Multilayer metal core PCB benefits you can’t ignore

You need the best performance when your project pushes the limits. A multilayer metal core pcb gives you a strong edge with its advanced thermal control and stability. Many engineers choose a multilayer pcb for critical power or lighting systems. This type of pcb helps you tackle tough environments with confidence.

Key Takeaways

Multilayer metal core PCBs excel in heat dissipation, keeping circuits cool and extending device life, especially in high-power applications.

The mechanical strength of multilayer metal core PCBs enhances durability, making them ideal for harsh environments and reducing the risk of damage during use.

These PCBs allow for lighter and thinner designs without sacrificing performance, making them perfect for compact, high-performance devices.

Multilayer metal core PCB overview

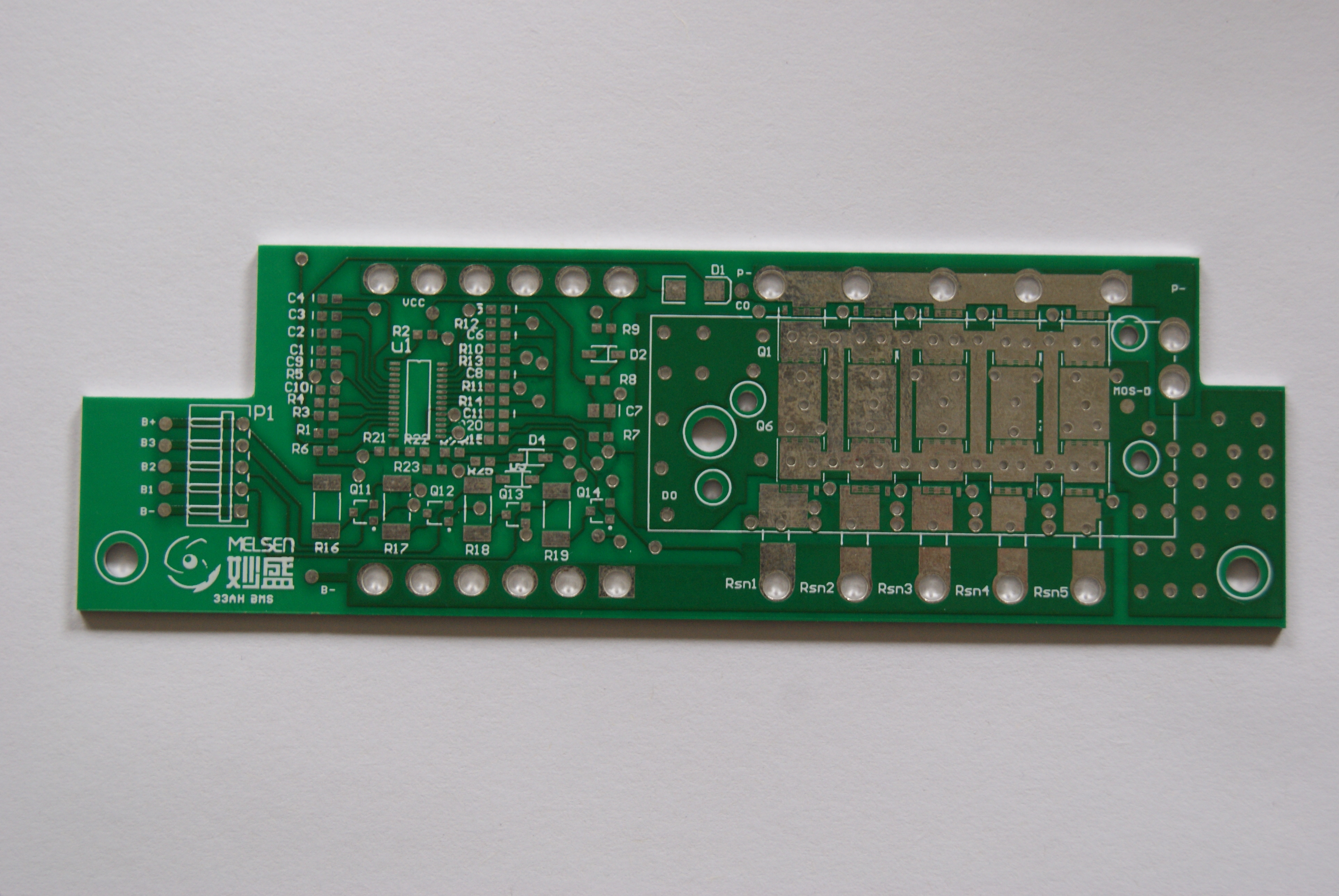

What is a multilayer metal core PCB

You may wonder what sets a multilayer metal core pcb apart from other boards. A multilayer pcb uses several layers of copper circuits, separated by insulating materials, stacked together. In a multilayer metal core pcb, you find a special metal core—often aluminum or copper—at the center. This core helps manage heat and adds strength. Here’s a simple breakdown of the structure:

Description | |

|---|---|

Copper Circuit Layer | The top layer for routing signals, often thicker to handle high currents. |

Dielectric Layer | Provides electrical insulation and enables heat transfer. |

Metal Core Base | Usually made of aluminum, copper, or hybrid alloys, supports the board and aids in heat dissipation. |

You often see aluminum used because it is lightweight, cost-effective, and resists corrosion. Copper works better for heat but weighs more and costs extra. Some high-strength applications use stainless steel or special alloys.

How it differs from standard PCB

When you compare a multilayer pcb with a standard pcb, you notice big differences in performance. The metal core pcb stands out for its ability to handle heat. The metal core pulls heat away from sensitive parts, so your circuits stay cool even under heavy loads. Take a look at this comparison:

Feature | Multilayer Metal Core PCBs | Standard PCBs |

|---|---|---|

Heat Dissipation | Enhanced due to metal core | Limited, relies on external methods |

Thermal Resistance | Low-thermal-resistance path | Higher thermal resistance |

Performance in High-Power Applications | Improved reliability and performance | Struggles with heat management |

You also get better mechanical stability with a multilayer pcb. The metal core makes the board stronger and less likely to break during assembly or use. This means your devices last longer and work better in tough environments.

Advantages of multilayer metal core PCB

Superior heat dissipation

You need reliable thermal management for high-performance devices. A multilayer metal core pcb gives you a clear advantage in heat dissipation. The metal core pulls heat away from sensitive components, keeping your circuits cool even under heavy loads. In one case study, switching to aluminum pcbs reduced temperatures by over 20°C at critical points. This improvement in thermal dissipation protects your devices from overheating and extends their service life. You can trust a multilayer pcb to handle the demands of power electronics, LED lighting, and other high-performance devices where thermal control is essential.

Tip: Efficient thermal dissipation means your circuit boards can run at higher power without risk of failure.

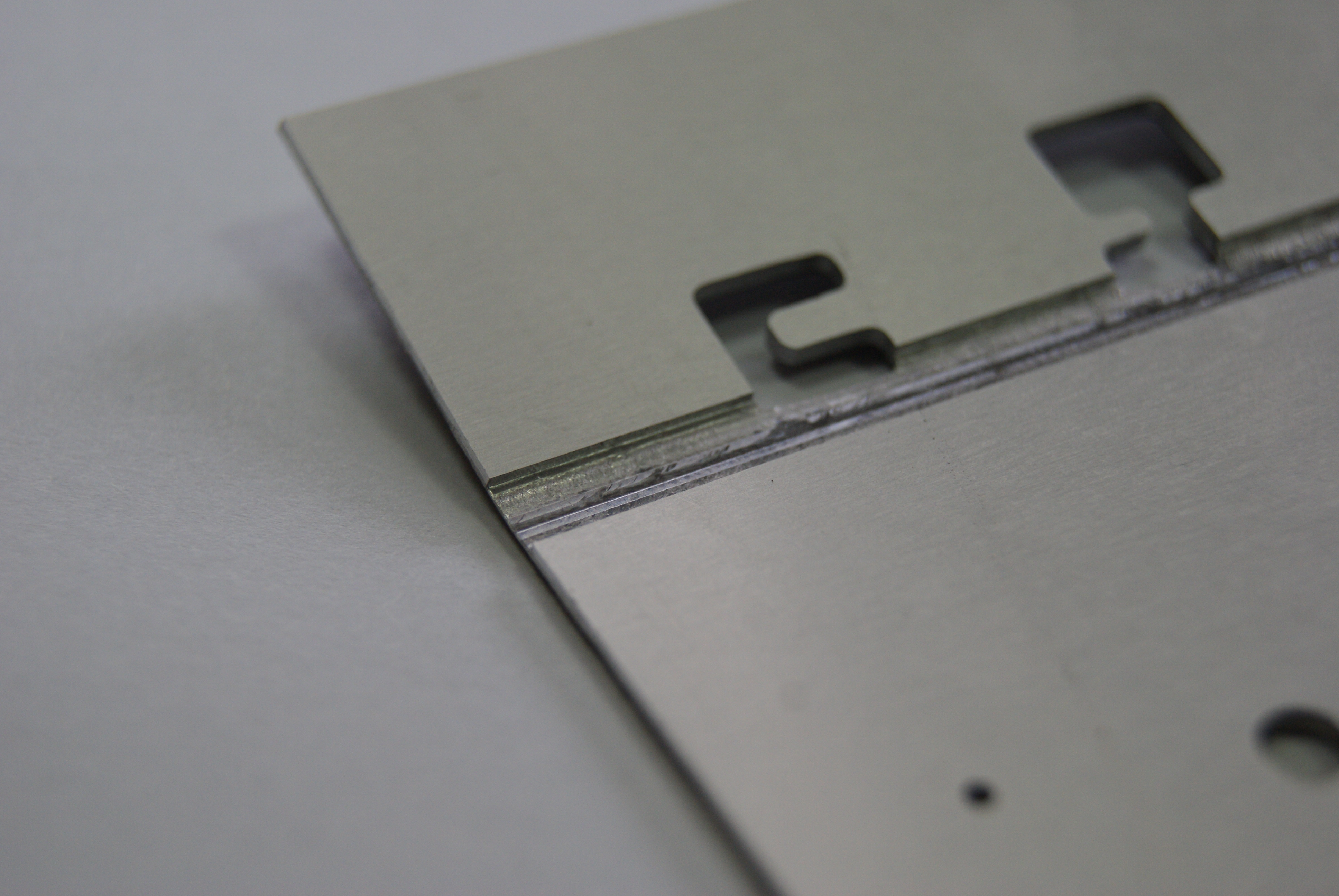

Mechanical strength and durability

A multilayer metal core pcb stands out for its mechanical strength. The metal core adds rigidity, making the board less likely to bend or break during assembly or use. This durability is vital for high-performance devices that face vibration, shock, or harsh environments. You get a pcb that resists damage and lasts longer, even in demanding applications. The metal core pcb also helps prevent common failure modes, such as plating voids or cold solder joints, by supporting better manufacturing practices and robust design.

Failure Mode | Description | Mitigation Strategies |

|---|---|---|

Plating Voids | Spotty metal deposition in plated through-holes leading to opens. | Contamination controls, proper catalyst activation, uniform copper distributions, smoothed hole walls. |

Insufficient Edge Clearances | Risks shorts from condensation or handling damage due to thin coatings. | Conservative spacing rules plus thorough DFM analysis. |

Cold Solder & Other Joint Defects | Incomplete reflow or contamination jeopardizing interconnections. | Process validations, materials improvements, training, and inspection checklists. |

Etching-Related Copper Slivers | Metal fragments causing short circuits from applied voltages. | Tight pattern density controls and more aggressive wash cycles. |

Exposed Inter-Pad Copper | Insulation layer removal leading to shorting from moisture or arcing. | Conservative mask dam widths and improved mask properties. |

You can see that a multilayer pcb with a metal core offers real advantages in reliability and durability.

Thermal expansibility

Thermal expansion can cause problems in standard pcbs, especially when temperatures change quickly. A multilayer metal core pcb controls expansion much better. The metal core keeps the board stable, so you avoid cracks or broken connections. This stability is important for high-performance devices that operate in extreme conditions.

Type of PCB | |

|---|---|

Standard FR-4 Laminate | 14 to 17 ppm/°C |

Metal Core CIC | 8 ppm/°C |

Metal Core CMC | 6 ppm/°C |

Overall CTE (CIC) | 12 ppm/°C |

Overall CTE (CMC) | 9 ppm/°C |

You get a pcb that stays reliable, even when the temperature changes fast. This advantage helps you build high-performance devices that last longer and work better.

Weight and thickness reduction

You want your devices to be lighter and thinner. A multilayer metal core pcb helps you achieve this goal. The metal core allows you to use thinner copper layers without losing strength or performance. This design reduces the overall weight and thickness of your pcb. You save space in your circuit design, which is important for compact high-performance devices.

Aluminum cores are lightweight and strong.

Thinner copper layers lower material costs.

You can fit more functionality into a smaller space.

Aluminum pcbs are also recyclable, which makes them environmentally friendly. This recyclability reduces environmental impact and supports electronic sustainability. As regulations become stricter, the benefits of metal core pcb solutions grow even more important.

Electrical performance and power distribution

A multilayer metal core pcb gives you better electrical performance and power distribution. The metal core acts as a heat sink, improving thermal management and allowing your circuits to handle higher currents. You can use wider traces and thicker copper layers, which reduces resistance and improves power flow. This advantage is critical for high-performance devices that need stable, reliable operation.

Aspect | Improvement Description |

|---|---|

Thermal Management | The metal core acts as an efficient heat sink, drawing heat away from high-power components. |

Current Handling | Thicker copper layers and wider traces help manage high current demands and reduce overheating. |

Power Distribution | Optimized trace layouts ensure smoother power flow and minimize resistance, enhancing overall performance. |

You also benefit from a longer service lifetime and fewer failures. The multilayer pcb structure supports better electrical performance, which means your high-performance devices can run at full capacity without risk.

Note: The use of thinner copper layers in a multilayer metal core pcb can lower costs while still delivering top performance.

Other key advantages

Metal core pcb solutions provide exceptional thermal conductivity, quickly transferring heat away from critical components.

The mechanical strength and dimensional stability of a multilayer pcb make it ideal for harsh environments, such as automotive or industrial settings.

These advantages ensure long-term reliability for battery management and other high-performance devices.

Efficient thermal management and recyclability make aluminum pcbs a smart choice for sustainable circuit boards.

You may wonder how are metal core pcbs fabricated. Manufacturers use advanced bonding and drilling techniques to create strong, precise multilayer structures. This process supports complex circuit design and high-density layouts.

PCB Type | Cost per Square Inch | Key Features |

|---|---|---|

Aluminum IMS PCB | Good balance of cost and thermal performance | |

Copper IMS PCB | $0.30 - $0.40 | Better thermal conductivity, higher durability |

FR4 PCB | $0.10 | Lower cost, less thermal handling capability |

Multi-Layer IMS PCB | 10%-30% more than single-layer | Complex bonding, precision drilling increases costs |

Specialty Fillers | +10%-25% | Improved thermal stability, higher material cost |

Overall IMS vs FR4 | 20%-50% higher | Longer lifespan and reduced maintenance in demanding applications |

You may pay more upfront for a multilayer metal core pcb, but you gain advantages in performance, reliability, and environmental impact. These benefits of metal core pcb solutions make them the best choice for high-performance devices and demanding applications.

Applications of multilayer PCB

You see multilayer pcb technology in many modern applications. These boards support high-performance needs across industries. Let’s look at where you find the most value.

LED lighting

Multilayer pcb solutions power advanced LED lighting. You find them in street lights, automotive lighting, and commercial fixtures. The metal core in these boards keeps LEDs cool, which extends their lifetime and improves brightness. You can trust these pcbs to handle the heat from high-power LEDs.

Automotive and EV

Automotive and electric vehicle systems rely on multilayer pcb designs for safety and efficiency. You benefit from:

Superior thermal conductivity for quick heat transfer in high-current circuits.

Enhanced durability and stability, even in harsh environments.

Compact design that saves space and weight.

Support for high-power components, such as fast chargers and battery management.

These features make multilayer applications essential for energy and power applications in vehicles.

Power electronics

You use multilayer pcb boards in energy and power applications like inverters and power supplies. The table below shows why they excel:

Benefit | Description |

|---|---|

Transfers heat away from components, boosting performance. | |

Enhanced Durability | Metal core prevents warping and cracking. |

Improved Performance | Ensures reliability and long device lifetime. |

Environmental Benefits | Recyclable materials support green manufacturing. |

Consumer devices

You see multilayer pcb technology in smartphones, tablets, and wearables. These boards allow for dense component placement and complex routing. You get smaller, lighter devices with reliable performance. The design flexibility supports miniaturization and longer lifetime.

Choosing multilayer PCB

When you select a multilayer pcb, consider:

Material selection for the core and dielectric layers.

Application-specific requirements.

Proper grounding, signal integrity, and manufacturability.

You should match the pcb design to your application’s demands. Multilayer applications of metal core pcb offer the best results for high-performance, energy and power applications.

You see multilayer metal core PCB design excel in high-power applications. The design supports mechanical strength, advanced thermal management, and high circuit density. You achieve reliability in LED lighting, automotive, wireless, and industrial control. The design offers compactness and increased density. You should evaluate design options, density requirements, and reliability standards. The design ensures reliability, density, and performance. You benefit from design flexibility, density optimization, and reliability assurance. The design meets density needs and reliability goals. You gain reliability, density, and design advantages. The design delivers reliability, density, and space-saving benefits. You should consult experts for design, density, and reliability solutions. The design supports density and reliability in every project. You maximize reliability, density, and design efficiency. The design enhances reliability, density, and compactness. You improve reliability, density, and design outcomes. The design guarantees reliability, density, and long-term success. You secure reliability, density, and design excellence. The design achieves density and reliability for modern electronics. You reach reliability, density, and design milestones. The design provides density, reliability, and future-ready solutions. You ensure reliability, density, and design innovation. The design unlocks density, reliability, and project potential.

One of the main benefits of metal core PCB design is its ability to dissipate heat more efficiently than traditional PCBs. The metal core acts as a heat sink, absorbing and dissipating heat away from the components.

Multilayer metal core PCB design offers mechanical strength, insulation, and high-frequency material options for advanced applications.

You should review design, density, and reliability certifications, prototyping capabilities, and customer support when choosing a manufacturer.

FAQ

What makes multilayer metal core PCBs better for heat management?

The metal core pulls heat away from components. You get cooler circuits and longer device life. This feature helps in high-power and LED applications.

Can you use multilayer metal core PCBs in flexible designs?

You usually find these PCBs in rigid designs. The metal core adds strength but limits flexibility. Choose them for durability, not for bendable circuits.

How do you choose the right metal core material?

Material | Best For |

|---|---|

Aluminum | Lightweight, cost-saving |

Copper | Maximum heat transfer |

Steel | Extra mechanical strength |

You select based on your device’s needs.

See Also

Exploring Multilayer PCB Uses In Various Industries

Understanding Multilayer PCBs And Their Role In Electronics

The Comprehensive Process Of Manufacturing Multilayer PCBs

A Guide To Heavy Copper Multilayer PCB Production Techniques

Challenges In Manufacturing And Prototyping Multilayer Circuit Boards