How Multilayer Ceramic PCBs Are Manufactured: A Complete Guide

The making of multilayer ceramic PCBs uses careful methods to build strong, high-quality parts. These PCBs are great at handling heat and work reliably, which makes them very useful in today’s electronics. Fields like aerospace, cars, and communication depend on these PCBs to manage faster data and higher frequencies. As the market is expected to grow by 9.91% each year until 2031, their importance keeps increasing.

Key Takeaways

Multilayer ceramic PCBs are important for advanced electronics. They manage heat well and keep signals strong, making them great for industries like space and cars.

Making ceramic PCBs needs careful steps like preparing materials, stacking layers, and checking quality. Each step makes sure the final product works well and lasts long.

Picking LT CIRCUIT for ceramic PCBs means getting top-quality, custom options. Their modern methods and strict checks make strong and useful PCBs for many uses.

Understanding Multilayer Ceramic PCBs

What Are Multilayer Ceramic PCBs?

Multilayer ceramic PCBs are special circuit boards made by stacking ceramic layers. These layers are joined tightly to form a strong and compact board. Unlike regular PCBs that use fiberglass or resin, ceramic PCBs use materials like alumina or aluminum nitride. These materials help move heat well and block electricity where needed.

Multilayer ceramic PCBs are used in devices where performance and reliability are key. They can handle high heat and fast signals better than regular boards. Their small size lets more parts fit into less space, making them perfect for modern gadgets.

Key Advantages of Ceramic Multilayer PCBs

Ceramic multilayer PCBs have many benefits that make them better than other PCBs. They manage heat well, helping electronics last longer. They also keep signals strong, which is important for fast data systems.

Here’s a simple look at their benefits in different industries:

Application | Key Benefits |

|---|---|

Automotive Radar Systems | - Detects farther with less signal loss |

- Fewer failures in hot conditions | |

- Better production quality without bending issues | |

- Smaller design without extra cooling parts | |

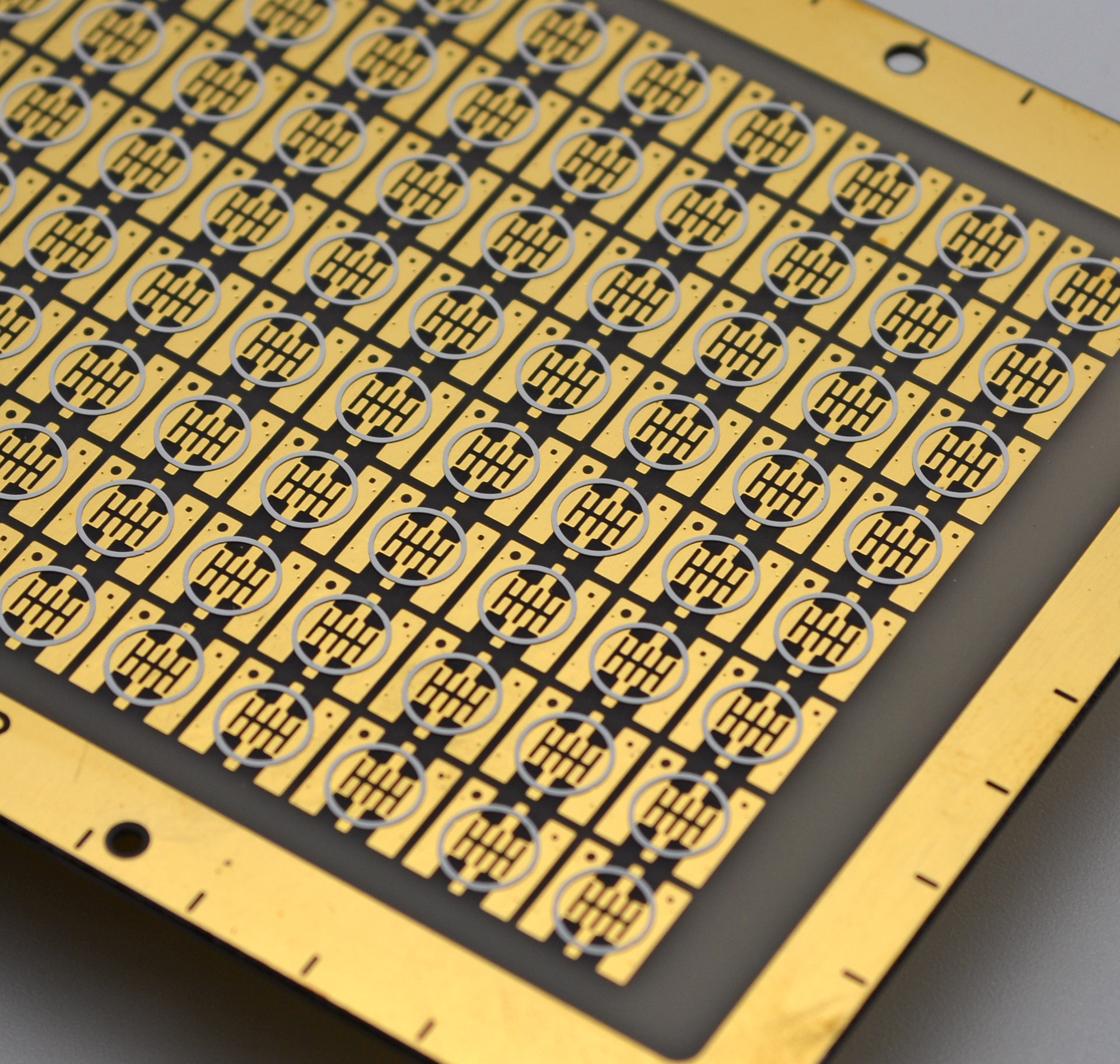

High-Power LED Lighting | - Brighter lights due to better heat control |

- Longer life, lasting over 100,000 hours | |

- Fewer warranty problems | |

- Lighter design without extra heat sinks | |

Military Communications Equipment | - Smaller systems with fewer parts |

- Works better in tough weather conditions | |

- Stronger signals for longer communication range | |

- Easier to build with fewer connections |

These benefits make ceramic multilayer PCBs a top choice for industries like cars, lighting, and military tools. They work well in tough situations, ensuring devices stay reliable and efficient.

Material Selection in Ceramic PCB Manufacturing

Ceramic Materials Used in PCBs

Choosing the right materials is very important for making ceramic PCBs. These PCBs often use alumina (Al₂O₃) and aluminum nitride (AlN). Both materials are great at handling heat and stopping electricity from passing through.

Alumina is popular because it costs less and works well. It can handle heat between 20 to 30 W/mK, which is good for medium heat needs. Aluminum nitride is better for high heat jobs, with heat handling between 170 to 200 W/mK. This makes it perfect for devices that need strong heat control.

Here’s a simple comparison of ceramic PCBs and regular FR4 PCBs:

Property | Ceramic PCB | FR4 PCB |

|---|---|---|

Thermal Conductivity | Low (0.2-0.3 W/mK) | |

Operating Temperature | Up to 350°C or higher | Typically up to 130°C |

Dielectric Loss | Low | Higher |

These features make ceramic PCBs better for devices that need to handle high heat and fast signals.

Properties That Make Ceramic Ideal for PCBs

Ceramic materials are special because they work well for multilayer PCBs. They move heat away quickly, keeping electronic parts safe and reliable. For example, aluminum nitride ceramic PCBs can handle heat up to 200 W/mK, much higher than FR4 PCBs, which only manage 0.2-0.3 W/mK.

Ceramic PCBs also stay strong in very hot places. They can handle temperatures as high as 1000°C without breaking down. Their low dielectric loss keeps signals clear, making them great for fast data systems.

Key benefits of ceramic materials include:

Staying stable in very hot conditions.

Managing heat well to make parts last longer.

Being tough and not bending or breaking easily.

These features make ceramic PCBs important for industries like airplanes, cars, and communication devices.

Preparing Materials for Multilayer Ceramic PCB Production

Making ceramic PCBs requires careful steps to ensure quality.

Material Preparation: Ceramic powders like alumina or aluminum nitride are mixed with binders to make a paste.

Tape Casting: The paste is spread into thin sheets to control layer thickness.

Screen Printing: Electrical paths are printed onto the sheets.

Layer Stacking: Layers of ceramic and conductive material are stacked together.

Integration of Components: Parts are added inside the layers during stacking.

Co-Firing Process: The stack is heated to bond layers and parts together.

Finishing Touches: The PCB is cooled, polished, and checked for quality.

These steps make sure the materials are prepared correctly, creating strong and reliable ceramic PCBs. Tests like Weibull analysis are used to check strength and avoid problems.

By following these steps, ceramic PCBs can be made to handle heat, last long, and work well.

How Are Ceramic PCBs Made? Step-by-Step Process

Substrate Preparation Techniques

The first step is getting the base material ready. High-quality ceramics like alumina or aluminum nitride are chosen. These materials are turned into fine powders and mixed with binders. This mixture becomes a paste, which is spread into thin layers using tape casting.

Tape casting makes sure the layers are evenly thick. This is important for keeping the layers consistent. Afterward, the sheets are dried and cut to the needed size. This step prepares the base for the rest of the process.

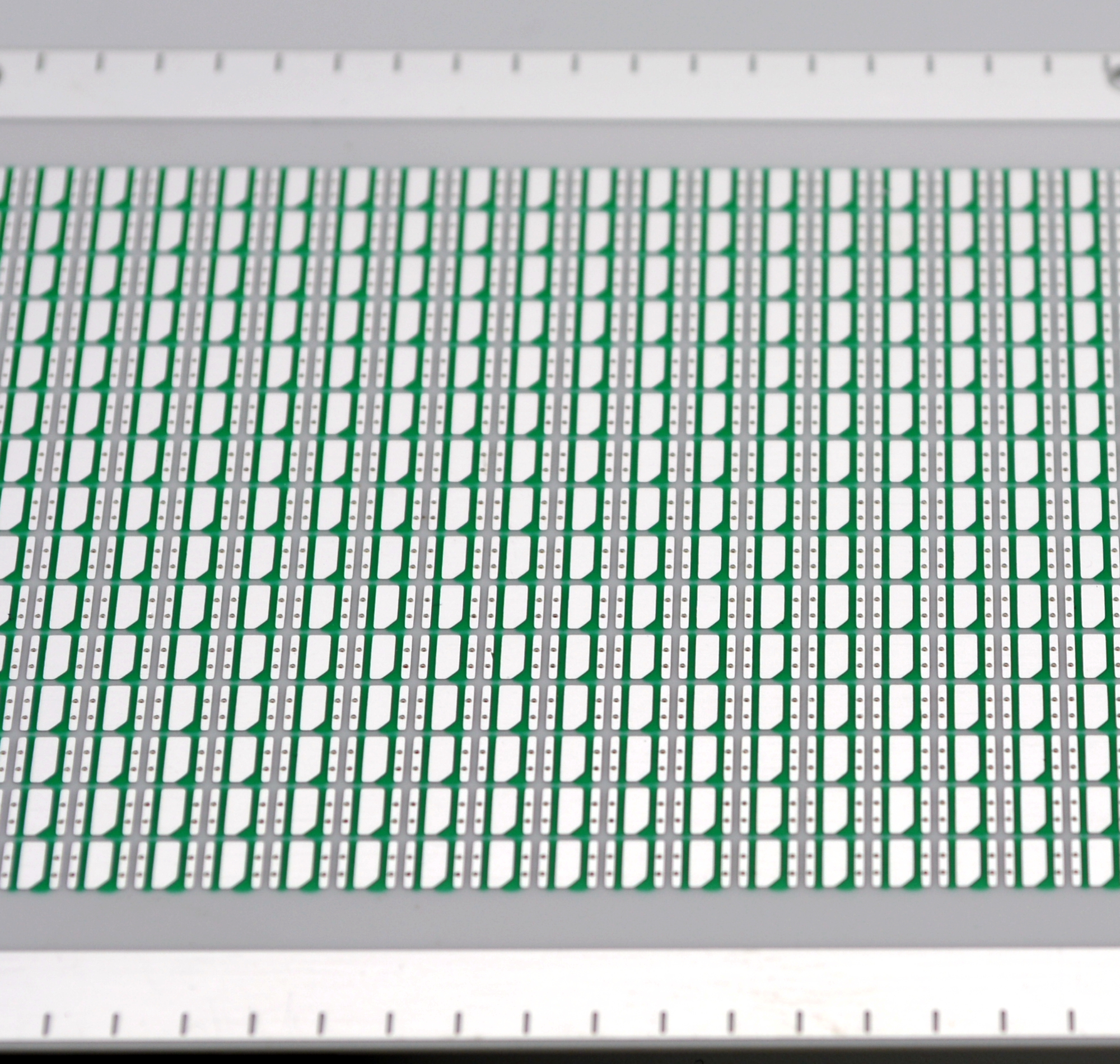

Layer Stacking and Lamination

Stacking layers is an important part of making ceramic PCBs. Ceramic sheets are stacked with metal layers in between. The metal layers are made by screen printing, which adds circuit patterns using metal paste.

The layers are carefully lined up using special tools. Once aligned, they are pressed together under heat and pressure. This step removes air gaps and bonds the layers tightly.

Factor | Description |

|---|---|

Layers are pressed together in a vacuum to bond them. | |

Air Entrapment | Air gaps are removed to prevent layers from separating. |

Tools like optical systems ensure layers are lined up correctly. | |

Pressure Control | Machines adjust pressure based on the board's thickness. |

This process makes the PCB stronger and more reliable.

Via Drilling and Hole Formation

Vias connect the layers in a ceramic PCB. Holes are made by drilling or punching through the stacked layers. Laser drilling is often used because it is precise and causes less damage.

After drilling, the holes are coated with metal like copper or silver. This creates pathways for electricity to flow between the layers. This step is key for making the PCB work properly.

Metallization and Circuit Patterning

Metallization adds metal layers to the ceramic base to form circuits. This can be done using screen printing or sputtering.

The metal paths must stick well to the ceramic surface. After adding the metal, extra material is removed to leave only the needed circuits. This step ensures the circuits are precise and ready for use.

Firing and Sintering for Enhanced Properties

Sintering is when the stacked layers are heated to high temperatures. This step makes the ceramic material denser and stronger.

Aspect | Description |

|---|---|

Transformation of Ceramic Powder | Heating turns ceramic powder into solid, strong material. |

Densification and Reduction of Porosity | Makes the material less porous and more durable. |

Formation of a Uniform Microstructure | Creates even material for better performance. |

Increases strength, heat resistance, and electrical insulation. |

Sintering also improves the PCB's ability to handle heat and electricity.

Surface Finishing and Final Assembly

The last steps include finishing the surface and assembling parts. Surface finishes like ENIG or HASL make the PCB stronger and easier to solder.

After finishing, components are added using methods like surface mount technology (SMT). The final product is tested to ensure it works well and meets quality standards. This makes the PCB ready for use in advanced electronics.

Quality Control in Ceramic PCB Manufacturing

Checking Ceramic Materials

Quality control starts by checking the raw materials. Ceramic powders like alumina or aluminum nitride must meet strict rules. Impurities or flaws can ruin the final product. Tools like scanning electron microscopes (SEM) help find tiny defects. These defects are too small to see with your eyes.

The ceramic's heat and electrical properties are also tested. This ensures it can handle the job of multilayer ceramic PCBs. Catching problems early saves time and money later in production.

Testing During Production

Testing happens at every step of making the PCB. During layer stacking, each layer must line up perfectly. Misaligned layers can cause the PCB to fail. Automated optical inspection (AOI) systems check for alignment issues.

Electrical testing is also very important. It checks if the pathways work correctly. For example, vias are tested to ensure they connect the layers properly. These tests fix problems before moving to the next step.

Final Testing and Reliability Checks

The last step is testing the finished PCB. Functional tests make sure the PCB works as planned. These tests check signals, heat handling, and strength.

Reliability tests are also done. These tests mimic real-world conditions like heat, humidity, and shaking. They ensure the PCB can survive tough environments.

Good quality control ensures ceramic PCBs are reliable and perform well. This makes them ready for demanding uses.

Applications and Benefits of Multilayer Ceramic PCBs

Industries That Use Ceramic PCBs

Ceramic PCBs are important in many industries because they work well and last long. In electronics, they are found in smartphones, IoT gadgets, and laptops. They help keep power steady and reduce noise. Cars use them in engines and entertainment systems to stay reliable in tough conditions. Telecom companies use them in 5G towers and network devices since they handle fast signals with little loss.

Industry | Applications | Key Benefits |

|---|---|---|

Electronics | Phones, IoT gadgets, laptops, etc. | Keeps power steady, reduces noise, and improves signal quality. |

Automotive | Engines, power systems, entertainment units. | Works well in tough conditions and lasts longer. |

Telecommunications | 5G towers, network devices, TV boxes. | Handles fast signals and supports large data for 5G technology. |

Benefits for High-Tech Electronics

Multilayer ceramic PCBs are key for advanced electronics. They manage heat well and resist high temperatures. This makes them great for harsh environments. Aerospace and defense use them in radars and planes because they are reliable. Cars use them in engine systems that face extreme heat. Telecoms rely on them for fast and stable data transfer.

Aerospace and Defense: Radars, planes, and satellites.

Automotive: Engine systems and power units.

Telecommunications: Fast data transfer tools.

Medical Devices: Scanners and diagnostic machines.

LED Lighting: Better heat control for longer-lasting lights.

Future of Ceramic PCB Use

The future of ceramic PCBs focuses on being smaller and greener. Smaller gadgets need tiny, dense PCBs. New ceramic materials like aluminum nitride improve heat and electricity handling for powerful devices. Eco-friendly methods aim to save energy and use sustainable materials. These changes will keep ceramic PCBs important for advanced electronics.

Smaller, denser PCBs for tiny gadgets.

Better ceramic materials and metal techniques.

Greener and energy-saving production methods.

Why Pick LT CIRCUIT for Ceramic PCB Production?

LT CIRCUIT's Skill in Making Ceramic PCBs

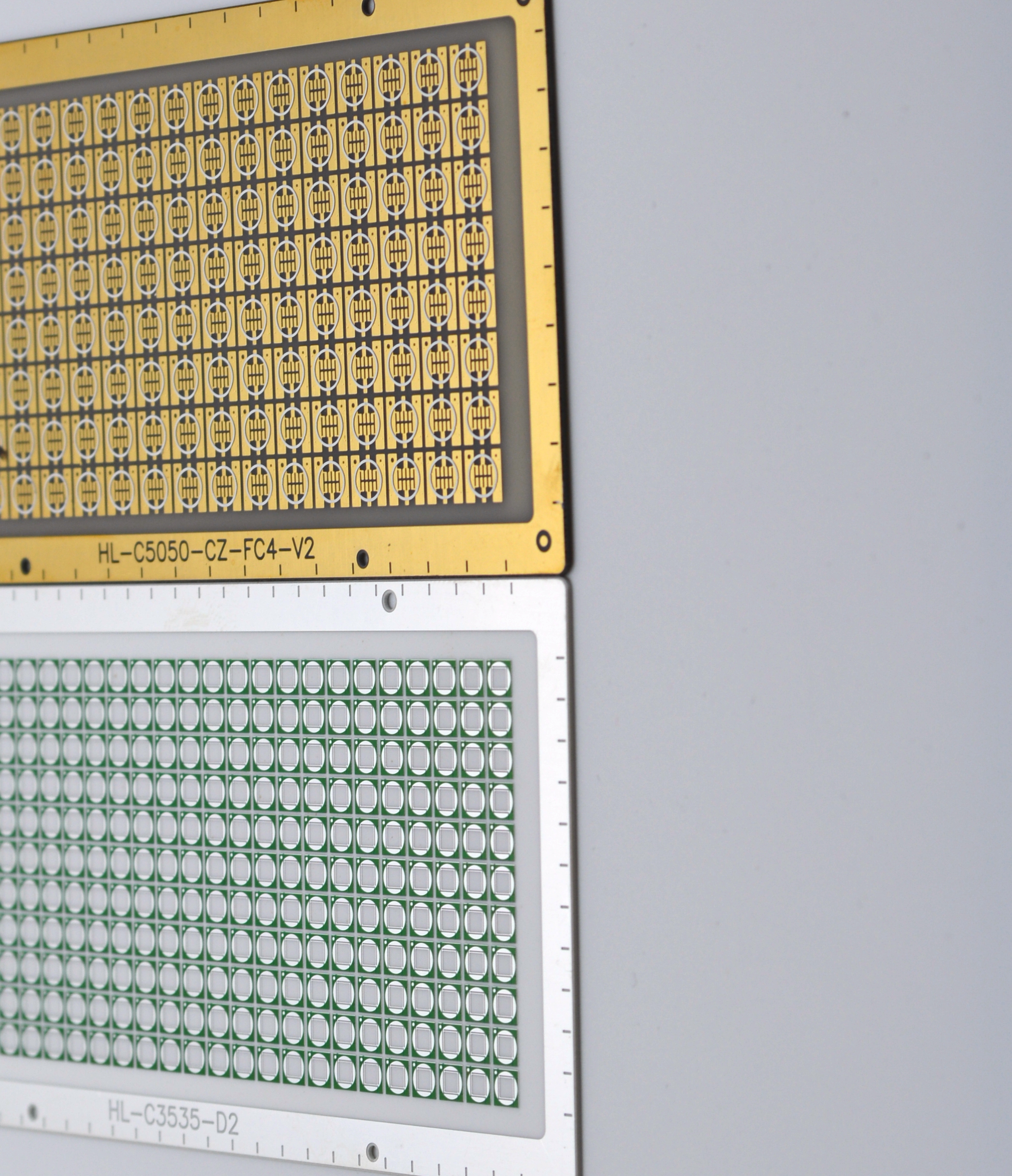

It’s important to have a maker who knows how to build multilayer ceramic PCBs. LT CIRCUIT has many years of experience making top-quality PCBs. They use advanced methods to ensure their boards are accurate and dependable. Their team works hard to create ceramic PCBs for industries like space, cars, and communication.

LT CIRCUIT is great at handling tricky designs. If you need a PCB for high-speed signals or very hot conditions, they can make one just for you.

High-Tech Tools and Quality Checks at LT CIRCUIT

LT CIRCUIT uses modern tools to create ceramic PCBs. They use special methods like tape casting, laser drilling, and adding metal layers to make sure every board is perfect. Machines check each step of the process to avoid mistakes and save time.

They care a lot about quality. LT CIRCUIT tests their PCBs carefully to make sure they work well in real-life situations. From checking materials to testing the final product, every step is reviewed. This focus on quality makes LT CIRCUIT a trusted name in ceramic PCBs.

Custom Options and Strong Products from LT CIRCUIT

LT CIRCUIT lets you customize your PCBs to fit your needs. You can pick different ceramic materials, layer setups, and finishes. Their flexible options help you design the perfect PCB for your project.

Their PCBs are also very strong. LT CIRCUIT makes boards that last, even in tough places. Whether it’s for bright LED lights or military tools, their PCBs are built to perform well and stay durable.

Choosing LT CIRCUIT means working with a company that values new ideas, top quality, and happy customers.

Making multilayer ceramic PCBs needs careful steps for good quality. First, the circuit is designed using special software. Then, the base material is prepared, layers are stacked, and metal layers are added. Holes are drilled and filled to link the layers. Heating makes the ceramic stronger. Parts are added, and tests are done to check reliability.

Ceramic PCBs are great at handling heat, lasting long, and keeping signals clear. LT CIRCUIT uses smart tools and strict checks to make strong ceramic PCBs. Their skill helps your projects with tough and efficient designs.

FAQ

Why are ceramic PCBs better than regular ones?

Ceramic PCBs handle heat well and last longer. They keep signals strong and work great in tough electronics like cars and airplanes.

Can ceramic PCBs be made for special uses?

Yes, ceramic PCBs can be designed for your needs. You can pick materials, layers, and finishes. LT CIRCUIT offers many choices for your projects.

How does LT CIRCUIT make sure ceramic PCBs are good quality?

LT CIRCUIT uses smart tools and careful tests. They check every step, from picking materials to building the final product, to ensure it works well.

See Also

Understanding How Multilayer Rigid-Flex Circuit Boards Are Made

Defining Multilayer PCBs and Their Role in Electronics

Challenges in Manufacturing and Prototyping Multi-Layer Circuit Boards

Investigating How Ceramic PCBs Are Used in Industries Today

Essential Skills for Designing PCB Multi-Layer Circuit Boards