What Are Rogers Ceramic PCB Materials and Their Unique Properties

You encounter rogers ceramic pcb in devices that require top-tier performance under demanding conditions. Rogers ceramic pcb materials are renowned for their high dielectric strength, excellent thermal conductivity, and outstanding reliability.

Material Type | Unique Properties | Applications |

|---|---|---|

Rogers 4350 | High dielectric strength, dimensional stability | High power RF designs, active devices |

Rogers 92ML | Halogen-free, thermally conductive | Metal substrate PCBs |

RO3000® Series | Electrical and mechanical excellence | RF and microwave applications |

As industries continue to push for miniaturization, enhanced thermal management, and more robust electronics, the demand for advanced pcb solutions like rogers ceramic pcb continues to rise. You’ll find rogers ceramic pcb widely used in automotive, telecommunications, and aerospace sectors, where reliability and performance are absolutely critical.

Key Takeaways

Rogers ceramic PCB materials excel in high-frequency applications due to their low dielectric loss and stable dielectric properties, ensuring strong signal integrity.

These materials provide excellent thermal management and durability, making them ideal for use in harsh environments where reliability is critical.

Industries such as telecommunications, aerospace, and automotive benefit from Rogers PCBs, which support miniaturization and high-performance designs.

Rogers Ceramic PCB: Definition and Composition

What Is Rogers Ceramic PCB Material?

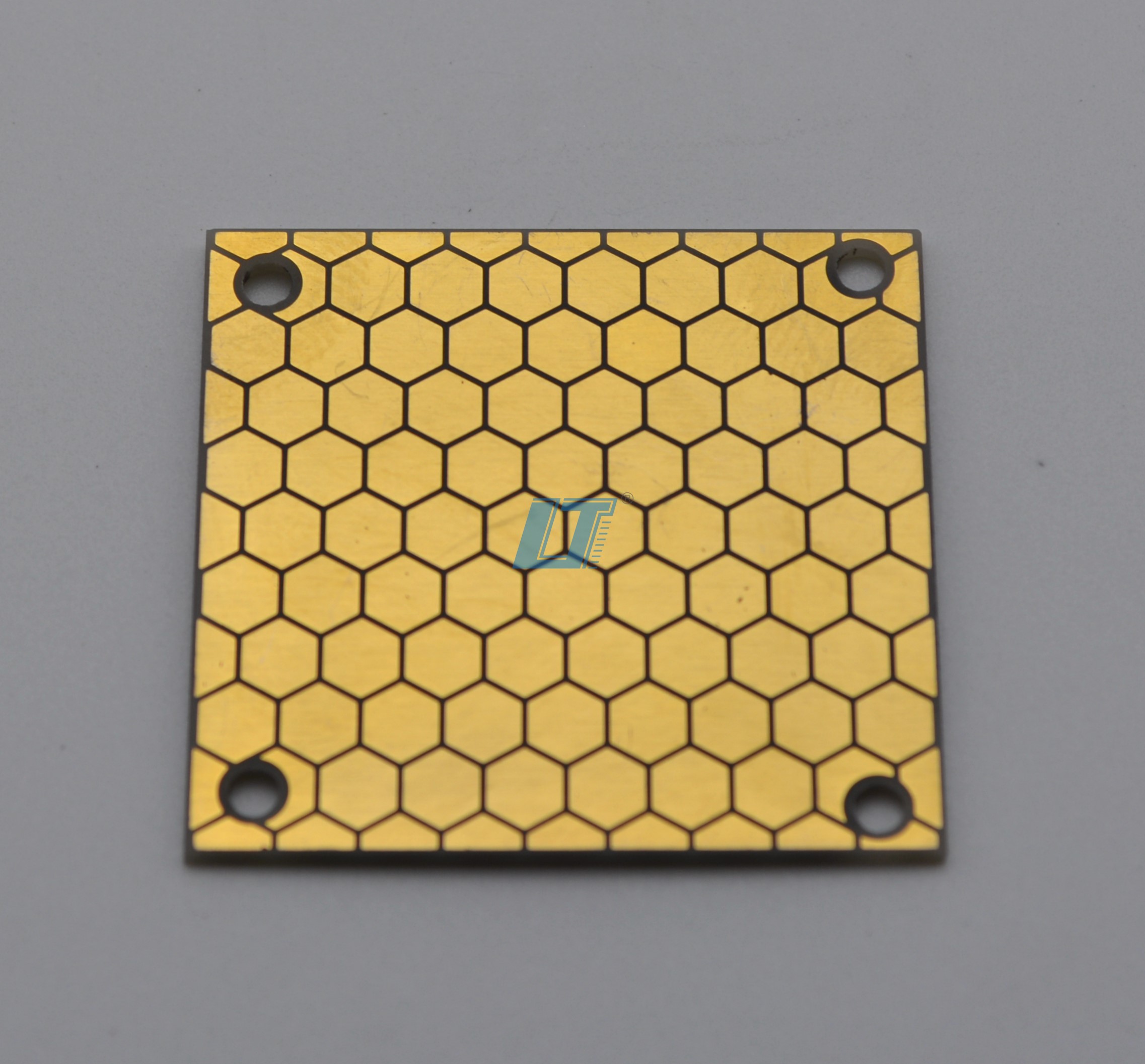

You find rogers ceramic pcb materials at the heart of high-frequency and high-performance electronics. These materials use a unique blend of polymers and ceramics to deliver outstanding electrical and thermal properties. The main structure combines a polymer matrix—often PTFE or hydrocarbon/ceramic composites—with reinforcement from woven glass fabric and ceramic fillers. Common ceramic fillers include titanium dioxide, barium titanate, and aluminum oxide. This combination gives rogers pcb material its signature stability and reliability.

Component Type | Specific Materials/Properties |

|---|---|

Polymer Matrix | PTFE, Hydrocarbon/ceramic composites, Thermoset resins |

Reinforcement Materials | Glass fiber, Ceramic fillers, Woven glass fabric |

Chemical Composition | PTFE resin, Ceramic fillers (TiO₂, BaTiO₃, Al₂O₃) |

Types of Rogers PCB | Rogers 4350B, 5880, RO4003, 3003C, 5870, 6002, 4533, 3730, 3210, TMM |

You see these materials used in many advanced pcb designs because they offer much lower dielectric loss and better thermal management than standard options.

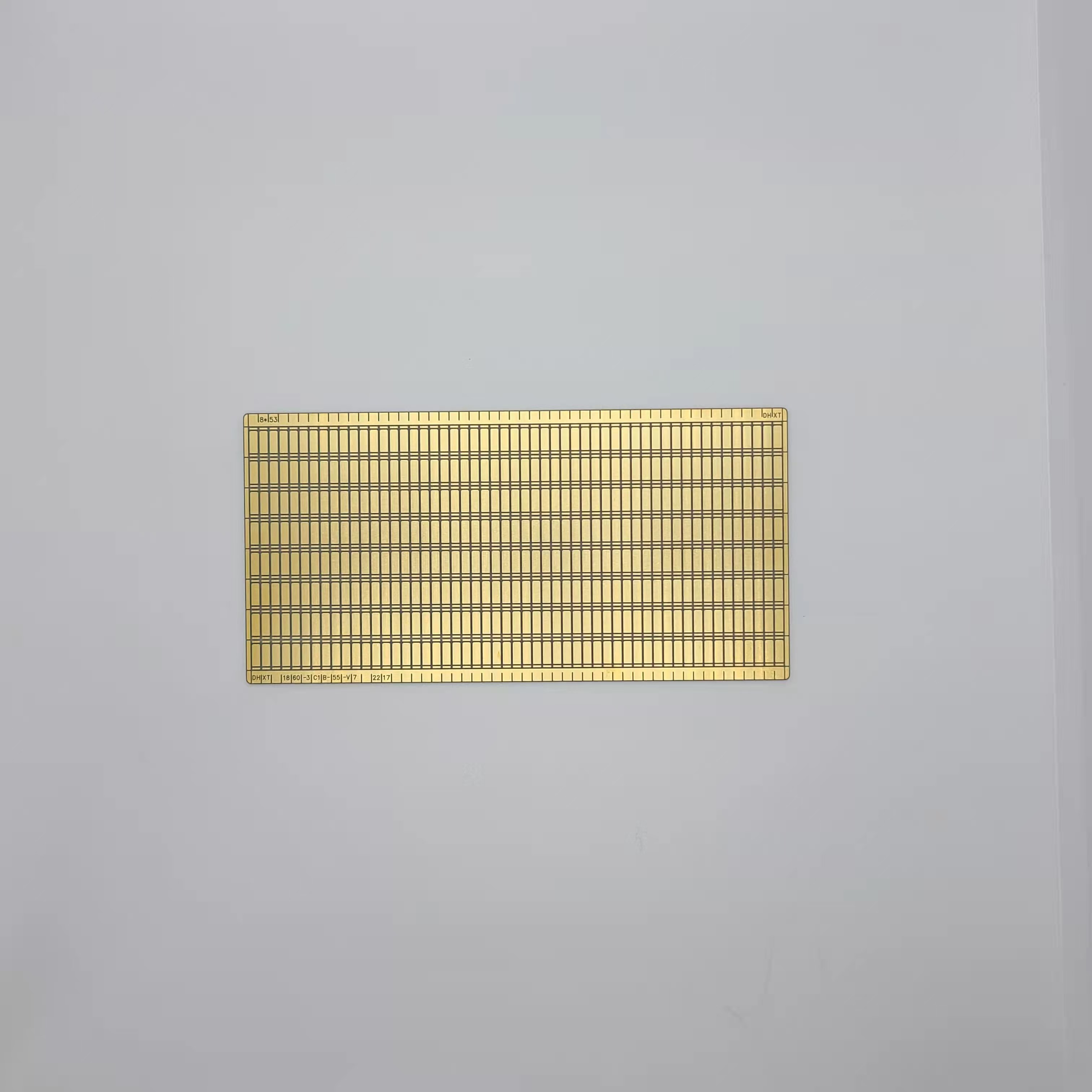

Rogers Laminates and Substrate Types

Rogers laminates come in several series, each designed for specific performance needs. The RO4000 series uses hydrocarbon ceramic laminates for excellent dimensional stability and low dielectric tolerance. The RO3000 series features ceramic-filled PTFE composites, which provide uniform mechanical and electrical properties at high frequencies.

Series Type | Description | Popular Types |

|---|---|---|

RO4000® Series | Hydrocarbon ceramic laminates, stable and precise for high frequency | RO4003C™, RO4350B™, RO4360G2™, RO4400™, etc. |

RO3000® Series | Ceramic-filled PTFE composites, excellent for high-frequency applications | RO3003™, RO3006™, RO3010™, RO3210™, etc. |

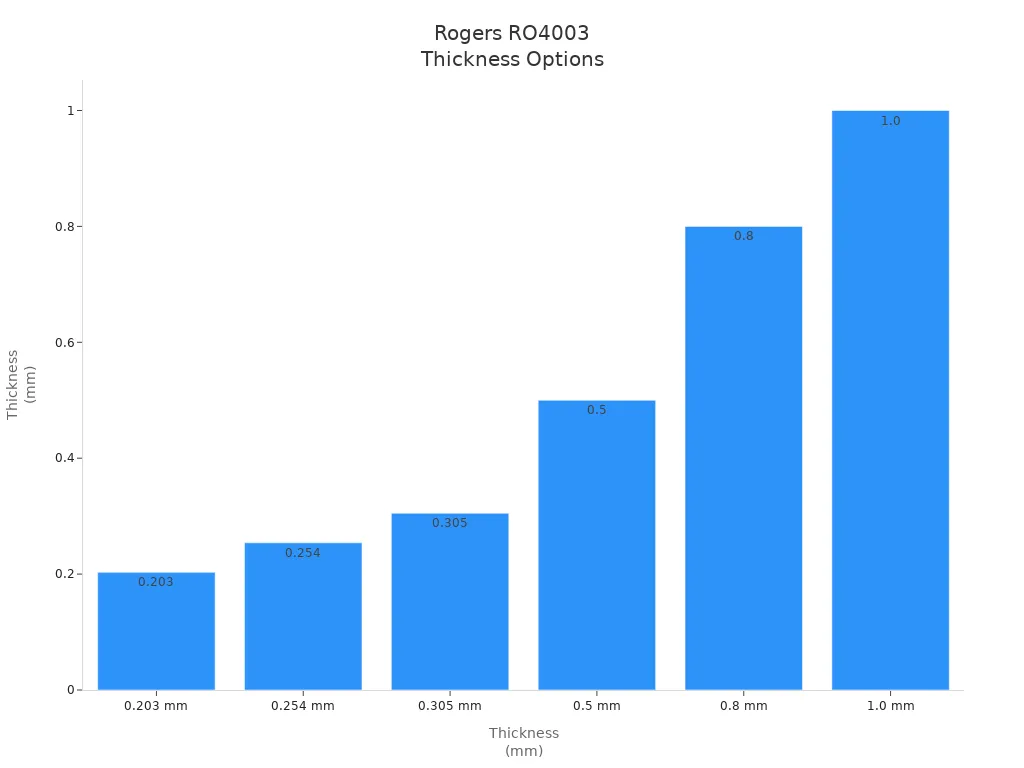

You can choose from a range of thicknesses to match your design needs. For example, Rogers RO4003 comes in sizes from 0.203 mm to 1.0 mm.

When you compare rogers laminates to standard FR-4 pcb materials, you notice key differences:

Feature | Rogers Ceramic PCB Materials | Standard PCB Materials (FR-4) |

|---|---|---|

Composition | Primarily ceramic-based, no glass fiber | Composite of glass fiber and epoxy |

Thermal Management | Prone to softening at high temperatures | |

Moisture Absorption Rate | Very low | Higher |

Dielectric Constant Stability | Stable over wide frequency range | Less stable, limited frequency range |

High-Frequency Performance | Ideal for RF, low dielectric loss | Not suitable for high-frequency |

Rogers laminates, such as the RO4000 and TC Series, stand out for their low loss, high thermal conductivity, and reliability in demanding environments. You benefit from these advanced materials when you need consistent performance in RF, microwave, and power applications.

Unique Properties of Rogers PCB Material

Dielectric Stability and Low Loss

When you work with rogers ceramic pcb, you notice how the unique blend of high-frequency material and advanced fillers creates a set of properties that stand out in the industry. Rogers pcb materials deliver a dielectric constant that is higher than standard pcb materials, which usually have a dielectric constant between 3 and 4. Some rogers material pcbs reach values of 10.2 or even higher. This higher dielectric constant lets you design more compact circuits, which is essential for high-speed and mission-critical applications.

Rogers pcb materials offer:

Dielectric constant typically ranging from 6.0 to 7.0, with some types even higher.

Loss tangent as low as 0.0037 at 10 GHz for Rogers 4350B.

Dissipation factor (Df) between 0.0014 and 0.003, which minimizes signal attenuation and distortion.

Loss tangent for the Rogers 4000 series ranges from 0.003 to 0.005, supporting excellent signal integrity in high-frequency applications.

Tip: A lower loss tangent means less energy is lost as heat, so your circuits maintain stronger signals and better high-frequency performance.

You can see the impact of these properties in the table below:

Property | Value Range | Impact on Signal Integrity |

|---|---|---|

Dielectric Constant | 6.0 to 7.0 | Efficient capacitive coupling for compact designs |

Loss Tangent (tan δ) | 0.003 to 0.005 | Minimizes signal degradation, ensures strong signals |

Rogers material pcbs maintain dielectric stability across a wide frequency range. This stability is critical for signal integrity, especially in high-speed and high-frequency applications. You get consistent electrical performance, which is vital for high-performance composite materials used in advanced communication systems. When you need to ensure signal integrity and electrical performance in high-frequency performance circuits, rogers pcb materials provide a clear advantage.

Thermal Management and Durability

You also benefit from the superior thermal management and durability of rogers material pcbs. Rogers materials have a low coefficient of thermal expansion (CTE) that closely matches copper, about 18 ppm/°C. Standard pcb materials like FR-4 have a much higher CTE, which can cause dimensional instability when temperatures change. With rogers, you avoid these issues, so your circuits stay reliable even in demanding environments.

Rogers ceramic pcb materials show:

Very low moisture absorption, which keeps electrical performance stable in high humidity.

Long-term reliability and durability, even in harsh conditions.

Stable electrical performance over time, making them ideal for mission-critical applications.

Excellent thermal conductivity, which helps dissipate heat quickly and protects sensitive components.

Note: When you use rogers material pcbs, you reduce the risk of warping or failure due to temperature swings. This makes them a top choice for high-speed, high-frequency, and high-performance applications.

You can trust rogers pcb materials to deliver outstanding electrical performance, signal integrity, and durability. These features make them the preferred choice for industries that demand the best from their pcb materials, such as aerospace, telecommunications, and advanced industrial electronics.

Rogers Printed Circuit Board Applications with LT CIRCUIT

Industry Uses and Real-World Benefits

You see rogers ceramic pcb materials used in industries that demand high performance and reliability. These materials outperform standard ceramics and FR-4 in both electrical and thermal properties. The table below shows how they compare:

Property | Rogers Materials | FR-4 Materials |

|---|---|---|

Dielectric Loss | Very low | Higher |

Thermal Conductivity | High | Moderate |

Glass Transition Temperature (Tg) | Substantially higher | Lower |

Coefficient of Thermal Expansion | Very low | Higher |

Mechanical Stress Resistance | Excellent | Moderate |

You find rogers printed circuit board solutions in many advanced applications, such as:

Cellular base station antennas

Servers and routers

Power amplifiers

Radar and sensors

Microwave equipment

RFID tags

5G stations

Automated test equipment

These applications benefit from minimal signal loss, high circuit density, and excellent impedance control. Rogers ceramic substrates also offer low moisture absorption and high dimensional stability, which means your devices work reliably even in harsh environments.

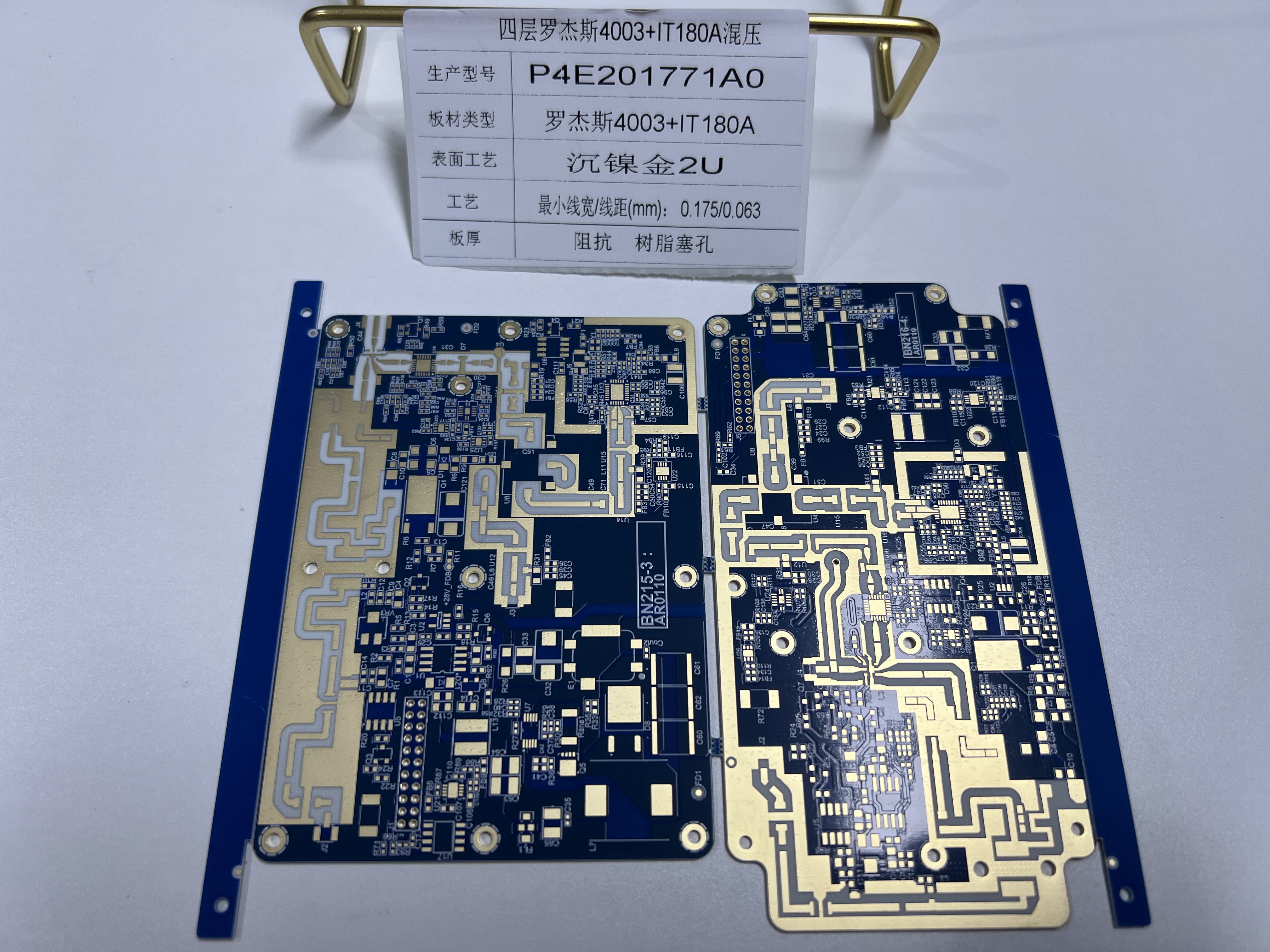

LT CIRCUIT Solutions with Rogers Laminates

When you choose LT CIRCUIT, you get more than just a supplier. You gain a partner with deep expertise in rogers laminate technology. LT CIRCUIT addresses technical challenges like fabrication complexity and material selection, ensuring you receive the right solution for your needs. The company’s certifications, including ISO 9001, ISO 14001, IATF 16949, UL, and CE, guarantee quality and safety in every printed circuit board.

LT CIRCUIT offers a wide range of ceramic substrates and advanced pcb options. You can rely on their commitment to quality and innovation for your most demanding projects. Their experience with rogers printed circuit board materials ensures your products meet the highest standards for performance and reliability.

You gain superior signal integrity, reduced crosstalk, and durability when you choose rogers ceramic pcb materials. LT CIRCUIT stands out with advanced solutions, strong design support, and excellent customer service.

Advantage | Description |

|---|---|

Support for Miniaturization | Enables compact, high-performance designs |

FAQ

What makes rogers materials better for high-frequency pcb designs?

You get stable dielectric properties and low signal loss with rogers materials. These features help your pcb perform well in high-frequency and RF applications.

Can you use rogers pcb materials in harsh environments?

Yes. Rogers pcb materials resist moisture and heat. You can trust them for reliable operation in demanding industrial or outdoor settings.

How do you choose the right rogers laminate for your pcb project?

You should consider your frequency, thermal needs, and design goals. Rogers offers many options, so you can match the right material to your pcb requirements.

See Also

Integrating Rogers Material and TG170 for Hybrid PCB Designs

Investigating the Uses of Ceramic PCBs Across Industries

Examining Rogers R4350B, R4003, and R5880 for RFPCB Applications

The Superior Heat Dissipation Capabilities of Ceramic PCBs

Analyzing Al₂O₃ Ceramic PCBs and Their Industrial Applications