The Key Advantages of Multilayer PCBs in High-Speed Electronics

Multilayer pcbs help make fast circuits better by giving strong signal quality, less EMI, and smaller size.

Controlled impedance routing and good layer stacks in multilayer pcbs keep signals clear and on time. This helps them work better and last longer.

EMI shielding and high-density integration let people make more complex printed circuit board designs.

LT CIRCUIT’s multilayer pcb advantages make sure these good things give real results for advanced electronics.

Key Takeaways

Multilayer PCBs keep signals strong and clear. They use special layer setups and ground planes. This helps fast electronics work better. It also helps them last longer.

These PCBs lower electromagnetic interference (EMI) and control impedance. This makes circuits more reliable. It also means fewer errors in high-speed designs.

Multilayer PCBs let more parts fit in small spaces. This helps make small and light devices like smartphones and medical tools. They do not lose performance.

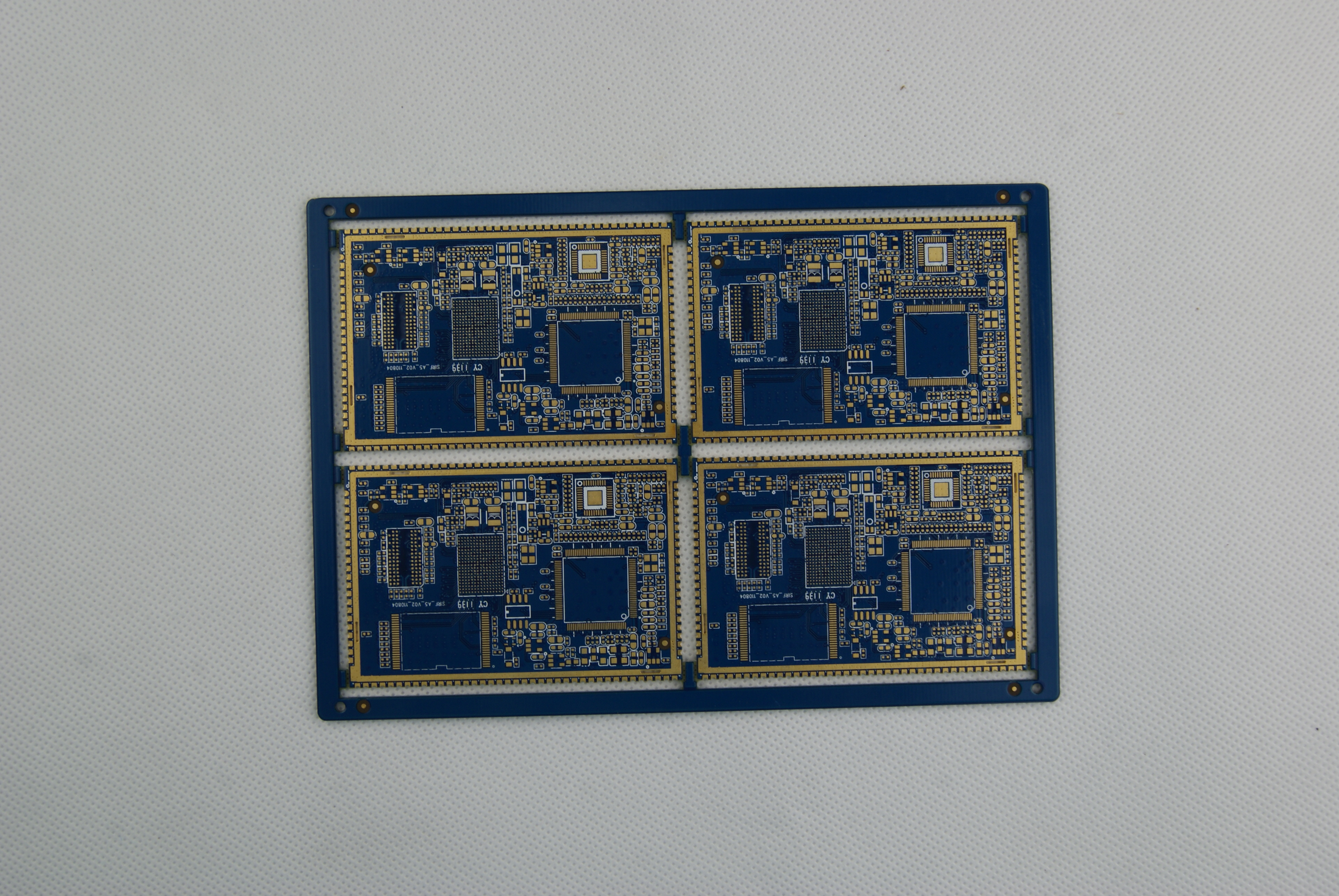

Multilayer PCB Structure

Multilayer pcbs have layers of copper and insulation stacked together. These boards let engineers fit many connections in a small space. The structure helps signals stay clear and steady, even at high speeds. LT CIRCUIT uses special ways to make high layer pcb board solutions that meet tough needs.

Layer Arrangement

How the layers are arranged is important for how the board works. Designers often pick even stacks to stop bending and keep things balanced. The table below shows some common ways to arrange layers in multilayer pcbs for fast electronics:

Layer Count | Example Stack-Up Layers | Purpose and Benefits |

|---|---|---|

4 Layers | Top Signal; Ground Plane; Power Plane; Bottom Signal | Good for routing and power; keeps signals strong |

6 Layers | Top Signal; Ground Plane; Signal 2; Power Plane; Signal 3; Bottom Signal | Adds more paths for tight circuits; keeps planes close |

8 Layers | Top Signal; Ground 1; Signal 2; Ground 2; Signal 3; Ground 3; Signal 4; Bottom Signal | Stops crosstalk; controls impedance; best for hard, fast circuits |

Boards with even numbers of layers are stronger and work better. Odd-layer pcbs are not used much because they can cause problems.

Signal and Power Planes

Special signal and power planes help high-speed circuits work well.

Power planes give steady voltage and stop drops, so things run right.

Ground planes are good for signals and lower noise and crosstalk.

Putting signal layers next to ground planes helps control impedance and keeps signals clean.

Multi-layer boards use these planes to handle heat and help with decoupling, which makes power better.

LT CIRCUIT knows how to design high layer pcb boards so each one helps advanced circuits work with strong signals and good power. Their multi-layer pcbs use special materials and careful stacks to meet the needs of new electronics.

Multilayer PCB Advantages

Multilayer pcb advantages help high-speed electronics get better. These boards have special benefits that single or double-layer pcbs do not have. Engineers use multilayer pcbs because they can handle hard circuits and keep signals strong. They also work well in tough places. LT CIRCUIT makes sure every board is made with high quality and works well.

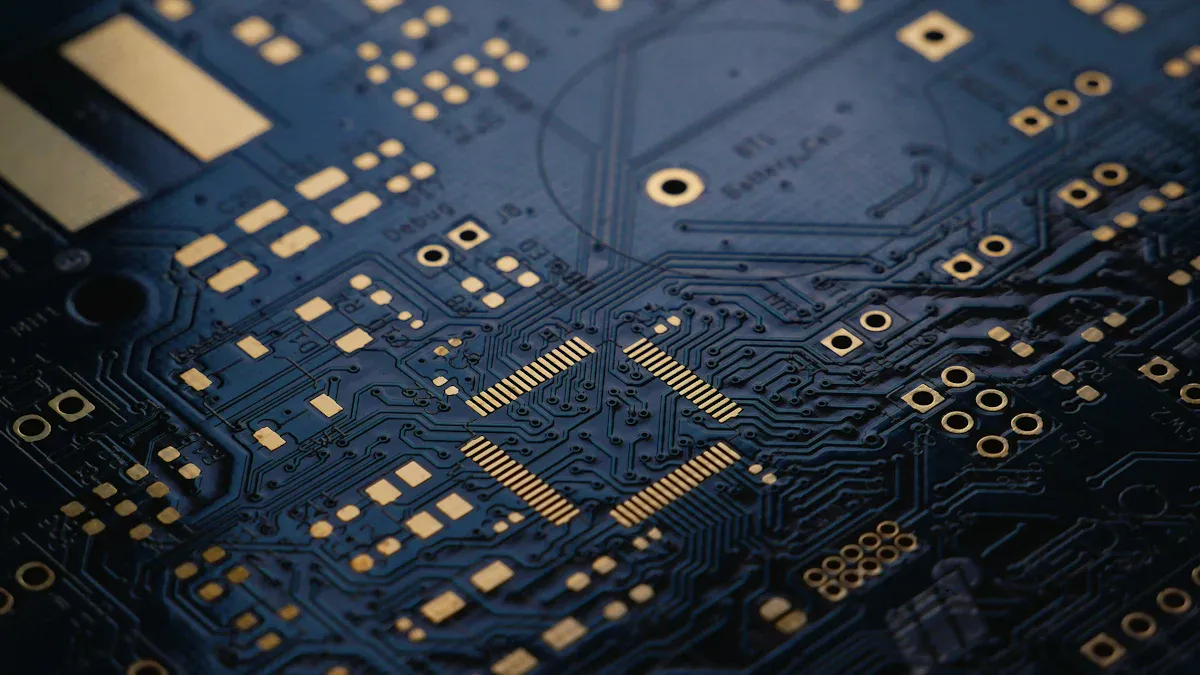

Signal Integrity

Signal integrity is very important in fast designs. Multilayer pcbs use ground planes and careful stacking to keep signals strong. When signals go over ground planes, they stay steady and do not mix with others. Designers put ground planes close to signal layers to stop unwanted signal mixing. This helps signals move right. LT CIRCUIT checks signal integrity with special tests like time-domain reflectometry. This stops signal loss and keeps signals clear, even in busy circuits.

EMI Reduction

Electromagnetic interference (EMI) can hurt circuits and make them work badly. Multilayer pcb advantages include EMI shielding with solid ground and power planes. These planes soak up extra fields and block noise from outside. Multi-layer boards can also use guard traces and via stitching to stop EMI. This keeps signals steady. LT CIRCUIT uses careful building and good materials to make EMI reduction better. This helps boards work well even when there is a lot of electrical noise.

Impedance Control

Controlled impedance is needed for fast signals to move right. Multilayer pcbs do this by changing trace width, spacing, and layer thickness. Keeping impedance the same stops signal bounce and mistakes in fast circuits. Multi-layer boards with ground planes between layers help keep impedance even and stop signal mixing. LT CIRCUIT works with customers to set impedance goals and make good stack-ups. Their boards help with differential pair routing and good via design. This keeps signals clear and steady at high speeds.

Density and Compactness

A big multilayer pcb advantage is fitting more parts in a small space. Multi-layer boards use things like microvias and via-in-pad to add more wires and make layouts smaller. This lets engineers make small, light devices that still work well. LT CIRCUIT’s boards help make things tiny by putting more parts and wires in less space. This is important for things like smartphones, medical tools, and cars, where space and weight are important.

Table: Real-World Performance Improvements with LT CIRCUIT Multilayer PCBs

Application | PCB Specification | Performance Improvement / Result |

|---|---|---|

Industrial Inverters | 3kV motor drive, 0.5mm PTFE layers (rated 15kV) | 70% fewer field failures than FR-4 designs |

EV Charging Stations | 600V, high-Tg FR-4, 0.3mm layers, conformal coating | 100% reliability for over 5,000 charging cycles |

Medical Imaging | 2kV X-ray, ceramic-filled laminates, 1mm layers | Passed IEC 60601-1 safety; no discharge at 3kV |

The multilayer pcb advantages from LT CIRCUIT’s boards include less signal loss, less crosstalk, special ground planes, controlled impedance, and help for high-density circuits. These things make electronics work better, last longer, and be smaller for today’s needs.

Applications and Best Practices

High-Speed Uses

Multilayer pcbs are used in many fast electronics. These boards are needed for strong performance, small size, and high reliability. The table below shows how different industries use multilayer pcbs for advanced uses:

Industry | Applications and Examples | Key Benefits for High-Speed Electronics |

|---|---|---|

Consumer Electronics | Smartphones, tablets, laptops, wearables | Small size, high component density, advanced processors |

Telecommunications | Routers, switches, communication systems | High-speed signal processing, reliable connections |

Computing & Storage | Servers, data storage equipment | Low power, high-speed signals, tight integration |

Automotive | Control units, infotainment, ADAS | Ruggedness, heat resistance, durability |

Medical Devices | Imaging equipment, patient monitors, diagnostic devices | Superior reliability, signal accuracy |

Aerospace & Defense | Avionics, satellites, radar, military electronics | Lightweight, high performance, shock resistance |

These uses need multilayer pcbs to handle hard circuits and keep signals stable at high speeds.

Design Tips

Engineers use some best ways to get the most from multilayer pcbs in fast circuits:

Keep noisy and sensitive parts apart with ground planes.

Use ferrite beads and capacitors to block noise on power lines.

Add metal shields to stop electromagnetic emissions.

Make sure ground planes are not broken and use vias for easy paths.

Try simulation tools to check impedance and crosstalk before making boards.

Tip: Always make trace lengths match and use differential pairs for fast signals to help performance.

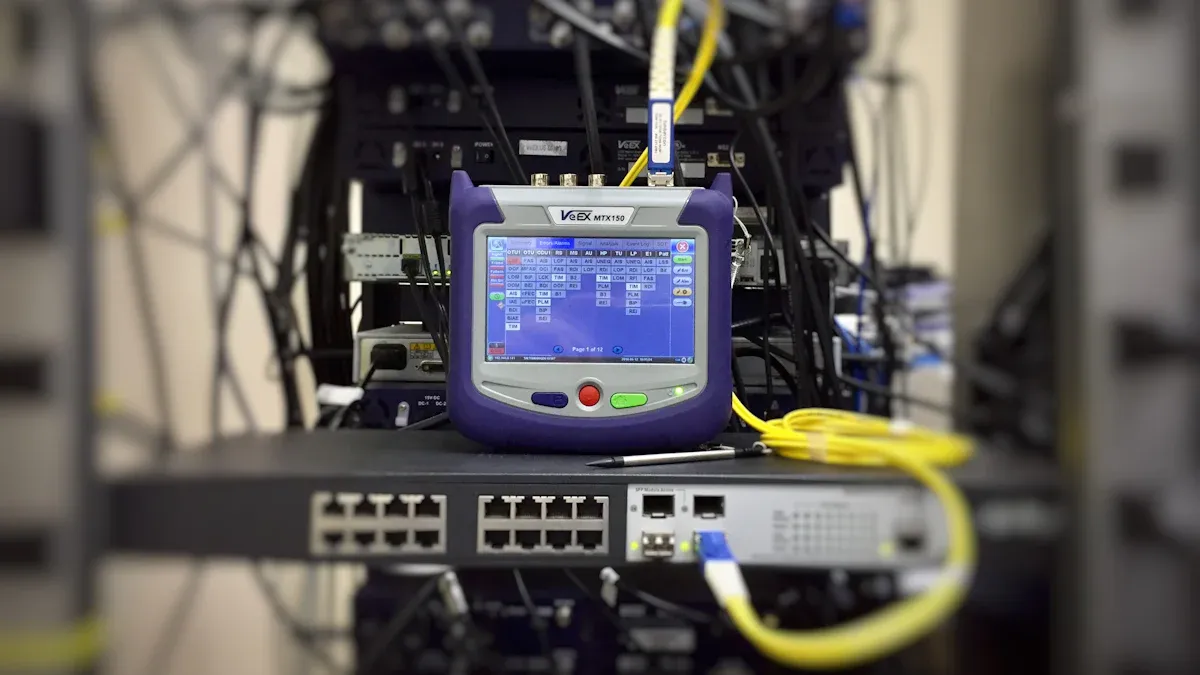

LT CIRCUIT Solutions

LT CIRCUIT helps customers solve multilayer pcb problems in tough uses. They use laser drilling, hybrid stacks, and good materials like FR-4 and Megtron 6. They check quality with AOI, X-ray, and ISO certifications to meet standards. LT CIRCUIT is skilled with microvias, buried vias, and VIPPO plating for small, dense boards. Customers say they like LT CIRCUIT’s quick delivery, engineering help, and reliable multilayer pcbs for important uses. These solutions make performance and reliability better in every use, from medical devices to cars and aerospace systems.

Multilayer pcbs work well in fast electronics. They help signals stay clear and strong. They also cut down on EMI and make boards smaller. The table below shows how these benefits help boards last longer and need less fixing:

Advantage | Long-Term Performance | Maintenance Impact |

|---|---|---|

Reduced EMI & Crosstalk | Signals stay steady | Fewer repairs needed |

Ground/Power Planes | Power stays reliable | Fewer problems happen |

Strong Lamination | Boards last longer | Less damage over time |

Compact Design | More parts fit in less space | Easier to put together |

Shorter Paths | Signals move faster | Fewer things go wrong |

Optimized Power | Boards run steady | Less fixing needed |

Engineers can learn more about multilayer pcbs and fast design with these resources:

Articles about signal integrity, routing, and picking materials

Guides from Altium about high-speed pcb design

LT CIRCUIT is ready to help with advanced multilayer solutions. They make sure pcbs are strong and work well for a long time.

FAQ

What makes multilayer pcbs better for high-speed circuit applications?

Engineers pick multilayer pcbs for fast circuits. These boards keep signals strong and clear. They let many parts fit close together. This helps signals move well in hard circuits.

How do multilayer pcbs improve signal integrity and reliability?

Multilayer pcbs have ground planes and stacked layers. These things cut down noise and help with tight circuits. They make sure the board works well in many uses.

Can multilayer pcbs handle a large number of interconnections?

Yes. Multi-layer boards can hold many connections. This lets engineers build advanced circuits. They work for fast signals and small designs.

See Also

Exploring Diverse Uses Of Multilayer PCBs In Industries

Understanding The Fundamentals Of High-Speed Printed Circuit Boards

Top Material Choices For Designing High-Speed PCBs Effectively

Challenges And Steps In Manufacturing Multi-Layer Circuit Boards

Comprehensive Guide To Producing Heavy Copper Multilayer PCBs