Top Advantages of Multilayer PCBs for Modern Electronics

Multilayer PCBs are found in many modern devices, offering multilayer PCB advantages that help make products smaller while adding more features. These boards deliver enhanced performance, allowing you to build compact and robust products. The multilayer PCB advantages are widely recognized across industries such as telecommunications and healthcare. Understanding these multilayer PCB advantages enables you to create better solutions that meet today’s demands for speed, miniaturization, and versatility.

Key Takeaways

Multilayer PCBs help you put more parts in less space. This makes devices smaller and lighter. It is easier to carry them around.

These PCBs help devices work better by lowering noise. They keep signals strong. This makes devices faster and more reliable.

Multilayer PCBs are tough and last a long time. They handle heat well and block interference. This makes them great for modern electronics.

Multilayer PCB Overview

Structure and Layers

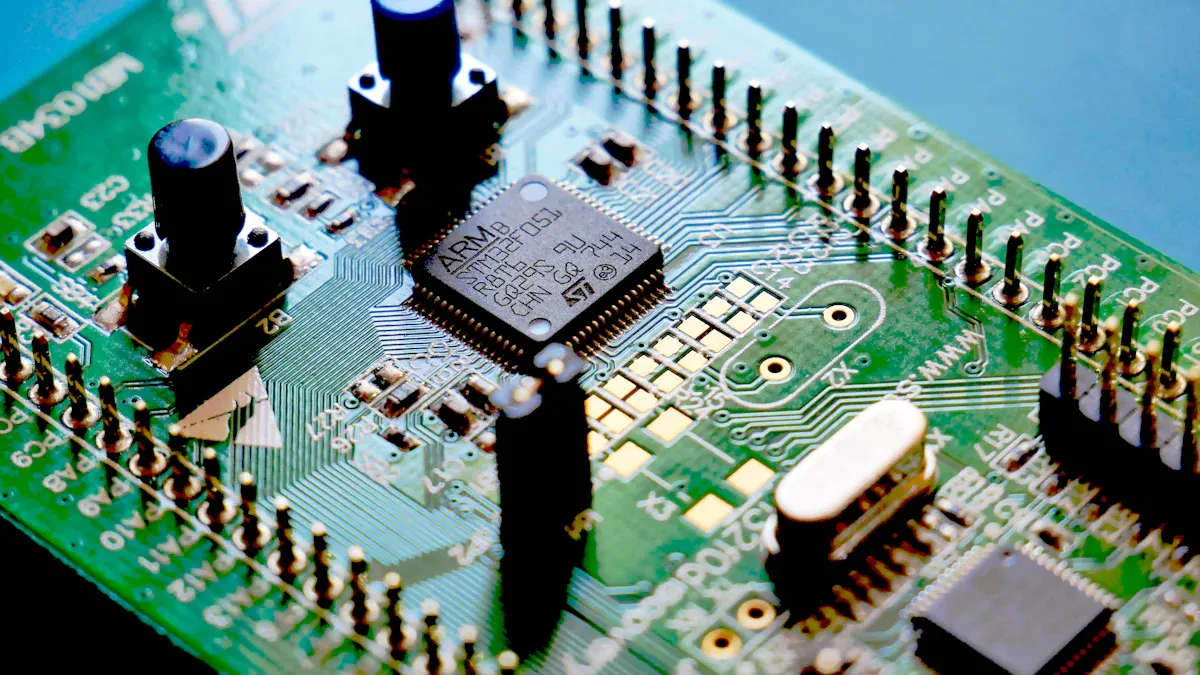

Multilayer PCBs are a smart way to make electronics. These printed circuit boards have three or more copper layers. Insulating materials are placed between each copper layer. The outside layers hold the parts and connect signals. The inside layers carry power, ground, and extra signals. Copper-plated holes, called vias, link all the layers together. This design keeps the boards flat and strong after soldering. Most multilayer PCBs have an even number of layers, like 4, 6, or 8. This helps stop the boards from bending. Each layer has its own job. Some layers move signals. Others give power or ground. This setup lowers noise, makes signals faster, and keeps devices small and light. You see this structure in many electronics where space and performance are important.

Tip: Using the same number of layers on both sides stops bending and keeps your printed circuit boards working well.

Comparison with Single and Double-Layer Printed Circuit Boards

You may wonder how multilayer PCBs are different from other circuit boards. Single-layer printed circuit boards have only one copper layer. They are simple and cost less. Double-layer printed circuit boards have two copper layers. This lets you make more connections but still has limits. Multilayer PCBs use special lamination and vias to join many layers. They are harder and more expensive to make, but they work much better. With multilayer PCBs, you can fit more parts in a small space. They also handle heat better and lower electrical noise. These printed circuit boards are great for devices that need to be fast, reliable, and small.

Feature | Single-Layer PCBs | Double-Layer PCBs | Multilayer PCBs |

|---|---|---|---|

Layers | 1 | 2 | 3 or more |

Complexity | Low | Moderate | High |

Cost | Low | Moderate | High |

Performance | Basic | Improved | Superior |

Applications | Simple devices | Moderate devices | Advanced electronics |

Multilayer PCB Advantages

High Component Density

Multilayer PCBs let you put more parts in less space. These boards have three or more layers stacked together. This gives you high assembly density. You can add more chips and resistors without making the board bigger. Smartphones and smartwatches use these boards for this reason. Medical devices also use them to fit many parts inside. For example, a smartphone holds its processor and memory on a small board. Industrial robots use these boards to control many motors at once. Stacking layers lets you make more connections and signals. This is why GPS devices and satellites use these boards. Automotive electronics also use them for more power in a small space.

Compact Size and Lightweight

Multilayer PCBs help make products small and light. Stacking layers means you do not need extra boards. This saves space and cuts weight. Laptops and tablets use these boards to stay thin and easy to carry. Aerospace engineers use them to keep equipment light for flying. Wearable devices need every millimeter, so these boards help. Smaller and lighter boards are easier to handle and ship. They also work better in portable devices. You see these benefits in electronics, medical tools, and cars.

Feature | Explanation |

|---|---|

Stacking layers fits more circuits in less space, reducing overall size. | |

Lightweight | Fewer connectors and a single board lower the device's weight. |

Higher Density | More components fit in a compact area, boosting performance. |

Integration | Combining functions into one board saves space and weight. |

Electrical Performance and Signal Integrity

Multilayer PCBs give you better electrical performance. They use special layers for power and ground. This keeps signals clean and strong. It also lowers noise and stops signals from mixing. High-speed computers and towers need good signal integrity. Medical machines like MRI and CT scanners use these boards for accurate signals. Robotics use them to control fast parts without mistakes. You get less signal loss and better speed. Data moves more reliably. These boards also help keep parts cool so they last longer.

Tip: Put ground and power layers close together. This shields signals and makes your board work better.

Reliability in Modern Electronics

Multilayer PCBs are strong and reliable. They go through tough tests to make sure they work well. Aerospace and medical devices need this reliability. These boards last longer and handle stress better. Good thermal management keeps parts from getting too hot. The design also gives better support against bumps and drops. LT CIRCUIT uses advanced materials and careful testing. They check every board with machines and X-rays. Their process makes sure each board is high quality. You get circuit boards that work well and last a long time.

EMI Shielding and Power Distribution

Multilayer PCBs protect devices from electromagnetic interference. They use special layer setups to shield signals. This is important for communication devices like satellites and GPS units. The boards have power and ground planes for steady voltage. This lowers power loss and keeps motors and sensors working right. LT CIRCUIT uses advanced designs and materials for better EMI shielding. Their boards handle complex paths and high currents. This makes them great for tough jobs.

Sector | Real-World Examples of Multilayer PCB Applications |

|---|---|

Smartphones, laptops, smart TVs, microwaves, washing machines | |

Telecommunications | GPS devices, satellites, communication towers, radar electronics |

Industrial Devices | Automated assembly lines, packaging conveyors, spray painting robots |

Multilayer PCBs give you more design choices. You can make products smaller, faster, and stronger. The multilayer PCB advantages are high component density, small size, better electrical performance, strong reliability, and great EMI shielding. LT CIRCUIT leads with new ideas and strict quality checks. These benefits make multilayer PCBs the best choice for modern electronics.

LT CIRCUIT and Multilayer PCBs

Industry Applications

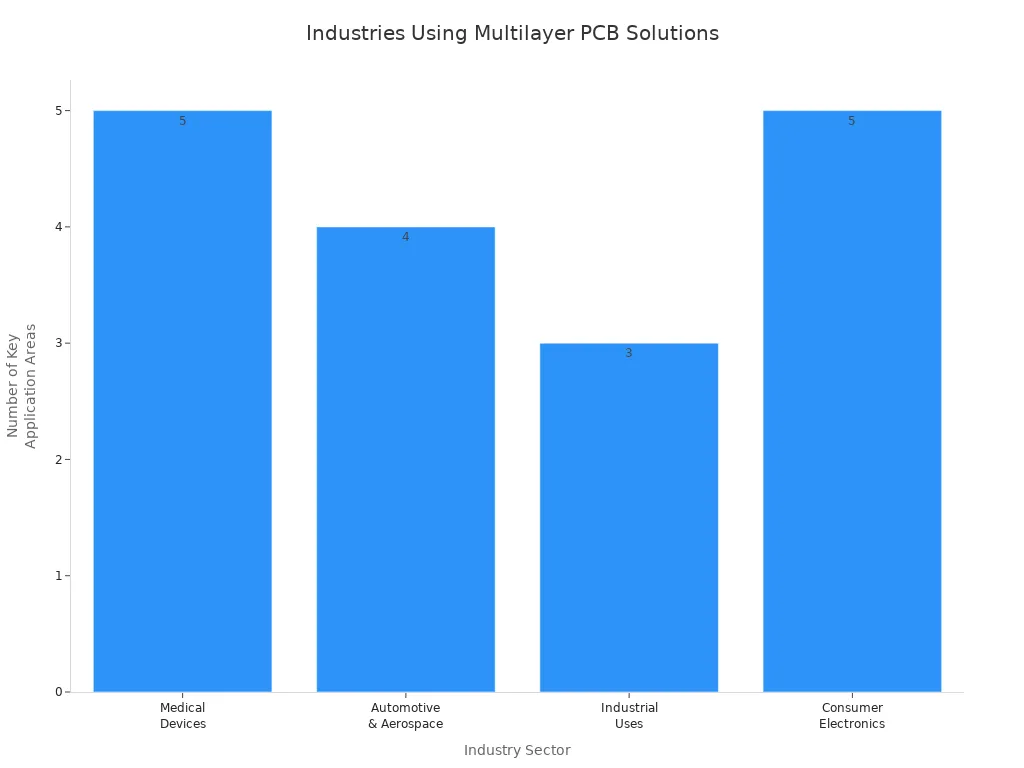

Multilayer PCBs are used in many fields. They help solve hard design problems. LT CIRCUIT makes advanced multilayer PCBs for many uses. These include medical, automotive, industrial, and consumer electronics. These boards help make devices small, light, and strong. In medical tools, multilayer PCBs keep signals clear and block noise. Car and airplane engineers use them for shock resistance and to save space. Industrial robots and machines need these boards for heat resistance and long life. Phones and tablets use them for thin shapes and strong signals.

Industry Sector | Key Application Areas | Key Features / Benefits |

|---|---|---|

Medical Devices | Implantable medical devices, health care tools, medical imaging, patient monitoring, wearable health devices | Small, lightweight, flexible, signal clarity, noise blocking, durability |

Automotive & Aerospace | Electric cars, ADAS, entertainment systems, satellites, space electronics | Shock and temperature resistance, lightweight, space-saving, rigid-flex designs for strength and flexibility |

Industrial Uses | Robots, factory machines, telecom equipment | Compact, powerful, heat resistant, easy assembly, long-lasting |

Consumer Electronics | Smartphones, tablets, laptops, smartwatches, foldable smartphones | Thin, flexible for curved screens, signal integrity, supports miniaturization, widely used in Asia Pacific |

LT CIRCUIT’s multilayer PCBs have solved real problems. For example, a 5G antenna needed a 16-layer PCB with low signal loss. LT CIRCUIT used laser-drilled microvias and special lamination to meet strict rules. In another case, a brain implant needed an 8-layer rigid-flex PCB. LT CIRCUIT made a safe, FDA-cleared board for deep brain stimulation.

Custom Solutions and Quality Assurance

You can trust LT CIRCUIT for custom multilayer PCBs. They help you from your first idea to final testing. Their team designs analog, digital, and mixed-signal circuits for many fields. You get help with circuit simulation, making things better, and even IoT hardware. LT CIRCUIT also helps with firmware and testing to make sure your boards work well.

LT CIRCUIT creates custom electronic circuit designs and hardware for special projects.

Their solutions work for factories, cars, home gadgets, planes, defense, wearables, security, and telecom.

You can ask for analog, digital, FPGA, microcontroller, or mixed circuit designs.

They offer technical papers, simulation, making things better, IoT hardware/software, embedded design, power electronics, firmware, and certification.

LT CIRCUIT works with you from the first idea to the prototype and testing.

Their custom multilayer PCBs help you save money, work faster, and be more efficient.

LT CIRCUIT uses advanced tests like 3D X-ray and flying probe tests. You get multilayer PCBs that meet high standards for reliability and performance. Their focus on quality and new ideas makes them a trusted partner for your next project.

You get lots of good things when you use multilayer pcbs in your work:

They are smaller and weigh less.

You can fit more parts on them.

They work better with electricity.

They last a long time.

You can design them in many ways.

Multilayer pcbs help make your gadgets strong and small. LT CIRCUIT makes smart multilayer pcbs that pass tough tests. Today’s electronics need multilayer pcbs for speed and power. If you want the best multilayer pcbs, LT CIRCUIT can help you. These boards let you make great products. You find multilayer pcbs in all kinds of things, like phones and hospital machines. Try multilayer pcbs for your next job and see how they help.

FAQ

What makes multilayer PCBs better for modern electronics?

Multilayer PCBs help devices work faster and last longer. They let you put more parts in a small space. This makes gadgets smaller and more powerful.

How does LT CIRCUIT ensure quality in multilayer PCBs?

LT CIRCUIT checks every board with special machines. They use 3D X-ray and flying probe tests. These tests make sure the boards are strong and work well.

Can you customize multilayer PCBs for special projects?

Yes! LT CIRCUIT can make PCBs just for your project. Their team helps with designs for cars, factories, or medical tools.

💡 Tip: Tell LT CIRCUIT about your project. This helps them give you the best custom PCB.

See Also

Exploring Multilayer PCB Uses In Various Industry Sectors

Challenges In Manufacturing And Prototyping Multilayer Circuit Boards

Understanding Differences Between Single Double And Multilayer PCBs

Comprehensive Guide To Heavy Copper Multilayer PCB Production

How LT CIRCUIT Uses Blind Via Tech To Enhance Multilayer PCBs