.

Why pick rigid-flex PCBs for small designs?

Rigid-flex PCBs mix bendy and stiff parts. They save room, weigh less, and work well in tiny gadgets.

See Also

Exploring Rigid Flex PCBs In Industrial And Medical Uses

A Comprehensive Guide To Rigid-Flex PCB Structures

The Advantages Of HDI Rigid Flex PCBs Explained