LDI and CCD machines in circuit board production equipment

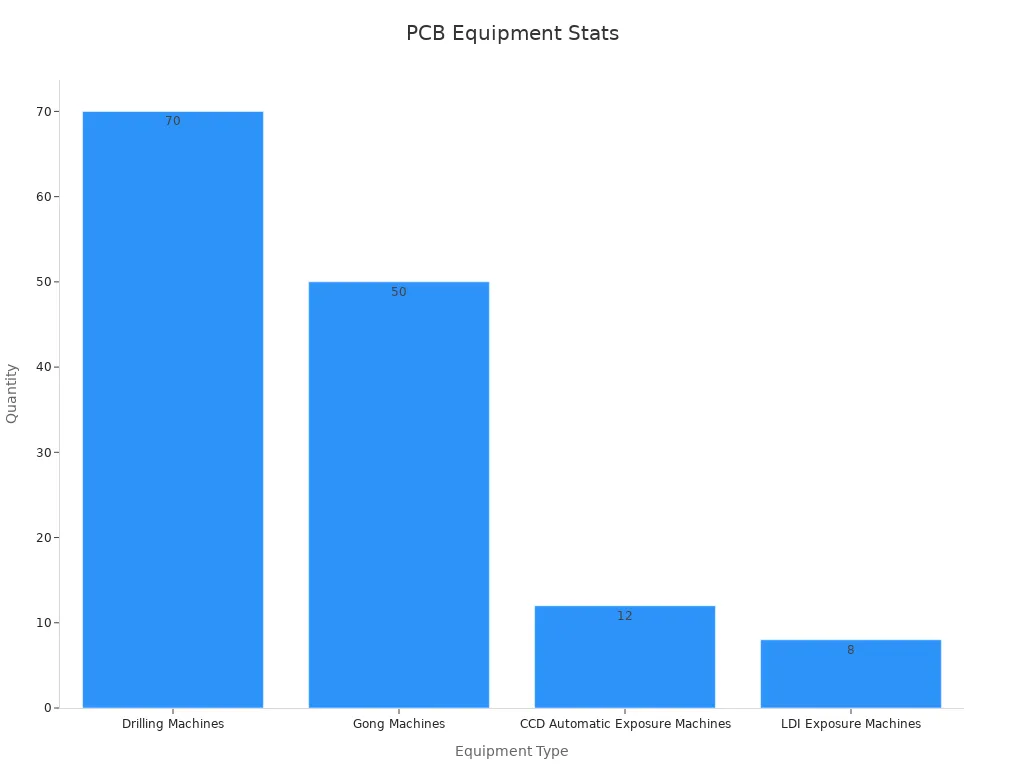

LDI and CCD machines are very important in making circuit boards. They help make the boards with great accuracy and speed. LT CIRCUIT uses these smart machines to make sure PCBs are very good. Many LDI and CCD machines are used in the factory. The chart below shows how many are used. These machines help the industry keep getting better.

Key Takeaways

LDI machines use lasers to make tiny lines on boards fast.

They do not need old tools.

This helps with detailed and hard designs.

CCD machines use cameras to take clear pictures of boards.

The pictures help match up layers and find mistakes.

This makes sure the boards are good quality.

LT CIRCUIT uses both LDI and CCD machines.

They pick the best machine for each job.

This gives strong and accurate boards for many customers.

LDI Machines

What is LDI?

Laser Direct Imaging, or LDI, is a new way to make PCBs. It uses a strong laser light to draw tiny lines on a board. The board is covered with a special layer that reacts to light. LDI does not need old tools like films. The laser follows computer designs to make patterns. This makes the work fast and correct. LT CIRCUIT uses LDI to make hard and detailed boards for many uses.

How LDI Works

First, the board is cleaned to get rid of dirt. Then, a thin light-sensitive layer goes on the board. The design is put into the LDI machine. The machine’s laser draws the pattern on the board. After this, the board is washed and etched. The extra layer comes off, leaving copper lines. This way, old tools are not needed and mistakes are less likely.

LDI Benefits

LDI has many good points in making PCBs:

Helps keep lines straight, even on many layers.

Stops mistakes from broken or old tools.

Makes boards faster by skipping tool-making steps.

Lets you change designs quickly with computers.

Wastes less material and is good for flexible work.

LT CIRCUIT uses LDI to make strong, tiny boards fast. This helps them meet the needs of new electronics. It also shows they like to use new ideas.

CCD Machines

What is a CCD Machine?

A CCD machine uses a special sensor to take clear pictures. This sensor is called a Charge-Coupled Device, or CCD. In making PCBs, the sensor helps line up and show circuit shapes. The CCD changes light into signals. These signals make a sharp image of the board. This lets the machine see small parts and match each layer.

Here is a table with some facts about CCD sensors:

Technical Aspect | Description |

|---|---|

Semiconductor Structure | Thin silicon layer on top of a thicker base. |

Doping Profiles | Special areas help move charges in channels. |

Channel Stops | Oxide parts keep charges in their own columns. |

Polysilicon Gates | Gates move charges by turning on and off. |

Charge Transfer Mechanism | Charges move under gates inside channels. |

CCD Architectures | There are full-frame, frame-transfer, and interline types. |

Output and Readout | Shift registers and amplifiers send out the signals. |

Buried-Channel Advantages | These channels move charges better and make less noise. |

CCD in PCB Production

CCD machines are important in making PCBs. They use cameras to find tiny marks called fiducials. These marks help line up each layer when drilling or shining light. The CCD checks where the marks are. It tells the machine where to drill holes or make patterns. LT CIRCUIT uses CCDs to make sure every board is made right.

Each drill uses its own CCD and moves on its own path.

The system can work with different parts of a big board.

CCDs help line up layers, even if the mask is hard to see.

CCD Benefits

CCD machines have many good points for making PCBs:

They take clear pictures for lining up layers.

The camera checks each step to stop mistakes.

CCDs let workers fix things fast if the design changes.

They help find problems early to keep boards good.

LT CIRCUIT uses CCD machines to make sure boards are always good. This helps them give customers what they want. Using both LDI and CCD machines, LT CIRCUIT can help many kinds of businesses.

LDI and CCD Machines Compared

Key Differences

LDI and CCD machines both help make circuit boards. But they work in different ways. LDI uses lasers to draw patterns on the board. CCD uses cameras to line up and shine light on the board. Each machine is good at different things.

Here is a table that shows how LDI and CCD are different:

Usage Scenario Factor | CCD Machines | LDI Machines |

|---|---|---|

Application | Semi-automatic insolation | High-end products and high-density materials |

Operation Mode | Semi-automatic | Fully automatic |

Registration Method | Uses 2 or 4 cameras to line up | Uses many cameras to line up in seconds |

Registration Precision | Good for basic control and lining up | Very tight control, as small as 50 micrometers |

Speed | Works at a medium speed | Works very fast |

Suitable For | Normal PCB making | Hard, detailed boards needing tight control |

LDI and CCD machines do imaging in different ways. LDI uses lasers for direct drawing. This makes it very fast and exact. CCD uses cameras to help line up and shine light. LDI is best for boards with tiny lines and tight control. CCD is good for normal boards that do not need high detail.

Note: LT CIRCUIT uses both LDI and CCD machines. This helps them pick the best one for each job. That way, every customer gets what they need.

When to Use Each

Choosing LDI or CCD depends on what the board needs. Each machine is good for different jobs.

Pick LDI for boards with tiny lines or many layers. LDI is best for fancy boards and hard jobs. It is fast and very correct. LDI is also good if the design changes a lot. You do not need new tools each time.

Pick CCD for normal PCB jobs. CCD is good for boards that do not need tight control. It helps line up layers and checks for mistakes. CCD is good for semi-automatic and simple jobs.

LT CIRCUIT looks at each order and picks the right machine. They check how hard the board is, how many are needed, and how much detail is needed. By using both LDI and CCD, LT CIRCUIT gives each customer the best answer. This helps keep quality high and meet many needs in electronics.

Choosing for Your Production

Selection Factors

Picking the right machine for making PCBs is important. Many things help decide if LDI or CCD is better. The table below shows these things:

Factor | Description | Impact on Equipment Choice and Cost |

|---|---|---|

Board Complexity | How many layers and tiny lines are needed | Hard boards need special machines, which cost more |

Production Volume | How many boards you need | Making lots of boards is cheaper with fast machines |

Cost Components | What you pay for materials and work | You must balance machine price and savings |

Design for Manufacturability | Making boards easy to build | Simple designs use normal machines and cost less |

Supply Chain | How you get parts and materials | Good supply helps save money and use machines well |

For example, a company made 10,000 car boards with six layers. They saved 25% by using fewer layers and a better design. This shows that board type and number change what machines you need and how much you pay.

Best Practices at LT CIRCUIT

LT CIRCUIT has steps to pick the best machines for each job. The team checks every order to match the right machine. For hard or detailed boards, they use LDI and CCD for good results. For simple boards, they pick machines that save money and keep quality.

LT CIRCUIT always tries to do better. They use robots to cut labor costs and keep boards good. The team checks every design to stop mistakes and save money. By using smart machines and good plans, LT CIRCUIT makes strong boards for many uses.

LDI and CCD machines help make PCBs in different ways.

LDI is very good at making tiny, exact lines.

CCD helps make sure all the parts line up right.

LT CIRCUIT uses both to make strong, good boards.

If you need special or hard PCBs, LT CIRCUIT can help.

They have smart tools and know how to use them well.

FAQ

What does LDI mean in making PCBs?

LDI means Laser Direct Imaging. It uses lasers to draw patterns. No old film tools are needed. The laser makes lines on the board. This helps make boards very exact.

How does a CCD machine help make PCBs?

A CCD machine uses cameras to line up layers. It checks for mistakes on the board. This helps every board be good quality.

Can LT CIRCUIT use both LDI and CCD for one job?

Yes. LT CIRCUIT can use both machines together. This helps make boards very accurate. It is good for hard or special orders.

See Also

Advantages Of LDI Exposure Machines In HDI PCB Circuit Production

How LDI Technology Impacts The Quality Of PCB Manufacturing

Step-By-Step Guide To Manufacturing Multilayer Rigid-Flex Boards

Comprehensive Guide To Heavy Copper Multilayer PCB Production

Utilizing Horizontal Copper Sinking Techniques In PCB Fabrication