Multilayer Circuit Boards vs. Traditional PCBs: When to Upgrade Your Electronics Design

You might need to change from traditional PCBs to multilayer circuit boards when your electronics have new problems. Consumer electronics and complex devices make design harder. Issues like bending, tiny cracks, or signal trouble can hurt a printed circuit board. Making things smaller and faster means you must think about your PCB choice again.

PCBs with more layers work better and handle hard designs.

Multilayer circuit boards help with heat problems and block unwanted signals in electronics.

What you pick changes the size, price, how easy it is to fix, and how well your PCBs work.

Always check your current PCB and future printed circuit boards to make sure they fit your design and work needs.

Key Takeaways

Pick multilayer PCBs if your design has many parts, needs to be small, or must work better for hard electronics. - Traditional PCBs are simple, cost less, and are easy to repair, but they are best for basic circuits with fewer parts. - Decide which PCB you need early so your project works well, is more reliable, and you do not make expensive errors.

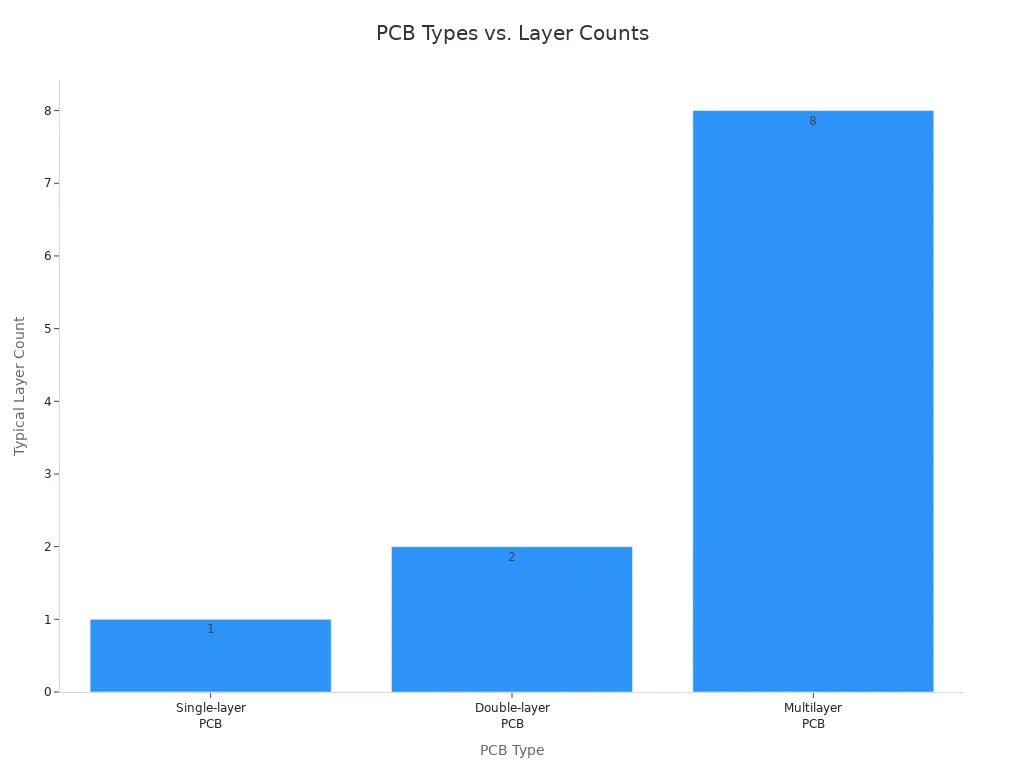

PCB Types Compared

Traditional PCBs

You see traditional PCBs in simple electronics. These boards have one or two layers. A single-layer PCB has copper on one side. Double-layer PCBs have copper on both sides. This lets you add more parts and connections. You find these boards in things like remote controls and toys. The design is simple and the materials are easy to use. Traditional PCBs use fiberglass and copper foil. You can fix these boards easily because you can reach all the layers. But traditional PCBs do not work well with high-speed or high-density circuits. They do not use things like microvias or special stack-ups. This limits how many parts you can add and how fast your design can be.

PCB Type | Number of Conductive Layers | Structure Description | Layer Count Range | Key Features and Differences |

|---|---|---|---|---|

Single-layer PCB | 1 | One copper conductive layer on one side of a substrate; components mounted on the opposite side. | Exactly 1 | Simple, cost-effective, linear design; all connections on one plane. |

Double-layer PCB | 2 | Copper layers on both sides of a single substrate; components can be mounted on both sides. | Exactly 2 | Allows connections on both sides; uses plated through-holes (vias) for inter-layer connections. |

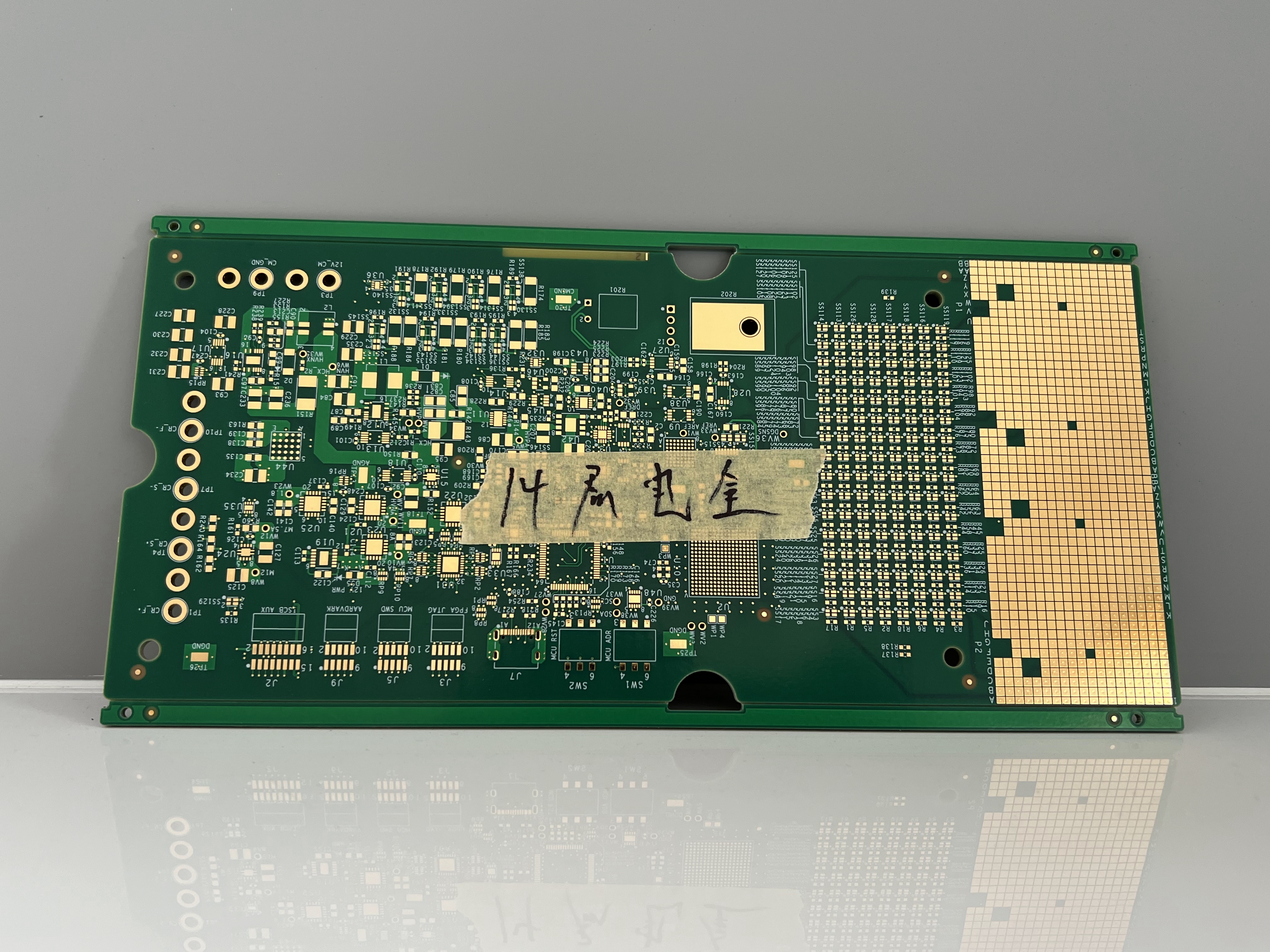

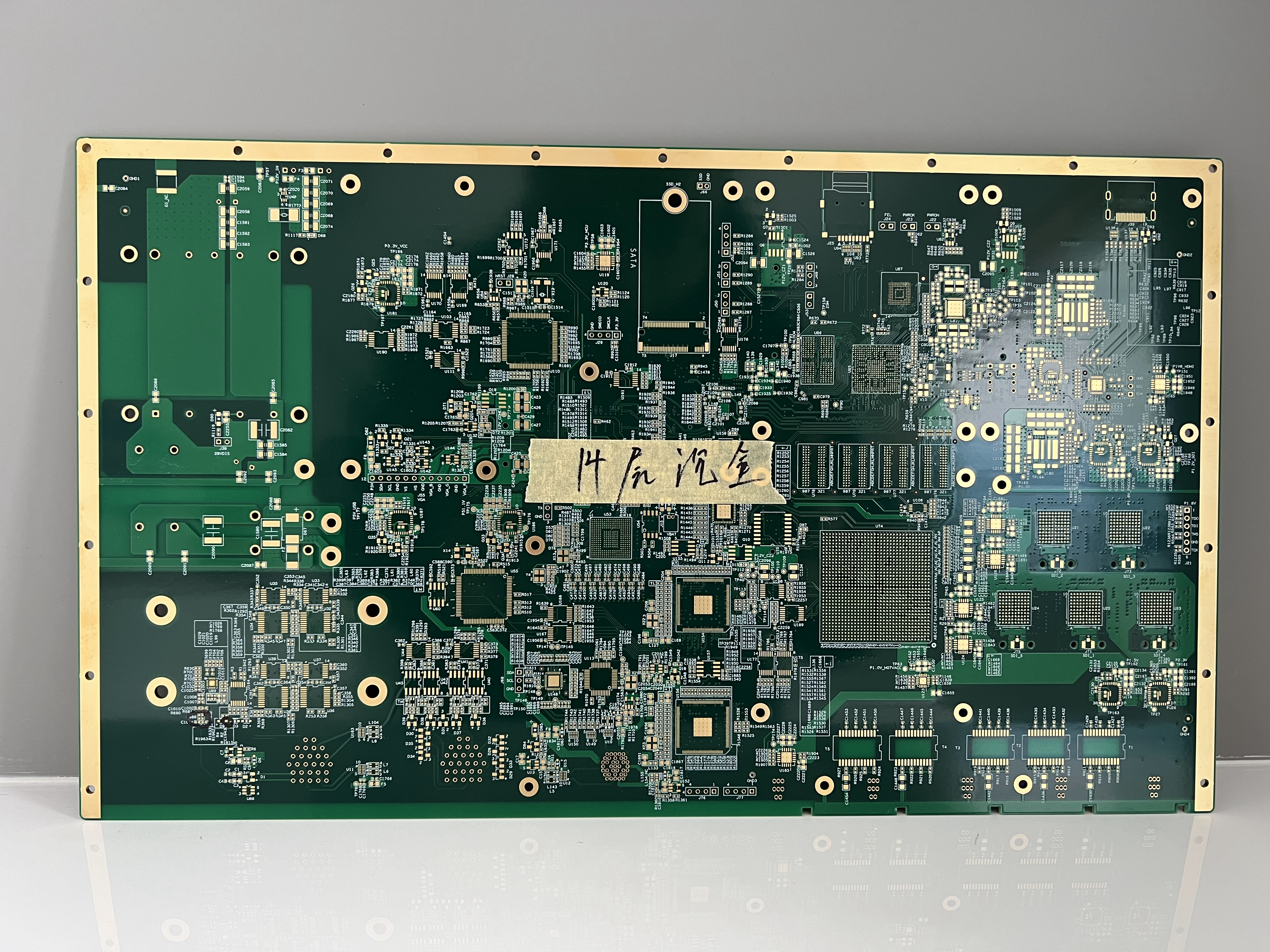

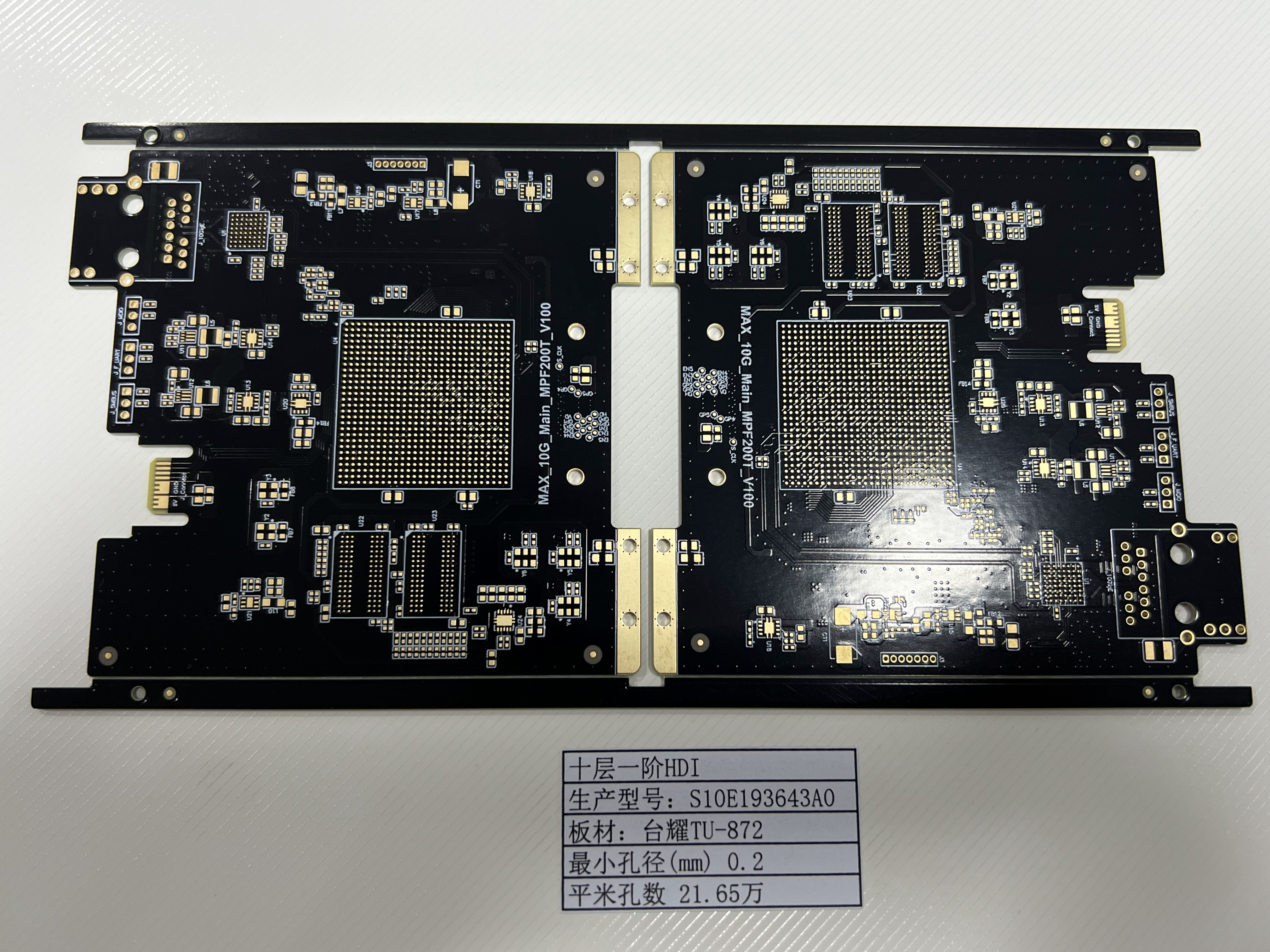

Multilayer Circuit Boards

Multilayer circuit boards have three or more layers. You see these boards in computers, smartphones, and medical equipment. The design stacks copper and insulation in many layers. This lets you fit more parts in a small space. Multilayer PCBs use special resins and high-quality copper. These boards have better signals and handle heat well. You can use them for fast and dense designs. Multilayer PCBs use microvias, HDI, and careful layer alignment. These features help stop unwanted signals and keep the board working well. But multilayer PCBs cost more and are harder to fix. The layers are packed close together. You need special tools and skills to work with these boards.

PCB Type | Layers and Structure | Key Characteristics |

|---|---|---|

Multilayer PCB | Multiple conductive layers sandwiched between insulating dielectric materials; connected by plated vias. | Supports dedicated power/ground planes, shielded signal layers, high-density interconnects; complex routing. |

Tip: If you want a small, strong device, think about multilayer PCBs. These boards let you use more parts and better materials. Your design will be stronger and more reliable.

Pros & Cons

Traditional PCBs: Pros & Cons

People pick traditional PCB designs for simple electronics. These boards use basic materials and have one or two layers. You can see and touch all the parts easily. This makes fixing and changing things much easier. If you make a mistake, you can fix it with simple tools. You can also repair broken traces or pads after using the board. Traditional PCBs can handle a few repairs before the materials get weak. If you fix them too many times, pads might lift or the board might bend.

Advantages of Traditional PCBs:

Simple design and easy to produce

Lower cost for materials and manufacturing

Easier to repair and rework

Limitations of Traditional PCBs:

Limited performance in complex electronics

Less reliability for high-speed or high-density circuits

Fewer layers mean less space for advanced features

Multilayer PCBs: Pros & Cons

You use multilayer PCBs when you need more power and reliability. These boards have three or more layers of copper and insulation. You can fit more parts in a smaller space. The materials help block unwanted signals and keep signals strong. You get better grounding and less noise. Devices like smartphones and computers need these features.

But multilayer PCBs have some problems. The many layers make fixing and changing things much harder. You need special tools and skills to avoid breaking the inside layers. Too much heat can cause layers to come apart or break hidden connections. The cost to make these boards is higher. You also need skilled people to plan the layers and paths.

Note: Multilayer PCBs work better and last longer, but they cost more and are harder to fix.

Aspect | Multilayer PCBs (Pros) | Multilayer PCBs (Cons) | Traditional PCBs (Implied Cons) |

|---|---|---|---|

Reliability | More durable due to layered construction; withstand heat and pressure; reduce electromagnetic interference; improve signal integrity | More difficult to repair due to complexity | Less durable; may not meet modern reliability demands |

Performance | Smaller size and lighter weight enable compact, powerful devices; better quality and higher density; improved grounding reduces noise | Require specialized design and manufacturing; longer production times | Simpler design limits performance in complex electronics |

Cost and Production | N/A | Higher cost at all manufacturing stages; need skilled designers; limited manufacturer availability | Cheaper and simpler to produce |

Design Complexity | Allows for single connection point and flexible designs in some cases | Complex production and design process | Simpler, easier to design and produce |

You should always pick the right PCB for your project. Think about how many layers you need, what materials to use, and how well you want it to work. Multilayer PCBs give you more for advanced electronics, but traditional PCBs are still good for simple designs.

Upgrade Factors

Complexity & Density

When your electronics get more complicated, you face new problems. Adding more parts and making circuits denser is hard with traditional pcbs. Multi-layer pcbs fix this by stacking layers of copper and insulation. This way, you can fit more parts in a small space. You can use special connections and new technology for tiny designs.

Multi-layer pcbs let you build complex circuits in small spaces.

Stacking layers and using microvias gives you higher circuit density.

Power and ground planes help keep power steady and match impedance.

More layers make the board stronger and more reliable.

Multi-layer pcbs work well for fast digital circuits and advanced electronics.

Traditional pcbs only have one or two layers, so you cannot add many parts. Multi-layer pcbs can have up to 40 layers, so you can make powerful and small devices. You can use surface mount technology to put tiny parts close together.

Size & Weight

Today’s electronics need to be small and light. Multi-layer pcbs help by stacking layers on top of each other. This lets you fit more circuits in less space. You do not need extra boards or connectors, so your device is smaller and lighter.

Feature | Explanation |

|---|---|

Stacking layers lets you fit more circuits in less space. | |

Lightweight Construction | Fewer connectors and one board make the device lighter. |

Single Connection Point | One board means fewer cables, saving space and weight. |

Higher Assembly Density | More layers let you put more parts in a small area. |

Integration Benefits | You can combine many boards into one, making your device lighter and smaller. |

Multi-layer pcbs can be thicker than traditional pcbs, but you still save space. You do not need extra boards. For example, a 4-layer pcb is about 0.8 to 2.4 mm thick. A 2-layer pcb is about 0.6 to 1.6 mm thick. Even with more layers, your device is smaller and lighter. This is important for things like portable electronics, wearables, and aerospace.

Signal Integrity & EMI

When you design fast digital circuits, signal quality and noise matter a lot. Multi-layer pcbs help by using special ground and power planes. These planes give signals a good path and lower noise.

You can set up layers to keep signals and power apart, which lowers EMI.

Ground planes act as shields and protect your circuits from outside noise.

Shorter paths and controlled impedance keep signals strong.

Multi-layer pcbs support special signaling and good trace spacing, which helps block noise.

For fast digital devices, you need strong signal quality. Multi-layer pcbs let you design for high speeds and good performance. Traditional pcbs cannot do this as well, especially for complex designs.

Cost & Manufacturing

Cost is important when picking between traditional and multi-layer pcbs. Multi-layer pcbs cost more because they use more materials and need careful building. Special materials like polyimide cost more, especially for fast or hot electronics.

More layers mean more cost because you use more materials.

Special vias like microvias make manufacturing more expensive.

Smaller features and tight spaces need better tools and more checks.

Bigger boards or more layers use more materials, so the price goes up.

For small batches, traditional pcbs are cheaper. If you order more, the price per board drops, but multi-layer pcbs still cost more. If you need high performance or small size, the extra cost might be worth it.

Note: Multi-layer pcbs need special planning for heat and the environment. You must plan for heat to escape, since it can get trapped inside. Using good materials and thermal vias helps with this. Green practices, like lead-free solder and recycled copper, help both traditional and multi-layer pcbs be better for the planet.

How to Choose the Right PCB

Decision Checklist

You want your electronics to work well and last a long time. Picking the right pcb helps your design fit your needs. Use this checklist to help you choose between traditional pcbs and multi-layer pcbs for your project:

Factor | Traditional PCBs (Single/Double Layer) | Multilayer PCBs |

|---|---|---|

Circuit Complexity | Low to Medium | High |

Component Density | Low to Medium | High |

Performance Needs | Basic to Moderate | Advanced |

Cost | Lower | Higher |

Manufacturing Time | Shorter | Longer |

Design Difficulty | Simple to Moderate | Complex |

Power Distribution | Limited to Moderate | Excellent |

Check how hard your design is. Simple circuits use traditional pcbs. If your electronics are complex, use multi-layer pcbs.

Look at how many parts you need. Multi-layer pcbs are best for high-density designs.

Think about how well it needs to work. Fast or high-frequency electronics need multi-layer pcbs for good signals.

Look at your budget. Traditional pcbs cost less, but multi-layer pcbs work better.

Ask about making the board. Multi-layer pcbs need special tools and skills.

When to Upgrade

You should switch to multi-layer pcbs if you need more power, smaller size, or better performance. Many industries use multi-layer pcbs for advanced electronics. Consumer electronics, medical equipment, and computers all use these boards for high performance and small size.

If you wait too long to upgrade, you might fall behind in the fast electronics world. Waiting can cause supply problems, higher costs, and missed deadlines. Upgrading your pcb design on time keeps your electronics working well and helps you stay ahead.

Tip: Always check what your design needs now and later. Knowing how to pick the right pcb helps you make better electronics and avoid mistakes that cost money.

When you pick a pcb, make sure it fits your project. Think about how well it works, how long it lasts, and how much it costs. Multilayer pcb choices work better for hard designs and last longer, but they are harder to fix. Use the checklist to check your design, pcb type, and how well it works. Ask people who know a lot for help with your design.

Tip: Start planning your pcb design early. This makes your project work better and last longer. It also helps you avoid big mistakes and keeps your design strong.

FAQ

What is the main reason to upgrade to a multilayer PCB?

You should switch if you need more parts or faster speed. Multilayer PCBs help when your design must be smaller too. These boards fix problems that simple PCBs cannot handle.

Can you repair a multilayer PCB easily?

No, fixing multilayer PCBs is not easy. The layers are hidden inside the board. You need special tools and skills to repair them.

Do multilayer PCBs cost more than traditional PCBs?

Yes, multilayer PCBs cost more money. They use extra materials and need special ways to make them. The higher price gives you better performance and makes your board last longer.

See Also

Exploring Multilayer PCB Uses In Various Industries

Challenges And Steps In Multi-Layer Circuit Board Production

Comparing Single, Double, And Multilayer PCBs Clearly

A Comprehensive Guide To Manufacturing Multilayer PCBs

Understanding The Fabrication Of Multilayer Rigid-Flex Boards