Comparing Aluminum, FR4, and Flexible LED PCBs for Your Needs

Have you ever wondered what makes LED technology so efficient and versatile? The answer often lies in the type of PCB that powers it. LED PCB Types like Aluminum, FR4, and Flexible PCBs play a major role in shaping how LEDs perform. The global market for these PCBs is booming, with a projected value of USD 81.67 billion by 2033 and an annual growth rate of 10.70%. Choosing the right PCB type can make all the difference for your project’s success.

Key Takeaways

Pick aluminum PCBs for strong power needs. They handle heat well, helping LEDs last longer and work better.

FR4 PCBs are cheap and useful. They are great for regular devices and can handle tricky designs with many layers.

Flexible PCBs are best for small and unique designs. They can bend, making them great for wearable tech and curved shapes.

Understanding LED PCB Types

What Are LED PCBs?

You’ve seen LED lights in homes, cars, and gadgets. But do you know what powers them? That’s where LED PCBs come in. A PCB, or printed circuit board, is like the brain of an LED system. It connects parts and makes electricity flow to light up LEDs.

LED PCBs are made to meet LED needs. They handle heat, which LEDs produce a lot of, and keep things working well. These PCBs can be stiff, bendable, or metal-based, depending on the material. For example, aluminum PCBs cool down heat fast, while flexible PCBs work for curved or tight spaces.

Here’s a simple look at common LED PCB types and their uses:

Type of LED PCB | Features | Uses |

|---|---|---|

FR4 Standard PCB | Cheap, common, bad at cooling heat | Low-power LEDs like small indicator lights |

Metal-Based PCB (MCPCB) | Metal layer cools heat fast, stops damage | High-power LEDs like car headlights |

Flexible PCB | Bendable, thin, fits non-flat spaces | Curved screens, wearable tech |

Why Are LED PCBs Important in LED Technology?

LED PCBs are the hidden helpers of modern lights. They don’t just hold LEDs; they also improve how they work. For example, they move heat away from LEDs, stopping them from overheating and lasting longer. This is key for strong LEDs, like those in car headlights or streetlights.

Using LED PCBs saves money too. They use less power than old lights, cutting electricity costs. Plus, LEDs last a long time—up to 25,000 hours or more. You won’t need to replace them often. That’s good for your wallet and the planet.

LEDs are now the best choice for lighting. They’re efficient, strong, and useful in many areas, like homes and space tech. At the center of it all are LED PCBs, making sure your lights stay bright and last long.

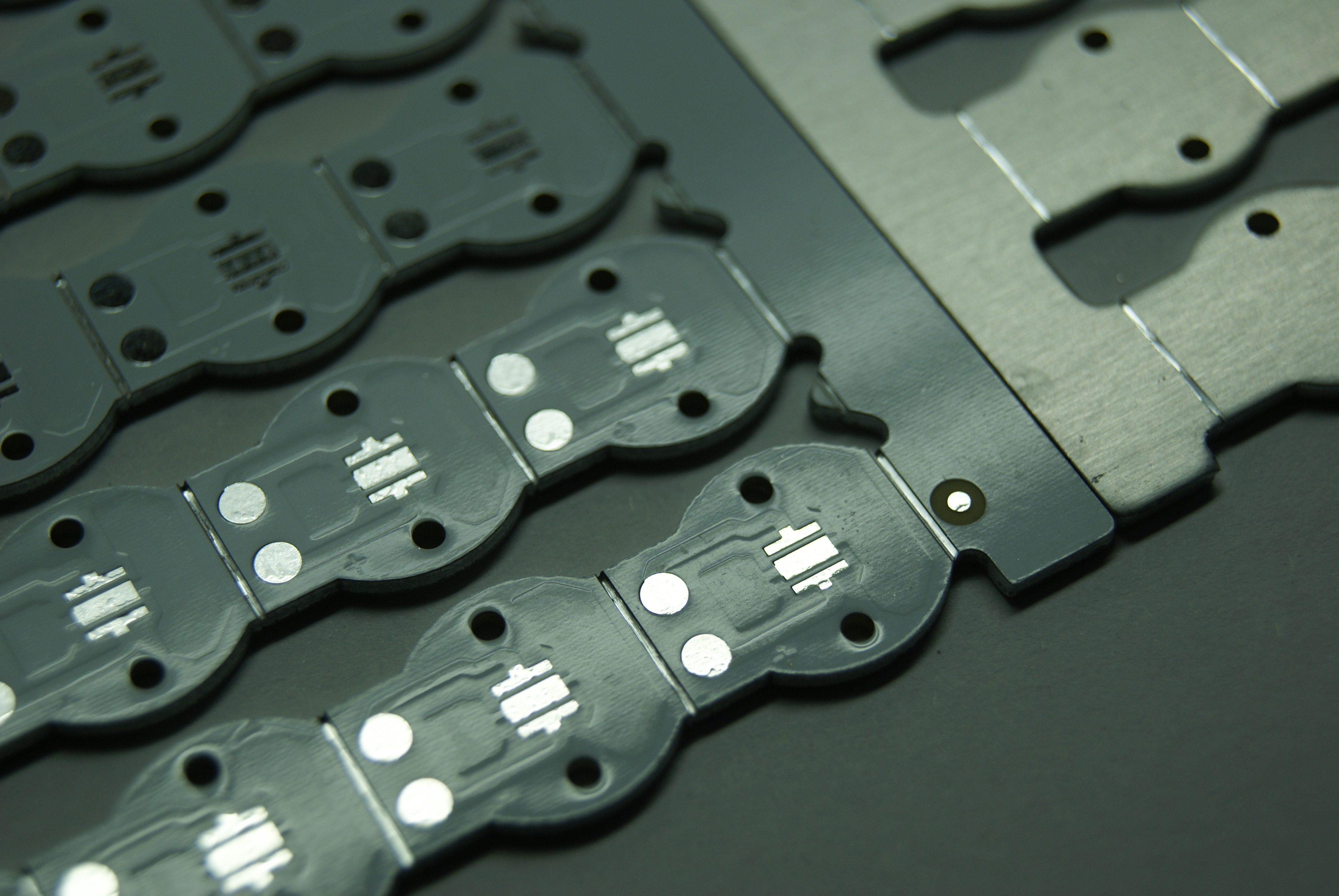

Aluminum LED PCBs by LT CIRCUIT

Properties of Aluminum LED PCBs

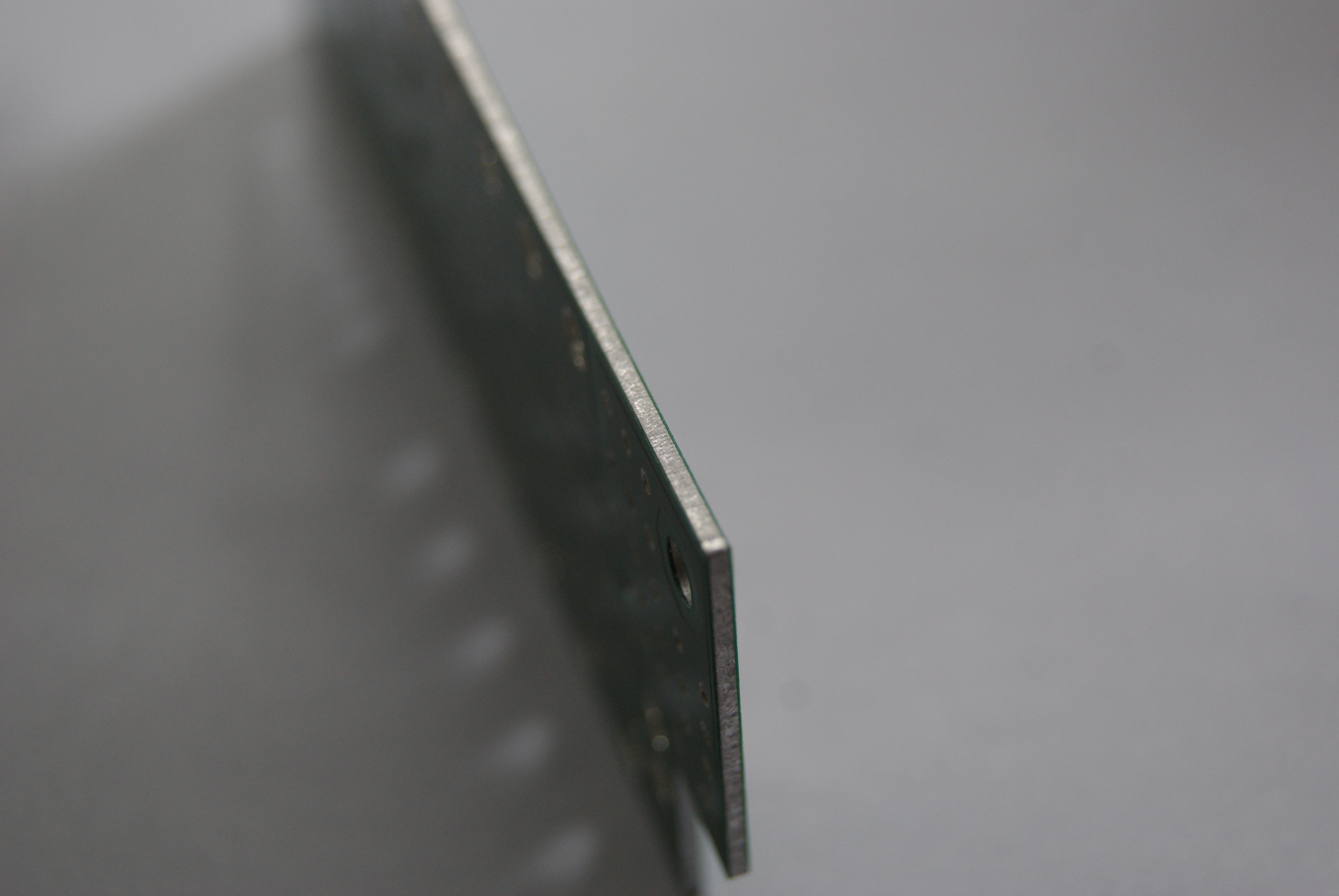

Aluminum LED PCBs are special because of their strong materials. The aluminum base moves heat away from LEDs, keeping them cool. This stops overheating and helps LEDs work better for longer. Aluminum is also tough, so these PCBs can handle rough conditions. They don’t break easily, making them great for hard-to-use places.

Here’s a simple table showing how Aluminum LED PCBs by LT CIRCUIT perform:

Performance Index | Measured Value |

|---|---|

Peeling strength (n/mm) | 1.8 |

Insulation resistance (ω) | >1*10 g |

Breakdown voltage (vdc) | >2 k |

Soakable soldering (°C/m) | 280°C / 260°C, 1 min, no bubble & delamination |

Thermal conductivity (ω/m-k) | >0.8 |

Thermal resistance (°C/ω) | < 1.2 |

Combustibility | fv-o |

Dielectric constant (1mhz) | 4 |

Dielectric loss angle (tangent) | 0.03 |

These features make aluminum PCBs a smart pick for powerful LED uses.

Advantages of Aluminum LED PCBs

Why choose aluminum PCBs? They do more than just manage heat. First, they have thermal conductivity between 1.0 and 3.0 W/m.k. This is great for low to medium-power tasks. It’s also twice as good as regular PCBs, making them more effective. Second, they last a long time, even in tough places. Lastly, while they cost more at first, they save money over time. They help LEDs last longer and need less fixing.

Here’s a quick comparison with regular PCBs:

Property | Aluminum LED PCBs | Standard PCBs |

|---|---|---|

Thermal Conductivity (W/m.k) | 1.0 - 3.0 | N/A |

Thermal Properties | Twice as high | N/A |

Applications of Aluminum LED PCBs

Aluminum LED PCBs are best where heat control is key. For example:

High-Power LED Lighting: These PCBs work well for strong LEDs, like in streetlights or car headlights. Some makers even use heat tests to improve designs.

Power Supplies: Aluminum PCBs handle high power and voltage safely. Engineers often use tools like SolidWorks Flow Simulation to make sure they work well.

You’ll also see them in medical tools, factory machines, and even space tech. Their heat control and toughness make them useful in many fields.

FR4 LED PCBs and Their Versatility

Characteristics of FR4 LED PCBs

FR4 LED PCBs are strong and reliable. They are made from fiberglass mixed with epoxy, which gives them good insulation and strength. This makes them useful for many electronic devices.

Here’s a simple table about their material features:

Property Type | Description |

|---|---|

Electrical Properties | Great insulation and helps control signals and impedance. |

Thermal Properties | Handles heat okay, useful for high-power devices. |

Mechanical Properties | Strong and stable, works well under pressure. |

These qualities make FR4 PCBs a solid choice for both small and big LED projects.

Benefits of FR4 LED PCBs

FR4 LED PCBs are super flexible. They can fit into complex designs with many layers. This is great for small gadgets. Their layers allow more parts to fit, while keeping signals clear in fast devices. They also lower electromagnetic interference, helping devices work better.

Here’s why they’re great:

Can be used in tricky designs with many layers.

Work well in fast devices because of signal control.

Reduce interference, making gadgets perform smoothly.

Common Uses of FR4 LED PCBs

FR4 LED PCBs are used in many industries! You’ll see them in phones, cars, and even hospitals. For example:

Telecommunication Industry: Used in LED displays because they’re light and tough.

Automotive Industry: Found in car dashboards, as they’re cheap and effective.

Medical Industry: Used in surgery lights, as they’re small and save power.

From home signs to advanced tools, FR4 PCBs are a top pick for many uses.

Flexible LED PCBs for Space-Saving Designs

Features of Flexible LED PCBs

Flexible LED PCBs are made to fit tight spaces. They work well on curved or uneven surfaces. These PCBs are very thin, less than 1mm thick. Their lightweight design makes them easy to use in small gadgets. This is why they’re common in phone backlights and car interiors.

Here’s a simple table of their features:

Feature | Description |

|---|---|

Adaptability | Works on curved or uneven surfaces easily. |

Lightweight Design | Thin and light, great for small spaces. |

Space-Saving Capability | Ideal for wearables and car lighting systems. |

These features make flexible PCBs important for modern devices.

Strengths of Flexible LED PCBs

Flexible LED PCBs are strong and reliable. They handle stress, vibrations, and shocks well. Their light weight helps lower costs for things like satellites. They don’t need connectors, which reduces problems and improves reliability.

Other key points include:

Can resist heat up to 400°C.

Can bend three times their thickness.

Works well with high-frequency signals.

These strengths make flexible PCBs useful for many tasks.

Ideal Applications for Flexible LED PCBs

Flexible LED PCBs are best for designs needing space-saving solutions. You’ll see them in:

Wearable Tech: Used in smartwatches and fitness trackers.

Automotive Lighting: Big brands use them for advanced car lights.

Ornamental Lighting: Great for creative and decorative displays.

Their ability to bend and fit different shapes makes them popular for unique designs.

Comparative Analysis of LED PCB Types

Material and Thermal Performance

Each LED PCB type has unique strengths in material and heat handling. FR4 PCBs are made from fiberglass and epoxy, offering great insulation and strength. They work well for general uses but aren’t great at handling heat. Their thermal conductivity is low, around 0.3 to 0.4 W/mK. Adding thermal vias can help them manage heat better.

Aluminum PCBs are excellent for heat control. They have thermal conductivities over 200 W/mK, making them ideal for high-power LEDs. A study showed that aluminum cores with copper layers spread heat well. This keeps LEDs cooler and improves performance. They’re often used in car headlights and industrial lights.

Flexible PCBs don’t handle heat as well as aluminum ones but still resist heat up to 400°C. This makes them good for devices with occasional heat spikes. They also bend easily, fitting into curved or tight spaces, which adds to their usefulness.

Flexibility and Design Versatility

If your project needs flexibility, flexible PCBs are the best choice. They are super thin, often under 1mm, and can bend without breaking. This makes them perfect for wearables, curved screens, and car interiors. Their ability to fit tight spaces gives designers more freedom.

FR4 PCBs aren’t flexible but are great for layered designs. You can stack layers to fit complex circuits, which is useful for phones and medical tools. They also reduce interference, helping devices run smoothly in fast systems.

Aluminum PCBs are not as adaptable but are very strong. Their rigid design works well in places with lots of mechanical stress. While they can’t bend like flexible PCBs, their toughness makes them reliable in tough conditions.

Cost and Budget Considerations

Cost is important when picking a PCB. FR4 PCBs are the cheapest, costing as little as $5 for a 150 sq. cm board. They’re a good choice for projects with moderate heat needs, especially if you add thermal vias to improve heat control.

Aluminum PCBs cost more but are worth it for heat-heavy tasks. Prices range from $10 to $20 per square foot, depending on the aluminum’s thickness. They last longer and reduce repair costs, making them a smart investment. For example, a 1mm aluminum core PCB costs about $15, compared to $5 for an FR4 version.

Flexible PCBs are priced between FR4 and aluminum. Their lightweight design and fewer connectors can save money in systems like satellites or wearables. While they cost more upfront than FR4, their special features often make them worth it.

Application Suitability

Each PCB type fits specific uses. Aluminum PCBs are the best for managing heat, making them great for high-power LED lights, power electronics, and car systems. They also work well for high-speed data transfer.

FR4 PCBs are versatile and used in phones, car dashboards, and medical tools. However, they don’t perform well in very hot environments because their dielectric loss increases above their Glass Transition Temperature (Tg).

Flexible PCBs are perfect for saving space. They’re used in wearables, curved displays, and decorative lighting. Their ability to bend and fit different shapes makes them essential for creative designs.

Pro Tip: Use aluminum PCBs for heat-heavy tasks. For moderate heat needs, FR4 PCBs with thermal vias are budget-friendly. Choose flexible PCBs for compact and creative designs.

Choosing the Right LED PCB with LT CIRCUIT

Evaluating Your Project Requirements

Picking the right LED PCB starts with knowing your project’s needs. Each project has specific factors to consider. Here’s a simple guide to help you decide:

Metric | Description |

|---|---|

Electrical Requirements | Make sure the PCB supports all needed connections and parts. |

Optical Design | Match PCB size and shape to get the right light output. |

Manufacturability | Keep designs simple for easier and cheaper production. |

Cost Considerations | Balance design complexity with cost to stay within budget. |

Environmental Factors | Pick materials that work well in your project’s conditions. |

Testing and Quality Control | Ensure the design allows easy testing without losing functionality. |

By checking these factors, you’ll know what your project needs. For example, high-power LEDs need PCBs with great heat control. Small designs may need flexible PCBs to fit tight spaces.

Tip: Always think about how easy it is to make your design. Complicated designs can cost more to produce.

Considering Environmental and Thermal Needs

Environmental and heat factors are key when picking a PCB. LEDs create heat, and without good heat control, they won’t last long. That’s why it’s important to follow thermal standards and tests.

Thermal standards like JESD51-50 and JESD51-51 help measure heat resistance and power use in LEDs. These tests ensure the PCB performs well. Here are some common thermal tests:

Thermal shock testing: Tests how the PCB handles sudden temperature changes.

Temperature cycling testing: Checks if the PCB stays reliable after repeated heating and cooling.

For tough environments, materials like ceramic or metal core PCBs (MCPCBs) are best. Aluminum or copper PCBs handle heat better than FR4 PCBs. For instance, aluminum PCBs work well with high-power LEDs in cars or factories. Ceramic PCBs are great for high-pressure and high-heat uses.

Note: If your project faces extreme heat or quick temperature changes, pick PCBs with strong heat control and durable materials.

Matching PCB Type to Application

Choosing the right PCB type ensures your project works well and stays affordable. Use this guide to match PCB features to your needs:

Category | Details |

|---|---|

Includes board size, layers, material, thickness, copper weight, and finish. | |

Design Rules and Constraints | Covers trace width, spacing, drill sizes, and critical nets. |

Signal and Power Integrity | Focuses on high-speed signals, sensitive circuits, and power needs. |

Compliance and Regulatory | Meets industry rules like IPC, UL, RoHS, and CE standards. |

Test and Validation Requirements | Includes testing points, design checks, and validation steps. |

Timeline and Milestones | Tracks project deadlines and key goals. |

For example, flexible PCBs are perfect for wearable tech. They’re light, bendable, and fit small spaces. Aluminum PCBs are great for high-power LED lights because they manage heat well. FR4 PCBs are affordable and versatile, ideal for general uses like LED displays or medical tools.

Pro Tip: Match your PCB choice to your project’s needs. This improves performance and saves money over time.

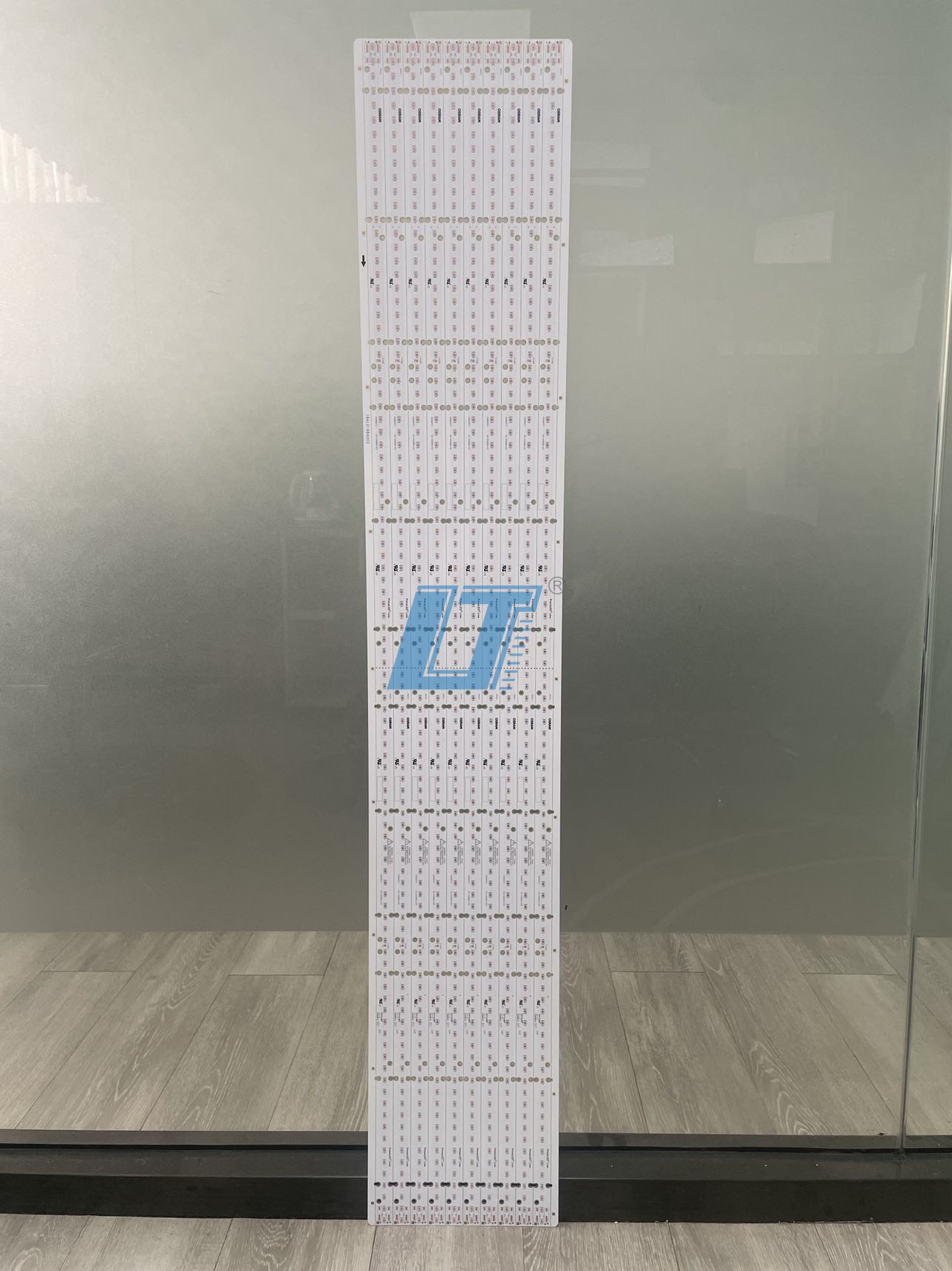

Why Choose LT CIRCUIT for Your LED PCB Needs?

LT CIRCUIT is a trusted name for LED PCBs. Here’s why you should choose us:

Unmatched Quality: We use top materials and tech to make reliable PCBs. Whether you need aluminum, FR4, or flexible PCBs, we deliver precision.

Customization Options: Every project is unique. We offer custom options like different solder mask colors and advanced finishes like ENIG and HASL.

Expertise Across Industries: Our PCBs are used in electronics, cars, medical tools, and more. We can meet your industry’s needs.

Commitment to Innovation: We push PCB technology forward. Our HDI and multilayer PCBs handle modern device demands.

Customer-Centric Approach: Your success matters to us. From design help to delivery, we work with you every step of the way.

Why wait? Work with LT CIRCUIT today and see the difference. Visit our official website to learn more.

Picking the right LED PCB depends on what you need. Aluminum PCBs are great at handling heat and are very strong. They work best for powerful electronics. FR4 PCBs are cheap and flexible, making them good for everyday gadgets. Flexible PCBs are thin and bendy, perfect for small or creative designs. Check out LT CIRCUIT’s smart options to find the best fit for your project.

FAQ

What’s the best LED PCB for high-power applications?

Aluminum PCBs are your best bet. They handle heat well and last longer, making them ideal for high-power LEDs like car headlights or industrial lighting.

Can flexible PCBs handle extreme temperatures?

Yes, flexible PCBs resist heat up to 400°C. They’re great for devices with occasional heat spikes, like wearables or automotive lighting systems.

Why should I choose LT CIRCUIT for my LED PCB needs?

LT CIRCUIT offers top-quality materials, custom options, and expert support. You’ll get reliable PCBs tailored to your project’s requirements. Visit LT CIRCUIT today!

Tip: Always match your PCB type to your project’s needs for the best results.

See Also

Choosing Flexible Circuits Over Rigid PCBs for Projects

Selecting Metal Core PCBs Over FR4 for Your Designs

Creating Efficient PCBs Specifically for LED Applications

Understanding Thermal and Electrical Benefits of Aluminum PCBs

Boosting LED and Power Electronics with Aluminum-Backed PCBs