Production challenge posed by double-sided printed circuit boards longer than 1.8 meters

Manufacturers face a significant production challenge when working with double-sided printed circuit board designs that extend beyond 1.8 meters. Handling these lengthy pcb panels demands precision and care to prevent damage. Equipment constraints often limit the ability to maintain quality during each pcb process. LT CIRCUIT leverages advanced pcb manufacturing expertise to overcome these issues, ensuring every pcb meets strict quality standards.

Key Takeaways

Handling and transporting long PCBs needs special tools and trained staff to avoid damage like warping or bending.

Manufacturers must upgrade equipment and use precise alignment methods to maintain quality for PCBs longer than 1.8 meters.

Controlling temperature during soldering prevents defects and keeps the PCB strong and reliable.

Automated inspection systems help catch defects early, reducing costs and improving product quality.

Following a clear design flow and choosing the right materials supports durability and lowers manufacturing risks.

Production Challenge Overview

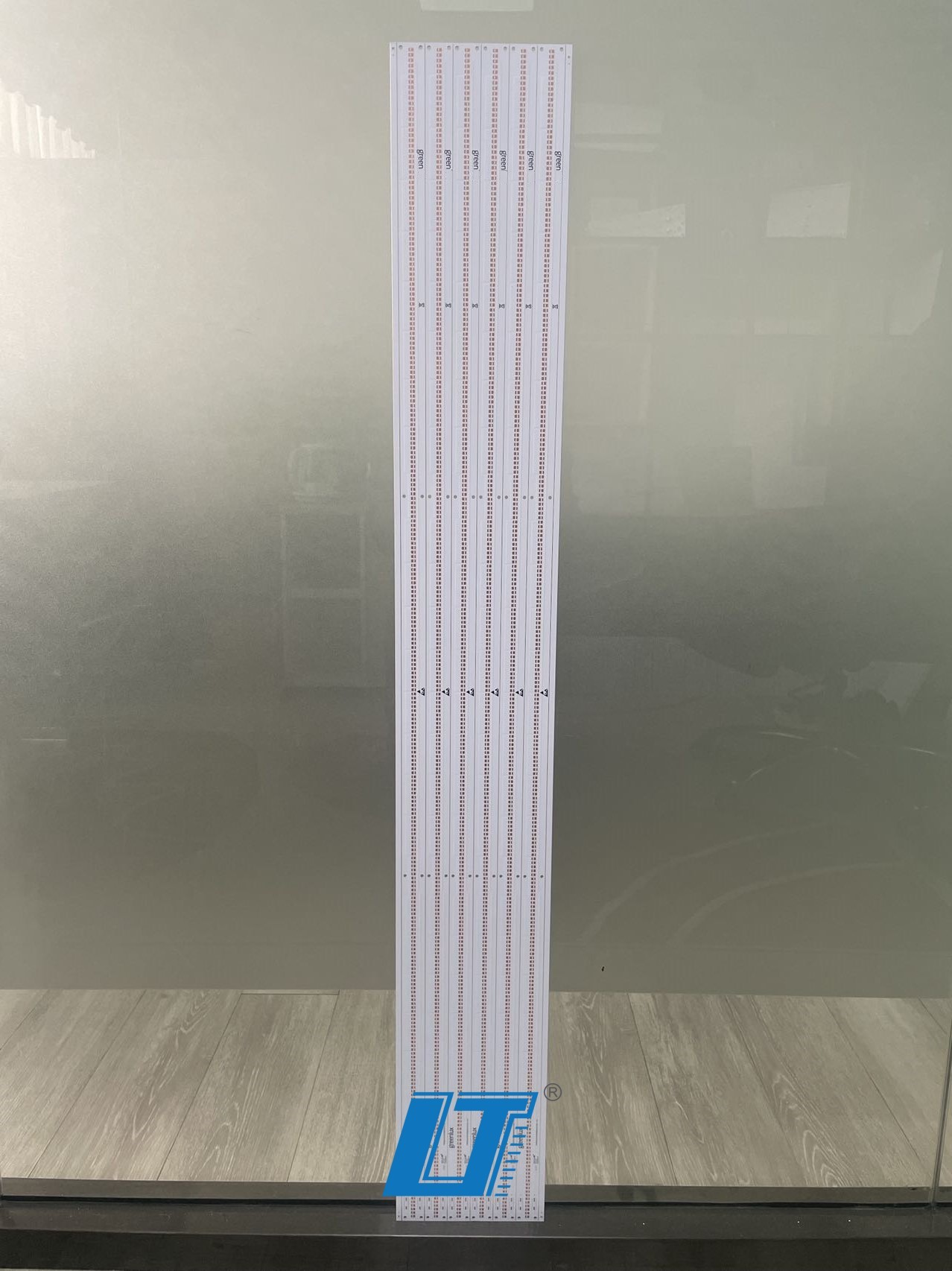

Long double-sided printed circuit boards present a unique production challenge for any manufacturer. LT CIRCUIT has extensive experience in this area. The company understands that the size and complexity of these pcb panels require special attention at every stage of the manufacturing process. The production challenge grows as the length of the pcb increases, especially beyond 1.8 meters. Each step, from initial fabrication to final inspection, demands careful planning and execution.

Handling and Transport

Handling and transporting a pcb longer than 1.8 meters introduces several risks. Workers must move these large panels with precision. Even a small mistake can cause damage. Warping and bending often occur if the panel does not receive proper support. LT CIRCUIT uses specialized equipment and trained staff to minimize these risks. The company employs custom carriers and lifting tools designed for long printed circuit board panels. These tools help distribute weight evenly and prevent stress on the pcb.

Tip: Always use dedicated carriers for long pcb panels to reduce the risk of mechanical damage during movement.

During transport within the facility, vibration and sudden movements can also threaten the structural integrity of the pcb. LT CIRCUIT addresses this production challenge by implementing strict handling protocols. Staff receive regular training on best practices for moving and storing large panels. The company also uses anti-static materials to protect sensitive circuits during transport.

Structural Integrity

Maintaining the structural integrity of a long double-sided pcb is a major production challenge. The length of the panel increases the risk of flexing, which can lead to micro-cracks or broken traces. These defects may not appear immediately but can cause failures later in the product’s life cycle. LT CIRCUIT uses advanced materials and precise manufacturing techniques to strengthen each printed circuit board.

The company selects high-quality base materials that resist bending and warping. Engineers design the pcb stack-up to provide extra rigidity. During manufacturing, LT CIRCUIT monitors temperature and humidity to prevent material deformation. The team also inspects each panel for signs of stress or damage before moving to the next stage.

Key risks to structural integrity:

Warping due to uneven support or temperature changes.

Bending from improper handling or storage.

Micro-cracks from repeated flexing or vibration.

LT CIRCUIT’s experience with long pcb panels allows the company to anticipate and address these risks early in the manufacturing process. By focusing on careful handling and robust design, LT CIRCUIT ensures that each printed circuit board meets the highest standards of quality and reliability.

Manufacturing Process Limits

Equipment Constraints

Manufacturers encounter significant equipment constraints when producing double-sided pcb panels longer than 1.8 meters. Standard pcb manufacturing machines often lack the capacity to handle such extended lengths. Many facilities must upgrade their technology to accommodate these larger pcb panels. LT CIRCUIT invests in advanced technology, including custom-built conveyors and oversized lamination presses. These machines support the entire pcb during each manufacturing step, reducing the risk of panel sagging or misalignment.

Operators monitor the pcb closely as it moves through the technology-driven process. Specialized clamps and fixtures hold the pcb securely in place. This approach prevents shifting and ensures consistent results. LT CIRCUIT’s commitment to technology innovation allows the company to maintain high standards in pcb manufacturing, even with challenging dimensions.

Note: Upgrading equipment is essential for reliable pcb production when working with panels longer than 1.8 meters.

Alignment Issues

Alignment presents another major challenge in the manufacturing of long double-sided pcb panels. Precise alignment is critical for both sides of the pcb to match perfectly. Even a small error can cause connectivity problems or reduce the effectiveness of the technology embedded in the pcb. LT CIRCUIT uses automated optical inspection systems to verify alignment at every stage of manufacturing.

Engineers rely on fiducial markers and registration holes to guide the technology during layer stacking and drilling. These features help maintain accuracy throughout the pcb manufacturing process. LT CIRCUIT’s technology-driven approach minimizes the risk of misalignment. The company also uses real-time monitoring systems to detect and correct any deviations immediately.

Common alignment solutions:

Automated optical inspection

Fiducial markers

Registration holes

Real-time monitoring

LT CIRCUIT’s expertise in pcb technology ensures that each panel meets strict alignment standards. The company’s advanced manufacturing methods deliver reliable performance for even the longest double-sided pcb designs.

Soldering and Assembly

Thermal Management

Thermal management plays a critical role in the assembly of double-sided pcb panels longer than 1.8 meters. These large pcb panels absorb and distribute heat differently compared to standard sizes. Engineers at LT CIRCUIT use advanced technology to monitor and control temperature during the soldering process. They select materials with high thermal conductivity to help spread heat evenly across the pcb. This approach prevents hot spots that can damage sensitive components.

The team uses infrared sensors and real-time monitoring systems to track temperature changes. These tools allow quick adjustments to the heating process. Proper thermal management ensures that the pcb maintains its structural integrity throughout assembly. LT CIRCUIT’s technology-driven solutions help avoid warping and delamination, which can occur if the pcb experiences uneven heating.

Tip: Consistent temperature control during assembly reduces the risk of defects and extends the lifespan of the pcb.

Uniform Soldering

Uniform soldering remains a challenge for long double-sided pcb panels. The length of the pcb increases the risk of uneven solder joints. LT CIRCUIT addresses this issue by using automated soldering technology. Machines apply solder paste with precise control, ensuring each joint receives the correct amount of material.

Engineers program the technology to adjust for variations in panel size and thickness. Automated inspection systems check every solder joint for quality and consistency. The team uses high-resolution cameras and advanced software to detect any irregularities. Uniform soldering improves the electrical performance of the pcb and reduces the chance of failure in the field.

Key steps for uniform soldering:

Automated solder paste application

Real-time inspection with advanced technology

Adjustment for panel size and thickness

LT CIRCUIT’s expertise in pcb technology ensures reliable assembly for even the most demanding projects. Their focus on precision and quality sets a high standard in the industry.

Quality Control by LT CIRCUIT

Inspection for Long Boards

LT CIRCUIT uses advanced technology to inspect every printed circuit board longer than 1.8 meters. The inspection team relies on automated optical systems that scan each pcb for defects. These systems use high-resolution cameras and specialized software to detect surface flaws, misalignments, and irregularities. Engineers review the data and make quick decisions to maintain quality. The company also uses flying probe tests and E-tests to check for electrical continuity and shorts. These tests help confirm that the pcb meets strict quality standards.

LT CIRCUIT’s inspection process combines technology and expertise to deliver reliable results. The team documents every step to ensure traceability and accountability.

A table summarizes the main inspection steps:

Inspection Step | Technology Used | Quality Focus |

|---|---|---|

Optical Scanning | High-res Cameras | Surface Defects |

Flying Probe Test | Automated Probes | Electrical Paths |

E-Test | Specialized Equipment | Circuit Integrity |

Manual Review | Expert Engineers | Final Quality |

Electrical Integrity

LT CIRCUIT places a strong emphasis on electrical integrity for long pcb panels. The company uses advanced technology to test each printed circuit board for signal reliability and performance. Engineers measure resistance, capacitance, and insulation levels at multiple points. Automated systems run stress tests to simulate real-world conditions. These tests help identify weak spots and ensure consistent quality.

Quality assurance teams analyze the results and compare them to industry benchmarks. If a pcb does not meet the required standards, the team investigates and resolves the issue. LT CIRCUIT’s commitment to technology and quality ensures that every pcb delivers dependable performance in demanding applications.

Key factors for electrical integrity:

Accurate resistance measurements

Consistent insulation checks

Real-world stress testing

Detailed quality analysis

Quality control at LT CIRCUIT relies on technology-driven solutions and expert oversight. The company’s process guarantees that each printed circuit board meets the highest standards for reliability and quality.

Cost, Yield, and Lead Time

Defect Risks

Manufacturers face significant defect risks when producing double-sided printed circuit boards longer than 1.8 meters. The extended length increases the chance of warping, misalignment, and soldering issues. Each defect can impact the overall quality of the finished product. LT CIRCUIT prioritizes quality at every stage of manufacturing. The team uses advanced inspection systems to catch defects early. This approach helps reduce manufacturing costs by preventing rework and scrap.

Defects can lead to higher cost for both materials and labor. When a defect appears, the team must spend extra time and resources to fix the issue. This process increases manufacturing costs and can affect the final cost for customers. LT CIRCUIT invests in quality control to keep defect rates low. The company tracks defect trends and adjusts manufacturing processes to improve yield. High yield means fewer defects and lower manufacturing costs.

Quality control plays a key role in managing defect risks and keeping manufacturing costs under control.

Production Delays

Production delays often result from defect risks and equipment limitations. When a defect is found, the team must stop production to address the problem. This pause increases manufacturing costs and can extend lead time. LT CIRCUIT works to minimize delays by streamlining manufacturing steps and using automated systems. The company schedules regular maintenance for equipment to avoid unexpected breakdowns.

Delays can also raise the cost of manufacturing. Longer lead times may require expedited shipping or overtime labor, which adds to the total manufacturing costs. LT CIRCUIT monitors production schedules closely to ensure on-time delivery. The team communicates with customers about lead times and cost expectations. By focusing on quality and efficient manufacturing, LT CIRCUIT keeps production delays to a minimum.

A table summarizes the impact of defect risks and production delays on manufacturing costs and quality:

Factor | Impact on Cost | Impact on Quality |

|---|---|---|

Defect Risks | Increased | Reduced |

Production Delays | Increased | Potentially Reduced |

Quality Control | Reduced | Improved |

Efficient manufacturing and strict quality standards help LT CIRCUIT control cost, improve yield, and deliver reliable products.

LT CIRCUIT Solutions

Design Best Practices

LT CIRCUIT recommends a structured design flow for long double-sided printed circuit boards. Engineers start by evaluating the application and selecting materials that match the project’s requirements. They use FR-4, a composite epoxy resin reinforced with fiberglass, for durability and stability. The design flow includes careful planning of copper weight and PCB thickness to support the board’s length and prevent warping. Teams choose silkscreen and solder resist colors to improve visibility and assembly accuracy.

A well-defined design flow helps reduce manufacturing costs and improves reliability. LT CIRCUIT’s experts advise using registration holes and fiducial markers for precise alignment. They also suggest dividing the design flow into clear stages, such as schematic capture, layout, and review. This approach ensures that every step receives proper attention and that technology supports each phase.

Tip: Early consultation with LT CIRCUIT’s technical support team can optimize material selection and streamline the design flow.

Customization Aspect | Details |

|---|---|

Raw Material | FR-4 (composite epoxy resin reinforced with fiberglass) |

Surface Finishes | HASL, ENIG, Immersion Tin, Immersion Silver, Gold Finger, OSP |

Copper Weight | 1 to 6 oz |

PCB Thickness | 1.6 mm (standard) |

Silkscreen Colors | White, Black, Yellow |

Solder Resist Colors | Green, Blue, Yellow |

Maximum PCB Length | Up to 1.5 meters (supports long double-sided PCBs) |

Quality Assurance | 100% Electrical Test (E-test) |

Technical Support | Expert consultation available for material selection |

Advanced Manufacturing Techniques

LT CIRCUIT uses advanced manufacturing technologies to produce long double-sided PCB panels. Automated optical inspection systems check alignment and surface quality at every stage. Infrared sensors and real-time monitoring technology control temperature during soldering. These steps help lower manufacturing costs and prevent defects.

Engineers rely on oversized lamination presses and custom-built conveyors to support the entire PCB during processing. This technology reduces the risk of sagging and misalignment. The design flow includes automated solder paste application and high-resolution cameras for inspection. These advanced manufacturing technologies ensure consistent quality and help manage manufacturing costs.

LT CIRCUIT’s technology-driven approach supports efficient production and reliable performance. The company’s design flow and advanced manufacturing technologies work together to deliver high-quality printed circuit boards while controlling manufacturing costs.

Manufacturers face unique production challenges with double-sided printed circuit boards longer than 1.8 meters. LT CIRCUIT addresses these issues by focusing on quality at every stage. The team uses advanced inspection systems to maintain quality and prevent defects. Engineers select materials that support quality and durability. Staff follow strict protocols to ensure quality during handling and assembly. Automated systems help achieve consistent quality in soldering and alignment. Quality assurance teams monitor each process to guarantee quality in the final product.

LT CIRCUIT’s commitment to quality drives innovation and sets industry standards.

Actionable steps for manufacturers:

Invest in equipment that supports quality for long panels.

Train staff to maintain quality during handling and transport.

Use automated inspection to verify quality at each stage.

Select materials that enhance quality and reliability.

Industry experts expect future trends to focus on smarter automation and new materials that improve quality for large printed circuit boards.

FAQ

What is the maximum length LT CIRCUIT can manufacture for double-sided PCBs?

LT CIRCUIT can produce double-sided printed circuit boards up to 1.8 meters in length. The company uses specialized equipment and advanced processes to ensure quality and reliability for these extended panels.

How does LT CIRCUIT prevent warping in long PCBs?

Engineers at LT CIRCUIT select high-quality base materials and use precise lamination techniques. They monitor temperature and humidity during production. These steps help maintain flatness and prevent warping throughout the manufacturing process.

What inspection methods does LT CIRCUIT use for long PCBs?

LT CIRCUIT uses automated optical inspection, flying probe tests, and E-tests. Engineers also perform manual reviews. These methods ensure each board meets strict quality standards.

Can LT CIRCUIT customize materials and finishes for large PCBs?

Yes. LT CIRCUIT offers a range of materials, copper weights, and surface finishes. Customers can choose options like ENIG, HASL, or immersion silver to match their project requirements.

What are the key tips for handling long double-sided PCBs?

Use dedicated carriers for support

Train staff on proper handling

Store panels flat

Avoid sudden movements

These practices help prevent damage and maintain board integrity.

See Also

Overcoming Production Issues With High Tg FR4 PCBs In Industry

Navigating Production And Prototype Challenges Of Multi-Layer Boards

Comprehensive Guide To Manufacturing Heavy Copper Multilayer PCBs

Choosing The Right PCB To Meet Automated Test Equipment Needs

Typical PCB Design Issues And Fixes For SMT Processing Standards