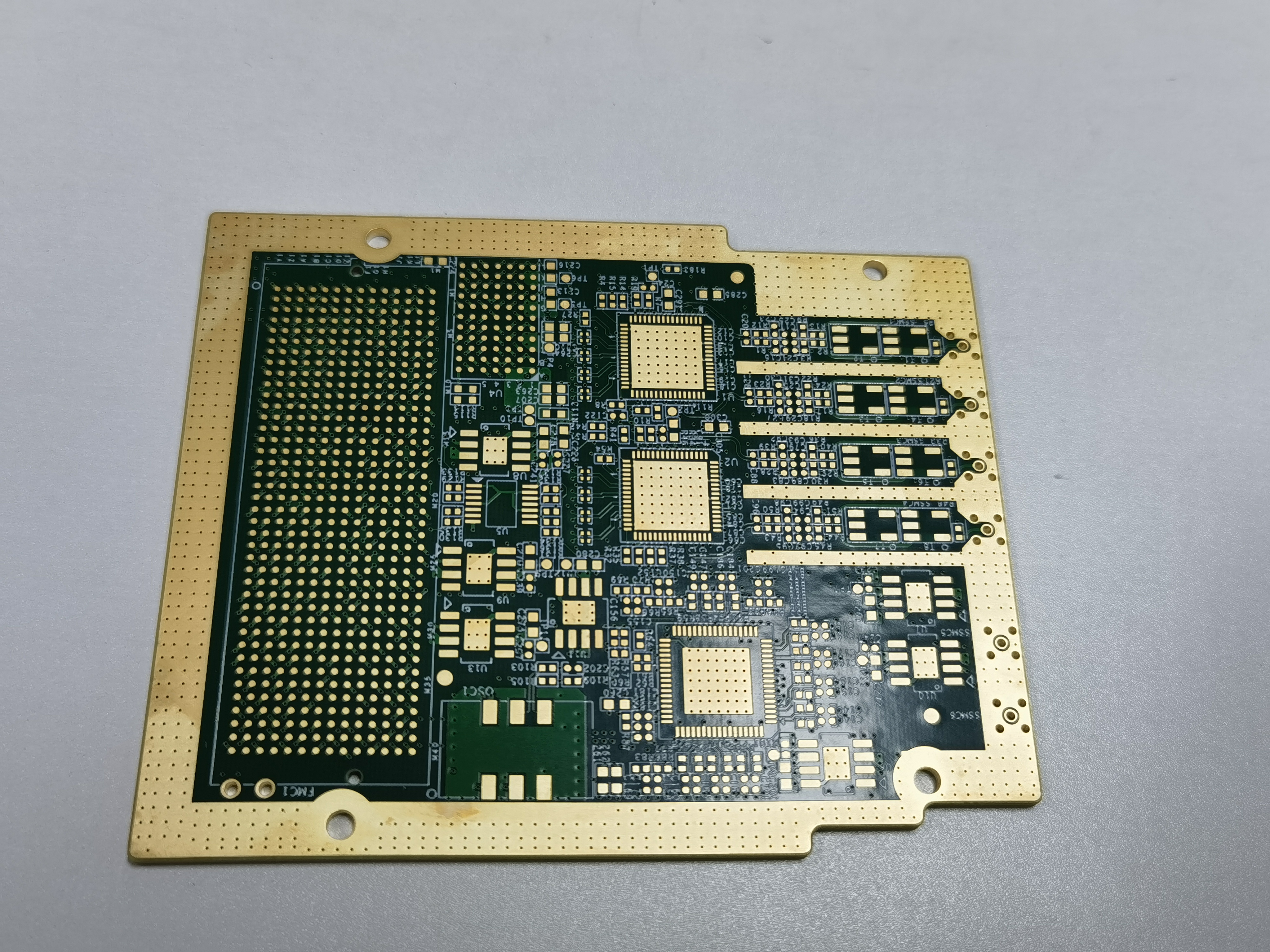

Manufacturing Challenges and Solutions for High TG FR4 Laminate PCBs in Industrial Control Systems

Manufacturing challenges often arise when engineers select pcb materials for high tg pcb used in industrial controls. High tg materials resist thermal stress, maintain electrical performance, and protect reliability in harsh settings. Experimental data shows standard pcb materials lose bond strength by 50% at high temperatures, while high tg pcb maintains integrity.

Metric | High TG PCB Value | Standard PCB Value |

|---|---|---|

Glass Transition Temperature (Tg) | >170°C | 130-140°C |

Thermal Endurance | Maintains mechanical strength and electrical properties after 200°C for 1000 hours | N/A |

Coefficient of Thermal Expansion (CTE) | 10-15 ppm/°C | 16-18 ppm/°C |

Dielectric Constant | 3.9 | 4.4 |

Operating Temperature Margin | N/A |

LT CIRCUIT delivers solutions and best practices that help manufacturers overcome these challenges and achieve consistent performance with high tg materials in every pcb.

Key Takeaways

High TG PCB materials resist heat and mechanical stress, ensuring reliable performance in harsh industrial environments.

Manufacturing high TG PCBs requires precise thermal management and advanced drilling techniques to prevent defects and maintain quality.

Choosing certified high TG materials and trusted suppliers guarantees durable, stable PCBs that meet strict industrial standards.

High TG Materials in Industrial Controls

Key Properties of High TG PCBs

High tg materials play a vital role in industrial electronics. These materials provide the foundation for high tg pcb designs that must withstand high-temperature environments and mechanical stress. The glass transition temperature (tg) of high tg pcb material often exceeds 170°C, which allows the pcb to maintain stability and performance even when exposed to extreme heat. High tg materials deliver superior thermal stability, durability, and electrical performance, making them essential for high-performance electronics.

Thermal/Electrical Property | Description and Impact on Industrial Control Systems |

|---|---|

Glass Transition Temperature (Tg) | ≥180°C, enabling pcbs to resist structural degradation in harsh industrial settings. |

High Heat Resistance | Supports reliable operation under fluctuating temperatures and heat-generating components. |

Low Z-Axis Thermal Expansion Coefficient | Reduces risk of cracks and solder joint failures during thermal cycling. |

High Reliability of Plated Through Holes | Maintains inter-layer connections under thermal stress, boosting electrical reliability. |

Improved Mechanical Strength and Rigidity | Minimizes warping and cracking, ensuring pcb stability and durability. |

Preserves pcb shape and size, preventing misalignment and ensuring precise interconnectivity. | |

Enhanced Solderability | Increases solder joint reliability, reducing cracks during reflow soldering. |

Efficient Heat Dissipation | Prevents heat buildup, protecting components and ensuring stable electrical performance. |

Resistance to Thermal Stress | Withstands rapid temperature changes without delamination or degradation, critical for industrial use. |

Requirements for Industrial Applications

Industrial electronics demand high tg pcb material that meets strict criteria for durability and stability. High tg pcb must use materials with a glass transition temperature above 170°C. This threshold ensures the pcb maintains dimensional stability and insulation reliability, even under high temperature pcb conditions. High tg materials include advanced epoxy resins, polyimide, and ceramic-filled polymers. These materials undergo rigorous testing for thermal stability, moisture endurance, and mechanical strength. High tg pcb material resists copper delamination and blistering, extending the service life of the pcb in demanding applications.

LT CIRCUIT demonstrates a strong commitment to quality and innovation by selecting high tg materials that meet or exceed industry benchmarks. The company’s expertise in high-performance electronics ensures every pcb delivers optimal performance, reliability, and durability for industrial control systems.

Manufacturing Challenges for High TG PCBs

Manufacturing high tg pcb for industrial electronics presents unique challenges. These challenges stem from the need for high temperature pcb stability, durability, and consistent performance in demanding environments. Manufacturers must address thermal stress, mechanical brittleness, lamination complexity, and strict quality assurance to ensure reliable pcbs.

Thermal Management Issues

High tg pcb materials offer superior thermal stability, but they also introduce new manufacturing challenges. High temperature pcb environments can cause uneven heat distribution during soldering and reflow processes. This heat can lead to warping, resin recession, or even microcracks in the pcb. High tg laminates have lower thermal conductivity, which means heat does not dissipate quickly. This increases the risk of localized overheating and affects the stability of the pcb.

Manufacturers must use advanced process controls to manage these issues. LT CIRCUIT implements precise temperature profiles during soldering and lamination. This approach ensures even heat distribution and protects the mechanical strength of the pcb. The company also uses materials with high tg values to maintain stability and performance under repeated thermal cycling. These solutions help prevent thermal degradation and extend the durability of high temperature pcb products.

Tip: Consistent monitoring of thermal profiles during manufacturing improves the stability and performance of high tg pcb, reducing the risk of thermal stress failures.

Drilling and Routing Difficulties

Drilling and routing high tg pcb materials require strict control over precision and process parameters. The hardness and brittleness of high tg materials make them more difficult to machine than standard pcb substrates. Drill bits wear out faster, and improper techniques can cause defects such as smear, breakout, or misalignment.

Metric | Typical Tolerance / Guideline | Impact on High Tg PCB Drilling Challenges |

|---|---|---|

±0.05 mm | Precise hole placement is critical to avoid misalignment, especially difficult with harder high Tg materials. | |

Hole Diameter Tolerance | ±0.025 mm | Variations affect component fit and plating quality; harder materials increase drill wear affecting tolerance. |

Circularity | Close to 1 (ratio) | Ensures round holes; deviations can cause plating and mechanical issues. |

Aspect Ratio (Depth:Diameter) | Max 10:1 | Higher ratios increase plating difficulty and risk of defects; high Tg boards often require careful control. |

Drill Smear | Minimized by process control | Resin debris affects plating adhesion; high Tg materials exacerbate heat buildup causing smear. |

Hole Breakout | Avoided by breakthrough detection | Prevents damage to outer layers; harder materials increase risk without proper technique. |

Drill Techniques | Peck drilling recommended | Reduces heat buildup in poor thermal conductivity high Tg materials, mitigating thermal stress. |

Manufacturers must maintain drill-to-copper clearance of at least 8 to 12 mils to prevent shorts or mechanical failures. Sufficient annular ring around holes is essential for solder joint reliability, which becomes more challenging with high tg pcb substrates. LT CIRCUIT uses advanced drilling equipment and techniques such as peck drilling to reduce heat buildup and tool wear. The company also employs laser drilling for micro vias in HDI pcbs, ensuring high precision and stability. These solutions guarantee the mechanical integrity and performance of the finished pcb.

Delamination and Quality Risks

Delamination remains a significant risk during the manufacturing of high tg pcb. High temperature pcb processes, such as multilayer lamination, expose the pcb to repeated thermal cycles. If the process does not control pressure, temperature, and moisture, layers may separate, leading to electrical failures and reduced durability.

Quality assurance plays a vital role in preventing these issues. LT CIRCUIT enforces strict process controls and uses high tg materials with proven adhesion properties. The company conducts rigorous testing, including flying probe and E-tests, to verify the stability and performance of every pcb. These measures ensure that each pcb meets the highest standards for industrial electronics.

Note: Reliable quality assurance and process control are essential for maintaining the stability, durability, and performance of high tg pcb in industrial environments.

Manufacturing challenges for high tg pcb require advanced solutions and a commitment to quality. LT CIRCUIT addresses these challenges with innovative processes, strict quality assurance, and a focus on stability and durability. This approach ensures that every pcb delivers consistent performance in high temperature pcb applications for industrial electronics.

Selecting High TG PCB Materials

Evaluating TG Ratings

Selecting the right high tg pcb material starts with understanding tg ratings. Tg, or glass transition temperature, shows the point where the pcb material changes from rigid to soft. For industrial control pcbs, engineers should choose high tg materials with a tg above 170°C. This ensures the pcb can handle high temperatures and thermal cycling.

Typical Application Areas | |

|---|---|

130-140°C | Consumer electronics |

170-180°C | Industrial, automotive, medical applications |

200°C+ | Aerospace, military, extreme environments |

High tg pcb material with a higher tg provides better thermal stability and reliability. LT CIRCUIT offers fr4 high tg material, polyimide, and ceramic-filled laminates. These materials help pcbs resist warping, delamination, and electrical failure in harsh environments.

Process Compatibility

Engineers must check if the high tg pcb material matches the manufacturing process and the needs of the industrial control system. Matching the coefficient of thermal expansion prevents mechanical stress during thermal cycling. High tg materials must also pass tests like Differential Scanning Calorimetry and Thermomechanical Analysis. LT CIRCUIT uses fr4 high tg material and other advanced materials that meet IPC and ISO standards. The company’s pcbs pass EMC, mechanical, and functional tests to ensure safe and stable operation.

Tip: Always confirm that the selected high tg pcb material supports lead-free assembly and meets all regulatory requirements.

Supplier and Certification

Choosing a reliable supplier for high tg pcb material is key. LT CIRCUIT provides a wide range of high tg materials, including fr4 high tg material, polyimide, and PTFE. The company holds ISO 9001, UL, and IPC certifications, showing strong quality control. LT CIRCUIT offers customization for thickness, layer count, and surface finish, helping customers get the best pcb for their needs.

Look for suppliers with:

Proven high tg pcb material performance

Certifications like ISO 9001 and IPC-4101

Strong testing and quality assurance systems

LT CIRCUIT’s expertise and certified processes ensure every pcb meets strict industrial standards for reliability and durability.

High TG PCBs face challenges in manufacturing, but advanced solutions improve reliability and quality.

Engineers should select materials that support strong reliability and stable performance.

LT CIRCUIT delivers quality products and supports customers who demand reliability in industrial control systems.

Reliable partners help ensure long-term reliability in every application.

FAQ

What makes high TG FR4 laminate ideal for industrial control PCBs?

High TG FR4 laminate resists high temperatures and mechanical stress. It maintains electrical performance in harsh environments.

This material ensures long-term reliability for industrial systems.

How does LT CIRCUIT ensure quality in high TG PCB manufacturing?

LT CIRCUIT uses certified materials, advanced process controls, and strict testing.

Quality Step | Description |

|---|---|

Material Selection | Certified suppliers |

Testing | Flying probe, E-test |

Can high TG PCBs support lead-free assembly processes?

Yes. High TG PCBs from LT CIRCUIT support lead-free assembly.

They withstand higher reflow temperatures.

They meet RoHS and IPC standards.

See Also

High Tg FR4 PCBs Deliver Outstanding Results In Harsh Temperatures

Key Factors And Needs For Industrial PCB Production In Tough Conditions

LT CIRCUIT’s Expertise In Handling Complex PCB Fabrication Projects

Advanced Production Techniques For Heavy Copper Multilayer PCB Fabrication

Typical PCB Design Challenges And Fixes For SMT Processing Needs