What Are PCB Printed Circuit Boards and Their Core Concepts

A PCB printed circuit board is key to modern electronics. It connects electronic parts using conductive paths, helping devices work smoothly. PCB printed circuit boards organize circuits well, making them simpler and more reliable.

PCB printed circuit boards are very important. Many industries, like cars and gadgets, depend on them. For example, the PCB printed circuit board market might grow from $84.24 billion in 2025 to $106.85 billion by 2030. Electric car sales also grew a lot, from 206,000 in 2013 to over 10 million in 2022. PCB printed circuit boards are used in healthcare, space, and factories, helping new technology improve everywhere.

Key Takeaways

PCBs are important for electronics, linking parts to make them work.

They have types, like Class 1 for simple devices and Class 3 for important ones like medical tools.

PCBs are built in layers, with a base for strength and copper for electric paths, making them small and strong.

Parts on PCBs include resistors, capacitors, and circuits, each helping the device work well.

Picking good materials, like FR-4 for heat protection, is key for making PCBs reliable.

What Is a PCB Printed Circuit Board?

Definition and Purpose

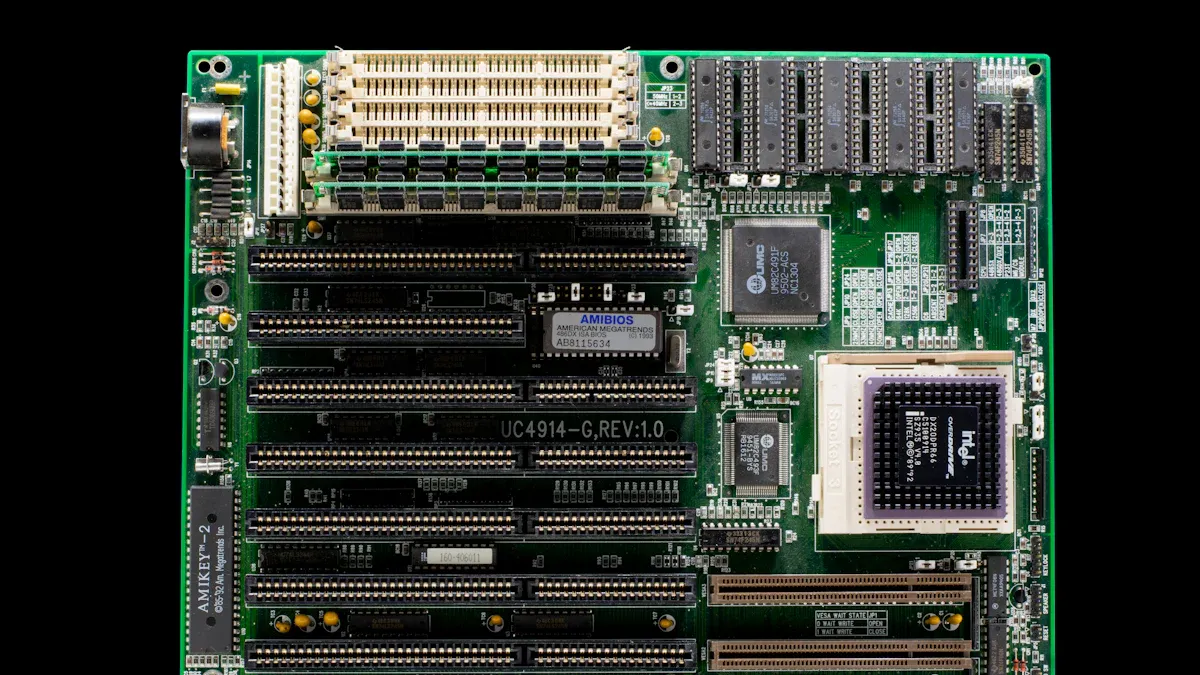

A printed circuit board (PCB) is the base of modern electronics. It is flat and made of layers with insulating and conductive materials. The conductive parts, usually copper, let electricity move between components. These paths, called traces, replace old-style wiring, making PCBs smaller and better.

PCBs connect parts like resistors, capacitors, and semiconductors. They are crucial for making electronics work correctly. You can find PCBs in almost all devices, like phones and factory machines. Their design makes building, fixing, and producing them cheaper and easier than older methods.

PCBs are grouped into three types based on use and reliability:

Class 1: Used in simple devices like toys and basic gadgets.

Class 2: Found in industrial tools and high-quality consumer products.

Class 3: Made for critical uses like medical tools and space systems.

Key Features of a Printed Circuit Board

PCBs are special because of their design and purpose. They act as the frame for electronics, giving support and connecting parts. Unlike older boards with wires, PCBs use copper traces for a neat and tidy setup.

Here are some features that make PCBs important:

Compact Design: PCBs fit many parts on one small board.

Durability: Strong materials like fiberglass handle heat and stress well.

Versatility: Rigid, flexible, and mixed designs suit many different uses.

Cost-Effectiveness: Making PCBs in large amounts lowers costs for companies.

PCBs come in two types: bare boards and assemblies. A bare PCB is just the structure. A printed circuit board assembly (PCBA) has all the parts, ready to work. This shows how PCBs can meet many tech needs.

Structure and Materials of a Printed Circuit Board

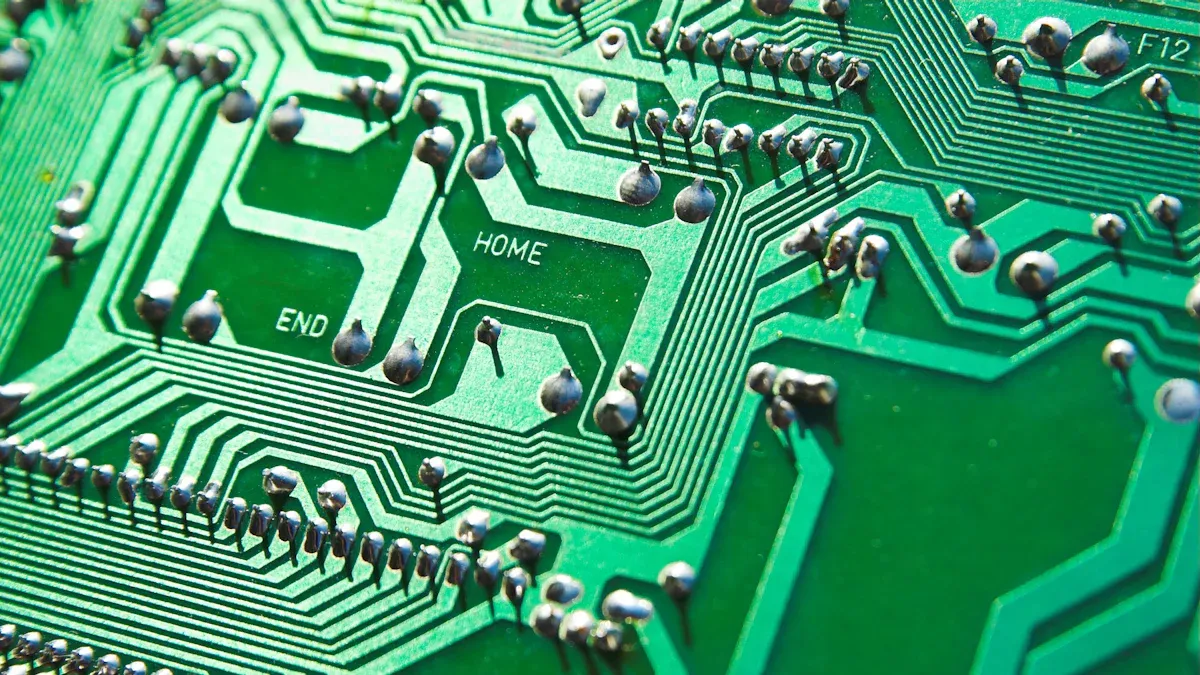

Layers of a PCB

A printed circuit board (PCB) is made with stacked layers. Each layer has a job to help the board work. Most PCBs are multilayered, with 2 to over 50 layers. The number of layers depends on how complex the device is.

Here’s what the layers do:

Substrate: This bottom layer is usually FR-4 fiberglass. It gives the board strength and thickness.

Copper Layer: A thin copper sheet is added to the substrate. It creates paths, called traces, for electrical signals.

Solder Mask: This layer covers the copper to insulate it. It stops short circuits from happening.

Silkscreen: The top layer has printed labels and symbols. These help identify parts and connections.

Advanced PCBs may have extra layers for power, grounding, or signals. Insulating materials separate these layers. Small holes, called vias, connect them.

Materials Used in PCB Construction

The materials in a PCB affect its strength, cost, and performance. FR-4 is the most common material for regular PCBs. It’s fiberglass mixed with epoxy resin, making it strong and heat-resistant. Flexible PCBs use polyimide, which bends without breaking.

Here’s a table of PCB materials:

Classification Standard | Material |

|---|---|

Reinforcing Material | FR-4 fiberglass, polyimide, composite epoxy material (CEM), paper-based |

Flammability | Flame-proof (UL94-VO, UL94-V1), Non-flameproof (UL-94-HB) |

CCL Performance | High heat resistance, low dielectric constant, low thermal expansion |

The material choice depends on the PCB’s use. High-frequency PCBs need special materials for fast signals. Metal-core PCBs are better for handling heat. Picking the right material ensures the PCB works well for its purpose.

Components of a PCB

Common Components on a PCB

A printed circuit board (PCB) has many parts that work together. These parts are placed carefully to make the board reliable. Below are some common components found on a PCB:

Resistors: Slow down the flow of electricity in the circuit.

Capacitors: Hold and release energy when the circuit needs it.

Diodes: Let electricity move one way but block it the other way.

Transistors: Work as switches or make signals stronger.

Integrated Circuits (ICs): Tiny circuits that handle tasks like data processing.

Inductors: Store energy in magnetic fields and clean up signals.

Connectors: Link the PCB to other devices or systems.

These parts are important for the PCB to work well. Copper traces connect them to keep the circuit running smoothly.

Roles of Each Component

Each part on a PCB has a job to help the device work. Knowing what they do shows how the PCB operates as a whole:

Resistors: Control electricity so parts get the right amount of power.

Capacitors: Keep voltage steady and remove unwanted noise.

Diodes: Stop electricity from going backward and damaging parts.

Transistors: Switch signals on and off or make them stronger.

Integrated Circuits: Act as the brain, doing tasks like storing data.

Inductors: Clean up signals by removing bad frequencies.

Connectors: Help the PCB connect to power or other devices.

For example, in phones, integrated circuits process data, while capacitors keep power steady. In factory machines, resistors and diodes protect circuits from power problems. All parts work together to make the PCB do its job.

💡 Tip: When building a PCB with many layers, place parts carefully. This helps signals move better and keeps the board cool.

Applications of PCB Printed Circuit Boards

Consumer Electronics

PCBs are important for the gadgets you use every day. Devices like phones, tablets, and laptops need PCBs to connect parts. These boards help them work well and stay small. For example, in cameras, PCBs handle image processing and storage. Wearable devices, like fitness bands and smartwatches, use PCBs to combine sensors and processors. This makes them light and effective.

The need for electronics boosts the PCB market. High-quality PCBs improve how gadgets work and last longer. TVs and monitors also use PCBs for advanced circuits, showing clear pictures. As technology grows, PCBs get better, helping make smaller and faster devices.

Industrial and Automotive Uses

In factories, PCBs help machines work faster and better. Companies like Toyo Electric use robots to build delicate PCBs. These boards are key for robots to do tasks correctly. PCBs are also used to make electrical parts for many purposes.

In cars, PCBs are vital for safety systems like ADAS. These systems connect sensors and processors for features like lane warnings. Hybrid and electric cars use strong PCBs to control energy. Car entertainment systems also depend on PCBs for better connectivity and fun.

Medical and Aerospace Applications

PCBs are crucial in healthcare and space industries. Custom PCBs power medical tools like heart monitors and scanners. In space, they keep navigation and communication systems working. Tests like heat and stress checks ensure they work in tough conditions.

Flexible PCBs are great for wearable health devices, offering comfort and use. In space, multilayer PCBs handle tricky circuits for big missions. These uses show how PCBs are reliable and useful in important fields.

How PCBs Help Devices Work

Electrical Connections and Signal Flow

A PCB printed circuit board is like a device's backbone. It creates paths, called traces, to connect parts and send signals. Without these paths, devices wouldn’t work properly. PCBs deliver power from the battery or power source to all parts. This ensures every component gets the energy it needs to function.

To keep signals clear, PCB designers focus on key points:

Layer stackup design: Organizes layers to keep signals strong and steady.

Impedance matching: Controls signal flow to avoid disruptions or delays.

Crosstalk reduction: Uses spacing and shielding to stop signal interference.

These methods help signals move correctly without errors. For example, in a smartphone, the PCB connects the processor, memory, and sensors. This ensures everything works together smoothly.

Connecting Software and Hardware

PCBs don’t just link parts; they also work with software and hardware. This teamwork helps devices handle complex tasks easily. For example, a computer’s PCB connects the CPU, RAM, and storage. It also works with the operating system to run programs.

Making a PCB involves several steps:

Schematic capture: Engineers draw a digital map of the circuit.

Layout: Parts are placed to balance function and easy production.

Routing: Traces are added to link parts for reliable connections.

Designers also think about heat and interference. Good heat control stops parts from overheating. Reducing electromagnetic interference (EMI) keeps devices running smoothly.

What It Does | Why It Matters | |

|---|---|---|

Signal Quality | Keeps signals clear and avoids errors. | Ensures data moves correctly without problems. |

Heat Control | Manages heat from working parts. | Stops overheating and makes devices last longer. |

Electromagnetic Interference (EMI) | Reduces unwanted signals that cause noise. | Keeps devices working without interruptions. |

By using these ideas, PCBs help devices work well, linking hardware and software perfectly.

PCB printed circuit boards are the base of today’s electronics. They use smart designs, key parts, and flexible uses to power devices. Their layers, made from materials like FR-4 and polyimide, make them strong and effective.

New PCB checks now reach almost 100% accuracy, improving quality.

Fast tools find thousands of parts in seconds, speeding up production.

Dielectric Constant at 1 MHz | Dissipation Factor | Thermal Conductivity (W/mK) | Flexural Strength (MPa) | Glass Transition Temperature (°C) | |

|---|---|---|---|---|---|

FR-4 | 4.5 | 0.02 | 0.3 | 400 - 800 | 130 - 180 |

Polyimide | 3.5 | 0.002 | 0.2 | 200 - 400 | 260 - 400 |

PTFE | 2.1 | 0.0002 | 0.25 | 10 - 20 | N/A |

PCBs keep improving, helping devices become smarter, quicker, and more dependable.

FAQ

What is the difference between a PCB and a PCBA?

A PCB is just the board without any parts. A PCBA has the board and all its components, ready to use.

How do you choose the right PCB material?

Pick materials based on what your device needs. Use FR-4 for heat resistance. Choose polyimide if flexibility is needed. Think about cost, heat handling, and signal quality.

💡 Tip: Match the material to where your device will be used.

Why are multilayer PCBs used in advanced devices?

Multilayer PCBs save space and work better. They allow more connections and smoother signals. This makes them great for complex devices like phones or medical tools.

Can PCBs be recycled?

Yes, PCBs can be recycled. Special methods recover metals like copper and gold. Recycling helps reduce waste and protects the environment.

What tools are used to design a PCB?

Engineers use programs like Eagle, Altium Designer, or KiCad. These tools help plan circuits, design layouts, and test ideas.

🛠️ Note: Beginners can try free tools like KiCad for simple projects.

See Also

Exploring Multilayer PCBs and Their Role in Electronics

Uncover Cutting-Edge HDI PCB Prototyping Methods Now