Understanding RoHS Compliance Standards in PCB Manufacturing

RoHS compliance standards ensure that electronics, such as PCBs, utilize fewer harmful materials. This not only helps keep people healthy but also protects the planet from toxic waste. Adhering to these standards allows you to sell in major markets like the EU. If you fail to comply, your products cannot be sold there.

Key Takeaways

RoHS rules reduce dangerous materials in electronics to protect people and nature.

Picking safe materials and improving how things are made is key for RoHS.

Working with companies like LT CIRCUIT helps get top-quality PCBs that follow RoHS rules worldwide.

What is the RoHS Compliance Standard in PCB Manufacturing?

Definition and origins of RoHS compliance standard

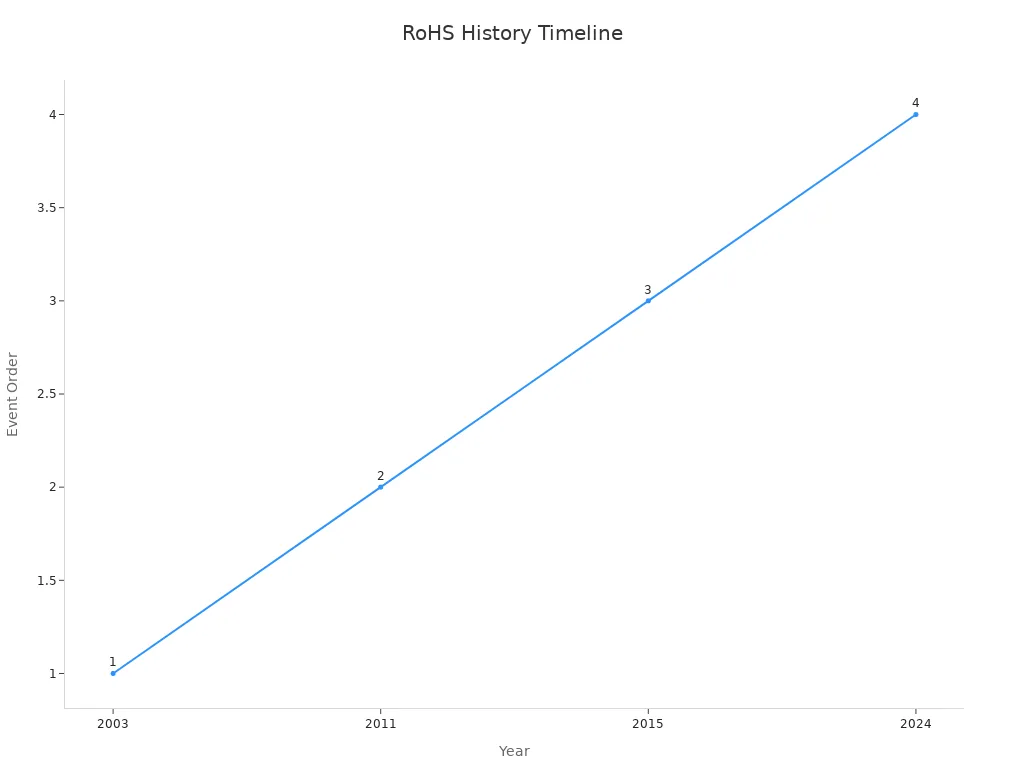

RoHS stands for "Restriction of Hazardous Substances." It started in the European Union. The rule was introduced in 2003 and enforced by July 1, 2006. Its goal was to reduce harmful materials in electronics. At first, it banned six dangerous substances like lead and mercury. These materials were harmful to people and the planet. Later, RoHS 2 (2011/65/EU) added CE marking rules. RoHS 3 (2015/863) included four more harmful chemicals called phthalates.

The first RoHS rule began on July 1, 2006. It banned six harmful materials in electronics. Updates like RoHS 2 and RoHS 3 added more rules and substances.

Here’s a simple timeline of RoHS changes:

Year | Directive | Key Changes |

|---|---|---|

2003 | 2002/95/EC (RoHS 1) | First rule banning six harmful materials. |

2011 | 2011/65/EU (RoHS 2) | Added CE marking and expanded rules. |

2015 | 2015/863 (RoHS 3) | Four new harmful chemicals were added to the list. |

2024 | Proposed (EU) 2024/232 | May include two more harmful substances. |

Importance of RoHS compliance in the electronics industry

RoHS rules are very important for electronics. They make products safer for people and better for the planet. Before RoHS, electronic waste had many toxic materials. These materials hurt the environment and people’s health. Now, RoHS encourages safer materials and greener manufacturing.

The need for RoHS-compliant products is growing worldwide. For example:

In 2023, the global compliance market was worth $4.6 billion.

By 2032, it may grow to $7.9 billion, with a 6.1% yearly growth rate.

This growth shows that people want eco-friendly products. Following RoHS rules helps companies sell in strict markets like the EU.

LT CIRCUIT’s commitment to RoHS-compliant PCB solutions

LT CIRCUIT is dedicated to following RoHS rules. All their circuit boards meet these strict standards. They use advanced methods to avoid harmful materials. This helps protect the planet and opens doors to global markets.

Here are some facts about LT CIRCUIT’s efforts:

Metric | Value |

|---|---|

Yes | |

Min. Trace Width/Spacing | 0.1mm |

Impedance Control | Yes |

By choosing LT CIRCUIT, you get safe, high-quality PCBs. These products meet modern needs and follow global environmental rules.

Restricted Substances and Their Impact on PCB Manufacturing

Overview of restricted substances under RoHS compliance standard

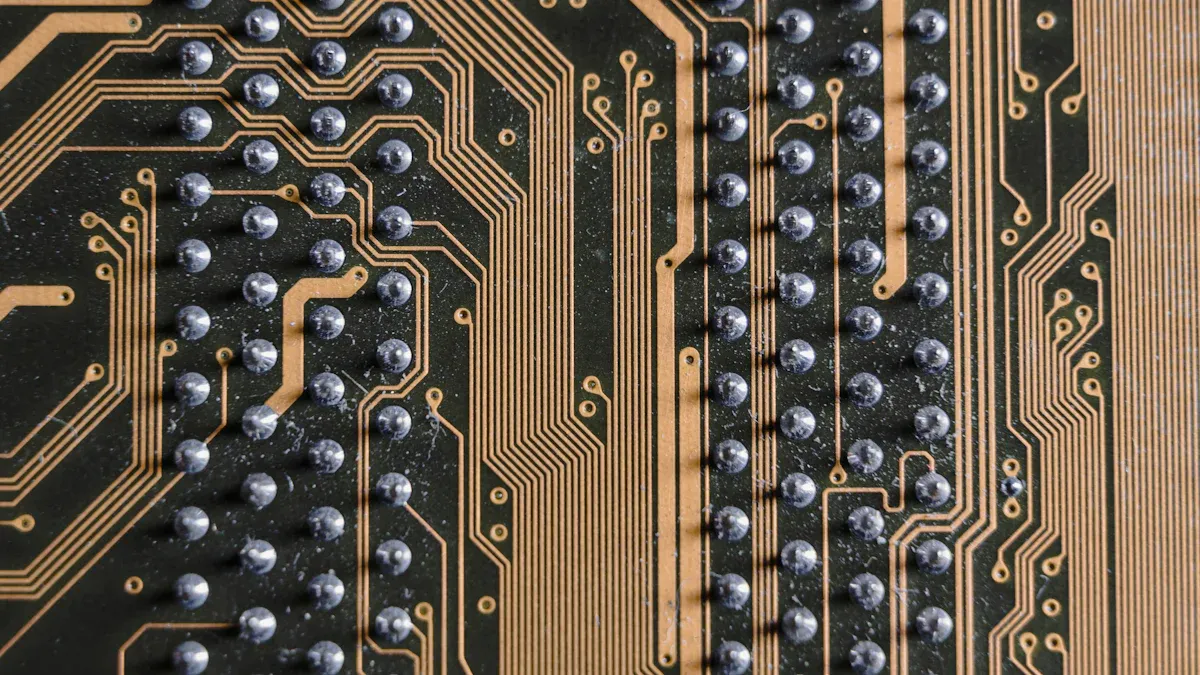

RoHS rules limit harmful materials in electronics. These include lead (Pb), mercury (Hg), cadmium (Cd), and hexavalent chromium (Cr6+). Some flame retardants like PBB and PBDE are also banned. RoHS 3 added four phthalates: DEHP, BBP, DBP, and DIBP. These materials can harm people and the planet. For example, lead damages the brain, and cadmium can cause cancer. By reducing these substances, RoHS makes electronics safer and cuts toxic waste.

Implications of restricted substances for PCB materials and processes

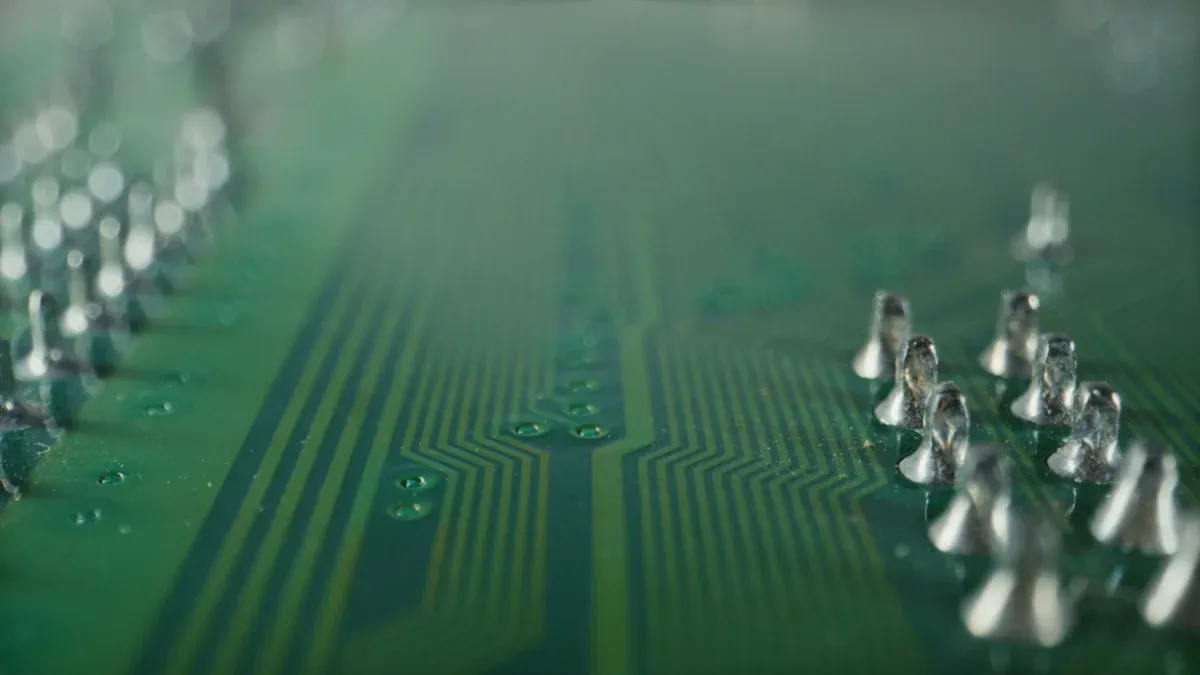

Banned materials change how PCBs are made. Old soldering methods used lead-based solder. Now, manufacturers use lead-free options like tin-silver-copper alloys. Surface finishes with hexavalent chromium are replaced by safer ones like immersion silver or ENIG. These changes need careful planning to keep products reliable. Manufacturers must also check that suppliers follow RoHS rules.

How LT CIRCUIT ensures compliance with restricted substance regulations

LT CIRCUIT works hard to follow RoHS rules. They use safe materials and eco-friendly methods. For example, they use lead-free solder and safe surface finishes. They also test their PCBs to ensure no banned substances are present. By choosing LT CIRCUIT, you get high-quality PCBs that meet global environmental standards.

Compliance Requirements for PCB Manufacturers

Choosing materials for RoHS compliance

Picking the right materials is the first step to follow RoHS rules. All parts and raw materials must not have banned substances like lead, mercury, or cadmium. To do this, work with reliable suppliers who give clear material details and certifications.

Here are steps to make it easier:

Check supplier documents: Ask for proof that materials meet RoHS rules.

Test materials: Use trusted labs to check for banned substances.

Keep records: Track where materials come from for future checks.

By focusing on materials, you can avoid breaking rules and make sure your PCBs meet global standards.

Changing manufacturing processes for RoHS compliance

Manufacturing methods must change to meet RoHS rules. Old ways, like using lead-based solder, are not allowed anymore. Instead, use lead-free solder, such as tin-silver-copper alloys. These are safer and work just as well.

Key changes to consider:

Use lead-free solder: Replace lead-based solder with safer options.

Update finishes: Choose eco-friendly finishes like immersion silver or ENIG.

Adjust temperatures: Lead-free soldering needs higher heat, so update tools.

These changes may cost more at first but help your products follow RoHS rules and sell better.

Keeping records and certifications for RoHS compliance

Good records are needed to prove you follow RoHS rules. You must keep details about materials, tests, and certifications. This shows you care about following the rules and helps during inspections.

Important steps include:

Testing: Use methods like XRF or lab tests to check for banned substances.

Process checks: Review your manufacturing steps to ensure they meet RoHS rules.

Organize documents: Keep a file with materials lists, test results, and certifications.

Step | What to Do |

|---|---|

Testing | Use XRF or lab tests to find banned substances. |

Process Check | Inspect manufacturing steps to ensure they follow RoHS rules. |

Document Review | Keep materials lists, test reports, and other important files. |

Certification | Get a RoHS Certificate of Compliance after passing audits. |

By following these steps, you can get a RoHS Certificate of Compliance. This is important for selling in global markets.

Tip: Always have your RoHS test reports ready. These reports explain the testing process and results, which are often needed during inspections.

Benefits and Challenges of RoHS Compliance

Environmental and safety benefits of RoHS compliance

RoHS compliance makes electronics safer and better for the planet. It limits harmful materials like lead and mercury. These substances can cause serious health problems. For example, lead can harm children’s brain development. By following RoHS rules, your products help reduce toxic waste. This means cleaner factories and less pollution in landfills. A healthier environment benefits everyone.

Using safer materials also protects workers. Employees handle fewer dangerous substances, making their jobs safer. This improves workplace conditions and supports global eco-friendly goals.

Market access and competitive advantages for RoHS-compliant products

Meeting RoHS rules helps you sell in global markets. Many places, like the EU, require RoHS compliance to sell products. Without it, you miss out on these big markets. Also, more people want eco-friendly products. Offering RoHS-compliant items attracts these buyers.

The demand for RoHS testing is growing as companies focus on compliance. This trend creates chances for businesses in electronics and cars. By following RoHS rules, your company shows leadership in green practices and innovation.

Challenges in achieving RoHS compliance, including cost and material compatibility

Following RoHS rules can be hard and costly. Switching to lead-free solder or new finishes needs money for materials and tools. Testing parts to meet the rules also takes time and money.

Here’s a cost breakdown:

Description | Calculation | Cost |

|---|---|---|

Engineering time per product | 1.0 to 1.5 hours | $225/product |

Total products per BOM | 50-100 products | $16,000 |

Total products across a company | 20-30 products | $400,000 |

These costs can be high, especially for small businesses. But the benefits, like selling in more markets and gaining customer trust, make it worth the investment.

How to Ensure RoHS Compliance in PCB Manufacturing

Steps for implementing RoHS-compliant processes

To follow RoHS rules, focus on three main steps: picking materials, changing how you make products, and testing. First, choose materials that meet RoHS standards. Work with suppliers who give proof and clear details about their products. This helps keep banned substances out of your materials.

Next, update your production methods. Stop using lead-based solder and switch to safer options like tin-silver-copper alloys. Change your tools to handle the higher heat needed for these materials. Lastly, test your products often to check for compliance. Use tools like X-ray fluorescence (XRF) to find banned substances.

Tip: Teach your team about RoHS rules so everyone knows why they matter.

Tools and resources for verifying RoHS compliance

You need good tools and resources to check compliance. Software and testing tools can make this easier. Here’s a quick list:

Resource | What It Does |

|---|---|

Tracks your supply chain to ensure it follows RoHS rules. | |

Understanding RoHS Compliance | Offers testing and reports to help with inspections. |

RoHS Guide | Gives software for tracking, risk checks, and compliance reports. |

These tools help you find problems, prove compliance, and get ready for audits. They make following RoHS rules simpler.

Partnering with LT CIRCUIT for RoHS-compliant PCB solutions

Working with LT CIRCUIT ensures your PCBs meet RoHS rules. They use safe materials and eco-friendly methods to make high-quality PCBs. Their strict testing ensures no banned substances are in their products. Choosing LT CIRCUIT gives you reliable solutions that meet global environmental standards.

Note: LT CIRCUIT’s knowledge of RoHS rules makes them a trusted choice for eco-friendly businesses.

The RoHS rules changed how PCBs are made. They encourage using safer materials and greener methods. This helps the environment and keeps people healthy. Following these rules supports sustainability and opens global markets. It also helps businesses grow over time. These changes are good for makers, buyers, and the Earth.

FAQ

What does RoHS mean, and why does it matter?

RoHS stands for "Restriction of Hazardous Substances." It helps make electronics safer for people and the planet. Harmful materials like lead and mercury are limited.

How do you check if a PCB follows RoHS rules?

You can check by looking at supplier certifications and testing materials. Also, make sure there’s a valid RoHS Certificate of Compliance.

Tip: Ask suppliers for clear documents to confirm they follow the rules.

Does following RoHS rules change how products work?

No, following RoHS rules doesn’t lower product quality. Manufacturers use better materials and methods to keep performance high while protecting the environment.

See Also

Why RoHS Compliance Matters in Today's PCB Production

Selecting a Reliable PCB Manufacturer for Your Company

Key Considerations When Designing PCB Circuit Boards