Exploring the Unique Properties of Special Rogers HDI PCB Boards

You see a special rogers hdi pcb board used when electrical performance matters most. Advanced materials help you achieve high-frequency signals and precise control. LT CIRCUIT gives you quality and expertise in every special rogers hdi pcb board. These special rogers hdi pcb boards support your most demanding applications.

Key Takeaways

Special Rogers HDI PCB boards offer exceptional dielectric properties, ensuring better signal integrity and low signal loss for high-frequency applications.

Advanced thermal management features in Rogers PCB boards help dissipate heat effectively, keeping devices cool and reliable in high-power environments.

Miniaturization capabilities allow for fine lines and small vias, enabling more functionality in compact designs, which is essential for modern electronics.

Features of Special Rogers HDI PCB Board

Dielectric Properties

You rely on special rogers hdi pcb boards when you need exceptional dielectric properties for your designs. These boards use high-frequency material that delivers stable electrical performance, especially in high-speed and RF applications. Rogers pcb materials stand out because they have a lower dielectric constant compared to standard substrates like FR-4. This difference means you get better signal integrity and low signal loss, which is critical for demanding performance requirements.

Rogers 4003C: Dielectric constant of approximately 3.38

Rogers 4350B: Dielectric constant of about 3.48

Rogers 3000: Dielectric constant around 2.94

Rogers 6010: Dielectric constant typically around 3.55

FR-4: Dielectric constant ranging from 4.0 to 4.8

You notice that rogers printed circuit board materials offer lower loss tangent values. This feature helps minimize signal degradation and keeps your circuits running efficiently. You achieve stable electrical performance and low signal loss, even at high frequencies. These features of rogers pcb materials make them ideal for applications where electrical performance matters most.

Tip: Choosing special rogers hdi pcb board materials with a lower dielectric constant and loss tangent helps you maintain high frequency performance and signal clarity.

Thermal Management

Special rogers hdi pcb boards give you advanced thermal management capabilities. You need this when your devices operate in high-power environments. Rogers pcb substrates have higher thermal conductivity than conventional FR-4, which means heat moves away from critical components faster. This keeps your devices cool and reliable.

Material | Thermal Conductivity (W/m-K) |

|---|---|

FR4 | 0.1 to 0.3 |

Rogers | 0.69 to 1.7 |

You benefit from features of rogers pcb boards like heat dissipation holes and thermal conductive materials. These design elements help manage heat efficiently. You can also use temperature sensors to monitor the board in real time, preventing overheating and ensuring stable electrical performance.

Aspect | Description |

|---|---|

Heat Dissipation Design | Heat dissipation holes and thermal conductive materials for effective thermal management capabilities. |

Temperature Monitoring | Temperature sensors at critical locations for real-time monitoring and stable electrical performance. |

You see that these thermal management capabilities support demanding performance requirements in high-power and high-frequency applications.

Miniaturization

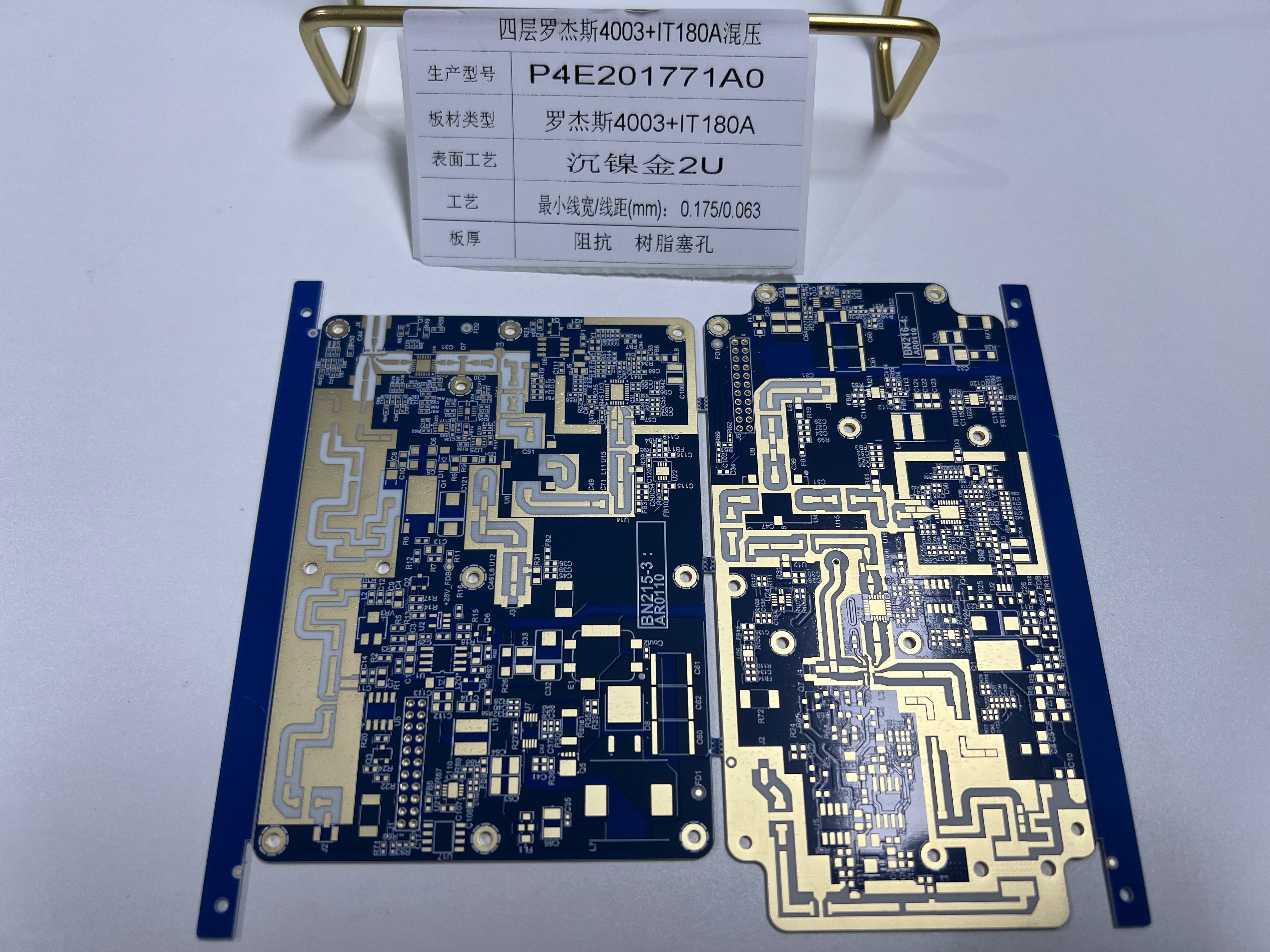

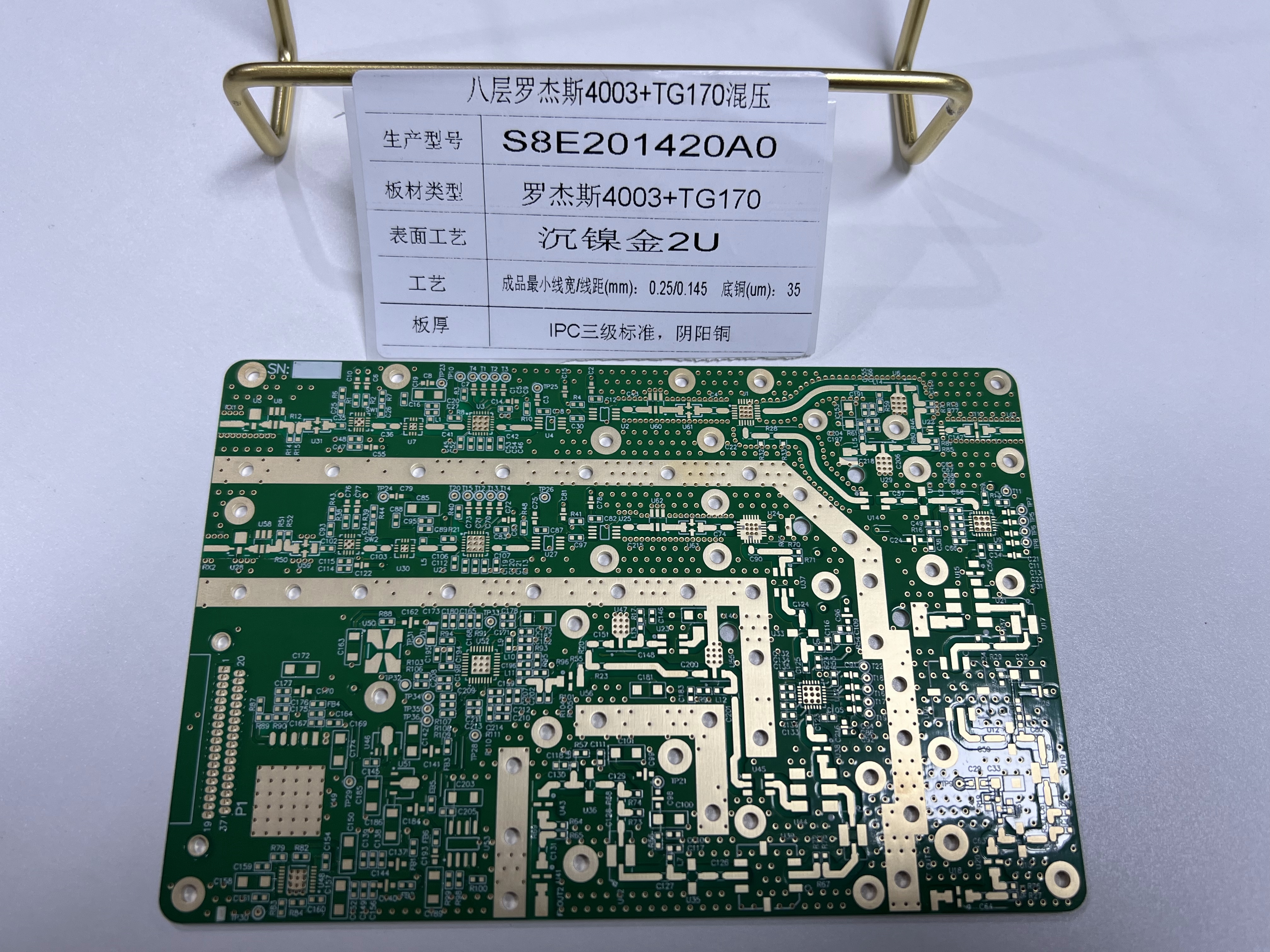

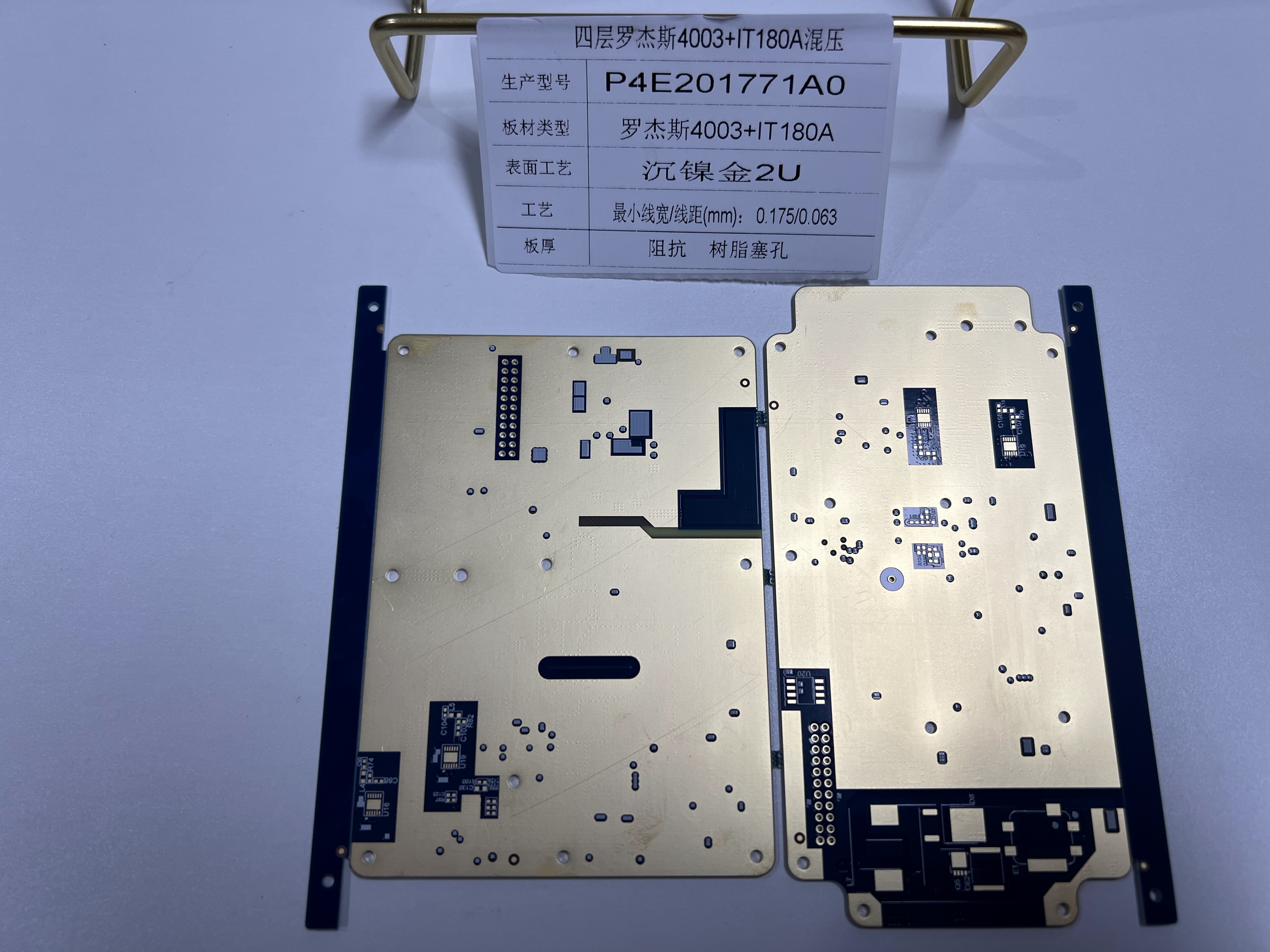

You achieve miniaturization with special rogers hdi pcb boards because they support fine lines, small vias, and high layer counts. LT CIRCUIT uses advanced manufacturing techniques to create hdi boards with minimum tracing and spacing of 2.5 mil, annular rings as small as 4 mil, and drilling holes down to 6 mil. These features of rogers pcb boards allow you to pack more functionality into a smaller space.

Feature | Capability |

|---|---|

Minimum Tracing/Spacing | 2.5 mil / 2.5 mil |

Minimum Annular Ring | 4 mil, 3 mil – laser drill |

Minimum Drilling Hole Diameter | 6 mil, 4 mil – laser drill |

You can increase the layer count to boost component density. This means you get improved signal integrity, enhanced thermal management capabilities, and stable electrical performance in compact devices. Miniaturization lets you design high-performance substrates for modern electronics.

LT CIRCUIT offers customization options to meet your specific needs. You choose from different surface finishes, layer counts, hole sizes, and copper weights. You also benefit from a multi-dimensional quality assurance system. LT CIRCUIT uses advanced testing equipment, international certifications, and comprehensive inspection methods to guarantee every special rogers hdi pcb board meets the highest standards.

Customization Option | Description |

|---|---|

Surface Finishes | HASL, ENIG, Immersion Silver, OSP for reliable solderability and oxidation protection. |

Layer Counts | Any layer count for complex designs. |

Hole Sizes | Minimum hole size of 0.1mm for intricate designs and HDI assembly systems. |

Copper Weights | Various copper weights for specific electrical requirements. |

Quality Assurance Process | Description |

|---|---|

Multi-dimensional Quality Assurance System | Online AOI and flying probe testers for precise monitoring. |

International Certifications | ISO 9001, UL, T16949 for global standards. |

Comprehensive Inspection Methods | Flying probe, test fixture, and appearance testing for 100% qualification. |

High-Precision Equipment | Inspection from raw material entry to finished product exit. |

You get reliable, high-performance substrates with every special rogers hdi pcb board from LT CIRCUIT. These features of rogers pcb boards help you meet the most demanding performance requirements in modern electronics.

Advantages of Rogers PCB with LT CIRCUIT

Signal Integrity

You need strong signal integrity when you design for high-frequency applications. Special rogers hdi pcb boards give you this advantage. Rogers pcb materials have a dissipation factor of only 0.004%. This value is much lower than the 0.02% you find in FR-4. You see less signal loss and better signal clarity. This difference matters most in RF and microwave circuits.

Rogers printed circuit board materials show low dielectric loss. You get reliable dielectric constants and less moisture absorption. These features help you keep signal integrity stable, even in tough environments.

HDI technology uses shorter traces and smaller vias. You reduce signal loss and cut down on electromagnetic interference. Your high density interconnect designs work better and faster.

You achieve complex and precise high-frequency circuit design with these substrates. You maintain electrical performance even as you shrink your devices.

Note: You can trust LT CIRCUIT to deliver high-performance printed circuit board solutions that keep your signals clean and strong.

Reliability

You want your devices to last. Special rogers hdi pcb boards help you reach high reliability and longevity. Rogers pcb substrates handle heat well. They move heat away from sensitive parts, which protects your circuits from damage. You see this benefit in high-power and high-frequency applications.

LT CIRCUIT uses strict quality checks. Every board goes through online AOI, flying probe tests, and full inspections. You get consistent quality and reliability of the circuit.

Rogers pcb boards resist moisture and chemicals. You can use them in harsh environments without worry.

You see less failure over time. Your products last longer, which means less maintenance and lower costs.

Tip: Choose LT CIRCUIT for special rogers hdi pcb boards if you want reliability and longevity in every project.

Application Versatility

You need flexibility in your designs. Special rogers hdi pcb boards support many industries and uses. You find them in RF, microwave, and high-speed digital electronics. LT CIRCUIT helps you meet the needs of modern technology.

Application Type | Description |

|---|---|

RF and Microwave | Specialized high-frequency laminate materials engineered for stringent requirements. |

High-Speed Digital Electronics | Outstanding electrical properties suitable for high-speed designs. |

5G Station | Used in advanced telecommunications for high-speed data transfer. |

Cellular Base Station Antennas | Essential for mobile communication infrastructure. |

Automotive Radar and Sensors | Critical for safety and navigation systems in vehicles. |

Microwave Point-to-Point Links | Facilitates high-frequency communication over distances. |

LNBs for Direct Broadcast Satellites | Used in satellite communication systems. |

Microwave Equipment | Applicable in various microwave technologies. |

RFID Tags | Utilized in identification and tracking systems. |

You see the advantages of rogers pcb in many fields. For example, a 5G antenna module used a 16-layer special rogers hdi pcb board with 75Ω controlled impedance for 28GHz mmWave signals. LT CIRCUIT used laser-drilled microvias and sequential lamination. The result was less than 0.3dB signal loss and certification by a major telecom OEM. This shows how you can trust LT CIRCUIT for advanced, high density pcbs.

You use special rogers hdi pcb boards in 5G stations, cellular base station antennas, power amplifiers, automotive radar, microwave links, and RFID tags.

You get the advantages of rogers pcb in every application, from telecommunications to automotive and medical devices.

Callout: LT CIRCUIT stands out for innovation, quality, and customer satisfaction. You get the best performance, reliability, and versatility with every special rogers hdi pcb board.

Rogers Printed Circuit Board vs. Traditional PCBs

Material Comparison

When you compare a rogers printed circuit board to a traditional FR-4 board, you see big differences in material properties. Rogers pcb materials offer a wide range of dielectric constants, from 2.2 to 10.2, while FR-4 stays around 4.5. Rogers pcb also has a much lower loss tangent, which means less signal loss and better electrical performance at high frequencies. This makes special rogers hdi pcb boards the top choice for advanced applications.

Material | Dielectric Constant Range | Loss Tangent Range |

|---|---|---|

FR-4 | ~4.5 | ~0.02 to 0.04 |

Rogers | 2.2 to 10.2 | 0.0009 to 0.0035 |

Rogers pcb substrates also show better thermal stability and mechanical strength. You get reliable operation even in high temperature or humid environments. This is why engineers pick special rogers hdi pcb boards for projects where signal clarity and reliability matter most.

Design Considerations

You face unique design challenges when working with special rogers hdi pcb boards. Rogers pcb laminates can be sensitive to moisture and temperature changes, so you must handle them with care. The advanced materials and dense routing in hdi designs require careful planning to avoid signal integrity issues. You may also see higher costs due to the high-performance materials and complex structures.

Rogers pcb boards allow you to combine more functions on a single board.

HDI technology lets you use shorter traces and smaller vias, which improves signal integrity and lowers power use.

You get fewer breakdowns and lower maintenance costs because of the improved reliability.

Tip: Always plan your layer stackup and routing carefully when designing with special rogers hdi pcb boards to get the best performance.

Manufacturing with LT CIRCUIT

LT CIRCUIT helps you overcome the manufacturing challenges of special rogers hdi pcb boards. The team focuses on design engineering, optimizing layer stackups, and using microvia architecture for better thermal management. You benefit from advanced material selection, which ensures tight dielectric control for high-frequency designs. The manufacturing process uses laser drilling, electroplating, and precise surface finishing to achieve the best results in hdi boards.

Description | |

|---|---|

Design Engineering | Optimizes stackup, microvias, and thermal strategies. |

Material Selection | Chooses advanced substrates for high-frequency needs. |

Manufacturing Processes | Uses laser drilling and advanced finishing for precision. |

You choose special rogers hdi pcb boards from LT CIRCUIT when you want superior dielectric constant, enhanced thermal management, and lower signal loss. These features make rogers pcb the preferred solution for high-frequency, high-density, and mission-critical applications.

You see special rogers hdi pcb boards deliver outstanding performance for your high-frequency and miniaturized designs.

Feature | Description |

|---|---|

Low and stable, helps maintain signal integrity by minimizing impedance changes. | |

Loss Tangent | Low loss tangent minimizes signal attenuation, ensuring efficient transmission of high frequency signals. |

Thermal Conductivity | High thermal conductivity effectively dissipates heat from electronic components. |

Dimensional Stability | Excellent stability in extreme temperatures allows for precise alignment of components. |

You benefit from hdi technology, which supports fine-line etching, laser-drilled microvias, and sequential build-up for complex layouts. LT CIRCUIT stands as your trusted partner, offering special rogers hdi pcb boards with reliable electrical performance and advanced hdi solutions.

Choose LT CIRCUIT for your next special rogers hdi pcb board project. You gain quality, innovation, and support for every hdi application.

FAQ

What makes special rogers hdi pcb boards more reliable than standard PCBs?

You get higher reliability with special rogers hdi pcb boards. The advanced materials and hdi technology help you maintain reliability in harsh environments and high-frequency applications.

How does LT CIRCUIT ensure the reliability of special rogers hdi pcb boards?

You benefit from strict quality checks at every stage. LT CIRCUIT uses advanced testing to guarantee reliability. You see consistent reliability in every special rogers hdi pcb board.

Why should you choose special rogers hdi pcb boards for applications needing high reliability?

You want reliability for mission-critical projects. Special rogers hdi pcb boards deliver reliability through stable performance, advanced hdi features, and proven reliability in demanding conditions.

See Also

Explore Cutting-Edge Techniques for HDI PCB Prototyping

Essential Design Factors for Reliable HDI PCB Manufacturing

Compact, Durable, Intelligent: The Benefits of HDI Rigid Flex PCBs

Exploring Rogers R4350B, R4003, and R5880 for RFPCB Applications