Rigid PCB Manufacturing: Materials, Processes, and Quality Standards for Industrial Applications

Rigid PCB manufacturing is crucial for operating modern industrial machines. These boards serve as robust foundations for circuits in cars, planes, and factory equipment. In 2021, they accounted for 85% of the market. LT CIRCUIT enhances rigid PCBs by utilizing premium materials, innovative designs, and meticulous manufacturing processes to withstand demanding applications.

Key Takeaways

Picking good materials, like FR-4 or metal cores, is key to making strong and useful rigid PCBs.

Using IPC rules makes sure rigid PCBs are high-quality and work well for industries.

Using the right design and steps in making them can greatly improve how reliable and useful rigid PCBs are.

Materials in Rigid PCB Manufacturing

Picking the right materials is very important for making rigid PCBs. It affects how well the boards work, how long they last, and how reliable they are. Knowing the features of different materials helps you choose the best one for your needs.

Common Substrate Materials in Rigid PCBs

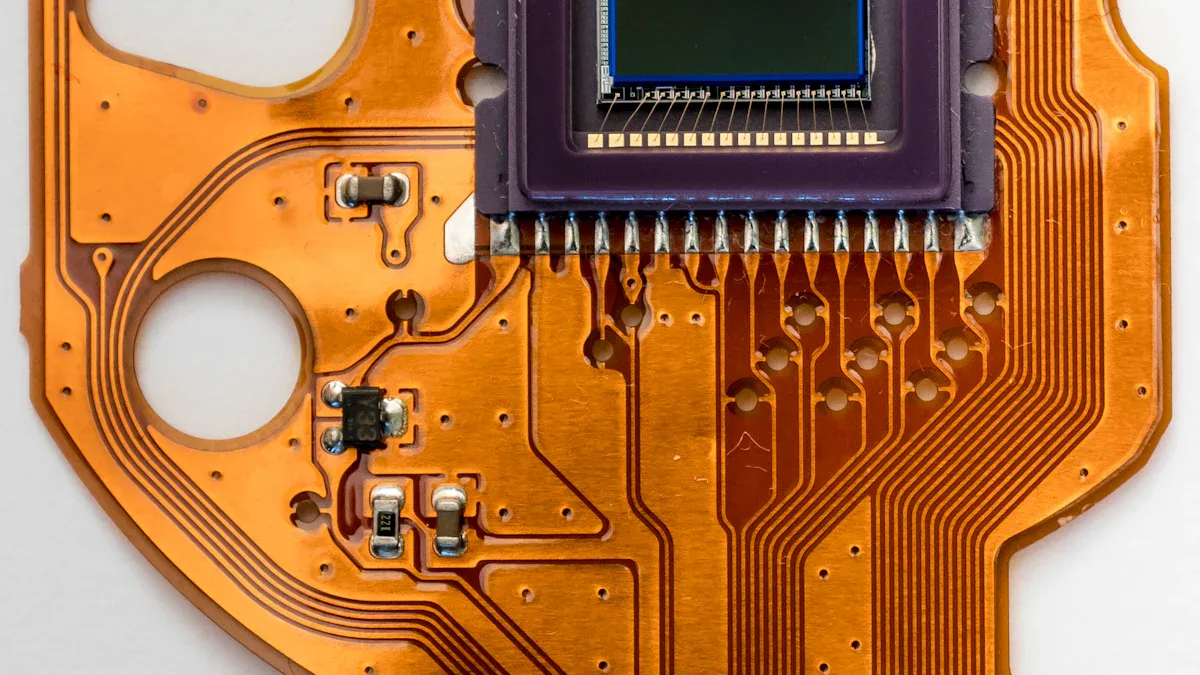

Substrate materials are the base of a PCB. They hold the parts and keep electricity from leaking. Popular materials include FR-4, metal cores, and special laminates for high frequencies. Each material has unique features for different uses. FR-4 is cheap and flexible, while metal cores handle heat better.

Here’s a table comparing rigid PCBs to stretchable devices:

Impact Type | Stretchable Device | Rigid Device |

|---|---|---|

Environmental Effect | Higher | |

Raw Material Use | Less Impact | More Impact |

Energy in Manufacturing | Less Electricity | More Electricity |

End of Life Benefits | Negligible Returns | More Positive Returns |

This shows how picking the right materials can balance good performance with being eco-friendly.

Properties of FR-4 and High Tg FR-4

FR-4 is a common material for rigid PCBs. It’s made of fiberglass and epoxy resin, giving it strength and insulation. High Tg FR-4 works better in hot conditions. Tg means the temperature where the material becomes less stiff.

Here’s a table comparing FR-4 and High Tg FR-4:

Resin Type | Tg Range | Features |

|---|---|---|

Epoxy | 130-180°C | Affordable and widely used. |

BT Resin | 170-190°C | Low expansion and absorbs less water. |

Polyimide | 240-270°C | Very high Tg. Used in flexible PCBs. |

Cyanate Ester | 230-290°C | Great for electrical properties. |

Another table compares specific FR-4 materials:

Material | Td Value | |

|---|---|---|

Regular FR-4 KB-6160 | 135°C | 305°C |

Lead-Free FR-4 KB-6168LE | 185°C | 359°C |

High Tg FR-4 is perfect for hot environments like cars and airplanes.

Metal Core PCBs for Thermal Management

Metal core PCBs (MCPCBs) solve heat problems. They use aluminum or copper bases to cool down faster than FR-4 boards. This makes them great for powerful devices like LED lights and power systems.

Benefits of metal core PCBs:

They spread heat 5-10 times better than FR-4 boards.

Lower heat means parts last longer.

They stay strong even when temperatures change a lot.

They save money by reducing extra cooling parts.

For example, aluminum PCBs have 32% less heat resistance than FR-4 boards. This shows how well they handle heat.

Specialized Materials for High-Frequency Applications

High-frequency PCBs need special materials to keep signals clear. These materials have low dielectric constant (Dk) and low dissipation factor (Df). Low Dk reduces signal problems, and low Df keeps signals strong without overheating.

Benefits of these materials:

They stay stable in high heat without bending.

They work well in tough places like telecom and radar systems.

They keep signals clean for fast circuits.

Choosing the right materials for high-frequency PCBs ensures they work reliably and efficiently.

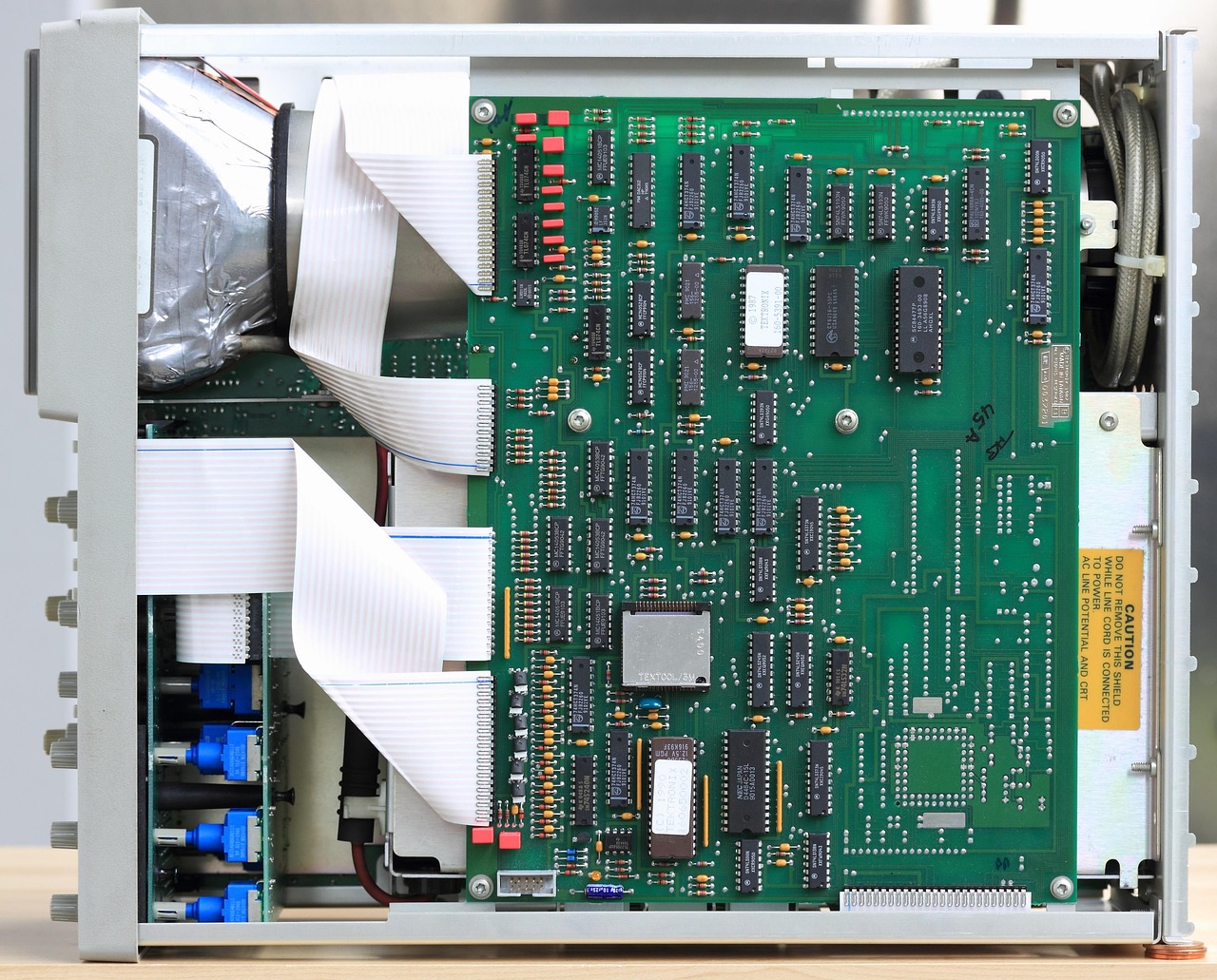

Rigid PCB Manufacturing Processes

PCB Design and Layout Optimization

Designing a rigid PCB well is key for it to work. Follow these steps to make a good design:

Keep enough space between wires, pads, and parts to avoid issues.

Make wires thicker or thinner based on how much current they carry.

Place holes (vias) carefully to keep signals strong.

Arrange parts to reduce signal problems and make wiring easier.

Put heat-making parts where they can cool down better.

Plan for easy manufacturing early to save time and money.

Grouping parts by what they do also helps. It shortens wires and keeps signals clear. Rules like IPC-2221 and IPC-7351 guide designers to make fast and reliable PCBs.

Etching and Lamination Techniques

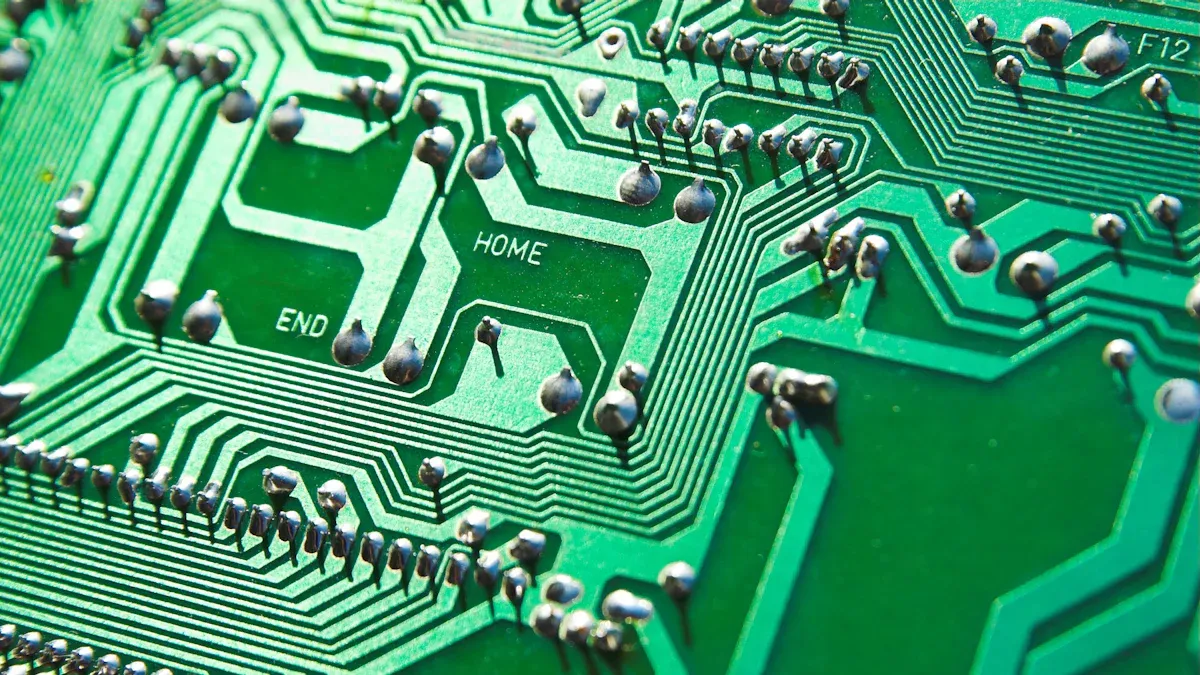

Etching and lamination are important steps in making rigid PCBs. Etching removes extra copper to form circuits. Acid etching, using ferric chloride or copper chloride, is cheap and precise. Alkaline etching is another option but used less often.

Lamination sticks PCB layers together. Treating copper surfaces first makes them bond better and resist damage. Smooth copper improves performance, especially for high-speed signals. These steps help PCBs stay strong and work well.

Drilling, Plating, and Via Formation

Drilling makes holes for parts and connections. Accurate drilling ensures everything lines up. Plating adds metal inside the holes to connect layers. Vias, like through-hole or blind vias, let signals pass between layers.

Good via placement and plating improve signal flow and strength. These steps are crucial for making strong and dependable rigid PCBs.

Assembly and Testing for Rigid PCBs

Assembling rigid PCBs means adding parts and soldering them in place. Testing checks if the board works properly.

Benefits | |

|---|---|

Visual Inspection | Spots surface problems but may miss small details. |

Automatic Optical Inspection (AOI) | Finds solder mistakes and missing parts quickly and accurately. |

X-ray Lamination System | Looks closely at solder joints for hidden issues. |

Electrical and functional tests confirm the PCB works as needed. These steps ensure rigid PCBs meet industrial standards and perform reliably.

Quality Standards in Rigid PCB Manufacturing

Making sure rigid PCBs are high-quality means following strict rules. These rules cover materials, processes, and checks to ensure they work well. By using IPC PCB standards, you can make boards that meet industrial needs.

Overview of IPC Standards for Rigid PCBs

IPC standards are global rules for making PCBs. They guide every step, from picking materials to final checks. These rules help PCBs work well in different situations.

Here’s a table showing key IPC standards and their focus:

IPC Standard | Focus Area | Description |

|---|---|---|

IPC-4101C | Base materials for rigid PCBs | Lists rules for materials used in rigid or multilayer boards. |

IPC-6012B | Qualification and performance for PCBs | Sets rules for making strong and solderable boards. |

IPC-A-600F | Acceptance criteria for PCBs | Explains what board conditions are okay or not okay. |

J-STD-001 | Soldered interconnections | Details how to do high-quality soldering. |

IPC-A-610 | Acceptability of electronic assemblies | Focuses on checking the quality of finished products. |

IPC-2221 | Best practices for PCB design | Gives tips for designing boards that work well and are easy to make. |

IPC-7711/7721 | Rework and repair of PCBs | Guides fixing or changing boards without losing quality. |

These standards group PCBs into three levels:

Level 1: Basic products with simple functions.

Level 2: Products needing long life and better reliability.

Level 3: High-reliability products for tough conditions.

Knowing these levels helps you pick the right rules for your needs.

IPC-6012: Ensuring Performance and Reliability

IPC-6012 is an important rule for rigid PCBs. It checks if boards are strong, solderable, and work as planned. This standard ensures PCBs are ready for tough industrial jobs.

Main points of IPC-6012:

Fabrication Rules: Makes sure boards don’t have problems like bending or peeling.

Solder Testing: Checks if solder joints are strong and reliable.

Electrical Testing: Confirms the board meets its electrical needs.

Following IPC-6012 ensures your PCBs work well, even in hard conditions.

UL 796: Safety and Performance Criteria

UL 796 is another key rule for rigid PCBs. It focuses on safety and making sure boards last. This rule checks if boards resist fire, heat, and electricity problems.

Benefits of following UL 796:

Better Safety: Lowers the chance of electrical fires.

Stronger Boards: Makes sure boards handle heat and tough conditions.

Easier Approvals: Helps get certifications faster for your products.

Using UL 796 improves both safety and the value of your PCBs.

LT CIRCUIT’s Commitment to Quality Standards

At LT CIRCUIT, quality is very important. They follow all major IPC standards, like IPC-6012 and IPC-A-600, to make sure their PCBs are reliable. They also meet UL 796 rules for safety and durability.

How LT CIRCUIT ensures quality:

Advanced Checks: Uses strict inspections to find and fix problems.

Modern Tools: Makes PCBs with the latest technology.

Customer Focus: Offers custom solutions for your needs.

Choosing LT CIRCUIT means getting PCBs that go beyond industry rules. Their boards work well in any industrial setting.

LT CIRCUIT’s Rigid PCB Manufacturing Capabilities

Advanced Materials and Customization Options

LT CIRCUIT uses special materials and custom designs for electronics. They make rigid-flex PCBs, HDI PCBs, and metal core PCBs. These materials help PCBs work better in different devices.

Advanced Material Type | How It Helps |

|---|---|

Rigid-Flex PCBs | |

High Density Interconnect PCBs | Fit more circuits into smaller spaces for compact designs. |

Metal Core PCBs | Perfect for LED lights, giving more brightness and less heat. |

These materials let you create PCBs that match your needs. Whether it’s cooling for LEDs or small designs for gadgets, LT CIRCUIT has the right solutions.

Cutting-Edge Manufacturing Technologies

LT CIRCUIT uses modern tools to improve how they make rigid PCBs. Rigid-flex PCBs are used in planes and military gear to make them lighter and stronger. Medical devices like pacemakers also use this tech to fit into small spaces.

A project cut weight from 3 lbs to under 3 ounces using rigid-flex PCBs.

Flexible materials replaced many connectors, saving space and weight.

Accurate machines ensure PCBs are ready for use.

These examples show how LT CIRCUIT uses advanced tools to make high-quality PCBs for tough jobs.

Testing and Quality Assurance Processes

LT CIRCUIT checks every PCB carefully to meet top standards. They test each board to make sure it works well and follows industry rules.

Application Area | Results |

|---|---|

5G Infrastructure | |

Portable Medical Devices | Achieved 99.9% accuracy in monitors for medical use. |

Multilayer & HDI Boards | Expertly made boards for advanced tech like 5G. |

Material Innovation | Uses new materials for better PCB performance. |

Sustainable Practices | Reduces waste and energy with eco-friendly etching methods. |

These steps ensure LT CIRCUIT’s PCBs are reliable and high-quality, making them a trusted choice in electronics.

Making rigid PCBs needs strong materials, smart methods, and strict rules. Materials like polyimide and metal cores make them tough and handle heat well. LT CIRCUIT makes dependable PCBs for cars, planes, and smart devices. Following industry rules helps these PCBs work well in hard conditions.

FAQ

What makes rigid PCBs different from flexible ones?

Rigid PCBs are hard and cannot bend. Flexible PCBs can bend to fit small or tight spaces. Rigid PCBs are better for tough jobs needing strength and stability.

How does LT CIRCUIT make sure PCBs are reliable?

LT CIRCUIT uses top-quality materials and careful manufacturing steps. They also do strict checks to ensure their PCBs work well for industrial use.

Why are metal core PCBs good for powerful devices?

Metal core PCBs handle heat very well. They keep parts cooler and prevent damage. This makes them great for strong devices like LED lights and power systems.

See Also

Exploring Rigid Flex PCBs In Medical And Industrial Applications

An Overview Of The PCB Manufacturing Process

Understanding The Production Of Multilayer Rigid-Flex Circuit Boards