Key Trends in Rogers PCB Materials for Next-Gen Electronics

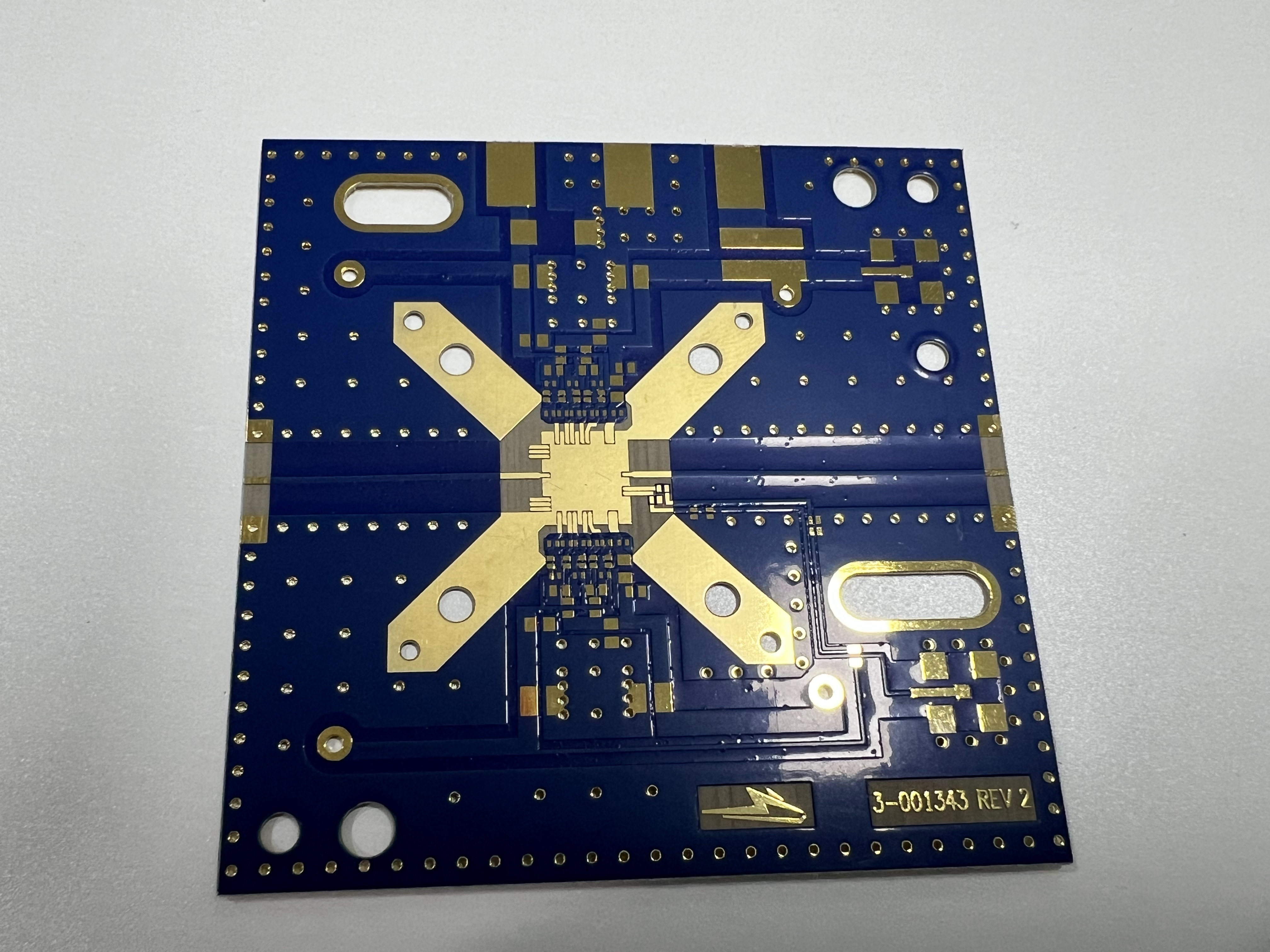

Rogers PCB materials drive next-gen electronics in 2025. Rogers delivers stable dielectric constant and low loss tangent, supporting high-frequency circuits. Rogers PCB material properties include thermal stability and high thermal conductivity, which enhance device reliability. Rogers PCB enables 5G, automotive, and IoT innovation. LT CIRCUIT uses Rogers PCB for advanced applications.

Rogers PCB Material Properties | Description |

|---|---|

Stable Dielectric Constant | Predictable signal behavior for high-frequency circuits |

Low Loss Tangent | Reduces signal loss in microwave and RF applications |

Thermal Stability | Maintains performance in changing temperatures |

High Thermal Conductivity | Improves heat dissipation for power electronics |

Mechanical Strength | Supports complex multilayer rogers pcb designs |

Key Takeaways

Rogers PCB materials excel in high-frequency performance, making them ideal for 5G and IoT applications. They ensure reliable signal transmission with minimal loss.

Thermal management is enhanced with Rogers PCB, thanks to high thermal conductivity and stability. This feature helps prevent overheating in high-power devices.

Sustainability is a priority in Rogers PCB production. Eco-friendly materials and green manufacturing processes reduce environmental impact while maintaining performance.

Rogers PCB Material Properties

High-Frequency Performance

Rogers PCB material properties set a new standard for high-frequency performance in next-generation electronics. Engineers select rogers pcb for circuits that operate above 1GHz, such as 5G networks and satellite communications. Rogers pcb material properties include excellent high-frequency performance, low loss, and dimensional stability. These features allow devices to transmit signals with minimal interference.

Rogers pcb material properties offer precise control of the dielectric constant.

Rogers pcb provides low loss tangent, which reduces signal loss in microwave and RF applications.

Rogers pcb supports stable signal transmission, even at high frequencies.

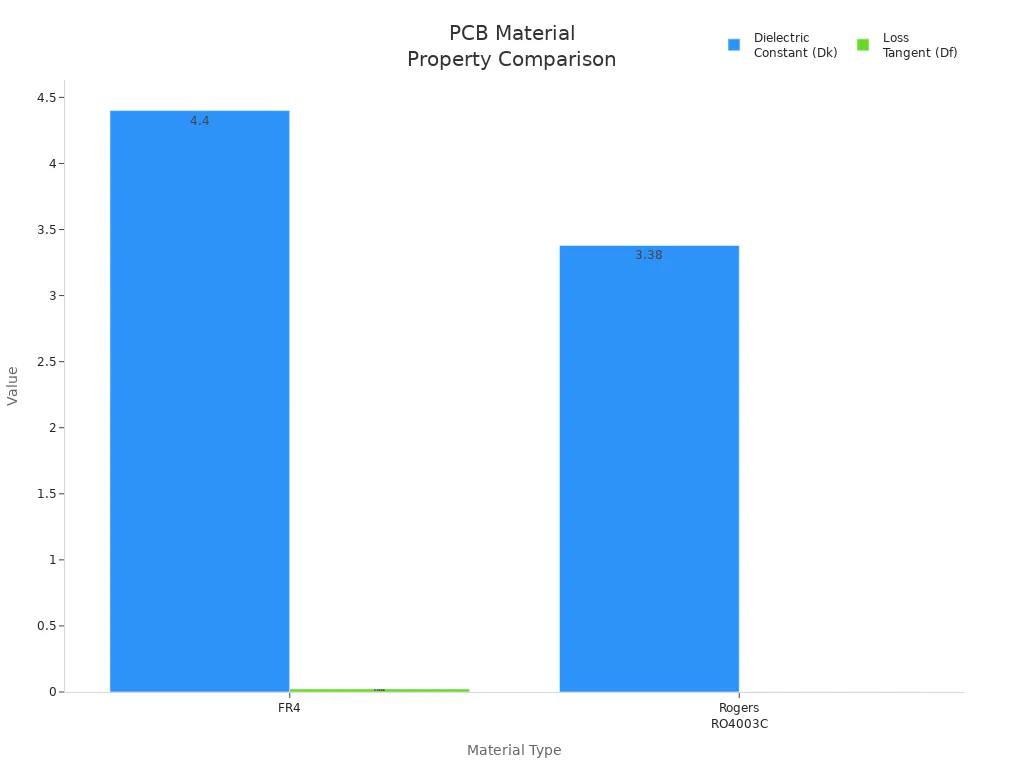

The table below compares rogers pcb material properties with traditional FR-4 substrates:

Property | FR4 | Rogers RO4003C |

|---|---|---|

Dielectric Constant (Dk) | ~4.4 (variable with temp/frequency) | 3.38 (stable up to 10+ GHz) |

Loss Tangent (Df) | 0.020–0.025 | 0.0027 |

Rogers pcb material properties deliver lower dielectric constant and loss tangent than FR-4. This advantage ensures reliable signal integrity for advanced applications. Rogers pcb supports telecommunications, aerospace, automotive, and medical devices.

Rogers pcb material properties provide engineers with the flexibility to design circuits for high-speed digital and RF applications.

Thermal and Electrical Advancements

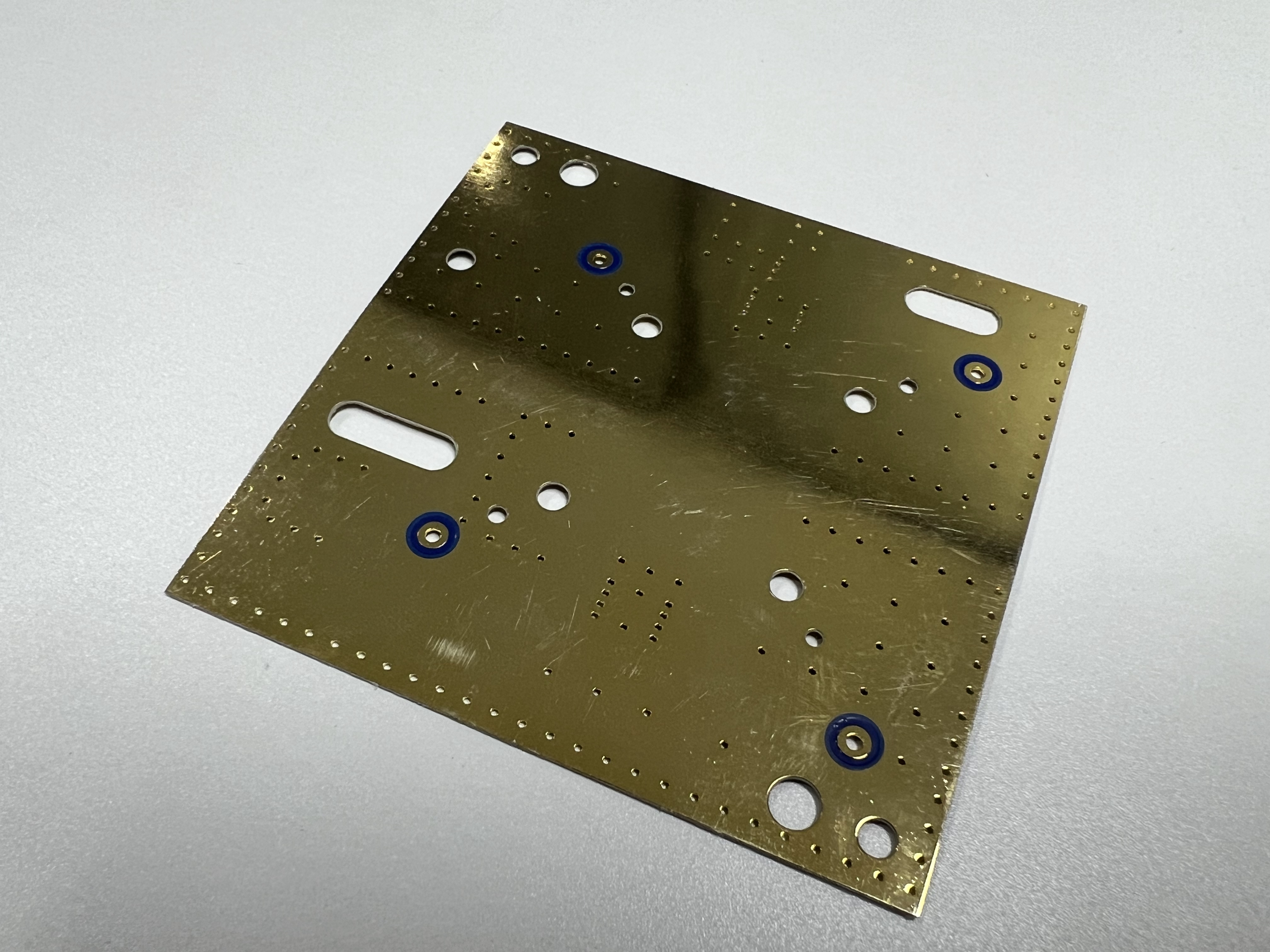

Rogers pcb material properties also excel in thermal and electrical performance. Rogers pcb integrates high thermal conductivity and low coefficients of thermal expansion. These features help dissipate heat efficiently and maintain dimensional stability.

Rogers pcb material properties include effective heat dissipation.

Rogers pcb offers low thermal expansion, which protects multilayer constructions from thermal shock.

Rogers pcb resists moisture absorption, maintaining stability in humid environments.

Rogers PCBs support higher thermal managing properties, which is essential for dissipating generated heat in high-power applications.

The table below highlights how rogers pcb material properties improve electrical performance in demanding environments:

Attribute | Description |

|---|---|

Prevents detrimental dielectric loss, ensuring reliable electrical design. | |

Minimal Moisture Absorption | Reduces insulation degradation and dimensional change in high humidity, maintaining stability. |

Low Thermal Expansion | Maintains dimensional stability, crucial for multilayer constructions and thermal shock resistance. |

Enhanced Impedance Control | Facilitates signal integrity, essential for high-speed digital applications. |

Reliable Resistance to Chemicals | Ensures compatibility and durability against aggressive chemicals, preventing deterioration. |

Rogers pcb material properties support advanced thermal management solutions. Rogers pcb withstands operational heat loads, which enhances performance and longevity. Rogers pcb enables high-power applications to operate safely and reliably.

Rogers pcb material properties deliver mechanical stability for complex multilayer designs.

Rogers pcb supports precise impedance control, which is essential for signal integrity.

Rogers pcb material properties continue to drive innovation in next-generation electronics. Rogers pcb enables manufacturers to meet the demands of high-frequency and high-power applications.

Emerging Trends in PCB Technology

HDI and Miniaturization

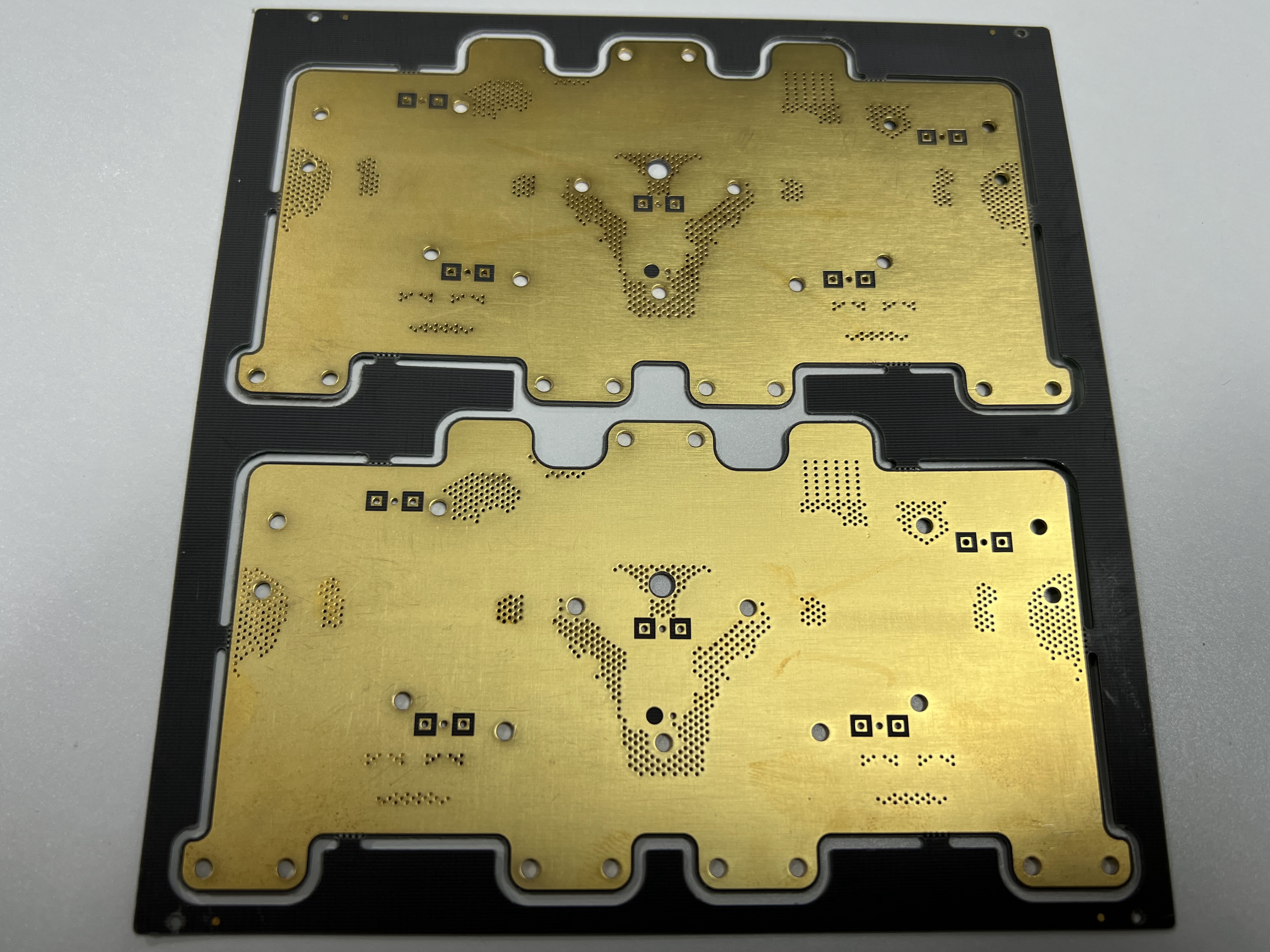

The electronics industry continues to see rapid growth in device complexity and shrinking form factors. High-Density Interconnect (HDI) technology stands at the center of these emerging trends in pcb technology. HDI PCBs use advanced integration techniques to fit more components into smaller spaces. This approach allows engineers to design compact, powerful devices for consumer electronics, medical technology, and automotive systems.

LT CIRCUIT leads the way in HDI PCB manufacturing. The company offers boards with 6 to 32 layers, supporting a wide range of applications. Their build-up technology, such as the 1+N+1 structure, enables compact layouts and the integration of more components. With a minimum hole size of 0.15mm and laser drilling down to 0.1mm, LT CIRCUIT achieves high precision for microvias. These features support high-speed performance and optimized PCB real estate.

Feature | Description |

|---|---|

Layer Capability | 6 to 32 layers for versatile applications |

Build-up Technology | 1+N+1 structure for compact integration |

Minimum Hole Size | 0.15mm for smaller vias |

Laser Drilling Hole Size | 0.1mm for precise microvias |

High Density Interconnector | More I/Os in a smaller footprint |

Rogers pcb materials play a crucial role in HDI and miniaturization. Rogers offers stable electrical properties and low dielectric loss, which are essential for high-speed signals in compact layouts. Rogers pcb enables shorter interconnects, reducing signal loss and crosstalk. The use of thinner rogers materials also results in lighter PCBs, which benefits aerospace and portable devices.

HDI technology, combined with rogers pcb, allows for up to 60% size reduction in PCBs. This advancement supports the ongoing demand for smaller, smarter, and more efficient electronics.

Engineers rely on rogers pcb for applications that require high component density and reliable signal integrity. Rogers supports the development of next-generation smartphones, wearables, and automotive electronics. These devices benefit from the superior performance and compactness that HDI and rogers pcb provide.

Nanocomposites and Dielectric Strength

Nanocomposite materials represent another key area in the emerging trends in pcb technology. Rogers continues to innovate by introducing advanced materials like the Rogers 6000 series and woven-glass-free laminates. These materials offer enhanced dielectric strength and improved thermal management, which are vital for high-frequency and high-power applications.

Rogers pcb materials in the 6000 series use nanocomposite technology to achieve low dielectric loss and stable performance at microwave and millimeter-wave frequencies. The absence of woven glass in some laminates reduces signal distortion and improves consistency across the board. Rogers pcb with nanocomposite layers supports the demands of 5G communications, aerospace, and automotive systems.

Rogers pcb with nanocomposites delivers higher dielectric strength, supporting higher voltages and frequencies.

Rogers pcb materials provide better heat dissipation, which protects sensitive components from thermal stress.

Rogers pcb enables precise impedance control, which is essential for high-speed digital and RF circuits.

Engineers choose rogers pcb for advanced applications that require both electrical and mechanical reliability. The combination of nanocomposite technology and rogers pcb materials ensures that devices can operate at higher speeds without sacrificing performance or safety.

Rogers pcb materials, such as the 6000 series, set new standards for dielectric strength and signal integrity. These innovations help manufacturers create compact, high-performance devices for the most demanding environments.

The use of rogers pcb in emerging trends in pcb technology supports the evolution of smart devices, IoT solutions, and next-generation communication systems. Rogers continues to drive progress by delivering materials that meet the needs of modern electronics.

Sustainability

Eco-Friendly Materials

Manufacturers now prioritize sustainability in rogers pcb production. Rogers supports the use of eco-friendly materials that reduce environmental impact. Halogen-free FR-4 and bio-based substrates have become popular choices. These materials offer low toxicity and come from renewable resources. The table below highlights some of the latest eco-friendly materials used in rogers pcb manufacturing:

Material Type | Description |

|---|---|

Halogen-free FR-4 | Low toxicity, reduced emissions |

Bio-based substrates | Derived from renewable resources |

A notable example involves the use of PLA biopolymer and cotton fabric in rogers pcb construction. PLA comes from renewable sources and is compostable. This approach provides a sustainable alternative to traditional FR-4 laminates. Rogers pcb designers select these materials to minimize waste and support environmental goals.

Rogers integrates environmental considerations into every decision. The company aims to economize on non-renewable resources and minimize adverse effects. Rogers pcb solutions help manufacturers meet sustainability targets while maintaining high performance.

Green Manufacturing

Rogers pcb production now features advanced green manufacturing processes. Rogers adopts lead-free soldering, using tin-silver-copper alloys to reduce toxic metals. Alternative etching solutions and dry etching techniques minimize chemical waste. Closed-loop systems recycle chemicals, cutting waste by up to 70%. Water recycling systems treat and reuse wastewater, reducing water usage by as much as 60%.

Strategy | Description |

|---|---|

Lead-Free Soldering | Uses tin-silver-copper alloys to reduce toxic metal usage |

Alternative Etching Solutions | Minimizes chemical waste with less toxic or dry etching techniques |

Closed-Loop Systems | Recycles and reuses chemicals, reducing waste |

Water Recycling Systems | Treats and reuses wastewater, lowering water consumption |

Rainwater Harvesting | Collects rainwater to reduce reliance on municipal supplies |

Biodegradable Substrates | Develops PCBs from biodegradable materials to reduce e-waste |

Recyclable Laminates | Uses easily recycled laminates to recover valuable materials |

Halogen-Free Materials | Adopts halogen-free alternatives to lower environmental risks |

Rogers pcb manufacturing also includes rainwater harvesting and optimized processes that cut water consumption. Rogers supports the development of biodegradable substrates and recyclable laminates. These efforts reduce long-term e-waste and recover valuable materials.

Rogers Corporation’s ESG Report shows a strong commitment to sustainability. The company supplies materials for electric vehicles and renewable energy, helping lower CO2 emissions. Rogers pcb production minimizes waste, recycles resources, and manages air and water impact. These initiatives improve environmental outcomes and support clean energy solutions.

Advanced Applications

5G and 6G

The demand for high-speed wireless communication continues to grow. Rogers pcb solutions play a vital role in 5G and 6G networks. These advanced materials support antennas, base stations, and backhaul radios. Rogers pcb materials like RO4350B offer low dielectric constant and low dissipation factor, which help maintain signal velocity and integrity. Engineers rely on rogers pcb for stable electrical performance and excellent thermal management, even in outdoor environments.

Property | Description |

|---|---|

Maintains high-frequency performance | |

Low Dissipation Factor (Df) | Reduces signal loss and heat |

Thermal Stability | Ensures reliability under temperature changes |

Moisture Absorption Resistance | Protects dielectric properties outdoors |

Rogers pcb enables high-speed data transmission in telecommunications. These advanced materials minimize signal loss and crosstalk, which is essential for network switches, routers, and data storage systems. LT CIRCUIT provides rogers pcb solutions for 5G antennas and flexible and rigid-flex pcbs, supporting the next wave of wireless technology.

Automotive and IoT

Automotive and IoT devices require advanced materials that deliver both reliability and performance. Rogers pcb materials like RO4003C support radar sensors and ADAS in vehicles. These advanced materials handle high frequencies and harsh conditions. Rogers pcb also supports embedded components, reducing size and weight in automotive electronics.

Industry | Application Example | Rogers Material |

|---|---|---|

Automotive | Radar Sensors | RO4003C™ |

IoT | Embedded Sensors, Gateways | RO4350B™, RT/duroid 5880 |

LT CIRCUIT manufactures rogers pcb for automotive radar and IoT gateways. Their advanced materials enable quick signal transmission and eco-friendly manufacturing. Flexible and rigid-flex pcbs from LT CIRCUIT meet the needs of compact, high-performance devices. Rogers pcb solutions support smart vehicles, industrial automation, and connected devices.

Rogers pcb and advanced materials drive innovation in 5G, automotive, and IoT applications. LT CIRCUIT delivers reliable solutions for next-generation electronics.

Market Drivers and Challenges

Adoption Factors

The adoption of rogers pcb materials in next-generation electronics continues to accelerate. Several market drivers shape this trend. The table below highlights the main factors:

Growing demand for consumer electronics |

Rising adoption of electric vehicles |

Advancements in medical technologies |

Manufacturers select rogers pcb for its ability to meet the needs of high-frequency and high-reliability applications. Regulatory standards, such as those from IPC, guide the selection of rogers materials. These standards emphasize properties like dielectric constant, dissipation factor, and thermal conductivity. Rogers pcb materials must meet these requirements to ensure performance in advanced electronics. Industry requirements also influence the choice of rogers. Designers consider thermal management, operational frequency, and cost. They often consult datasheets and work closely with fabrication partners to match rogers pcb materials to project needs.

Supply Chain

The supply chain for rogers pcb materials faces several challenges. Sourcing raw materials remains difficult due to the need for rare earth metals and specialized components. Logistic bottlenecks, such as container shortages and port congestion, can delay shipments and increase costs. Geopolitical tensions and trade policies sometimes disrupt the flow of rogers materials. Shortages of substrates and chemicals also impact rogers pcb manufacturing. Natural disasters, pandemics, or factory shutdowns may create further bottlenecks.

Manufacturers address these risks with several strategies:

Strategy | Description |

|---|---|

Diversify Suppliers | Source from multiple suppliers in different regions to minimize risks of shortages. |

Amass Inventory Buffers | Keep additional inventory of key materials to cushion against supply chain interruptions. |

Improve Tracking and Planning | Use GPS tracking for shipments to monitor progress and reroute if necessary. |

Find Local Warehousing | Lease warehouse space near production facilities for quick access to essential parts. |

Embrace AI and Automation | Utilize AI to enhance maintenance processes and prevent unexpected equipment failures. |

Upgrade Old Equipment | Stay updated on new manufacturing technologies to improve production efficiency. |

Continuously Train Workforce | Regular training sessions for staff on the latest technologies and best practices. |

These approaches help ensure a steady supply of rogers pcb materials for advanced electronics.

The rogers pcb market shapes next-gen electronics with rapid growth and innovation.

The global PCB market will reach $90.4 billion by 2028.

Multilayer PCB demand rises, driven by AI, IoT, and automotive electronics.

Rogers pcb enables high-frequency, reliable devices.

LT CIRCUIT Rogers PCB Innovation | Details |

|---|---|

Layer Count | |

Trace/Space | 3/3 mil for dense routing |

Microvia Size | 50μm laser-drilled microvias |

Quality Assurance | IPC-A-600 Class 3, traceability |

Custom Solutions | Surface finishes, rapid prototyping |

Rogers pcb supports future-ready solutions. Rogers pcb drives performance in every sector. Rogers pcb powers advanced applications. Rogers pcb ensures reliability in harsh environments. Rogers pcb delivers stable signal transmission. Rogers pcb meets industry standards. Rogers pcb adapts to evolving needs. Rogers pcb enables compact designs. Rogers pcb leads in sustainability. Rogers pcb defines the future of electronics.

LT CIRCUIT stands as a leader in rogers pcb innovation. Rogers pcb from LT CIRCUIT supports the next wave of technology. Explore LT CIRCUIT’s rogers pcb solutions for your next project.

FAQ

What makes rogers pcb materials ideal for high-frequency applications?

Rogers pcb materials provide stable dielectric properties. Rogers supports high-frequency signals. Rogers pcb reduces signal loss. Rogers ensures reliable performance. Rogers pcb enables advanced wireless communication. Rogers supports 5G and 6G.

How does rogers pcb improve thermal management in electronics?

Rogers pcb offers high thermal conductivity. Rogers dissipates heat efficiently. Rogers pcb maintains stability. Rogers prevents overheating. Rogers supports power electronics. Rogers pcb extends device lifespan. Rogers ensures safe operation.

Can rogers pcb support miniaturized and complex designs?

Rogers pcb enables compact layouts. Rogers supports HDI technology. Rogers pcb allows more components. Rogers maintains signal integrity. Rogers supports multilayer boards. Rogers pcb meets modern device needs. Rogers enables innovation.

See Also

Choosing The Right Pcb Materials For Communication Devices

Exploring Rogers R4350B R4003 R5880 For RFPCB Applications

Identifying Top Materials For High-Speed Pcb Development

Integrating Rogers Material With TG170 In Hybrid Pcb Designs