How to Master Quality Control in PCB Manufacturing

Quality control is very important in making PCBs. It helps make products reliable and last longer. Using tools like Statistical Process Control (SPC) and Pareto Analysis helps find problems early. These tools reduce mistakes and make better PCBs. Checking solder height also improves how well things work. Quality is needed at every step.

Key Takeaways

Quality control is very important in making PCBs. It makes products last longer and work better.

Use tools like Statistical Process Control (SPC) to find and fix problems early. This lowers mistakes and saves money.

Design PCBs with test points for easy checking. This finds problems during production and keeps quality high.

Quality Control in PCB Design

Checking Design Files for Good PCB Quality

Checking design files is the first step to ensure good PCB quality. By carefully reviewing your files, you can spot problems early. This prevents expensive mistakes during manufacturing. For example, thermal checks find overheating risks, and signal checks ensure stable performance. These steps are very important in industries like electronics and industrial systems, where reliability is a must.

Problems Found | Review Steps | Results | |

|---|---|---|---|

Consumer Electronics | Overheating, Signal Issues | Thermal Checks, Signal Analysis | Better Performance, Reliable Use |

Industrial Control System | Part Placement, Electrical Errors | Placement Review, Rule Checks | Easier Maintenance, Error-Free Design |

By checking your design files, you can avoid common mistakes like bad part placement or rule-breaking errors. This step improves PCB quality and makes them work better in real-world uses.

Making PCBs Easy to Manufacture

Making PCBs easy to produce is another key part of quality control. You should design PCBs that are simple to make but still work well. Tools like Statistical Process Control (SPC) help track production. SPC finds problems early, reducing defects and keeping quality steady.

For example, good process control can lower setup costs a lot. Combining four 25 sq. cm PCBs into one 100 sq. cm panel can save up to 25% per order. Also, using fewer layers in a PCB can cut costs by 10-30% without losing functionality.

Description | Cost Before | Cost After | Savings | Percentage Saved |

|---|---|---|---|---|

6-layer IoT PCB | $12 | $8 | $4 | 33% |

Automotive PCB (8 to 6 layers) | $20 | $15 | $5 | 25% |

By focusing on easy manufacturing, you save money and make high-quality PCBs more affordable.

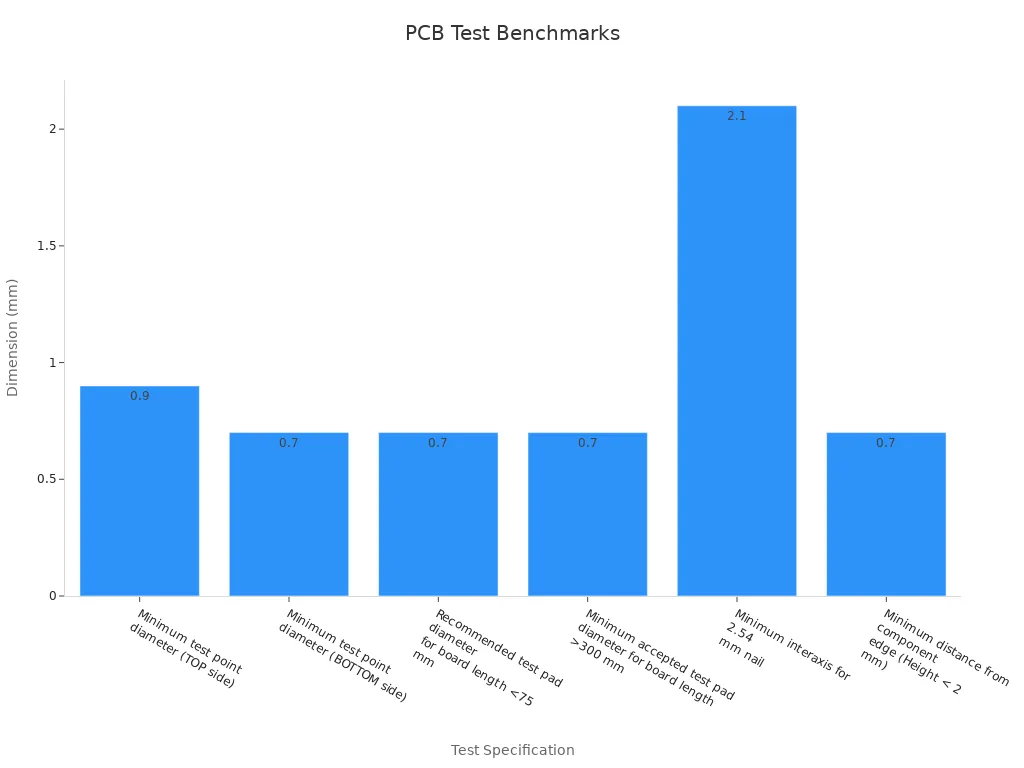

Designing PCBs for Easy Testing

Designing PCBs for easy testing is crucial for quality control. Adding test points and simple layouts helps find and fix problems during production. This ensures your PCBs meet top quality standards.

Here are some important rules for testable PCBs:

Value | |

|---|---|

Smallest test point size (TOP side) | 0.9 mm |

Smallest test point size (BOTTOM side) | 0.7 mm |

Suggested test pad size for boards <75 mm | 0.7 mm |

Smallest test pad size for boards >300 mm | 0.7 mm |

Minimum space for 2.54 mm nail | 2.1 mm |

Space from part edge (Height < 2 mm) | 0.7 mm |

Following these rules makes testing easier and ensures reliable PCBs. This is especially important in fields like cars and healthcare, where even small problems can cause big issues.

Quality Control in PCB Production

Picking the Right Manufacturer for PCB Quality

Choosing a good manufacturer is very important for quality PCBs. Look at how well they meet standards and control quality. Check things like fewer defects, better yield rates, and efficient processes.

Metric | What It Means | Why It Matters |

|---|---|---|

Defect Reduction | Tracks how many mistakes are fixed during production. | Helps improve product success. |

Yield Rates | Shows the percentage of good products made. | Tells how reliable the process is. |

Quality Control Efficiency | Measures how well quality checks are done. | Affects the final product quality. |

By studying these details, you can find manufacturers who are great at quality control. This helps make sure your PCBs are reliable and reduces problems during production.

Pre-Manufacturing Checks with LT CIRCUIT

Checking everything before making PCBs is very important. LT CIRCUIT has tools and experts to help with this. They check designs, pick materials, and improve processes. These steps make sure your PCBs follow industry rules before production starts. Working with LT CIRCUIT makes the process smoother and keeps quality high.

Watching Production Steps for Better PCB Quality

Keeping an eye on production steps is key for good PCBs. Tools like the chi-square test find defect patterns to fix problems. Automation helps by reducing mistakes and applying materials correctly. Machines like optical inspection systems catch errors quickly. These tools lower mistakes, save money, and make production easier.

Quality Control in PCB Inspection

Ways to Check PCB Quality

Good inspection methods are key to making great PCBs. You can use both manual checks and machines to find problems and ensure quality.

Looking at PCBs by hand is a basic method. Skilled workers check for surface flaws, solder mask issues, and hole placement. But for making many PCBs, machines like Automated Optical Inspection (AOI) systems are better. AOI uses cameras and software to spot problems like misplaced parts or bad soldering. X-ray inspection is another tool that finds hidden issues, especially in crowded boards.

Inspection Method | Key Features |

|---|---|

Manual Visual Inspection | Cheap but can miss errors, not ideal for large batches. |

Automated Optical Inspection (AOI) | Uses cameras to find defects, saves time and money. |

X-ray Inspection | Finds hidden problems, great for dense circuit boards. |

New tools have made PCB checks much better. For example, a phone company cut defects by 40% using AOI and X-ray tools. These methods not only find more problems but also make production faster and more reliable.

Testing PCBs for Quality

Testing is very important to make sure PCBs work well. It helps find problems and ensures the boards do their job, avoiding costly mistakes.

Two main tests are AOI and Functional Testing (FCT). AOI looks for surface problems, while FCT checks if the PCB works electrically. Using data analysis with these tests helps find patterns and improves accuracy. This reduces wrong results and ensures better testing.

Method | Description | Effectiveness |

|---|---|---|

SEPDNet | Uses AI to find tiny defects fast. | Spots 2 mm flaws in 10 seconds. |

Ensemble Learning | Combines different AI models for better results. | Finds 95% of PCB problems. |

Testing is especially important in fields like healthcare and space, where mistakes are not allowed. For example, a car part maker improved PCB reliability by 30% with heat and vibration tests. Using these advanced tests ensures your PCBs meet high standards.

Following Rules for PCB Quality

Following industry rules is a must for good PCB quality. These rules make sure PCBs are safe, reliable, and work as expected.

Rules cover materials, design, and how PCBs are made. For example, they set standards for copper thickness and solder mask strength. They also explain how to test PCBs for electrical and physical performance.

Aspect | Description |

|---|---|

Materials | Lists what materials to use, like copper and laminates. |

Design | Gives tips for layout, like trace width and spacing. |

Manufacturing | Explains steps like drilling and plating. |

Testing | Details how to test for strength and performance. |

By following these rules, you can make sure your PCBs meet customer needs and legal requirements. Regular checks and data tracking help keep quality high and consistent.

Doing quality checks at every PCB-making step gives better results. Working with LT CIRCUIT offers smart tools like AI and digital twins. These tools make production faster and more reliable.

Methodology | What It Does |

|---|---|

Uses AI to improve machine work and predict problems. | |

Digital Twin Model | Creates a virtual model for better teamwork between people and machines. |

Good quality control lowers mistakes and boosts performance. For instance, a medical company launched products 40% faster. An aerospace firm made 99.8% of their PCBs right the first time.

Example | Improvement Type | Outcome |

|---|---|---|

Medical Device Company | Faster product launch | 40% |

Aerospace Firm | Better first-pass rate | 99.8% |

Use advanced testing tools and follow rules to ensure great PCBs. These actions help meet customer needs and industry standards.

FAQ

What is the most important step in PCB quality control?

Inspection is the most important step. It checks if your PCBs follow design rules and meet industry standards. This step reduces errors and makes PCBs more reliable.

How does LT CIRCUIT help make better PCBs?

LT CIRCUIT provides smart tools, expert advice, and early checks. These services make sure your PCBs meet rules and work well in real-life situations.

💡 Tip: Working with LT CIRCUIT can make PCB production easier and improve quality checks.

Why is it important to design PCBs for testing?

Designing for testing makes finding problems easier. It helps fix issues during production so your PCBs work as they should.

See Also

Understanding The Process Behind PCB Manufacturing Techniques

Key Skills Required For Multi-Layer PCB Layout Design

Selecting A Reliable PCB Manufacturer For Your Company