Exploring the Advantages and Applications of Multilayer Flex PCBs

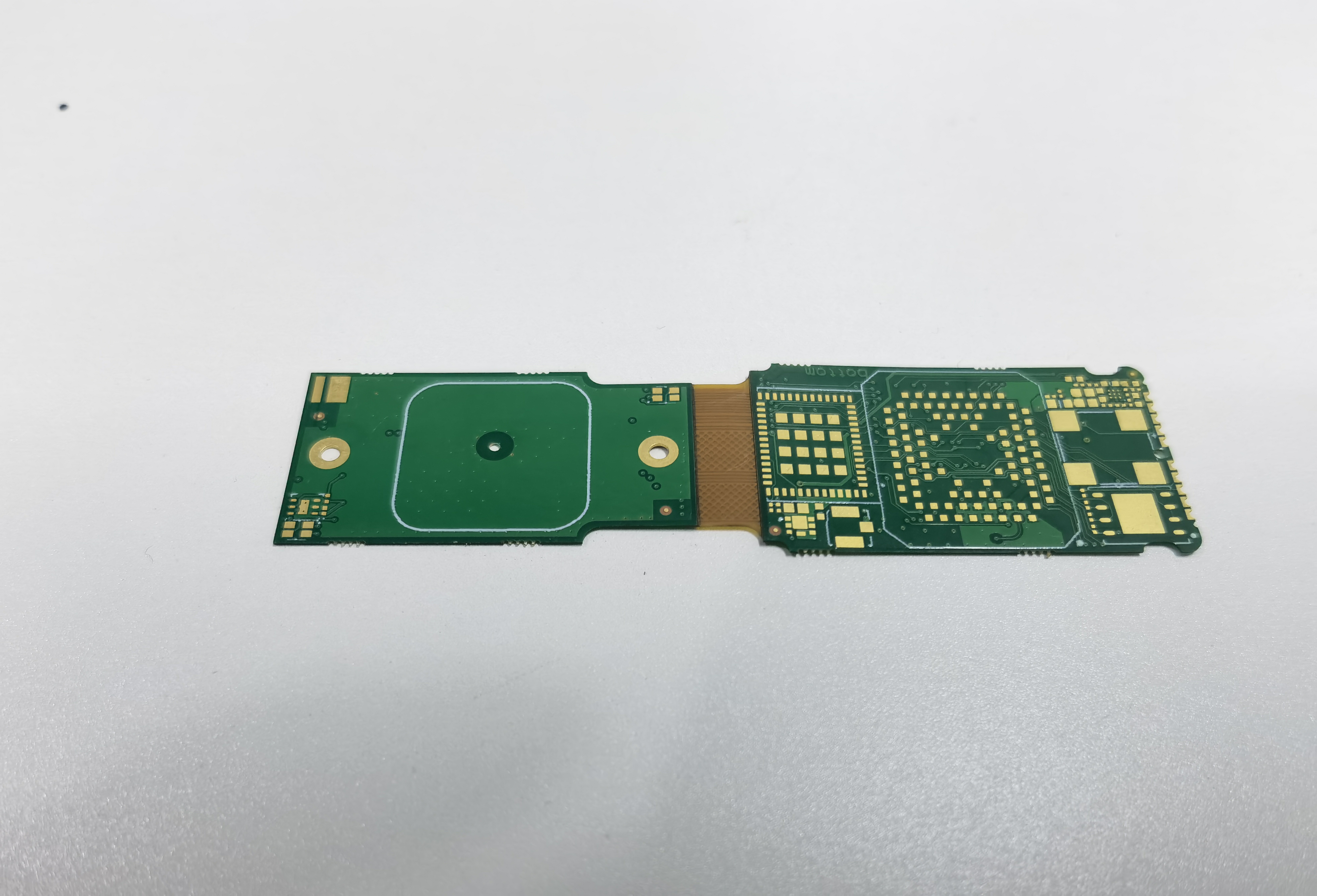

You need multilayer flex pcb technology to keep your electronics at the cutting edge. With multilayer flex pcb solutions, you benefit from both flexibility and reliability, while also saving valuable space in your devices. Leading brands like LT CIRCUIT specialize in producing multilayer flex pcbs for demanding applications. These advanced multilayer flex pcb designs enhance the performance of electronic components and are perfectly suited for compact, high-performance devices.

Key Takeaways

Multilayer flex PCBs are very reliable and flexible. They help save space in devices. This makes devices smaller and lighter. It also makes them last longer.

These PCBs help electronics work better by lowering interference. They can be used for hard designs in many industries. Some examples are consumer electronics, cars, medical tools, and airplanes.

LT CIRCUIT gives expert help with custom multilayer flex PCB solutions. They offer fast samples and high quality. They use advanced technology to help you make better and stronger products.

Advantages of Multilayer Flex PCB

Reliability and Durability

You want your devices to work for a long time. Multilayer flexible pcbs are very strong and reliable in many uses. These circuits can handle hot and cold temperatures. They also survive lots of bending and tough places. LT CIRCUIT uses polyimide, which works up to 400°C and is very strong. They test each multilayer pcb with heat and shaking to make sure it lasts.

Did you know?

In cars, multilayer flexible pcbs can go through about 150,000 heat cycles. In robots, they can bend up to 200,000 times. Medical devices with these circuits can last over 20 years before failing.

Industry Sector | Operating Temperature Range | Durability Metric | Application Context |

|---|---|---|---|

Aerospace | -55°C to 125°C | > 2,000 thermal cycles | High thermal endurance in harsh environments |

Automotive | -40°C to 125°C | ~150,000 thermal cycles | Robustness under thermal stress in vehicles |

Medical | 0°C to 70°C | MTBF > 20 years | Long-term reliability for critical medical devices |

Industrial Robotics | N/A | Up to 200,000 bending cycles | High flex endurance in robotic joints |

LT CIRCUIT makes sure their products are strong and last longer. You can count on these multilayer pcb solutions in tough places.

Design Flexibility

You need freedom to make cool new products. Multilayer flexible pcbs let you fit circuits in small or odd spaces. The layers help you put more parts in tiny devices. You can bend the circuits around corners or fit them in tight spots.

Multilayer flex pcb technology helps you make better layouts, add more parts, and do more in small devices.

You can design things like phones, heart monitors, cameras, and satellites with more ideas and less trouble.

LT CIRCUIT’s team uses smart tools and good materials to help you get the best results.

With multilayer flexible pcbs, you get high circuit density, thin size, and great flexibility. This helps you make advanced electronics that work well.

Space and Weight Savings

You want your devices to be small and light. Multilayer flexible pcbs help by removing big connectors and extra wires. The multilayer pcb design lets you fit more circuits in less space. This means your products weigh less and take up less room.

Industry | Reported Benefits of Multilayer Flex PCBs |

|---|---|

Automotive | Significant size and weight reduction in navigation and electronics |

Consumer Electronics | |

Medical Devices | Use in compact health monitoring and implantable devices |

Industrial Automation | Aids in device miniaturization and weight reduction |

LT CIRCUIT’s multilayer flex pcb solutions help make tiny, powerful devices. You can build slim, easy-to-carry products that still work great. That is why top brands use multilayer pcb technology for their best products.

Electrical Performance

You want your circuits to work really well. Multilayer flexible pcbs give better electrical performance than old pcb types. The layers help stop electromagnetic interference and crosstalk. This keeps signals clear and devices working right.

Controlled impedance matching keeps signals strong in fast designs.

Good ground and power planes keep signals steady and cut down noise.

Shielding layers protect important traces from interference.

Most multilayer pcb designs have 50 ohms for single signals and 100 ohms for pairs, with very close limits. LT CIRCUIT uses smart tools and careful work to make high-quality, reliable multilayer flexible pcbs for hard jobs.

Tip:

Multilayer flexible pcbs let you have high circuit density, thin size, and great electrical performance. They are perfect for fast, high-frequency, and packed designs.

Why Choose LT CIRCUIT for Multilayer Flexible PCBs?

LT CIRCUIT is known for skill, quality, and new ideas. You get:

Multilayer pcb solutions with up to 12 layers and advanced HDI choices.

High-density connections, thin shapes, and flexible designs.

Custom options for finishes, solder masks, and built-in parts.

Careful testing and quality checks, including ISO 9001 and UL.

Fast samples and help from expert engineers.

When you pick LT CIRCUIT, you get strong and reliable multilayer flexible pcbs. They help you make better designs, improve reliability, and lower mistakes. You get the flexibility and quality you need to win in today’s market.

Applications of Multilayer Flexible PCBs

Multilayer flexible pcbs have changed how people make electronics. You can find these pcbs in many modern devices. They are in things like smartwatches and even satellites. Many industries use multilayer flexible pcbs because they need small, strong, and useful parts. LT CIRCUIT gives custom solutions to help you meet these needs.

Consumer Electronics

People want their devices to be small, light, and strong. Multilayer flexible pcbs help make this happen. You can find them in:

Smartphones and foldable phones. Flexible circuits connect screens and batteries in tight spots.

Smartwatches and fitness trackers. These need thin, bendy pcbs for comfort and strength.

Laptops and tablets. Small multilayer pcb designs help lower weight and size.

Gaming consoles and smart TVs. These need high-density circuits for cool features.

With multilayer pcb technology, you get:

Small size and good use of space for tiny devices.

Better performance and clear signals for gadgets with many uses.

More design choices, so you can make tricky layouts in small spaces.

Light builds, so your products are easy to carry.

Manufacturer | Location | Key Clients | Application Areas |

|---|---|---|---|

Taiwan | Apple, Samsung, Tesla | Smartphones, wearables, automotive | |

Interflex Co., Ltd. | S. Korea | Samsung | Flexible OLED displays, foldables |

Flexium Interconnect | Taiwan | Apple | High-end electronics, wearables |

LT CIRCUIT helps with your electronics projects by making good multilayer pcb solutions. You can trust them to give you strong, useful circuits for your next idea.

Automotive

Electronics in cars must be tough and smart. Multilayer flexible pcbs are important in car electronics. You can find them in:

Infotainment systems. They connect screens, cameras, and controls.

Sensors for heat, pressure, and movement. These fit in small, rough places.

Lighting systems. Curved LED headlights and taillights use them.

Battery management in electric cars. They handle high power and heat.

Multilayer pcb uses in cars give you:

More wires and complex circuits for smart driving and power control.

Lower car weight, which helps save gas and makes electric cars go farther.

Flexibility to fit circuits in tight engine and dashboard spaces.

Strength against shaking, heat, and wetness, so they last longer.

LT CIRCUIT’s car solutions meet strict rules. You get custom designs, strong materials, and quick samples for your car electronics.

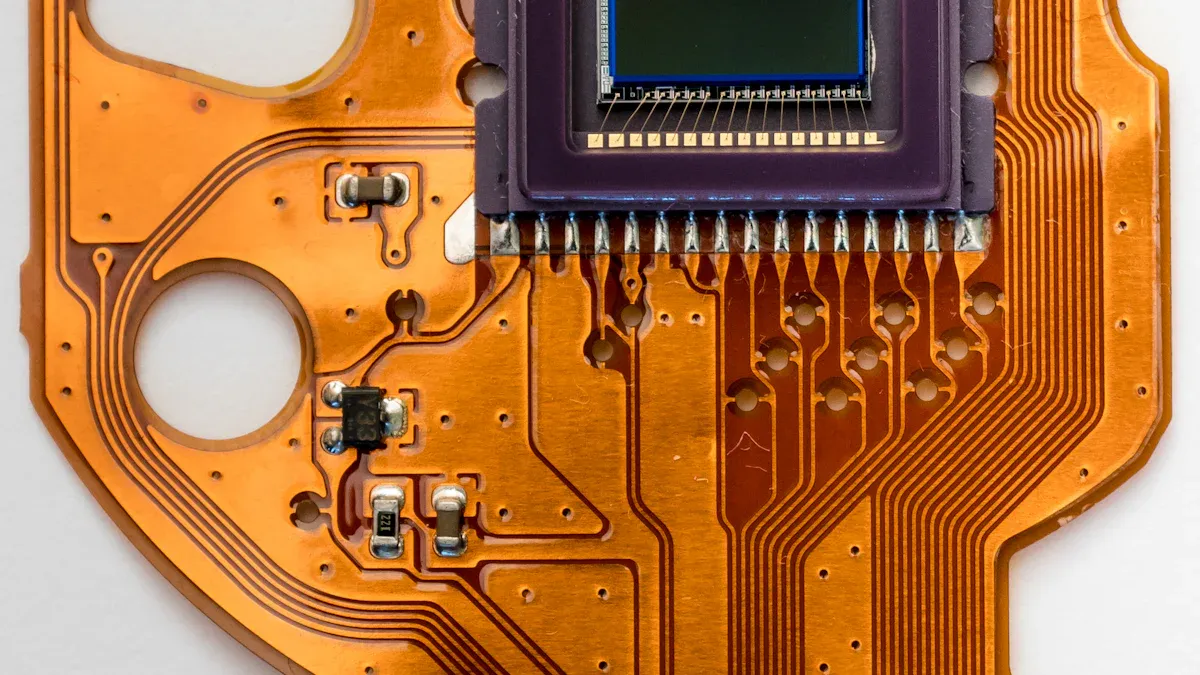

Medical Devices

Medical devices must be small, safe, and work well. Multilayer flexible pcbs help you reach these goals. You can find them in:

Wearable health monitors. These must be light and comfy for daily use.

Implantable devices like pacemakers. Size and safe materials are important.

Diagnostic machines like MRI and X-ray. They need small, dense circuits.

Surgical tools and endoscopes. These need to bend and be very exact.

With multilayer pcb technology, you get:

Smaller devices that are easier and nicer to wear.

High reliability, which is very important for saving lives.

Flexibility to fit circuits in tiny or moving parts.

More features, so you can check health in real time.

LT CIRCUIT works with you to make medical devices that are safe and high quality. Their multilayer pcb solutions help you make products faster and help patients more.

Industrial

Industrial machines must work in hard places. Multilayer flexible pcbs give you the strength and performance you need. You can find them in:

Automation systems. They connect sensors, motors, and controllers.

Robotics. Flexible circuits handle lots of movement and shaking.

CNC machines and control panels. They need fast, steady connections.

Test equipment. These face heat, dust, and bumps.

Multilayer pcb uses in industry give you:

More strength from tough multilayer builds.

More ways to place parts where you want.

Better cooling, so your machines do not get too hot.

Less noise, so signals stay clear in fast machines.

LT CIRCUIT’s industrial solutions use strong materials and coatings. You get pcbs that fight heat, chemicals, and shaking, so your machines keep working.

Aerospace and Military

Aerospace and military systems must be light, small, and very strong. Multilayer flexible pcbs are key for:

Flight control, navigation, and radar in planes.

Engine control and avionics, where saving weight and space matters.

Communication and spy gear in defense systems.

Drones and robots, which need small, tough circuits.

With multilayer pcb technology, you get:

Smaller systems that weigh less, sometimes by 30%.

High strength in extreme heat, shaking, and bumps.

Fewer connectors and wires, so there are fewer problems and better signals.

More features, so you can send fast data and do important jobs.

LT CIRCUIT has special certificates for aerospace and cars. You get custom multilayer pcb solutions that meet the highest safety and quality rules.

A top aerospace company made 99.8% of their products right the first time using LT CIRCUIT’s multilayer pcbs. You can trust their skill for your hardest projects.

Industry Sector | Typical Flexible PCB Applications and Examples |

|---|---|

Smartwatches, fitness trackers using flexible pcbs for curved shapes and lightweight design | |

Medical | Implantable devices, diagnostic tools, hearing aids with flexible circuits fitting compact spaces |

Automotive | Sensors and control units designed to withstand vibration and temperature extremes, used in dashboards and vehicle electronics |

Aerospace | Satellites and drones benefiting from weight savings and complex multilayer routing |

Smartphones and foldable devices using flexible pcbs to connect displays and components across hinges |

You can see that multilayer flexible pcbs are used in almost every new technology. LT CIRCUIT is ready to help you make your next project smaller, stronger, and more useful.

You get lots of good things with multilayer flex pcb solutions.

You can make small products because of design flexibility and high-density pcb integration.

People use pcb technology in many areas like consumer, automotive, medical, industrial, and aerospace.

LT CIRCUIT’s pcb skills, quality, and help make your pcb projects simple.

Why Pick LT CIRCUIT for Your Next PCB Project? |

|---|

Quick pcb samples, custom pcb designs, and strong pcb making. |

Go to LT CIRCUIT’s website for pcb help, fast pcb prices, and expert pcb tips.

FAQ

What makes a multilayer flex pcb better than a regular pcb?

You get more design freedom with a multilayer flex pcb. You save space and weight. Your device works better because the pcb handles more complex circuits.

Can you use a multilayer flex pcb in harsh environments?

Yes, you can trust a multilayer flex pcb in tough places. The pcb resists heat, vibration, and moisture. Your product stays reliable with this advanced pcb technology.

How does LT CIRCUIT help you with custom pcb needs?

LT CIRCUIT gives you expert support for every pcb project. You get fast samples, custom layouts, and high-quality pcb solutions. Your ideas become real with their pcb expertise.

See Also

Exploring Multilayer PCB Uses In Various Industry Sectors

How Multilayer Rigid-Flex Circuit Boards Are Manufactured

Understanding Flexible PCBs And Their Primary Uses Today

Challenges And Steps In Producing Multi-Layer Circuit Boards