Why Multilayer Ceramic PCBs Deliver Superior Performance in Modern Electronics

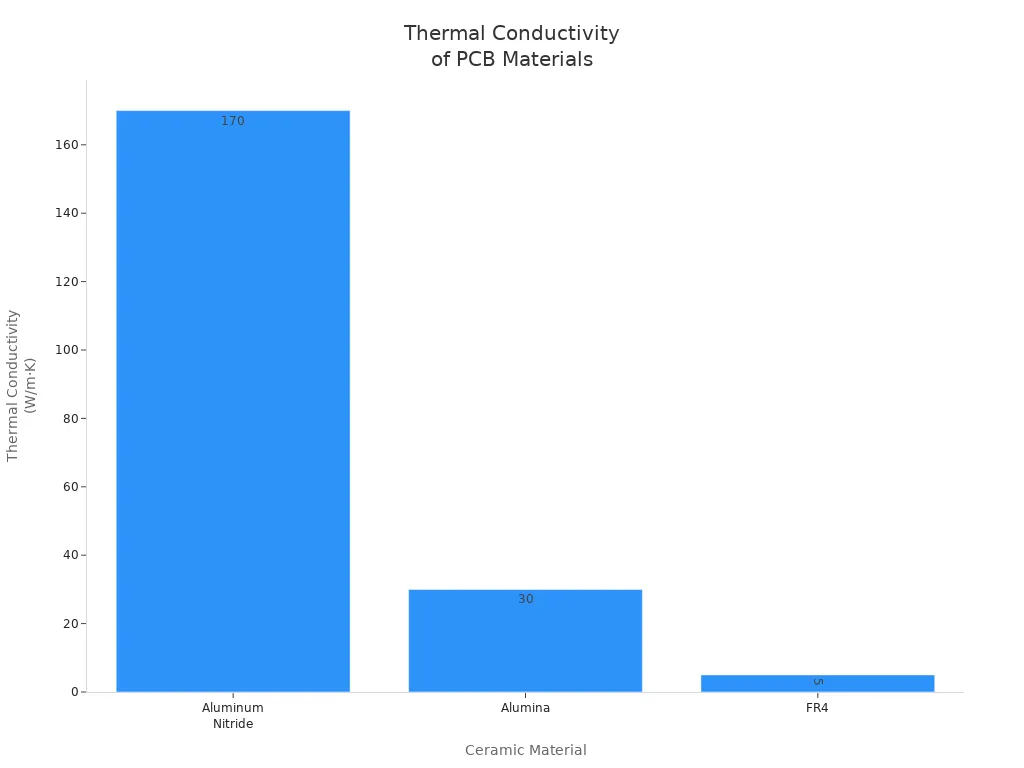

You can expect unmatched performance when you choose a multilayer ceramic pcb for high-performance electronics. A multilayer ceramic pcb provides superior thermal management, setting it apart from other options. For instance, aluminum nitride multilayer ceramic pcbs offer thermal conductivity up to 170 W/m·K, which is far beyond what FR4 can deliver.

With a multilayer ceramic pcb, you also benefit from excellent electrical insulation and reliability, making it an ideal choice for demanding applications like 5G and automotive systems.

Key Takeaways

Multilayer ceramic PCBs offer superior thermal management, with thermal conductivity up to 170 W/m·K, ensuring your electronics stay cool and stable.

These PCBs provide excellent electrical insulation, making them ideal for high-voltage and high-frequency applications like 5G and automotive systems.

Ceramic PCBs allow for complex designs with high integration, enabling compact layouts that enhance performance and reduce signal path lengths.

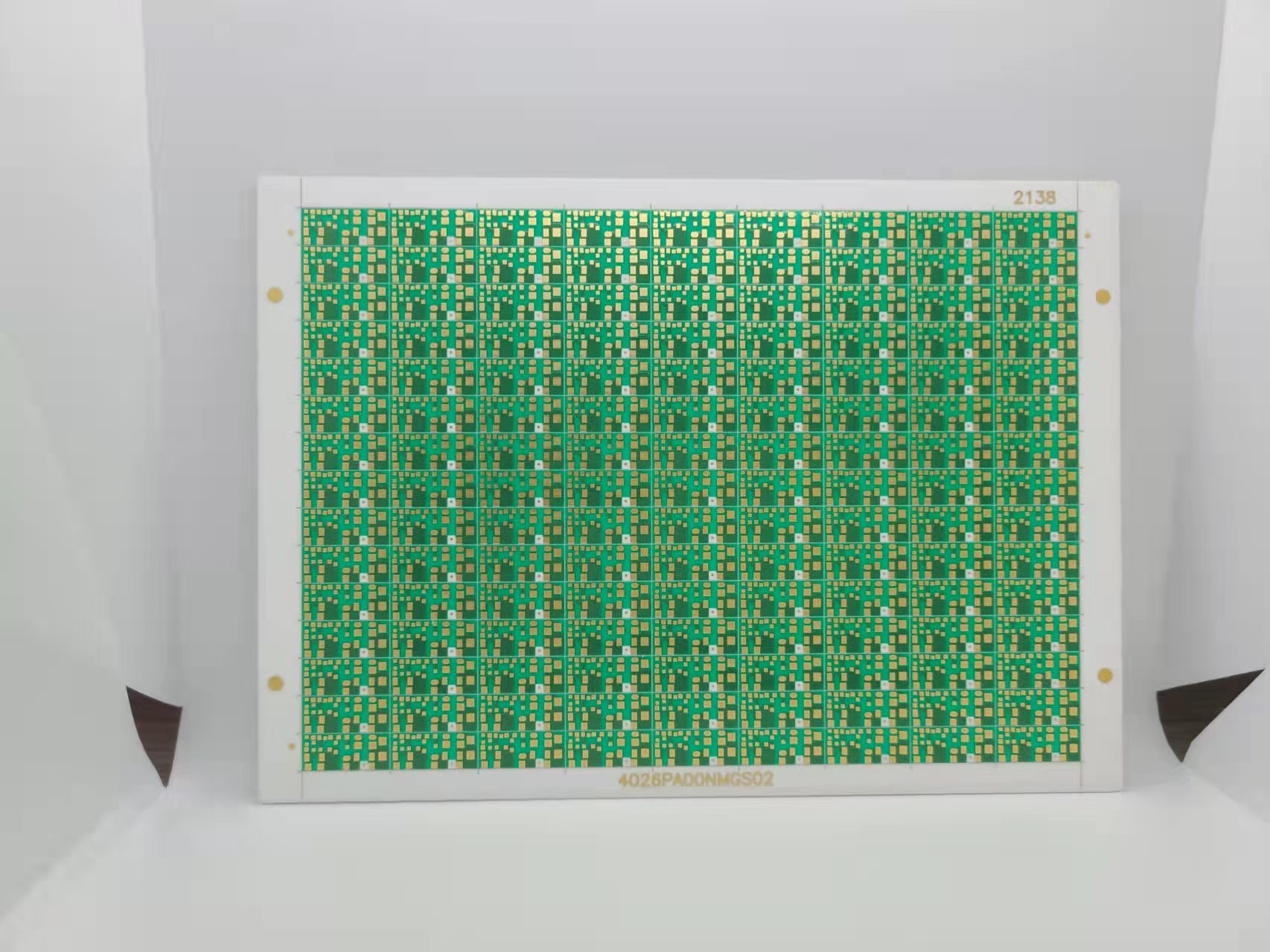

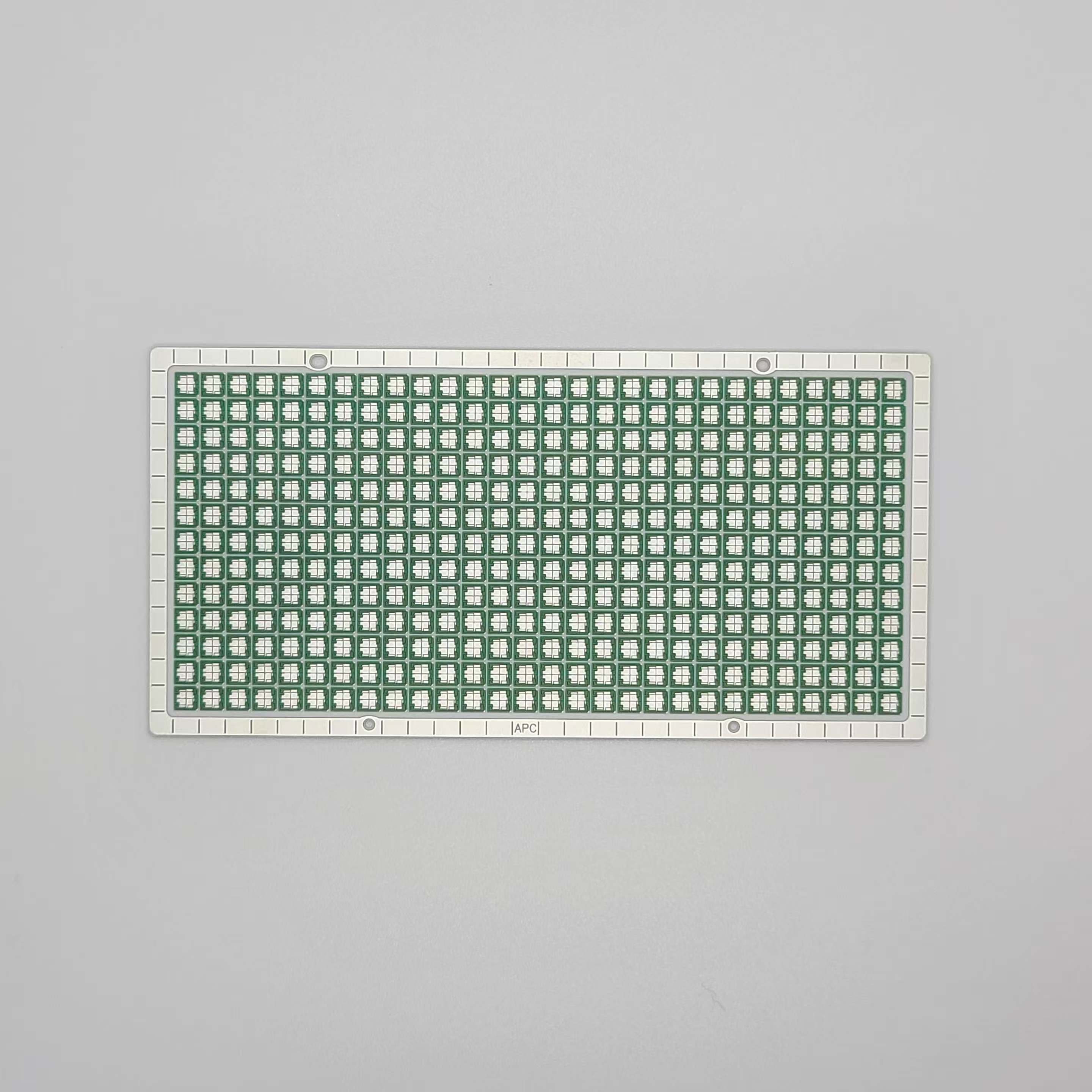

Multilayer Ceramic PCB Structure and Features

Layered Design and Materials

You will find that the layered design of a ceramic pcb uses advanced ceramic substrates to deliver top performance. Each layer can use different materials, and each material brings unique benefits. The most common ceramic substrates include alumina, aluminum nitride, and beryllium oxide. These materials help you manage heat, maintain stability, and support high-frequency signals. The table below shows how each material contributes to the performance of your ceramic pcb:

Material | Properties | Contribution to Performance |

|---|---|---|

Alumina (Al2O3) | Exceptional thermal conductivity, dimensional stability | Minimizes temperature rise in high-power circuits |

Aluminum Nitride (AlN) | High-frequency compatibility, low dielectric loss | Maintains performance at microwave or millimeter-wave signals |

Beryllium Oxide (BeO) | High thermal conductivity, mechanical rigidity | Suitable for high-temperature, high-reliability applications |

Electrical Insulation and Dielectric Strength

You need strong electrical insulation for safe and reliable operation. Ceramic substrates provide excellent electrical insulation, which protects your circuits from unwanted current flow. This feature is critical in high-voltage and high-frequency environments. The dielectric strength of these materials ensures that your ceramic pcb can handle demanding electrical loads. The table below highlights the dielectric strength values for common ceramic substrates:

Material | Dielectric Strength (V/mil) | Applications |

|---|---|---|

Ceramics | 100–200 | Automotive, aerospace, high-voltage systems |

Alumina | 4–8 kV/mm | Rugged, high-voltage designs |

Note: High dielectric strength and electrical insulation help you prevent breakdowns and ensure long-term reliability.

Flexibility for Complex Designs

You can create complex and compact layouts with multilayer ceramic pcb technology. The structure allows you to stack multiple layers, which increases the density of your circuits. This flexibility supports advanced designs and helps you reduce signal path lengths. The following table explains the design features that make ceramic substrates ideal for complex electronics:

Design Feature | Explanation |

|---|---|

High Integration | Enables arrangement of more components and circuits in a limited space for complex designs. |

Strong Design Flexibility | Allows for optimization of circuit design and reduction of signal path lengths, enhancing speed. |

High-Density Assembly | Facilitates integration of more electronic components, supporting complex circuit layouts. |

You will benefit from high-temperature resistance and robust electrical insulation, which make ceramic pcb solutions perfect for demanding environments. These features let you push the boundaries of modern electronics.

Performance Benefits of Ceramic PCBs

Thermal Conductivity and Heat Dissipation

You need excellent thermal conductivity and heat dissipation to keep your electronics running at peak performance. Multilayer ceramic pcb technology gives you a clear advantage in this area. Ceramic pcbs use materials that move heat away from critical components much faster than traditional options. This helps you avoid overheating and keeps your devices stable, even when they work hard.

Take a look at the table below. It shows how different PCB types compare in thermal conductivity:

Type of PCB | Thermal Conductivity (W/m·K) |

|---|---|

Ceramic PCB | 20 - 200 |

Traditional PCB (FR-4) | 0.3 |

Metal Core PCB | 1 - 8 |

You can see that ceramic pcbs offer thermal conductivity values from 20 to 200 W/m·K. Traditional FR-4 boards only reach about 0.3 W/m·K. This means you get much better heat dissipation with ceramic pcbs. In high-power applications, such as 5G base stations or electric vehicles, this difference can make or break your system’s performance.

Tip: Thermally conductive ceramics, thermal vias, and cooling fans all work together to boost heat dissipation and keep your multilayer ceramic pcb cool under pressure.

Ceramic pcb packaging has become essential for high-end electronics. You benefit from superior thermal performance, strong electrical insulation, and resistance to extreme temperatures and corrosion. These features help you achieve high reliability in demanding industries.

High-Frequency Performance

When you design for high-frequency applications, you want your signals to stay sharp and clear. Ceramic pcbs deliver low dielectric loss, with loss tangent values below 0.001. This means your signals travel with less energy loss and less distortion. You get predictable circuit behavior, even as frequencies climb into the gigahertz range.

Ceramic pcbs also maintain signal integrity above 10 GHz. The dielectric constant of ceramic materials keeps your transmission line impedance stable. You can count on consistent signal propagation velocity, which is vital for high-frequency performance. Low loss tangent values reduce energy dissipation, so your signals remain strong. Careful control of trace geometry and dielectric properties ensures you get reliable, low-attenuation transmission lines.

Note: Ceramic pcbs provide excellent surface finish and dimensional stability. This helps you maintain impedance control and signal quality, even in the most advanced designs.

Reliability in Harsh Environments

You need your electronics to last, even in tough conditions. Ceramic pcbs give you high reliability in environments with heat, humidity, and vibration. These boards pass strict reliability tests, such as damp heat, thermal cycling, and salt spray tests. The table below shows how ceramic pcbs perform under these challenges:

Test Type | Conditions | Main Failure Mechanisms |

|---|---|---|

Damp Heat Test | 85℃, 85% RH, >1,000 hours | Moisture absorption, metal migration, solder mask blistering |

Thermal Cycling Test | -40°C to +125°C, hundreds to thousands of cycles | Solder joint fatigue, interfacial delamination |

Salt Spray Test | 5% salt spray at 35°C for 24–hundreds of hours | Corrosion resistance in salty, humid environments |

Ceramic pcbs absorb almost no moisture and resist corrosion better than traditional boards. For example, a ceramic pcb in an industrial furnace controller can last 10 years at 200°C. An FR4 board would fail after just 2–3 years in the same conditions. You get high reliability and peace of mind, even when your electronics face extreme stress.

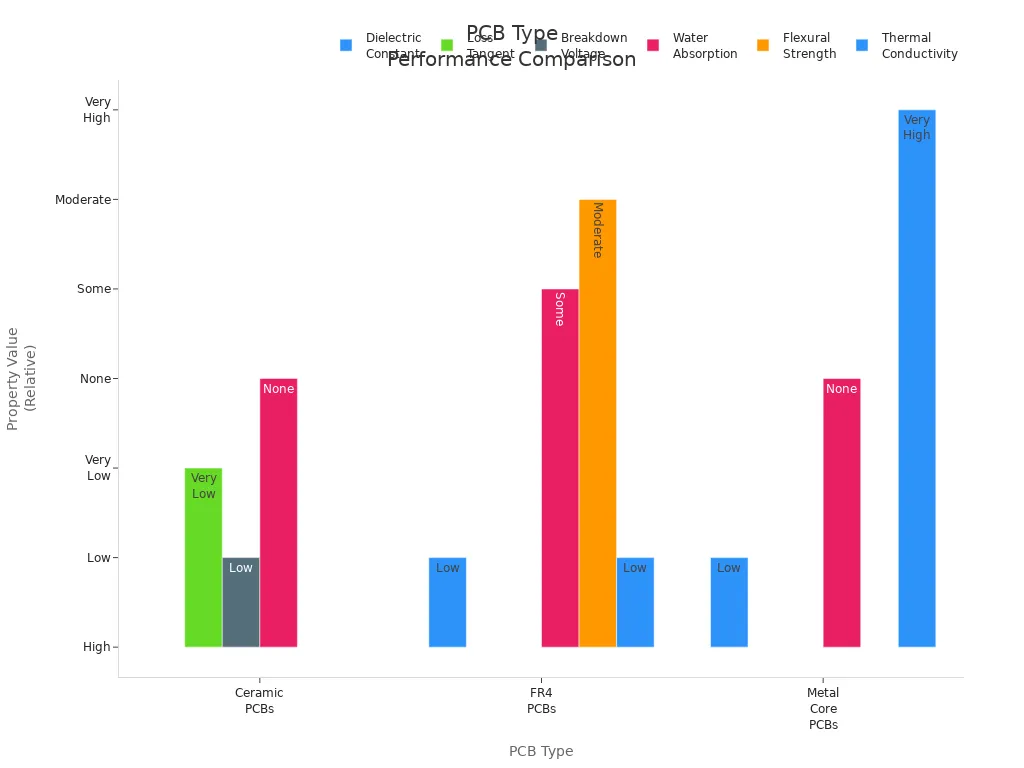

Comparison with Traditional PCB Types

You want to know how multilayer ceramic pcb stacks up against other options. The table below compares key properties of ceramic pcbs, FR4 pcbs, and metal core pcbs:

Property | Ceramic PCBs | FR4 PCBs | Metal Core PCBs (MCPCBs) |

|---|---|---|---|

Dielectric Constant | Higher than FR4, influences impedance | Lower than ceramic | Varies, generally lower than ceramic |

Loss Tangent | Extremely low, ideal for high frequency | Higher than ceramic | Varies, generally higher than ceramic |

Breakdown Voltage | Lower but sufficient for most applications | Higher than ceramic | Varies, generally higher than ceramic |

Water Absorption | None, highly dense structure | Some absorption | None |

Flexural Strength | High, extremely rugged | Moderate | High |

Thermal Conductivity | High, but lower than MCPCBs | Lower than ceramic | 5-10X higher than FR4 |

Typical Applications | High frequency, ruggedness needed | Low frequency, low power electronics | High thermal loads in power electronics/lighting |

You get higher flexural strength, better vibration resistance, and almost no water absorption with ceramic pcbs. They also offer high reliability and excellent heat dissipation. In demanding applications, ceramic pcbs outperform traditional boards in both performance and durability.

Note: While multilayer ceramic pcb solutions may cost more to produce, you can achieve up to 50% cost savings over time by reducing failures and extending product life.

You can trust ceramic pcbs to deliver the performance, electrical stability, and heat management you need for modern electronics. Their high reliability and superior thermal conductivity make them the best choice for challenging environments and advanced applications.

Applications of Ceramic PCB Technology

5G and High-Frequency Communication

You see ceramic pcbs leading the way in 5G and high-frequency communication systems. These boards support fast data transmission and stable signals. You benefit from low dielectric loss and high dielectric constant, which help maintain signal integrity. The table below shows how a multilayer ceramic pcb meets the needs of 5G systems:

Performance Requirement | Solution Provided by Multilayer Ceramic PCBs |

|---|---|

Material Selection | Low dielectric constant materials |

Thermal Management | High thermal conductivity, stable dielectric constant |

Signal Integrity | Precise impedance control |

Electromagnetic Interference | Shielding and trace separation |

Ceramic pcbs also work well in radio frequency and microwave applications. You get reliable performance across a wide temperature range.

Automotive and Power Electronics

You rely on ceramic pcbs for automotive and power electronics because they handle heat and stress better than other boards. These boards keep engine control modules and EV powertrains cool and stable. You avoid common failures like soldering defects and component fatigue. Ceramic pcbs offer:

High power handling for demanding circuits

Miniaturization for compact designs

Reliability in harsh environments

Stable high-frequency signal transmission

You use ceramic pcbs in high-power electronic applications to ensure your systems run safely and efficiently.

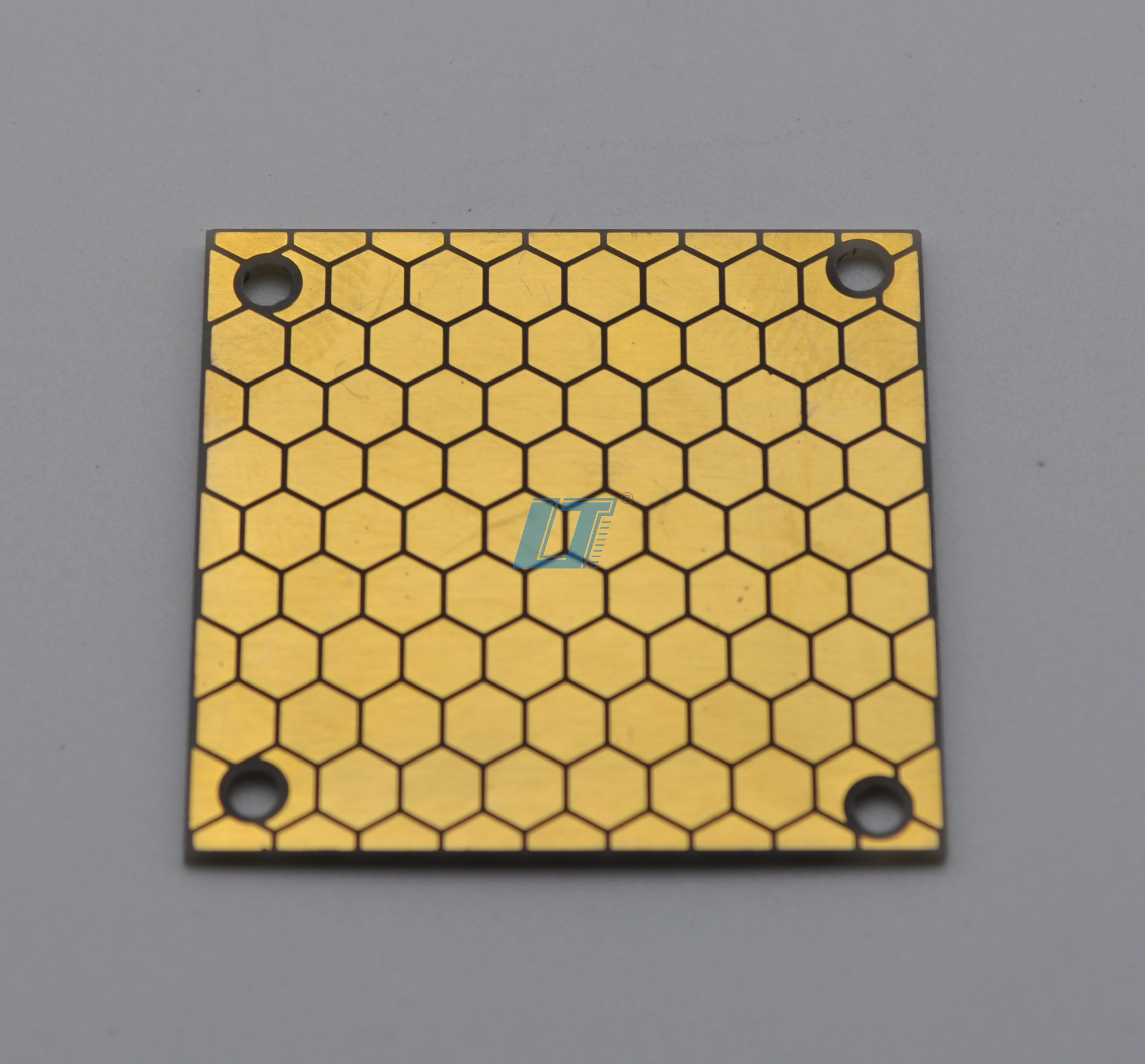

Custom Solutions for Advanced Electronics

You can customize ceramic pcbs for advanced electronics. You choose materials, layer counts, and board shapes to fit your needs. The table below highlights custom solutions:

Industry | Application Description | Key Features |

|---|---|---|

Automotive | Handles high power, keeps low temperatures | |

Telecommunications | 5G base stations | Manages power, supports zero signal loss |

Medical Devices | Imaging and monitoring systems | Provides thermal management and electrical insulation |

You benefit from specialized manufacturing processes like tape casting and laser drilling. Rigorous testing ensures your multilayer ceramic pcb meets high standards for reliability.

Tip: Custom ceramic pcbs let you design for unique requirements in power electronics, medical devices, and communication systems.

You see ceramic pcbs transform modern electronics with unmatched thermal, electrical, and mechanical performance.

Ceramic pcbs power aerospace, automotive, and 5G innovations.

You benefit from compact, reliable designs and long-term efficiency.

Ceramic pcbs support sustainability by reducing waste and energy use.

Challenge | Note |

|---|---|

Ceramic pcbs last longer | |

Careful handling | Ceramic pcbs resist stress |

You should choose ceramic pcbs for your next advanced project.

FAQ

What makes multilayer ceramic PCBs better for heat management?

You get high thermal conductivity. Ceramic materials move heat away from components quickly. This keeps your electronics cool and stable.

Can you use multilayer ceramic PCBs in harsh environments?

You can rely on ceramic PCBs in extreme heat, humidity, or vibration.

They resist corrosion

They absorb almost no moisture

They last longer than FR4 boards

Are multilayer ceramic PCBs more expensive than traditional PCBs?

PCB Type | Typical Cost | Lifespan |

|---|---|---|

Ceramic PCB | Higher | Longer |

FR4 PCB | Lower | Shorter |

You pay more upfront, but you save money over time with fewer failures.

See Also

A Comprehensive Overview of Multilayer Ceramic PCB Production

Diverse Uses of Multilayer PCBs in Various Sectors

The Superior Heat Dissipation Properties of Ceramic PCBs