Single-Layer, Double-Layer, and Multilayer Flexible PCBs Compared

Single-layer, double-layer, and multilayer flexible PCBs each have unique structures, circuit complexity, and applications. Single-layer PCBs are ideal for simple devices, while double-layer PCBs provide additional circuit paths for more complex electronics. Multilayer flexible PCB designs are essential for high-density and advanced electronic applications, offering superior performance and versatility. LT CIRCUIT specializes in innovative and high-quality multilayer flexible PCB solutions, earning the trust of leading industries worldwide.

Key Takeaways

Single-layer flexible PCBs are easy to use and light. They do not cost much money. They work well for simple devices. These devices need to bend a lot. They also need to fit in small spaces.

Double-sided flexible PCBs have more circuit paths. They are stronger than single-layer ones. They are good for electronics that are not too simple. These include smartphones and medical devices.

Multilayer flexible PCBs can handle advanced circuits. They work for powerful devices like tablets and cars. They are also used in aerospace equipment. They give better performance and last longer.

Flexible Printed Circuits Overview

What Are Flexible Printed Circuits

Flexible printed circuits are thin and can bend easily. They do not break when twisted or bent. Engineers use them in many new devices. These circuits fit into small spaces. They also move with the device. The electronics industry sorts flexible printed circuits by their shape and how many layers they have.

Single-sided flexible PCBs have one layer that conducts electricity. This layer sits on a flexible polyimide base.

Double-sided flexible PCBs have two layers that conduct electricity. Each layer is on a different side of the base. Plated through holes or vias connect these layers.

Multi-layer flexible PCBs have three or more layers. Plated through holes connect all the layers. These are used for more complex circuit designs.

Rigid-flex PCBs mix stiff and bendable parts. This gives both strength and flexibility.

HDI flexible PCBs use high-density interconnects and micro-vias. They also use thinner bases for better performance.

These types help designers pick the best pcb for each job.

Key Benefits

Flexible printed circuits have many good points over rigid pcb options. They can bend and fit many shapes. This makes them great for wearable tech and handheld gadgets. They also work well in things that shake or get bumped. Flexible circuits need fewer connectors and cables. This makes assemblies smaller, lighter, and easier to put together. Fewer connection points mean they last longer and break less often.

Manufacturers like flexible pcb solutions because they are easy to put together. There are fewer connectors and cables to test. This saves money and time. These benefits help companies make new products that look better and cost less over time.

Single-Layer Flexible PCBs

Structure and Features

A single-layer pcb has a basic design with one conductive layer. This layer is placed on a bendable base, usually polyimide or polyester film. The conductive layer is usually copper foil. Rolled-annealed copper is best for things that bend a lot. Electro-deposited copper is better for things that do not move. Adhesives like acrylic or epoxy glue the layers together. A coverlay made from polyimide protects the circuit from water and damage. Some single-layer fpcs have stiffeners for more support or EMI shielding for sensitive parts. This design lets single-sided boards bend but also stay strong.

Advantages

Single-layer fpcs have many good points:

They are smaller and lighter because they use thin bases and no big connectors.

These pcbs can wrap around parts, making devices up to half as small.

Fewer parts and steps mean lower assembly costs, saving up to one-fifth on labor.

They can bend and twist, so designers can make creative shapes in tight spaces.

Single-sided boards weigh about one-tenth of old wired solutions, which helps them handle shocks and bumps.

Fewer parts and easy setup mean less fixing and fewer mistakes.

Note: The simple design of single-layer pcb makes them a smart and cheap choice for many uses.

Applications

Many fields use single-layer fpcs because they last long and work well. The table below lists common uses:

Industry | Typical Applications and Devices |

|---|---|

Consumer Electronics | Mobile phones, wearable devices, cameras |

Medical Equipment | Hearing aids, pulse generators |

Automotive & Power | Relays |

Household Appliances | Coffee machines, microwave ovens |

LED Lighting | LED lighting systems |

Sensors | Sensor devices |

Security | Security monitors |

Power Supplies | Digital and analog power supplies |

Single-sided boards are great for products that need to be light, small, and bendable.

Double-Sided PCBs

Structure and Features

Double-sided pcbs have circuits on both sides of one flexible base. This is different from single-layer pcbs, which only have circuits on one side. Plated via holes connect the two sides, so signals can move between them. Making these boards needs careful alignment. The extra layer makes the board more complex and costs more. But it lets engineers design more advanced circuits. Double-sided fpcs can hold more parts and traces in a small space. The structure usually has:

Conductive traces on both sides of the flexible base

Asymmetrical layers, which can change how much the board bends

Careful layout to stop circuits from overlapping and to keep the board strong

Note: Double-sided fpcs do not bend as much as single-layer types, but they give more ways to design and are tougher.

Advantages

Double-layer fpcs have many good points over single-layer boards. They let engineers put more parts in a small area. Vias and traces on both sides help with routing and make the board work better. Devices can be smaller and lighter because double-sided fpcs help shrink the size. These boards can handle harder circuits and manage heat better. The table below shows the main advantages:

Performance Aspect | Double-Sided PCB Advantages |

|---|---|

Parts go on both sides for harder designs | |

Routing Capabilities | Vias connect traces, so fewer jumper wires are needed |

Electrical Performance | Better signal quality and works for fast circuits |

Space Utilization | Makes layouts better for small devices |

Durability | Gets stronger with good materials and lamination |

Applications

Double-sided fpcs are used in many new electronics. Consumer products like smartphones, smartwatches, and earbuds use these boards for small and strong connections. Medical devices such as wearable monitors and hearing aids use double-sided pcbs because they are small and last long. Cars use double-layer fpcs in dashboards, sensors, and control units. Aerospace and defense gear, like satellites and drones, need double-sided pcbs for light weight and to resist shaking. Industrial robots and machines also use these boards because they are tough and can handle hard jobs.

Industry | Applications & Examples |

|---|---|

Consumer Electronics | Smartphones, wearables, earbuds, foldable screens |

Medical Devices | Wearable monitors, hearing aids, implants |

Automotive | Dashboards, sensors, control units |

Aerospace & Defense | Satellites, drones, military equipment |

Industrial | Robotics, automation systems |

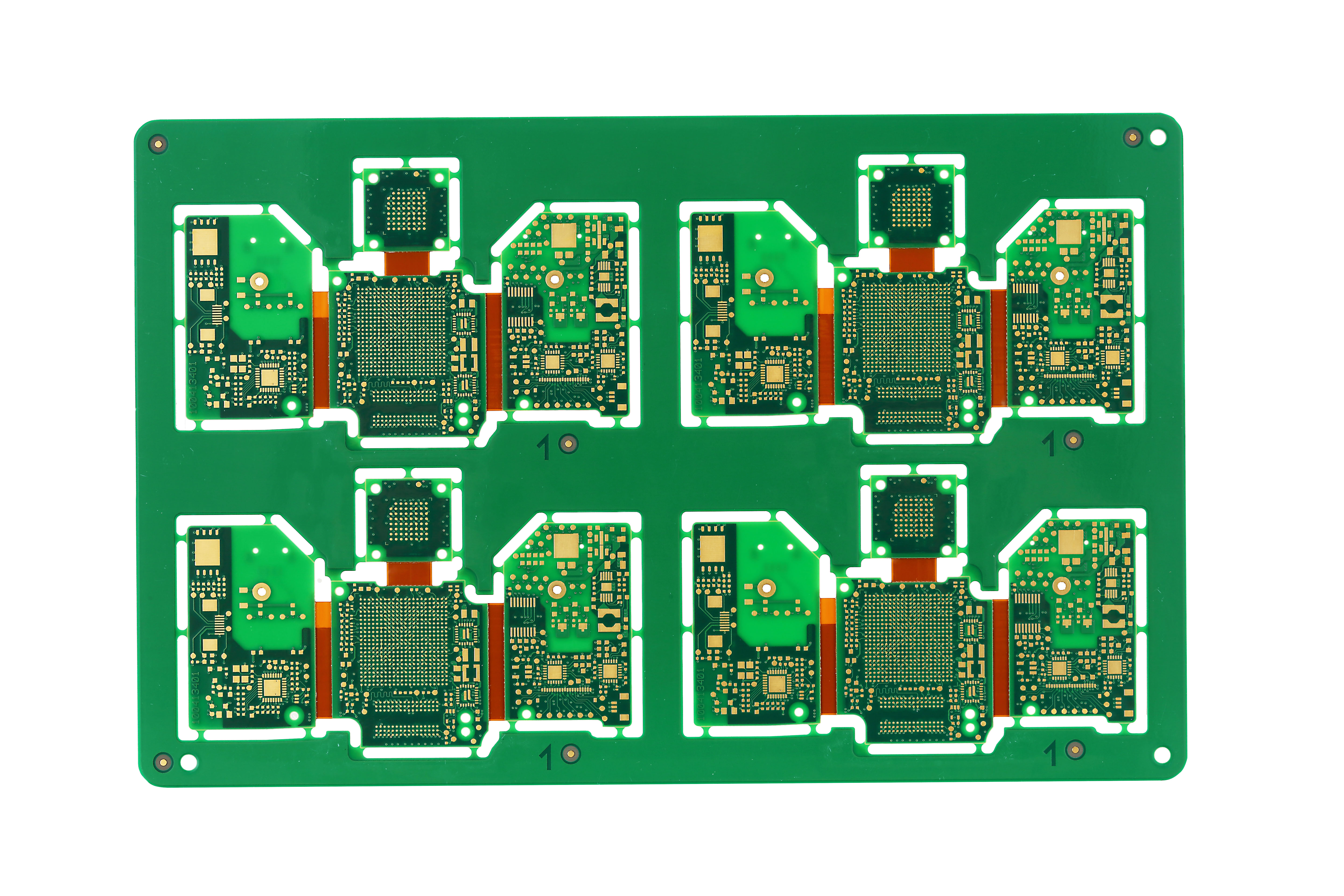

Multilayer Flexible PCB

Structure and Features

A multilayer flexible pcb has three or more copper layers. These layers are separated by thin insulating films. Polyimide films make the board bend and stay even. Copper foils, like 0.5oz or 1oz, create the paths for electricity. Flexible Copper-Clad Laminates stack the copper and polyimide together. Bondply, made from polyimide and glue, holds the layers in place. Plated through-holes link the layers so signals can move. Coverlay and special films protect the copper from harm. Stiffeners, such as FR4 or aluminum, give extra support where needed. LT CIRCUIT uses strong materials to make the boards last longer. They use laser drilling and careful tools to build complex designs.

Advantages

Multilayer flexible pcb designs have many good points. They let engineers put more circuits in a small space. Power and ground planes help cut down noise and make signals better. Shorter wires help signals move fast and stay clear. The layers help block outside signals and keep signals safe. These boards work well with fast circuits and smart chips. LT CIRCUIT uses new ideas like microvias and HDI technology. They add coatings to stop water and heat damage. They check each board with AOI and X-ray to make sure it is strong and works well.

Applications

Many top industries use multilayer flexible pcb solutions. These boards are in smartphones, tablets, and smartwatches because they are thin and bendy. Cars use multilayer fpcs for control, batteries, and safety. Medical devices, like monitors and endoscopes, need these boards to last and fit tight spaces. Planes and satellites use them for controls and to handle heat and shaking. Robots, game consoles, and LED screens also use these boards for better results.

Industry | Application Details and Requirements |

|---|---|

Smartphones, tablets, smartwatches, health bands; valued for flexibility and thinness. | |

Automotive Electronics | Control systems, engine management, safety, battery management; needs high reliability and heat resistance. |

Medical Devices | Monitors, ultrasound, endoscopes; needs stability and ability to fit complex shapes. |

Aerospace | Avionics, satellite systems; must withstand extreme temperatures and vibration. |

Military & Defense | Requires high durability and reliability in harsh conditions. |

Industrial Control | Automation, robotics; connects sensors and controllers for complex processes. |

Consumer Electronics | Cameras, gaming consoles, e-readers; improves performance and reliability. |

Lighting & Display | LED lighting, OLED displays; controls panels for high-quality effects. |

LT CIRCUIT is a leader by making custom multilayer fpcs with strong materials and careful checks. Their skills help many companies get good, high-performing boards.

Comparison

Summary Table

PCB Type | Structure | Cost | Complexity | Applications | Durability | Flexibility | Manufacturing Time |

|---|---|---|---|---|---|---|---|

Single-layer FPC | One copper layer on flexible substrate | Low | Low | Basic circuits, printers, scanners, displays | Low | High | Short |

Double-sided FPC | Two copper layers, connected by vias | Moderate | Moderate | Mobile phones, cameras, medical devices | Moderate | Moderate | Moderate |

Multilayer FPC | Three or more copper layers, bonded by vias | High | High | High | Moderate | Long |

This table helps you see how each pcb type is different. They do not all have the same structure, cost, or use. Single-layer boards are the easiest and can bend a lot. Double-sided boards have more wires and can do harder jobs. Multilayer fpcs are for the toughest tasks.

Key Differences

Single-layer flexible PCBs have a simple build. They use one copper layer on a bendy base. This makes them cheap and fast to make. These boards are best for easy circuits in things like printers and displays. They bend the most but are not as strong. They also cannot hold many wires.

Double-sided pcbs have two copper layers, one on each side. Vias connect the layers together. This lets them hold more wires and do harder work. Double-sided boards cost more than single-layer ones. They can fit more parts and work better. Many wearables, phones, and medical tools use double-sided pcbs. These boards are a good mix of bending and strength. They also help make devices smaller.

Multilayer flexible pcb designs use three or more copper layers. Thin films keep the layers apart. Vias connect all the layers. Making these boards takes more steps and time. This makes them cost more. But multilayer fpcs can hold lots of wires and make signals better. They are needed for small, powerful devices like smartphones and medical tools. These boards last longer and handle heat well. They do not bend as much as single-layer boards.

LT CIRCUIT can make any kind of flexible pcb you need. Their team uses special tools like lasers and drills for tiny spaces. LT CIRCUIT lets you pick finishes, colors, and stiffeners. Their engineers help you choose the best materials and layout. They check every pcb with AOI and X-ray to make sure it works. This helps customers in many fields get the right pcb for their needs.

Single-layer boards are good for easy, cheap projects.

Double-sided boards work for medium jobs that need more wires.

Multilayer boards are for small, powerful, and tough electronics.

LT CIRCUIT helps every customer get a pcb that fits their project, from simple boards to the most advanced multilayer pcb designs.

Multi-Layer PCB Selection Guide

Factors to Consider

Picking the right pcb for a project is important. Engineers need to think about how hard the circuit is. They also look at how many parts go on the board. What the device does matters too. Some projects only need simple boards. Others need advanced multilayer flexible pcb designs. The table below shows how each flexible pcb type is different:

Factor | Single-Layer PCB | Double-Sided PCB | Multilayer / Flexible PCB |

|---|---|---|---|

Circuit Complexity | Simple circuits with few parts | More complex circuits with vias and two layers | Highly complex, high-speed circuits with many layers |

Component Density | Low; needs more space | Higher; parts on both sides save space | Very high; fits many parts in small areas |

Performance Needs | Good for basic, low-speed jobs | Better for faster, more reliable circuits | Best for high-speed, low-noise, and shielded circuits |

Budget | Lowest cost | Moderate cost | Highest cost |

Manufacturing Capability | Easy to make | Needs better tools | Needs special tools and skills |

Application Type | Simple, low-cost devices | Phones, cars, medical tools | Telecom, wearables, aerospace, medical implants |

Additional Notes | Not for tight spaces or complex jobs | Good balance of size and power | Up to 32 layers; best for bendable, light designs |

Tip: Always pick the pcb that fits your project. For example, a smartwatch needs a small, packed board. A simple LED light can use a single-layer pcb.

Engineers should also think about how much the board will bend. They need to know where to put stiffeners. They must protect the board from heat and water. Traces should not go in places that bend a lot. Each layer should use the right material. Testing a sample board helps find problems before making many boards.

Cost and Complexity

The price and difficulty of a pcb depend on its layers and build. Single-layer boards are the cheapest and easiest to make. Double-sided boards cost more and need extra steps. These steps include drilling holes and adding copper to both sides. Multilayer pcbs cost the most. They have many layers and need special materials. Making them takes careful work.

PCB Type | Cost Level | Manufacturing Complexity | Description |

|---|---|---|---|

Single-layer | Lowest | Simplest | One layer; best for easy circuits and low budgets. |

Double-sided | Moderate | Moderate | Two layers; fits more parts and wires; costs more. |

Multilayer | Highest | Most Complex | Many layers; supports advanced designs; needs expert tools and skills. |

Note: Harder circuits and better performance mean higher costs. They also take longer to make. Planning ahead helps save money and avoid mistakes.

LT CIRCUIT Solutions

LT CIRCUIT helps customers pick the best pcb for their project. Their engineers listen to what each project needs. They suggest the right board, from simple single-layer to complex multilayer flexible pcb. LT CIRCUIT uses top tools and strong materials to make good boards. They offer custom choices, like special finishes, stiffeners, and testing.

LT CIRCUIT helps customers at every step:

They check what the project needs and suggest the best design.

They help pick the right materials and plan the layers.

They give samples and test boards for checking.

They use strict checks, like AOI and X-ray, to make sure every board works.

Customers trust LT CIRCUIT for smart advice and custom solutions. Their skill with multilayer pcbs and flexible boards helps companies make better products, from medical tools to smart gadgets.

PCB Type | Structure | Key Benefit | Typical Use |

|---|---|---|---|

Single-Layer | One flexible layer | Easy to make, low price | Used in displays, sensors |

Double-Sided | Two layers, via holes | More links, saves space | Used in wearables, medical |

Multilayer | Stacked flexible layers | Fits more parts, advanced | Used in phones, cars |

Picking the right type helps your project work well and last long. It also helps save money.

LT CIRCUIT gives smart help and new ideas for any flexible circuit problem.

Engineers count on LT CIRCUIT for good results and special designs they can trust.

FAQ

What is the main difference between single-layer and multilayer flexible PCBs?

Single-layer PCBs have just one copper layer. Multilayer PCBs have at least three layers. Multilayer types can handle harder circuits and work better.

Can flexible PCBs be used in high-temperature environments?

Flexible PCBs with polyimide bases can handle high heat. LT CIRCUIT uses special materials to make them resist heat even more.

How does LT CIRCUIT ensure the quality of flexible PCBs?

LT CIRCUIT checks every board with AOI and X-ray.

Engineers test each board to make sure it is strong and works well.

Customers always get products that are safe and high quality.

See Also

Understanding Differences Between Single, Double, And Multilayer PCBs

How Multilayer Rigid-Flex Circuit Boards Are Manufactured

Exploring Various Industry Uses For Multilayer PCBs Today