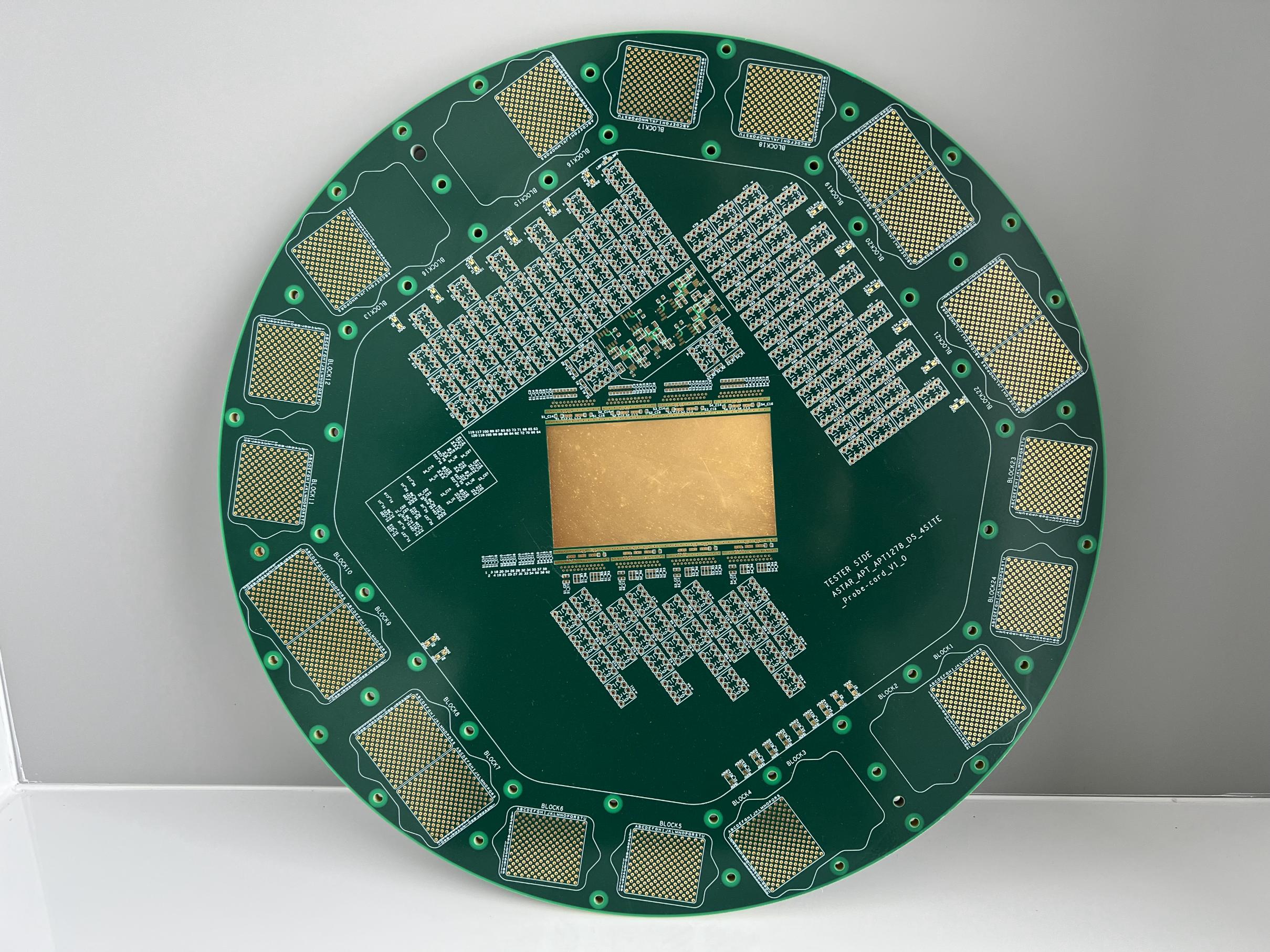

What Kind of PCB Fits ATE Challenges?

Automated test machines require specific circuit boards that are precise and reliable. When considering what kind of PCB is required for the Automated Test Equipment (ATE), challenges include keeping signals clear, managing heat, and ensuring fast operation. Reports indicate more issues such as fitting different designs, testing new packages, and adhering to quality regulations. LT CIRCUIT addresses these challenges with innovative designs and superior materials, providing solutions to keep everything running smoothly.

Key Takeaways

Clear signals are key for accurate tests in test machines. Use good materials and designs to reduce problems like crosstalk and EMI.

Fast testing needs special PCBs to keep signals strong. Use modular designs and advanced methods to make them reliable.

Good heat control helps PCBs last longer. Use heat sinks and thermal materials to manage heat well.

Signal Integrity in Automated Test Equipment

Why Signal Integrity Matters in ATE

Signal clarity is very important for automated test machines. If signals are unclear, test results can be wrong. This can lead to expensive mistakes. Clear signals help tests stay accurate and repeatable.

Many things can mess up signal clarity, like crosstalk, attenuation, and EMI. Crosstalk happens when signals mix with nearby ones. Attenuation makes signals weaker as they move through circuits. EMI adds noise that can change the signal. These problems hurt circuit board performance, especially in fast systems.

Here are examples of signal clarity problems:

Problem Type | How It Affects Signals |

|---|---|

Shows why good test setups are needed to check signal clarity. | |

Adding signal problems for Bit Error Rate (BER) tests | Explains how channel issues affect standards like 802.3bj and OIF CEI 25G LR. |

Time simulation with measured S-parameters | Shows how single bits react to signal clarity problems. |

Crosstalk in communication systems | Shows how mixed signals hurt overall system performance. |

Good switching systems also help keep signals clear. They stop voltage drops and keep signals strong. Automatic switches reduce mistakes and make tests better. Modular testing setups improve signal clarity by reducing signal loss.

LT CIRCUIT’s Approach to Signal Integrity Solutions

LT CIRCUIT knows how important clear signals are for test machines. We pick special materials to improve signal clarity. These materials handle heat well and reduce signal loss at high speeds.

We design boards to keep analog and digital parts apart. This stops noise from mixing signals. We also use power and ground layers to block EMI and keep circuits stable.

Our team plans layouts to avoid crosstalk and signal weakening. We use tools to predict problems before making the boards. This helps ensure the boards work well in tough conditions.

With LT CIRCUIT, your test machines will work with great accuracy. Our smart designs and quality materials make testing reliable and efficient. You can trust us to help you succeed.

High-Speed Testing and PCB Design

Challenges in High-Speed Testing for ATE

Testing fast systems brings tough problems needing careful solutions. As data moves faster, keeping it accurate gets harder. Problems like weak signals, timing mistakes, and EMI can mess up tests. These issues make testing systems less reliable.

Some key factors show how tricky fast testing is. For example, how much your processor and memory work affects data speed. System throughput shows how well your setup handles tasks. Jitter and latency measure how steady and quick your system is. The table below explains these important points:

Metric | Description |

|---|---|

Checks how fast data is processed and stored under limits. | |

System Throughput | Shows how well the system handles tasks and control sharing. |

Real Time Jitter | Measures uneven data timing to check system stability. |

Latency | Tracks the time between sending and receiving messages. |

Round Trip Time | Measures how long it takes for a message to be sent and confirmed. |

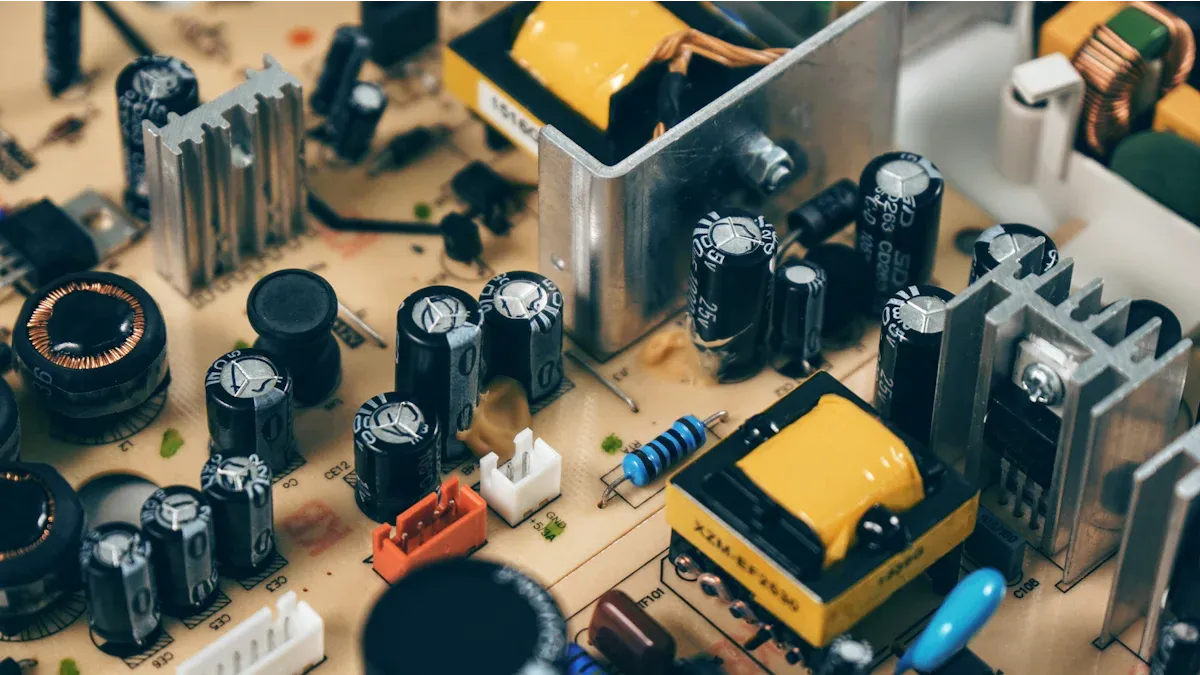

To fix these problems, advanced testing methods are needed. Automated optical inspection finds surface flaws early. In-circuit testing checks parts inside the board. Functional testing makes sure the board works in different situations. Stress tests check how strong the board is. These methods help meet industry rules and give steady results.

What Kind of PCB is Required for High-Speed Automated Test Equipment?

For fast test machines, you need a PCB that works quickly and stays reliable. Special designs keep signals clear at high speeds. For example, ADI’s 34 GHz MEMS switch helps with both fast and slow tests. It keeps signals moving smoothly through the switch.

A loopback test setup is also important. It checks input and output paths using both fast and slow signals. This keeps tests accurate even at high speeds. Using better materials in the PCB reduces signal loss and blocks EMI, which is key for fast systems.

Testing methods are crucial for checking these designs. Automated optical inspection spots surface problems. In-circuit testing finds issues in parts. Functional testing ensures the board does its job. Stress tests check how well it holds up under pressure. These steps make sure the PCB works for fast test machines.

To get the best results, focus on designs that are easy to test. Modular layouts make testing simpler and reduce signal problems. By using these ideas, your PCB can handle fast testing while staying accurate and dependable.

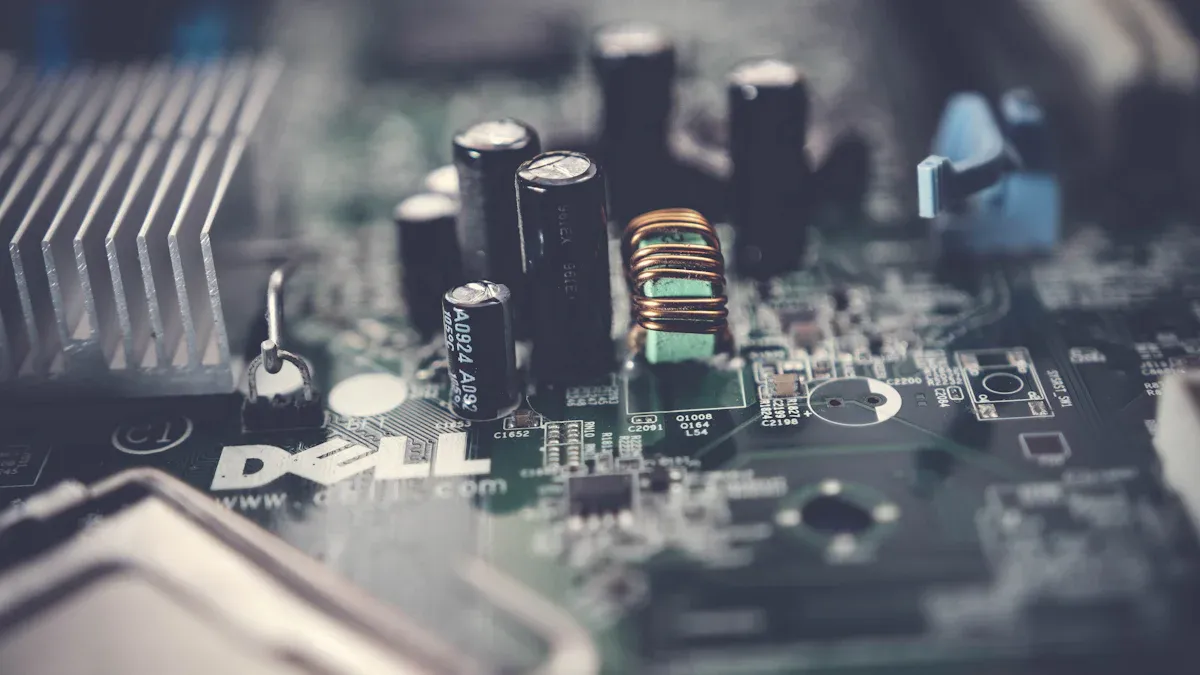

Thermal Management in ATE PCBs

Solving Heat Problems

Controlling heat in test machines is very important. Too much heat can harm parts, lower performance, and shorten PCB life. Engineers use smart ways to handle heat better.

Here are some helpful methods:

Ultrasonic guided waves: These waves find hot spots on PCBs.

Machine learning: Smart programs spot and study hot areas.

Thermal interface materials (TIM): These improve heat flow between parts and heat sinks.

Heat sinks: Metal pieces like aluminum or copper remove heat faster.

Heat pipes: These pipes move heat using liquid changes.

Thermoelectric modules: These use special effects to control heat.

Thermally conductive adhesives: These glue parts together and help with heat flow.

Using these methods keeps PCBs cool and safe, even when working hard.

LT CIRCUIT’s Heat Control Solutions

LT CIRCUIT gives advanced ways to manage heat for test machines. Our designs focus on keeping temperatures steady and removing heat well. Tests show how good our solutions are:

Heat Control Method | Hot End Temp (°C) | Power (W) | Features |

|---|---|---|---|

Custom AHP | 4 | 3D cooling, great temperature balance | |

Regular Flat Micro Heat Pipe | >100 | 4 | 2D cooling, uneven temperature |

Flexible Graphene Film | 84.7 | 4 | Single-phase cooling, big temperature changes |

Our custom AHP tech cools better and keeps temperatures steady. This helps PCBs handle high power without overheating. With LT CIRCUIT, you get top heat control solutions for reliable and strong test systems.

PCBs for test machines must fix problems like unclear signals, speed, and heat. They need to work well and not cost too much.

LT CIRCUIT uses better materials and clever designs to solve these issues. Our ideas make systems stronger and easier to upgrade for future needs.

FAQ

What is PCB testing, and why does it matter?

PCB testing checks if circuit boards work without problems. It finds defects and ensures they meet industry rules. This makes them reliable and safe to use.

How does LT CIRCUIT make PCB manufacturing better?

LT CIRCUIT uses special materials and accurate methods to improve production. This creates strong PCBs that work well with modern electronics.

What are advanced ways to test PCBs?

Advanced tests include automated inspections, in-circuit checks, and function tests. These steps make sure PCBs perform well and meet quality standards.

See Also

Explore Cutting-Edge HDI PCB Prototyping Methods Right Now

Frequent Issues and Fixes in PCB Design for SMT Needs

Understanding The Materials Used In Printed Circuit Boards