How Quick Turn HDI PCBs Can Save Your Project Costs in 2025

Quick turn HDI PCB Board quick turn solutions are revolutionizing project development. These specialized circuit boards utilize high-density interconnect (HDI) technology and rapid production techniques. They deliver faster results by reducing production time from weeks to just days. This efficiency allows you to meet deadlines and lower costs.

Quality metrics comparison between HDI PCB Board quick turn and traditional PCB manufacturing:

Metric

HDI PCB Board Quick Turn

Traditional PCB

Average Cycle Time

1-5 days

2-6 weeks

On-Time Delivery

95-98%

85-95%

By 2025, industries requiring swift design modifications will increasingly rely on HDI PCB Board quick turn solutions. This approach not only saves time but also optimizes material usage, making it a smart and cost-effective option for various projects.

Key Takeaways

Quick turn HDI PCBs make production faster, cutting time from weeks to days. This speed helps meet deadlines and saves money.

HDI technology uses materials better, reducing waste and helping the environment. This saves money and makes products work better.

Simple PCB designs can save money. Using fewer layers and common materials makes production easier and cheaper.

Designers and manufacturers need to work together. Early teamwork finds problems early, making production smoother and cheaper.

Automation and smart tools make quick turn PCBs better. These tools improve accuracy, speed, and productivity.

Understanding HDI PCB Board Quick Turn

What Are Quick Turn HDI PCBs?

Quick turn HDI PCBs are special circuit boards made quickly. They use HDI technology to fit more parts in small spaces. This makes them great for fast devices and tiny gadgets. Unlike regular PCBs, quickturn ones are faster to make but still high quality.

Main features of quick turn HDI boards:

Layer Count: Usually 2 to 30 layers, based on design needs.

Trace Space: As small as 1.5-mil for detailed designs.

Hole Size: Microvias as tiny as 2-mil for dense layouts.

Surface Finish: Finishes like HASL or ENIG speed up production.

These features help you finish projects faster without losing reliability.

Why Quick Turn Manufacturing Matters in 2025

In 2025, quickturn PCB solutions will be even more important. Industries like electronics, cars, and telecom need fast production to stay ahead. Quick turn manufacturing helps meet deadlines and adjust to changes.

By avoiding delays, you can cut project costs. For instance, using common board sizes and easy-to-find parts speeds up production. Also, using through-hole vias and standard copper weights makes building easier. These steps save both time and money.

Tip: Work with your PCB maker early to find ways to save money.

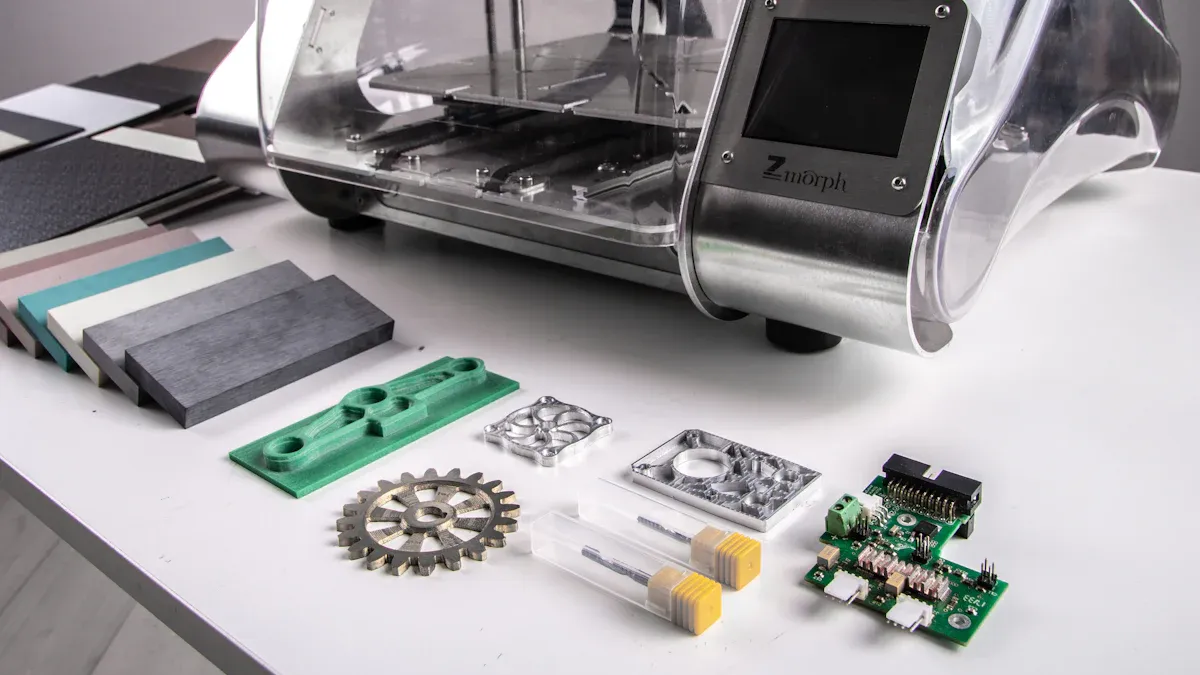

The Role of HDI Technology in Cost Reduction

HDI technology helps lower production costs. It handles tricky designs with many parts better than regular PCBs. Here’s how HDI saves money:

Design Complexity: HDI boards use less material for dense designs.

Production Volume: In big batches, HDI improves success rates, balancing costs.

Total Product Cost: Smaller HDI boards cut shipping and case costs.

Using HDI lets you make small, powerful products while saving money.

Note: Follow rules like IPC and RoHS to keep quality high during quickturn production.

Cost-Saving Benefits of Quickturn PCB Manufacturing

Faster Turnaround Time and Reduced Delays

Quickturn PCBs are made faster, cutting down delays. Shorter production times help meet deadlines and market needs. Many industries already see big improvements. For example:

Industry | Metric | Result |

|---|---|---|

Manufacturing | 15% better on-time delivery | |

Software Development | 50% faster development cycles | Quicker launches and responses |

Healthcare | 30% less wait time in emergencies | Better patient care and efficiency |

These examples show how quickturn PCBs keep projects on schedule. Using HDI PCB quick turn tech, you get fast results without losing quality.

Optimized Design Processes for Efficiency

Better design processes make manufacturing smoother and more efficient. HDI tech helps create small, dense boards that waste less material. This keeps costs low while meeting performance needs. Here are some benefits of better design:

Benefit | Description |

|---|---|

Finds the best settings to save time and reduce waste. | |

Better product quality | Fixes problems early, making products more reliable. |

Lower costs | Cuts waste and avoids extra spending, saving money. |

Smarter decisions | Uses data to improve processes and make better choices. |

Faster market time | Speeds up development by finding the best methods quickly. |

By improving designs, you can make quickturn PCBs faster and cheaper.

Material Efficiencies and Lower Production Costs

HDI boards use materials wisely, which lowers costs. Their small size means fewer materials are needed but still work well. Smaller boards also cost less to ship and pack, saving even more. HDI tech uses advanced methods to meet standards without extra costs.

With HDI PCB quick turn solutions, you use materials better and waste less. This saves money and supports eco-friendly practices, making it a smart choice for today’s projects.

Faster Prototyping and Quicker Product Launches

Quickturn PCB manufacturing helps make prototypes faster. It also shortens the time to launch products. This speed is very important for industries needing quick changes. With quickturn methods, production time drops from weeks to just days or hours. This lets you test ideas, fix designs, and release products much faster.

For instance, a medical company used smart design tools and skilled manufacturers. This helped them finish and launch their products three months early. Similarly, Capel used automation and new tech to cut production time by 40%. These examples show how quickturn PCBs can speed up your projects.

Quickturn PCB manufacturing also offers:

Quick design updates and improvements.

Fewer risks of costly mistakes or delays.

Faster testing and proof-of-concept cycles.

If you need only a few prototype boards, quickturn processes are even better. They let you test and improve designs without making too many boards. This saves materials and ensures your product is ready before mass production.

By cutting production time, quickturn PCBs help you beat competitors. Faster prototypes mean you can meet market needs quickly, lower costs, and deliver new products on time.

Key Factors That Affect PCB Costs

How Design Complexity and Layers Impact Cost

The way your PCB is designed changes its cost. Complex designs with tiny parts and thin lines need special tools. These tools take more time and money to use. For example, making a PCB with many layers is harder. A two-layer PCB costs 30-40% more than a single-layer one. Adding layers to a 10-layer PCB may only add 20-30% more cost. But the total price stays high because of the hard work needed.

Factor | What It Means | How It Affects Cost |

|---|---|---|

Layer Count | Number of layers in the PCB. | More layers mean harder and pricier work. |

Design Complexity | Tiny parts and tricky layouts. | Needs special tools, raising the cost. |

To save money, keep your design simple but useful. A less tricky design can make HDI PCBs cheaper.

Choosing the Right Materials

The materials for your PCB change how it works and costs. Common ones like FR-4 are cheap and work well for most uses. Fancy materials like Rogers or Polyimide work better but cost more. For example, Polyimide costs 3-5 times more than FR-4. PTFE materials can cost 10-50 times more.

Material | Cost Level | What It’s Good At |

|---|---|---|

FR-4 | Low to Medium | Strong, good insulation, handles heat well. |

Aluminum | Medium to High | Great at cooling and lightweight. |

Rogers | High | Stable and loses less energy. |

Polyimide | High | Flexible and resists chemicals. |

If materials are rare or in high demand, prices go up. Picking easy-to-find materials makes quickturn production faster and cheaper.

Using Advanced HDI Manufacturing Methods

New HDI methods cut costs and improve quality. For example, stacked vias in 8- or 14-layer PCBs save space and reduce problems. These methods let you make small designs that still work well. Quick HDI prototyping also saves time and money by speeding up production.

Using these methods helps you do more with less. This lowers PCB costs and makes your product better for the market.

Teamwork Between Designers and Makers

Teamwork between designers and makers helps lower PCB costs. When they work together early, they can spot problems and avoid mistakes. This teamwork makes sure designs match what makers can build, leading to smoother production.

Working together also boosts efficiency. For example:

Teams can make up to 2,600 units a year, beating the 2,250-unit goal.

This teamwork lowers defects, cutting production costs.

Even for small batches, teamwork works better than manual setups when quality matters.

Involving makers during design helps use materials wisely and speeds up production. Makers can suggest cheaper materials or methods that keep quality high. For instance, they might use common board sizes or parts to save time and money.

Talking between teams reduces delays. Designers can change layouts based on maker advice, so designs are ready without extra fixes. This saves time and keeps projects on track.

To get the most from teamwork, set up clear ways to talk and share design details with makers. Regular updates and feedback keep everyone on the same page, making the process faster and cheaper.

When designers and makers team up, you get faster builds, better products, and lower costs. This teamwork is key to keeping PCB costs low in today’s busy market.

Best Practices for Using Quick Turn HDI PCBs

Picking the Right PCB Maker

Choosing the best PCB maker is very important. A good maker gives you high-quality boards, fast delivery, and saves money. When picking a maker, think about these things:

Factor | Why It Matters |

|---|---|

Making Skills | Shows if they can make your board well. |

Quality Checks | Makes sure your boards work every time. |

Speed of Delivery | Helps you stay ahead in busy markets. |

Knowledge and Advice | Gives helpful tips during the project. |

Tools and Machines | Makes production faster and more accurate. |

Price and Value | Balances cost with good service and quality. |

Customer Help | Makes talking and working together easy. |

Flexibility | Adjusts to your needs and helps you grow. |

Supply Chain | Gets parts on time and avoids delays. |

Green Practices | Shows care for the environment. |

Focus on these points to find a partner who fits your needs.

Making Designs Simple to Save Money

Simpler designs save money and time. They also make production easier and reduce mistakes. Follow these tips to simplify your designs:

Use DFM (Design for Manufacturing) rules to make building easier.

Keep layers between 2 and 4 for quicker production.

Pick common board sizes and easy-to-find parts to avoid delays.

Use wider lines and bigger spaces for easier manufacturing.

Stick to standard copper thickness and finishes for faster processing.

Simple designs help you finish projects faster and better. Companies that simplify often save money and improve their work.

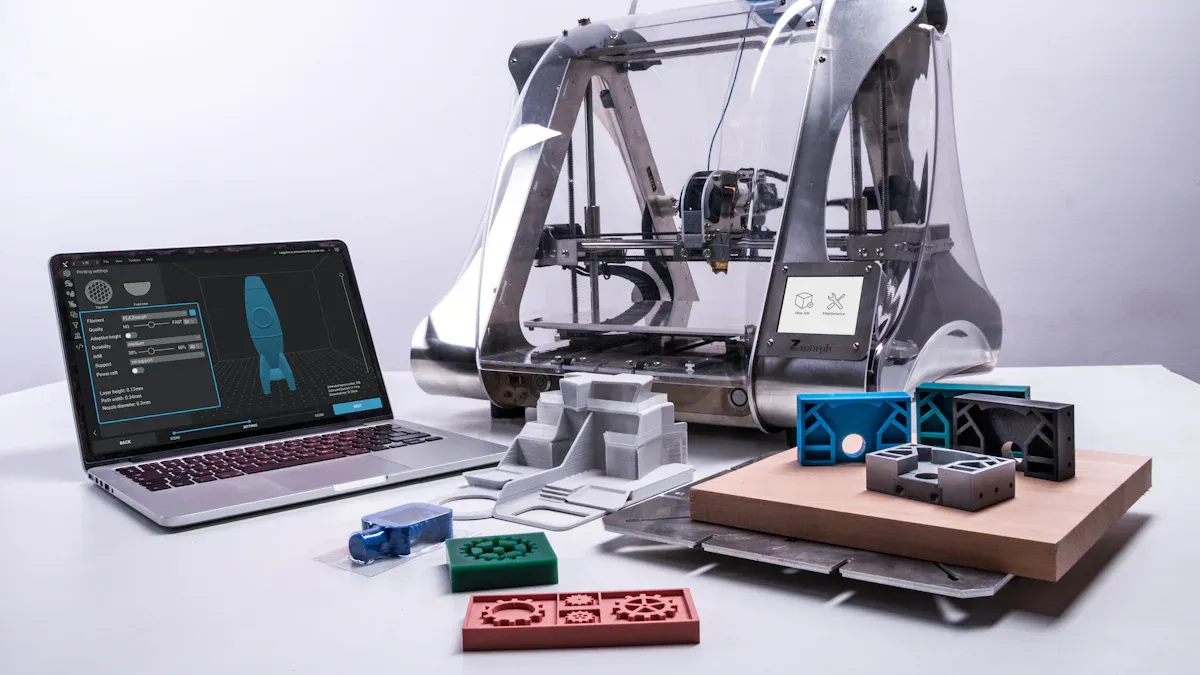

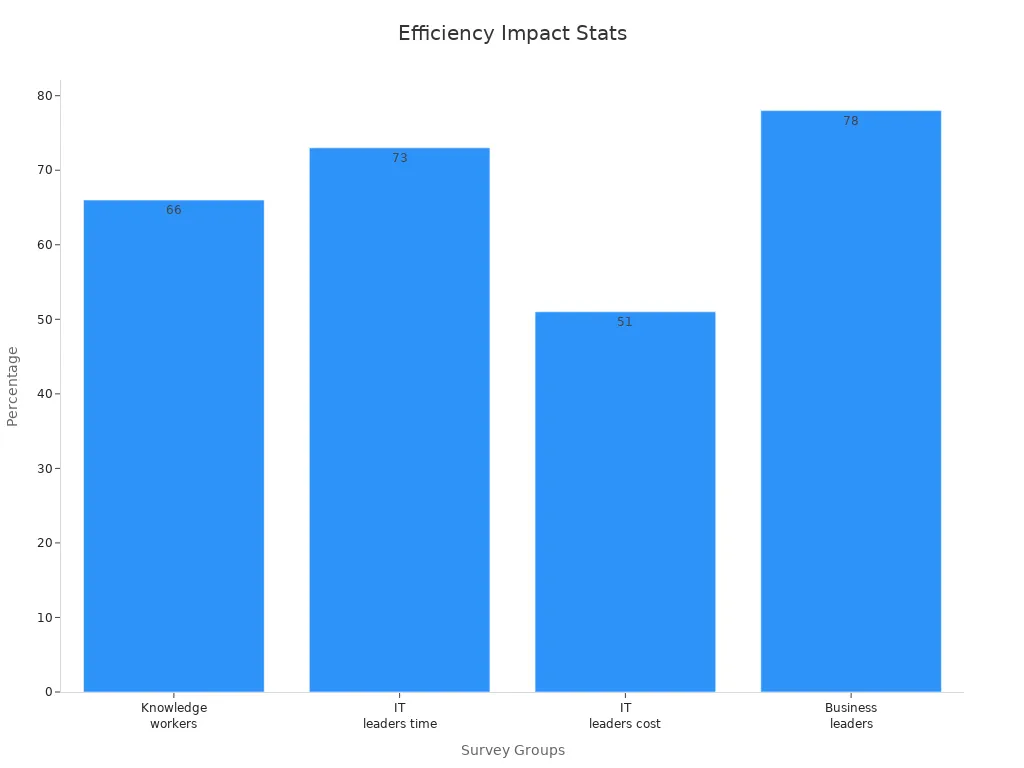

Using Automation and Smart Tools

Automation and smart tools make quick PCB production faster and better. These tools cut mistakes, speed up work, and lower costs. Studies show 78% of leaders say automation boosts productivity. Over half use automation to improve workflows.

To use automation well, try these ideas:

Use software to check designs and find mistakes early.

Add DevOps and CI/CD methods to speed up development.

Buy advanced machines to make production faster and more accurate.

Automation helps you work faster and keeps quality high. It’s a key part of quick PCB manufacturing.

Planning for Growth and Future Needs

Planning for growth helps your projects handle future changes easily. As technology improves, scaling production well will be key to success. Quickturn PCB solutions help by being flexible and speeding up production.

To get ready for the future, use tools that support growth. For example:

Cloud tools make managing data easier. They collect and process data automatically, saving money.

Teams managing their own data improve accuracy and reliability in projects.

Using these tools lets you handle more data and work faster.

In the future, planning for workers will be very important. By 2030, AI tools will match employee skills with work needs. These tools can:

Find skill gaps in your team.

Offer training to keep workers skilled.

Help manage teams based on their abilities.

Using smart tools for planning keeps your team ready for new challenges.

When growing quickturn PCB production, focus on flexible designs and processes. Modular designs let you change production sizes without starting over. Flexible methods make switching between small and big production easier.

Growth also needs strong partnerships. Work with PCB makers who can grow with you and meet your needs. A good partner helps you stay ahead as markets change.

Planning for growth saves money and prepares your business for the future. This strategy ensures long-term success and keeps you competitive.

Quick turn HDI PCBs can lower project costs in 2025. They speed up production, helping you meet deadlines and avoid delays. For instance, Capel Technology used automation to cut production time. This saved money and improved product quality. A medical company also launched products three months early. They used quick turn HDI PCBs to reduce production time by 40%.

These PCBs use materials wisely, staying efficient without losing quality. Faster production and strong performance give you an advantage. Working with skilled makers and following smart tips will boost these benefits.

FAQ

1. What is the main advantage of using quick turn HDI PCBs?

Quick turn HDI PCBs are made very quickly. They help finish projects faster and meet deadlines. These boards also allow small, powerful designs, perfect for modern gadgets.

2. How do quick turn HDI PCBs help reduce material waste?

HDI PCBs use tiny holes and smart layouts to save materials. This design cuts waste but keeps performance high. Using fewer materials saves money and helps the environment.

Tip: Work with your PCB maker to use materials wisely.

3. Are quick turn HDI PCBs suitable for prototyping?

Yes, they are great for prototypes. Their fast production lets you test ideas quickly. You can fix designs faster and get ready for mass production sooner.

4. Can quick turn HDI PCBs handle complex designs?

Yes, they are perfect for tricky designs. HDI tech works well with dense layouts and many parts. You can make multi-layer boards that perform well without extra cost.

5. How do I choose the right manufacturer for quick turn HDI PCBs?

Pick a maker with good skills and tools. Check if they deliver on time and offer quality checks. A good partner will help you finish your project smoothly.

Note: Read reviews and ask for samples before deciding.