Single-Sided vs Double-Sided vs Multilayer PCBs Explained

Printed circuit boards (PCBs) are key parts of electronics. However, not all PCBs are alike. Single-sided PCBs are simple to use, while DOUBLE SIDED PCBs connect better than single-sided ones. Multilayer PCBs work best for complex tasks. The PCB market may reach $123.5 billion by 2033. Picking the right PCB saves money and works efficiently.

Key Takeaways

Single-sided PCBs cost less and are simple to make. They work well for basic gadgets like radios and calculators.

Double-sided PCBs handle more complex designs and stronger links. They are great for things like phones and HVAC systems.

Multilayer PCBs are strong and work really well. They are used in advanced tech like telecom and space tools.

Single-Sided PCBs: Definition and Characteristics

What Are Single-Sided PCBs?

A single-sided PCB is the easiest type of circuit board. It has one layer of copper on one side. The other side is non-conductive and acts as the base. These boards are great for simple designs where parts don’t overlap. They are popular in basic electronics because they are cheap and easy to make.

Key Features of Single-Sided PCBs

Single-sided PCBs have special traits that make them useful.

Single-layer PCB structure: Only one copper layer is used.

Easy to make: The design process is simple and quick.

Low cost: Making these boards costs less than other types.

Simple designs: Best for circuits that aren’t complicated.

Advantages of Single-Sided PCBs

Single-sided PCBs offer many benefits for basic uses.

Affordable pricing: Their simple design keeps costs low.

Fast production: These boards are quicker to make than others.

Easy to fix: Problems are easier to spot with parts on one side.

Good for beginners: Great for learning circuit board design.

Applications of Single-Sided PCBs

Single-sided PCBs are used in devices with simple circuits.

Consumer electronics: Radios, calculators, and LED lights use them.

Home appliances: Toasters and coffee makers often have these boards.

Automotive systems: Simple car sensors and controls use single-sided PCBs.

Industrial equipment: Cheap machine parts often include these boards.

Double-Sided PCBs: Features and Benefits

What Are Double-Sided PCBs?

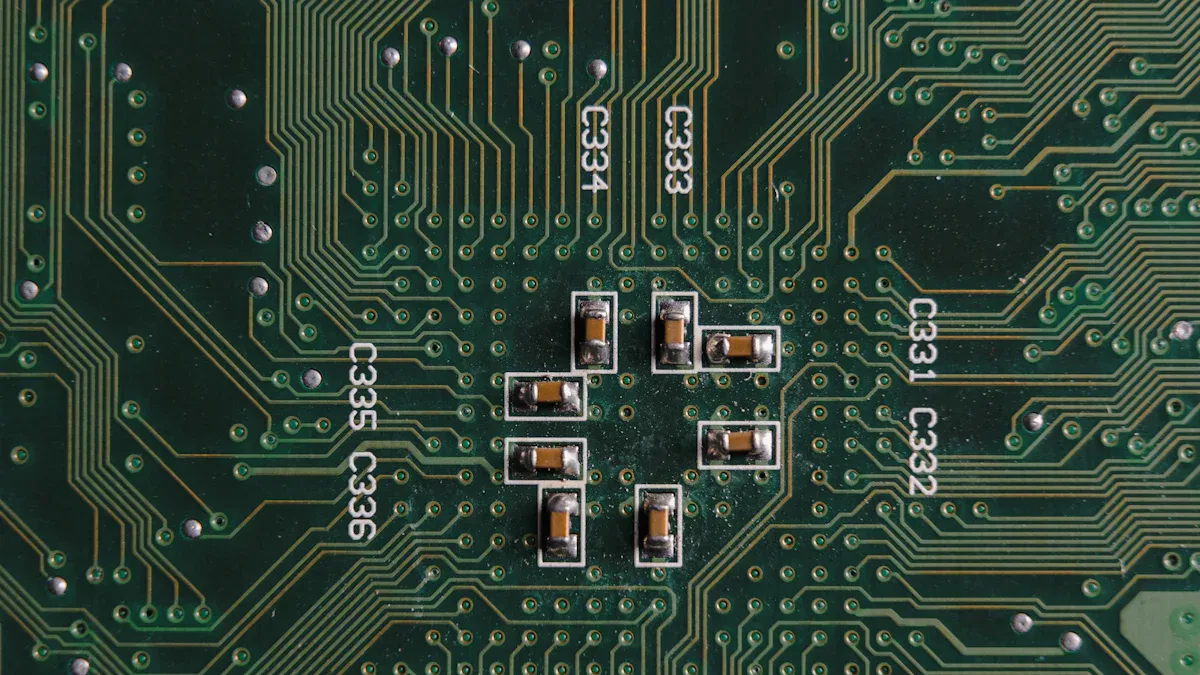

A double-sided PCB has copper layers on both sides. Unlike single-sided boards, parts can go on both surfaces. This allows for more complex circuits and better connections. These boards are common in modern electronics because they are flexible and efficient.

Characteristics of Double-Sided PCBs

Double-sided PCBs have special features for advanced uses:

Two copper layers: Both sides hold circuits, increasing design space.

Through-hole method: Holes link parts on the top and bottom.

Better connections: Tracks and holes join parts for detailed designs.

Material effects: Things like air bubbles and copper texture affect performance.

Advantages of Double-Sided PCBs

Double-sided PCBs have many helpful benefits:

More complex circuits: They allow for detailed and advanced designs.

Smaller size: Using both sides saves space in devices.

Affordable option: They balance cost and functionality well.

Improved performance: They handle heat better and connect parts efficiently.

Applications of Double-Sided PCBs

Double-sided PCBs are used in many fields:

Electronics: Phones use them for compact and smart designs.

HVAC systems: They help heating and cooling machines work well.

Power supplies: UPS systems use them for better performance.

Aerospace: Autopilot systems use them to manage heat in GPUs.

Double-sided PCBs are affordable, flexible, and efficient, making them ideal for today’s electronics.

Multilayer PCBs: Advanced Solutions by LT CIRCUIT

What Are Multilayer PCBs?

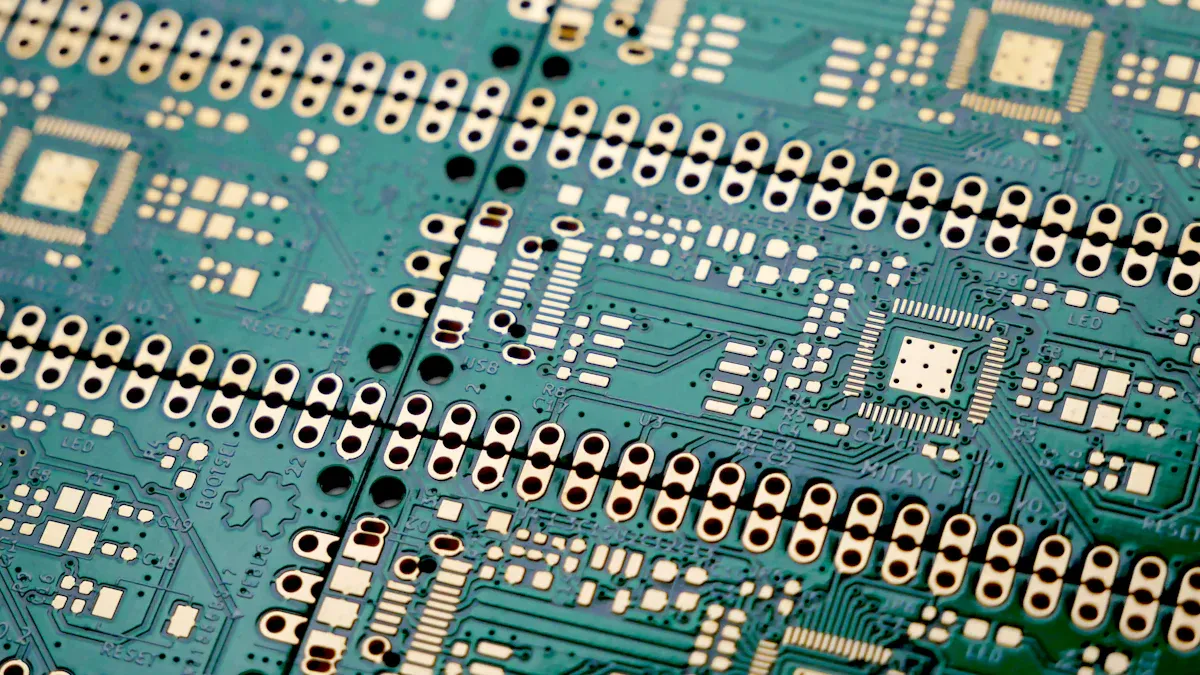

A multilayer PCB has three or more conductive layers. These layers are stacked with insulating materials in between. This design allows for small and complex circuits. Unlike single-sided or double-sided boards, multilayer PCBs work better for advanced electronics.

At LT CIRCUIT, these boards are made carefully for modern needs. They handle tough circuits while staying reliable and efficient. Whether you need 4 layers or 40 layers, LT CIRCUIT offers options to fit your requirements.

Characteristics of Multilayer PCBs

Multilayer PCBs have unique traits that make them special:

Layer Count: They can have 4 to over 40 layers for complex designs.

Materials Used: Strong materials like FR-4 and Polyimide ensure durability.

Compact Design: Stacked layers save space for small, powerful devices.

Enhanced Signal Integrity: Layers close together reduce noise and improve signals.

Here’s a quick look at multilayer PCB details:

PCB Type | Description | Typical Applications | Layer Count | Materials |

|---|---|---|---|---|

Multilayer PCBs | High-end computing, telecommunications, industrial control systems | 4 to 40+ | FR-4, High Tg FR-4, Polyimide |

Advantages of Multilayer PCBs

Multilayer PCBs have many benefits for advanced electronics:

High Performance: They offer great signal quality and heat control.

Space Efficiency: Their design fits more parts into smaller spaces.

Durability: Strong materials make them last longer.

Versatility: They work well in many industries, like telecom and aerospace.

This table shows how multilayer PCBs compare to other types:

Metric | Multilayer PCBs | Double-Layer PCBs | Single-Layer PCBs |

|---|---|---|---|

Signal Integrity | High | Moderate | Low |

Thermal Management | Excellent | Good | Poor |

Mechanical Strength | High | Moderate | Low |

Multilayer PCBs are also cost-effective for big production runs. Here’s a cost comparison:

Production Volume | Multilayer PCBs Cost (USD) | Double-Layer PCBs Cost (USD) | Single-Layer PCBs Cost (USD) |

|---|---|---|---|

1-10 units | 100-200 | 50-100 | 20-50 |

11-100 units | 500-1000 | 200-500 | 100-200 |

101-1000 units | 2000-5000 | 1000-2000 | 500-1000 |

Applications of Multilayer PCBs

Multilayer PCBs are used in many industries because they perform well. Common uses include:

High-End Computing: Servers and data centers need their processing power.

Telecommunications: Phones and network tools use them for compact designs.

Industrial Control Systems: They ensure machines and automation systems work reliably.

Aerospace and Defense: Radar and avionics benefit from their strength and precision.

A study showed multilayer 3D electronics can deposit molten metal drops on demand. This improves scalability and reduces waste, helping the environment. Vertical vias and custom setups show their flexibility for different uses.

Comparing Single-Sided, Double-Sided, and Multilayer PCBs

Structural Differences

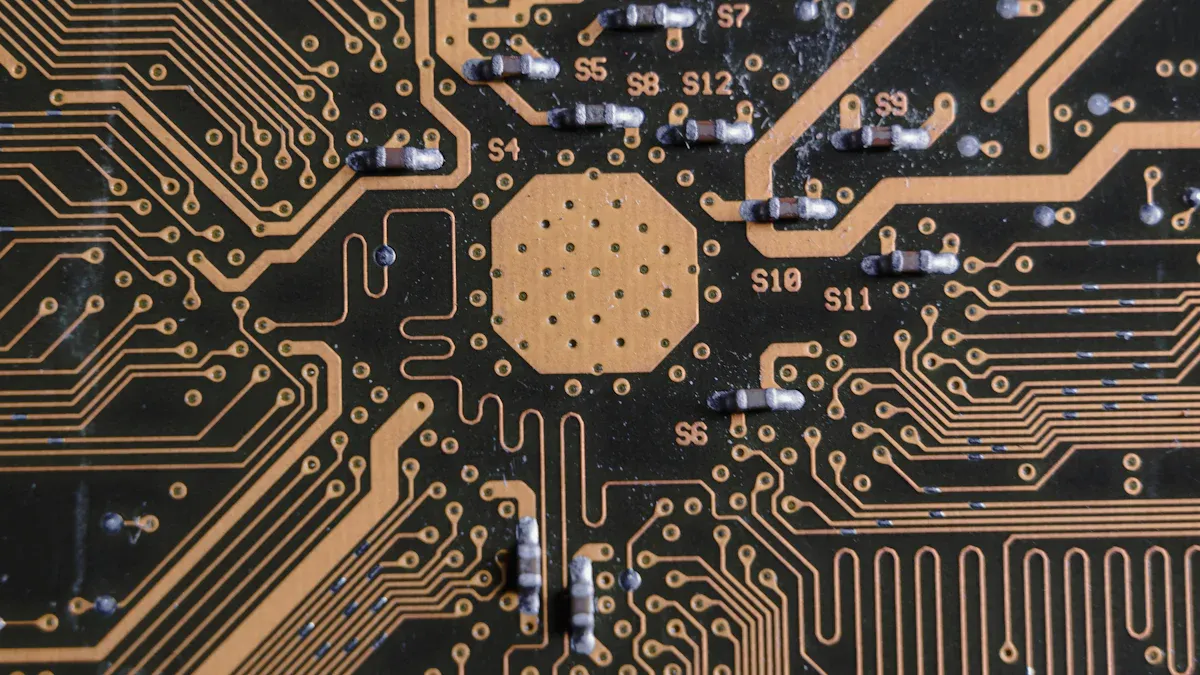

The way a PCB is built affects how it works. Single-sided PCBs are simple, with parts on one side and copper on the other. Double-sided PCBs have copper on both sides and use vias to connect layers. Multilayer PCBs stack three or more layers with insulation between them.

Here’s a quick look at their structures:

Type of PCB | Description | Applications |

|---|---|---|

Single-Sided | Basic design with parts on one side. | Cameras, Audio devices, Power supplies, etc. |

Double-Sided | Parts on both sides, connected with vias. | More complex gadgets needing extra space. |

Multilayer | Stacked layers for advanced circuit designs. | High-tech electronics with detailed layouts. |

Multilayer PCBs are compact and handle dense circuits well, perfect for modern tech.

Cost and Complexity

PCB costs and difficulty depend on their type. Single-sided PCBs are cheapest because they’re easy to make. Double-sided PCBs balance cost and features, good for medium-level uses. Multilayer PCBs cost the most but work best for advanced devices.

This table shows the differences:

Factor | Single-Sided | Double-Sided | Multilayer |

|---|---|---|---|

Component Density | Low | Medium | High |

Layer Count | 1 | 2 | 3+ |

Assembly Difficulty | Easy | Medium | Hard |

Cost | Low | Medium | High |

Build Time | Short | Medium | Long |

Pick a PCB based on your budget and project needs. Single-sided PCBs are great for simple tasks. Double-sided PCBs fit mid-level projects. Multilayer PCBs are worth it for top performance.

Performance and Functionality

How well a PCB works matters a lot. Single-sided PCBs are fine for basic uses but lack advanced features. Double-sided PCBs improve connections and heat control, ideal for medium-level devices. Multilayer PCBs are best for signal quality, heat handling, and strength, great for high-tech industries.

Multilayer PCBs are used in aerospace and defense because they handle tough conditions. Their stacked layers reduce noise and improve signals, making them reliable for hard tasks.

Common Use Cases

Each PCB type fits certain jobs based on its design. Single-sided PCBs are used in simple gadgets like cameras and speakers. Double-sided PCBs are flexible and made up 36% of global revenue in 2023, especially in cars. They’re great for lights and power systems. Multilayer PCBs are chosen for advanced fields like telecom, aerospace, and modern electronics.

Here’s a market overview:

PCB Type | Market Trends |

|---|---|

Multilayer | Leads the market with compact designs for modern devices. |

Double-sided | Big in cars, making up 36% of global revenue in 2023. |

Single-sided | Less common, mainly used in basic electronics. |

Multilayer PCBs are growing in aerospace for their strong materials and small size. Double-sided PCBs are affordable for car systems. Single-sided PCBs are best for simple electronics.

Picking the right PCB depends on what your project needs. Single-sided PCBs are good for simple and cheap devices. Double-sided PCBs work well for medium-complexity items like phones. Multilayer PCBs are best for advanced tools like medical machines. Think about production, cost, and performance when deciding. This table shows important factors to consider:

Metric | Why It Matters |

|---|---|

Helps success by tracking speed, cost, and quality. | |

Cost of Goods Sold (COGS) | Important since materials can be 70% of total costs. |

Return on Investment (ROI) | Technology and automation can boost results by 20% or more. |

FAQ

What makes single-sided and double-sided PCBs different?

Single-sided PCBs have parts on just one side. Double-sided PCBs use both sides for parts and connections. This helps double-sided boards handle harder circuits.

Why are multilayer PCBs better for advanced electronics?

Multilayer PCBs work faster and save space. They also improve signals, making them great for high-tech uses like phones and airplanes.

How do you pick the right PCB for your project?

Think about how hard your project is and your budget. Single-sided boards are good for simple gadgets. Multilayer PCBs are best for tough, high-tech projects.

See Also

Understanding Multilayer PCBs and Their Role in Electronics

Challenges in Manufacturing and Prototyping Multilayer Circuit Boards

Overview of Producing Rigid-Flex Multilayer Circuit Boards