Exploring LED PCBs and Their Role in Modern Lighting

PCBs for LEDs are specialized boards designed for contemporary LED lighting solutions. They enable lights to consume less energy and extend their lifespan. These boards also facilitate more compact designs, making them incredibly versatile. From residential spaces to industrial settings, they have revolutionized our approach to lighting across various environments.

Key Takeaways

LED PCBs use less energy and lower electricity bills. They are a great option for today's lighting needs.

These boards are small and light, making creative designs possible. They are used in gadgets, cars, and more.

LED PCBs handle heat well, helping lights last longer. This makes them work better and stay reliable in hard situations.

Anatomy of LED PCBs

LED Chips and Their Functionality

LED chips are the main part of an LED PCB. These small parts turn electricity into light, making them very important. To work well, manufacturers test LED chips in different conditions. This testing helps save energy and stops them from breaking. Signal checks make sure signals stay clear and don’t get messed up. Cooling methods keep the chips from overheating, which helps them last longer. By focusing on these things, LED PCBs give us strong and long-lasting lights.

Substrate Materials for LED PCBs

The substrate is the base of an LED PCB. It gives support and helps manage heat. Materials like polyimide are popular because they work well in hot or cold temperatures. Special materials, like CooLam™, help get rid of heat better. This keeps the LED working smoothly. The table below shows common substrate materials and their benefits:

Material Type | Benefit |

|---|---|

Polyimide Properties | Stays strong and works well in tough conditions. |

Thermal Management | CooLam™ helps remove heat for better performance. |

Reliability Testing | Makes sure it’s safe and strong for lighting use. |

Mechanical Stress Mitigation | Lowers stress, helping LEDs last longer. |

Bendable Substrate Technology | Allows flexible designs to save money and improve lighting. |

Copper Traces and Electrical Connections

Copper traces are like roads for electricity on the PCB. They connect LED chips to the power source, letting energy flow easily. The size and design of these traces are made to handle power safely. Good copper traces make LED PCBs work better and are great for high-performance uses.

Solder Mask and Silkscreen Features

The solder mask keeps copper traces safe from rust and short circuits. It also stops solder from connecting parts by accident during assembly. Tests make sure the solder mask sticks well and lasts a long time. The silkscreen layer adds labels to show where parts go. This makes building and fixing the PCB easier. Important checks include looking for holes, testing how well it sticks, and checking the labels are correct.

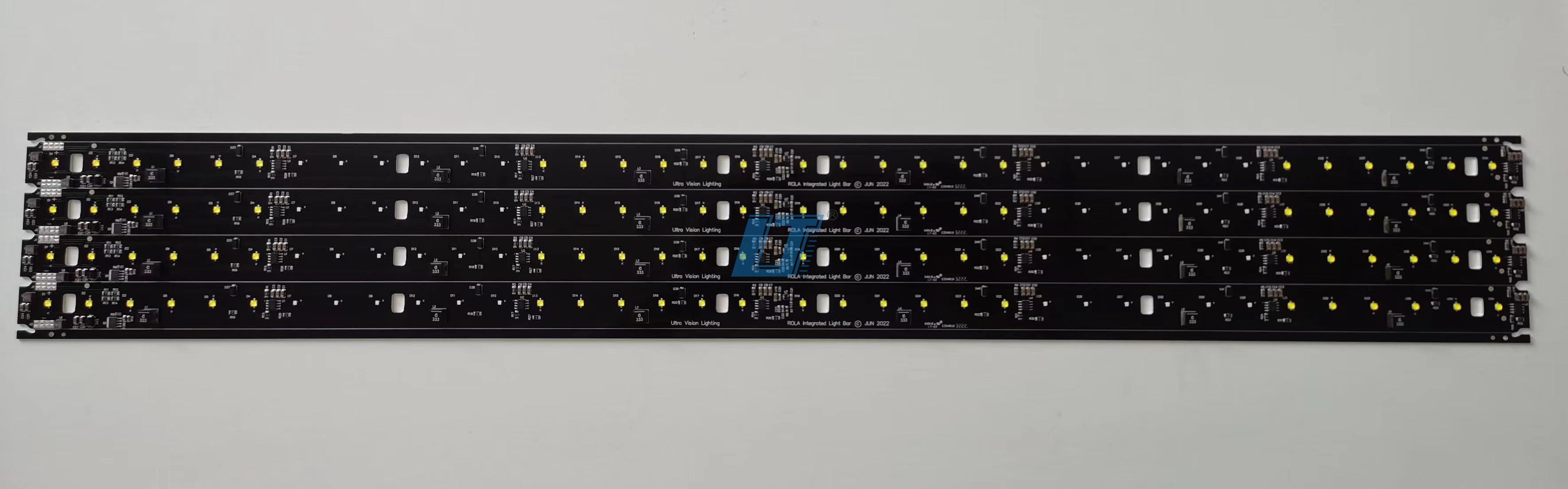

Types of LED PCBs by LT CIRCUIT

Single-Layer LED PCBs

Single-layer LED PCBs are the easiest type of circuit boards. They have one layer that carries electricity, making them great for simple LED uses. These boards are found in small LED lights that don’t need complicated designs. Their simple structure makes them cheaper and faster to produce.

Feature | Multi-Layer PCBs | |

|---|---|---|

Cost | Cheaper because of easy design and production. | More expensive due to complex design and needs. |

Design Complexity | Simple, good for basic devices. | Complex, good for advanced devices. |

Speed and Operating Capacity | Slower with fewer connections. | Faster with more circuits. |

Single-layer LED PCBs are a budget-friendly option for simple and low-cost projects.

Double-Layer LED PCBs

Double-layer LED PCBs are better than single-layer ones. They have layers on both sides, allowing more parts and better connections. These boards are great for devices needing stronger signals and better power flow.

More Space for Connections: Handles more complex wiring.

Higher Part Density: Parts can go on both sides.

Better Heat Control: Spreads heat well for better LED performance.

Double-layer LED PCBs are a flexible choice for gadgets needing reliability and efficiency.

Multi-Layer LED PCBs

Multi-layer LED PCBs have three or more layers stacked together. They are made for advanced LED systems where space is tight, and performance is key. These boards handle tricky circuits while staying small.

Benefit | Description |

|---|---|

Heat Control | Removes heat better, helping LEDs last longer. |

Uses less power and shines brighter. | |

Strong Build | Resists water, chemicals, and pressure. |

Multi-layer LED PCBs work best for high-tech uses like factory lights and smart gadgets.

Aluminum-Backed PCBs for LEDs

Aluminum-backed PCBs, also called metal core PCBs, manage heat very well. The aluminum base moves heat away from LED chips, stopping them from overheating and keeping them steady.

Special holes send heat to the aluminum base.

Thick copper layers help remove heat faster.

Material | Thermal Conductivity (W/m·K) |

|---|---|

Aluminum | 1.0 to 9.0 |

FR4 | 0.3 to 0.4 |

Aluminum-backed PCBs are perfect for bright and tough uses, like car and factory LED lights.

Benefits of LED PCBs in Modern Lighting

Energy Efficiency and Cost Savings

LED PCBs help save energy in lighting systems. They use less power by improving how LEDs work. This means bright lights with lower electricity bills. Centralized LED drivers, used with LED PCBs, cut starting costs by up to 35%. Yearly running costs drop by about 20%, making them a smart choice for saving money over time.

Compact Design and Lightweight Features

LED PCBs are small and fit in tight spaces. This makes them perfect for modern devices like smart gadgets or car lights. They are also light, so they are easy to move and install.

Advantage | Description |

|---|---|

Efficient Thermal Management | LED PCBs handle heat well, helping LEDs last longer. |

Compact Design | Small size fits into tight spaces, great for limited areas. |

Lightweight Features | Light boards are easy to use in many lighting setups. |

Their small size and light weight allow creative designs for LED lighting.

Durability and Longevity in Applications

LED PCBs are strong and last a long time. They can handle tough conditions without breaking. They also protect LEDs from damage caused by water, chemicals, or pressure. This makes them great for cars, planes, and electronics.

Effective Heat Dissipation for Performance

Managing heat is important for LED lights. LED PCBs are great at removing heat, keeping LEDs working well. Metal core PCBs, like aluminum ones, move heat 6 to 10 times better than regular boards. Aluminum heatsinks and special materials like aluminum nitrate improve this even more. By stopping heat buildup, LED PCBs help LEDs last longer.

Metal core PCBs remove heat very well.

Aluminum alloys with 190 W/mk improve heat flow.

Good heat control stops overheating and keeps LEDs working.

Environmental Friendliness and Sustainability

LED PCBs are eco-friendly because they use recyclable metals like copper and aluminum. These materials save resources and cut down on waste. Recycling parts also helps the environment by reducing harm. This makes LED PCBs a green choice for lighting.

Sustainability Practice | Benefit |

|---|---|

Recyclable Metals | Saves resources and supports eco-friendly goals. |

Material Optimization | Cuts waste and helps make products greener. |

Circular Economy Model | Reuses materials and reduces resource use. |

Using LED PCBs means saving energy and helping the planet.

Applications of LED PCBs Across Industries

Consumer Electronics and Smart Devices

LED PCBs are important in today’s electronics. They are used in phones, tablets, laptops, and smartwatches. Their small size and light weight make them perfect for these gadgets. LED PCBs help screens shine brighter while using less power. This saves battery life and improves features like brightness and color.

New ideas keep increasing the need for LED PCBs. As devices get smarter, LED PCBs make lighting and displays work better. They handle complex circuits, fitting easily into small devices.

Sector | Key Drivers |

|---|---|

Consumer Electronics | New ideas, demand for phones, tablets, laptops, and wearables. |

Automotive Lighting and Safety Systems

LED PCBs are key in car lights and safety systems. They power headlights, taillights, and inside lights. These lights are bright and save energy. LED PCBs also help safety systems like ADAS. These systems need good lighting for cameras and sensors to work well.

Managing heat is very important in car lights. LED PCBs use thermal pads, adhesives, and heat sinks to control heat. This stops overheating and helps LED systems last longer.

Metric Type | Description |

|---|---|

Thermal Pads | Help remove heat, needed for powerful car lights. |

Thermal Conductive Adhesives | Move heat well and keep parts connected strongly. |

Integrated Heat Sinks | Spread heat better, making LED systems last longer. |

Medical Devices and Surgical Lighting

LED PCBs are changing medical tools and surgery lights. They are reliable and precise, making them great for operating rooms and medical machines. LED PCBs give steady light, which is important for accurate work.

Manufacturers test them carefully to ensure they work well. Tests like thermal cycling and HALT find weak spots. Following safety rules like IEC 60601-1 and ISO 13485 ensures quality. LED PCBs also manage power well, keeping lights steady during long use.

Evidence Type | Description |

|---|---|

Rigorous Testing | Tests like thermal cycling and HALT ensure reliability. |

Medical Compliance Standards | Meets safety and quality rules like IEC 60601-1 and ISO 13485. |

Power Distribution Optimization | Uses power planes and regulators for steady LED performance. |

Industrial and Commercial LED Lighting

LED PCBs are common in factory and office lights. They provide bright, energy-saving light for workspaces. They are tough and can handle heat and stress.

More factories use automation and smart tech, increasing the need for LED PCBs. Industry 4.0 tools need good lighting for machines and sensors. LED PCBs help improve safety and productivity in these places.

Sector | Key Drivers |

|---|---|

Industrial Electronics | Automation, smart tech, and Industry 4.0 tools. |

Aerospace and Aviation LED Solutions

LED PCBs are used in planes for cabin lights, navigation, and cockpit displays. They work well in extreme conditions, making them perfect for these uses.

New aerospace technology increases the need for LED PCBs. They are small and light, helping reduce plane weight and save fuel. LED PCBs also support military planes by providing reliable lighting systems.

Sector | Key Drivers |

|---|---|

Aerospace & Defense | High-performance needs, new aerospace tech, and bigger defense budgets. |

Practical Considerations for Using LED PCBs

Design Tips for Optimal LED PCB Performance

To make LED PCBs work well, focus on key designs. Use materials that handle heat well to stop overheating. Make circuit paths wide and spaced out to avoid problems. Place LEDs carefully for even light and good color. Protect the board with coatings that resist water and handle temperature changes. Ensure steady power by checking voltage drops and picking the right parts.

Tip: Add resistors directly to the PCB to make assembly easier and improve how it works.

Material Selection for Heat Management

Picking the right materials is important to control heat in LED systems. Bases like ceramics or metal-core PCBs move heat away fast, stopping overheating. Match how materials expand with heat to avoid stress. Use thermal vias with special glue to move heat better. Place these vias in the right spots to improve heat flow and reduce problems, making the board work better.

Thermal Management Techniques in LED PCBs

Good heat control keeps LEDs working their best. Arrange thermal vias in a grid to spread heat. Use metal bases with low heat resistance for better cooling. Add copper areas under strong LEDs to spread heat evenly. Gaps between LED groups help air move and cool them. Coatings like anodized finishes help release heat. Tools like thermal imaging find hot spots and fix heat issues in LED boards.

Manufacturing Processes by LT CIRCUIT

LT CIRCUIT uses advanced methods to make great LED PCBs. Laser tools improve accuracy by skipping extra steps. Surface treatments stop copper from rusting and make soldering easier. V-CUTs split boards into smaller pieces for flexible use. Flying probe testers check circuits to ensure they work. Special hole methods add more connections while keeping boards light. Eco-friendly materials and recycling systems protect the environment and support green practices.

LED PCBs are important in today’s lighting systems. They save energy, last longer, and allow creative designs. These boards are used in cars, planes, and gadgets. They handle heat well and are eco-friendly, making them a great option.

Explore LT CIRCUIT: Find smart LED PCB solutions for efficient and green lighting.

FAQ

Why are LED PCBs better than old lighting systems?

LED PCBs save energy and last a long time. They handle heat well, keeping lights steady. Their small size allows cool and modern designs.

How do LED PCBs help the environment?

LED PCBs use metals like aluminum and copper that can be recycled. This cuts down waste and helps the planet. They also save energy, lowering pollution.

Can LED PCBs work in tough conditions?

Yes, LED PCBs are built to be strong. They can handle heat, water, and pressure. This makes them great for cars, planes, and medical tools.

Tip: Pick good-quality LED PCBs for better results and longer use in hard conditions.

See Also

Why RoHS Compliance Matters in Today's PCB Production

How LDI Technology Affects PCB Product Quality

A Look at Common Stack-Up Designs for HDI PCBs

Understanding Single-Sided, Double-Sided, and Multilayer PCBs

Defining PCB Printed Circuit Boards and Their Key Principles