Why Multilayer Rogers PCBs Are the Top Choice for RF and Microwave Designs

You demand reliability and performance in high-frequency designs. Multilayer rogers pcb delivers both, thanks to advanced materials with stable dielectric constants. LT CIRCUIT uses trusted Rogers options for unmatched precision.

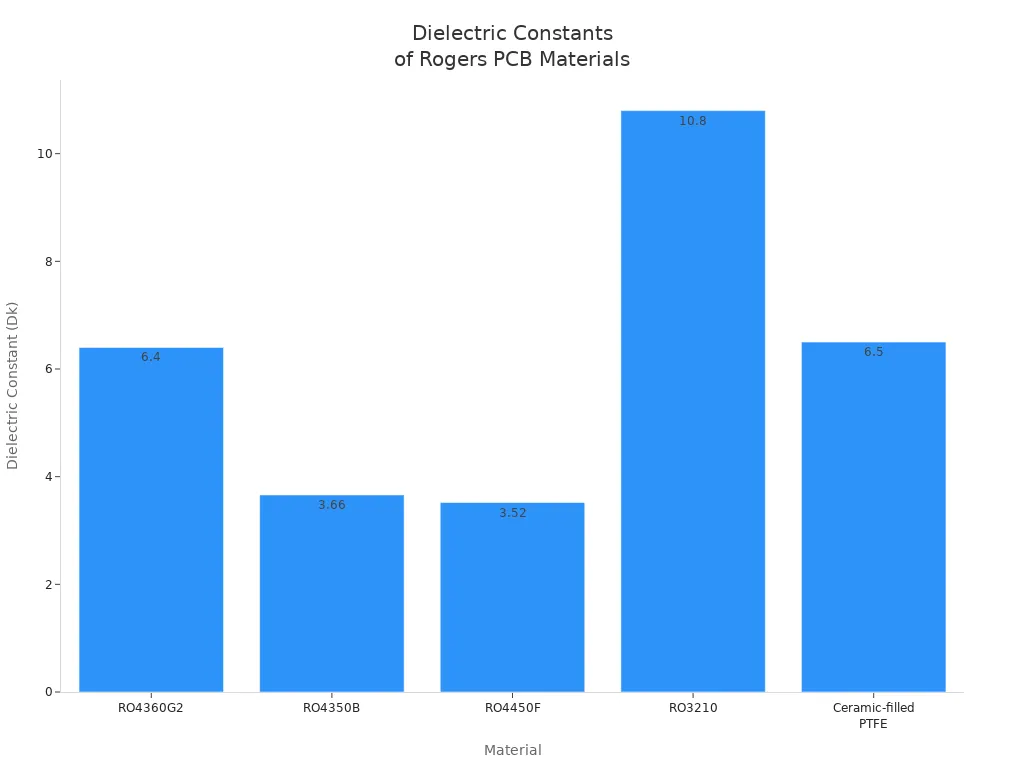

Material | Dielectric Constant (Dk) |

|---|---|

RO4360G2 | 6.4 |

RO4350B | 3.66 |

RO4450F | 3.52 |

RO3210 | 10.8 |

Ceramic-filled PTFE | 6.5 |

Key Takeaways

Multilayer Rogers PCBs provide stable dielectric properties, ensuring reliable performance in high-frequency applications.

These PCBs minimize signal loss and maintain signal integrity, making them ideal for RF and microwave designs.

Rogers materials offer excellent thermal management, protecting components from overheating in demanding environments.

Rogers PCB Materials Overview

Rogers vs. FR4

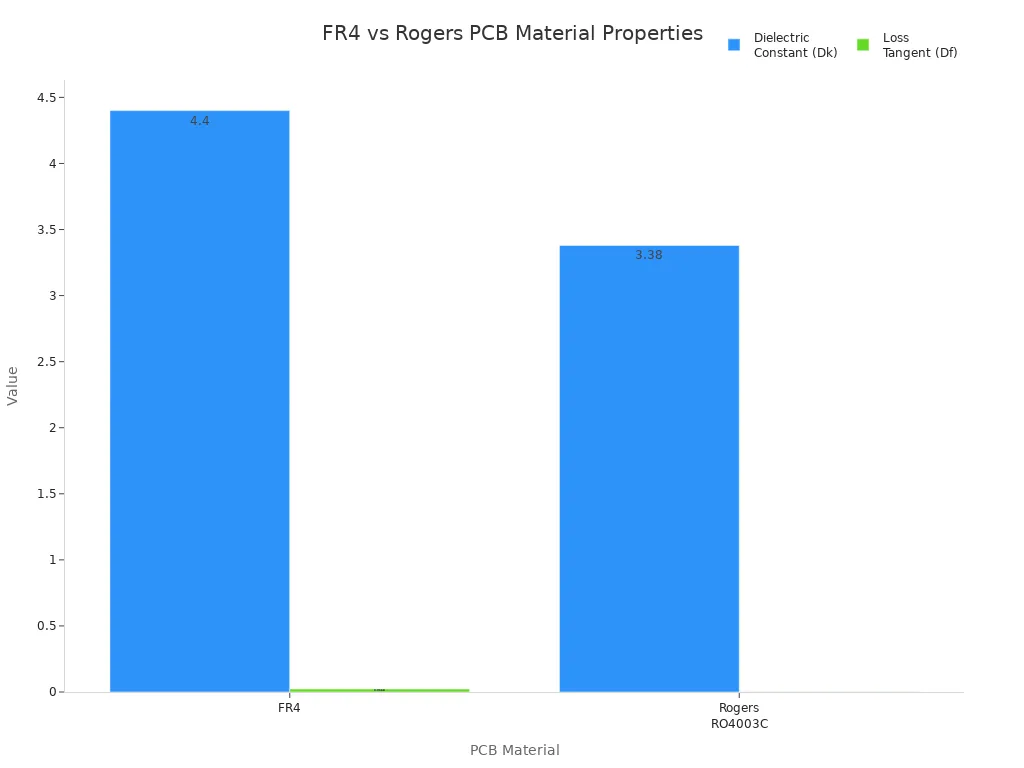

You want your RF and microwave designs to perform at their best. Rogers PCB materials help you achieve this by offering properties that standard FR4 cannot match. FR4 often struggles with high-frequency signals because its dielectric constant changes with temperature and frequency. Rogers materials, such as RO4003C, keep their dielectric constant stable even above 10 GHz. This stability means your signals stay clear and accurate.

Property | FR4 | Rogers RO4003C |

|---|---|---|

Dielectric Constant (Dk) | ~4.4 (variable) | 3.38 (stable) |

Loss Tangent (Df) | 0.020–0.025 | 0.0027 |

Rogers substrates also handle heat better than FR4. You get effective heat dissipation, which protects your components in high-power circuits. In high-speed applications, Rogers laminates manage heat more efficiently, while FR4 can overheat.

Key Properties for RF/Microwave

When you choose Rogers materials for your multilayer rogers pcb, you gain several advantages:

Property | Description |

|---|---|

Minimizes power loss during signal transmission, crucial for maintaining signal integrity in high-frequency applications. | |

Stable Dielectric Constant | Ensures consistent impedance control, preventing signal distortion and timing errors. |

Thermal Stability | Resists temperature fluctuations, suitable for environments with high thermal cycling. |

Mechanical Strength | Provides robustness against environmental factors, ensuring long-term reliability. |

Low Moisture Absorption | Maintains stable electrical characteristics in humid conditions, critical for outdoor applications. |

Dimensional Stability | Preserves size and shape under varying conditions, essential for precise signal transmission. |

You benefit from consistent dielectric constant, low signal loss, and reliable performance across a wide temperature range. LT CIRCUIT uses high-quality Rogers materials in their PCB solutions, so your designs stay robust and precise.

Advantages of Multilayer Rogers PCB

Electrical Performance

You gain significant electrical performance benefits when you choose a multilayer rogers pcb for your RF and microwave projects. Multiple layers allow you to design more complex circuits in a smaller area. You can dedicate layers to ground and power, which reduces noise and interference. This structure improves signal integrity and provides better electromagnetic and radio-frequency interference shielding. You also achieve higher circuit density and increased functionality, which is essential for advanced electronic devices.

Advantage | Description |

|---|---|

Higher circuit density | Multiple layers allow for more complex circuit designs in a smaller area. |

Improved signal integrity | Dedicated ground and power planes reduce noise and interference. |

Better EMI/RFI shielding | Multiple layers provide better electromagnetic and radio-frequency interference protection. |

Increased functionality | Suitable for complex, high-performance electronic devices. |

Reduced board size | More compact designs possible due to higher component density. |

Enhanced reliability | Better thermal management and reduced signal crosstalk. |

You also benefit from miniaturization. Multilayer rogers pcb technology supports more components and connections per unit area, which helps you build smaller and lighter devices. This is important for modern wireless communication systems and portable electronics.

Signal Loss and Stability

You want your signals to stay strong and clear, especially at high frequencies. Multilayer rogers pcb materials help you achieve this by minimizing signal loss. Rogers materials have a low dielectric loss and a stable dielectric constant across a wide frequency range. This means your signals experience less degradation, even in demanding RF and microwave environments.

Rogers PCB materials are known for their low dielectric loss, which is crucial for minimizing signal loss in RF and microwave circuits.

They maintain a stable dielectric constant across a wide frequency range, ensuring consistent performance.

The low loss tangent of Rogers materials contributes to reduced signal degradation in high-frequency applications.

The stable dielectric constant (Dk) of Rogers materials ranges from 3.48 to 3.55, which is essential for maintaining signal integrity.

A low dissipation factor (Df) as low as 0.0027 minimizes signal loss and enhances power handling in RF filters.

Feature | Description |

|---|---|

Superior Dielectric Properties | Rogers PCBs have a steady dielectric constant, crucial for maintaining signal integrity at high frequencies. |

Minimal Dielectric Losses | This characteristic reduces signal attenuation, ensuring better performance in high-frequency applications. |

Stable Dielectric Properties | Essential for RF, microwave, and millimeter-wave applications, allowing devices to function effectively at higher frequencies. |

You see these benefits in real-world applications. For example, LT CIRCUIT’s multilayer rogers pcb solutions power 5G base station antennas, military radar, and automotive radar systems. These applications require stable, low-loss signal transmission to function reliably.

Thermal Reliability

Thermal management is critical in RF and microwave designs. Multilayer rogers pcb materials provide excellent thermal conductivity, which helps you manage heat in high-power circuits. Rogers laminates offer thermal conductivity values between 0.6 and 0.8 W/mK, enabling efficient heat dissipation. Low moisture absorption rates, as low as 0.1%, help maintain electrical performance in humid environments. Dimensional stability, due to a low coefficient of thermal expansion, ensures your PCB remains reliable across temperature changes.

Metric | Description |

|---|---|

Thermal Conductivity | Rogers laminates provide thermal conductivity of 0.6-0.8 W/mK, enabling efficient heat dissipation. |

Moisture Absorption | Moisture absorption rates as low as 0.1% maintain electrical performance in humid environments. |

Dimensional Stability | Low coefficient of thermal expansion (CTE) ensures stability across temperature ranges. |

Multilayer rogers pcb materials have low thermal expansion coefficients.

They exhibit excellent thermal stability, making them effective in extreme temperature cycling.

Compared to FR4, Rogers materials have lower signal loss and superior thermal management.

You can trust these materials to perform under harsh conditions, such as rapid temperature changes or high humidity. This reliability is why industries like aerospace and automotive rely on LT CIRCUIT’s multilayer rogers pcb solutions.

LT CIRCUIT Solutions

LT CIRCUIT uses advanced Rogers materials, including the TMM series, to deliver high-performance multilayer rogers pcb products. These materials offer unique features for demanding applications:

Material | Description | Key Features |

|---|---|---|

TMM 3 | Thermally-conductive laminate suitable for high-frequency applications. | High thermal conductivity, low dielectric constant, humidity resistant. |

TMM 4 | Similar to TMM 3 with slight variations in dielectric properties. | Cost-effective, reliable for multilayer PCBs. |

TMM 6 | Offers enhanced thermal and dielectric properties. | Ideal for high-speed communication and extreme environments. |

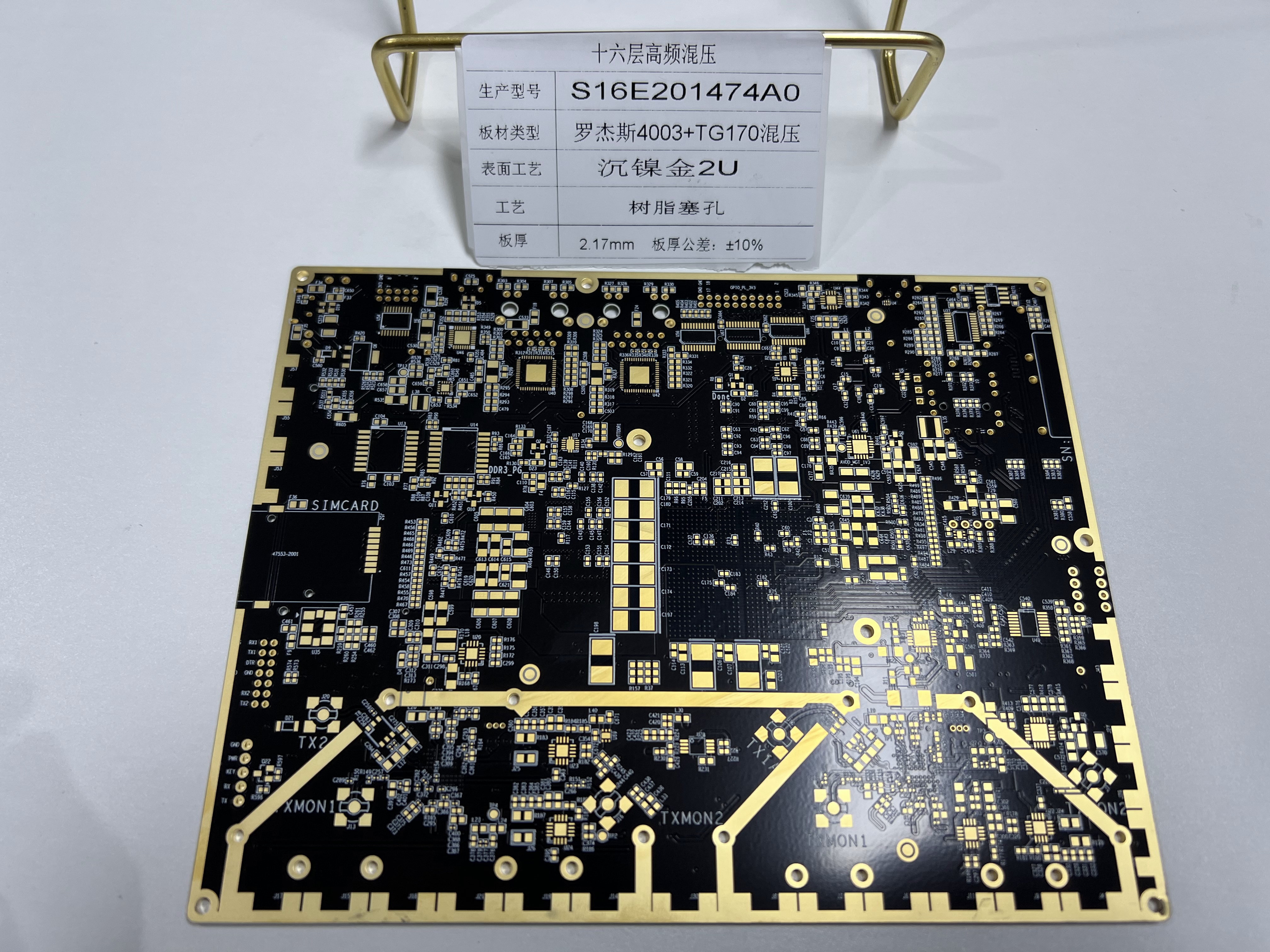

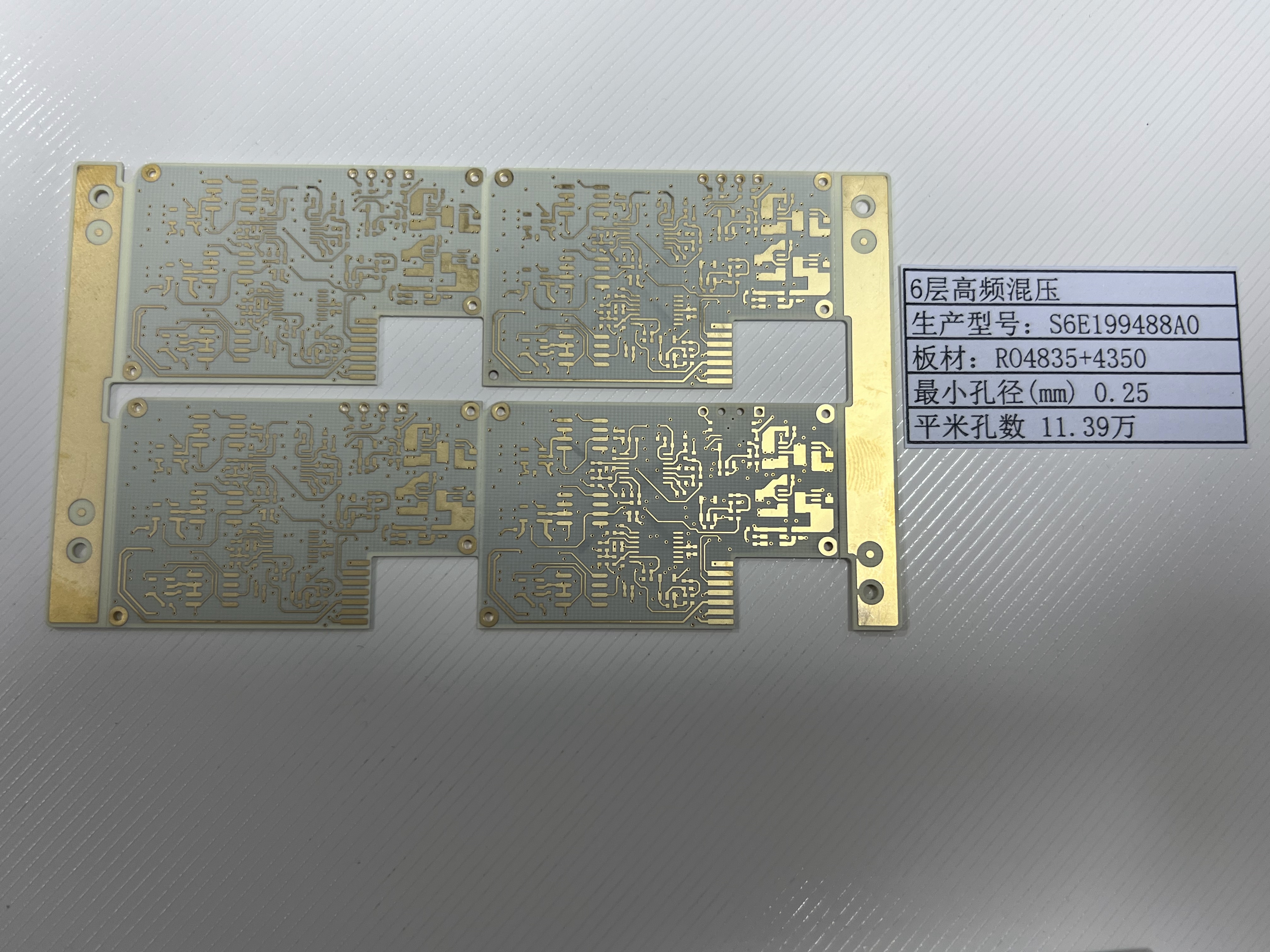

You find LT CIRCUIT’s multilayer rogers pcb solutions in telecommunications, aerospace, and automotive industries. For example, 5G macro base station antennas use Rogers R4350B, while military radar and satellite transceivers rely on Rogers R5880. Automotive radar systems in vehicles like the Tesla Model 3 use Rogers R4003 for reliable, high-frequency performance.

LT CIRCUIT ensures quality and reliability through advanced manufacturing methods. Every board undergoes Automated Optical Inspection (AOI) and X-ray testing. Heat tests confirm durability for high-speed applications. The company follows strict quality rules, including ISO 9001 standards, to guarantee consistent results.

Design Considerations for Engineers

When you design with multilayer rogers pcb technology, you should keep several factors in mind:

Define Application Requirements: Identify your operating frequency, power needs, and environmental conditions.

Consider Signal Integrity: Select materials with low and stable dielectric constant and low dissipation factor.

Evaluate Thermal Management Needs: Choose materials with good thermal conductivity and high glass transition temperature.

Balance Performance and Cost: Use higher-performance materials where necessary.

Assess Manufacturability: Ensure compatibility with standard PCB processes.

Factor in Long-Term Reliability: Prioritize materials with low moisture absorption and high resistance to thermal cycling.

Stay Compliant with Regulations: Confirm that your materials meet industry standards.

Tip: Maintaining consistent impedance and proper trace lengths helps you avoid signal degradation and crosstalk in high-frequency designs.

You can rely on LT CIRCUIT’s expertise to guide you through these design choices, ensuring your multilayer rogers pcb meets the highest standards for RF and microwave performance.

You see why engineers choose multilayer rogers pcb for RF and microwave projects.

Attribute | Description |

|---|---|

Prevents detrimental dielectric loss, ensuring proper electrical design. | |

Minimal Moisture Absorption | Reduces insulation degradation and dimensional change in high humidity conditions. |

Low Thermal Expansion | Maintains stability through temperature variations, preventing material weakening. |

Enhanced Impedance Control | Facilitates signal performance and integrity in complex PCB designs. |

Reliable Resistance to Various Chemicals | Ensures compatibility and durability against aggressive chemicals. |

LT CIRCUIT stands out as a trusted provider because:

Rogers PCB fabrication ensures superior signal integrity and reliability.

Expert support helps you select the right materials and optimize your design.

Certifications and advanced testing guarantee quality for every project.

Choose LT CIRCUIT for reliable, high-performance PCB solutions that meet your toughest RF and microwave needs.

FAQ

What makes Rogers PCBs better for RF and microwave designs?

You get stable dielectric properties, low signal loss, and strong thermal reliability. Rogers PCBs help your high-frequency circuits perform with greater accuracy and consistency.

Tip: Rogers materials keep your signals clear, even at very high frequencies.

Can you use multilayer Rogers PCBs in outdoor or harsh environments?

You can rely on multilayer Rogers PCBs in tough conditions. They resist moisture, temperature changes, and chemicals, making them ideal for outdoor and industrial use.

Feature | Benefit |

|---|---|

Moisture Resistant | Reliable outdoors |

Chemically Stable | Durable in harsh areas |

How does LT CIRCUIT ensure quality in Rogers PCB manufacturing?

You benefit from strict testing, including AOI and X-ray inspections. LT CIRCUIT follows ISO 9001 standards to guarantee consistent, high-quality PCBs for your projects.

See Also

Exploring Rogers R4350B, R4003, and R5880 for RFPCB Use

Diverse Industry Applications of Multilayer PCBs

A Comprehensive Guide to PCB Types: Single, Double, and Multilayer

Integrating Rogers Materials with TG170 for Hybrid PCB Solutions

Design and Manufacturing Insights for High Frequency PCBs in RF