How Special Rogers HDI PCB Boards Improve High-Frequency Performance

When you encounter high-frequency challenges that standard materials can't address, a special rogers hdi pcb board is the solution. Utilizing advanced materials and HDI design, a special rogers hdi pcb board ensures stable signal integrity and minimizes interference. With HDI technology, you benefit from superior electrical performance and enhanced reliability in even the most demanding designs. LT CIRCUIT delivers innovation and quality with every special rogers hdi pcb board, supporting your critical projects with cutting-edge solutions.

Key Takeaways

Special Rogers HDI PCB boards provide superior electrical performance with low dielectric losses, ensuring reliable signal integrity in high-frequency applications.

Microvias in HDI technology allow for compact designs, enabling more components in smaller spaces while maintaining high performance and low signal loss.

Choosing LT CIRCUIT's special Rogers HDI PCB boards guarantees rigorous quality control, ensuring consistent high-frequency performance and long-term reliability.

Features of Special Rogers HDI PCB Boards

Advanced Dielectric Properties

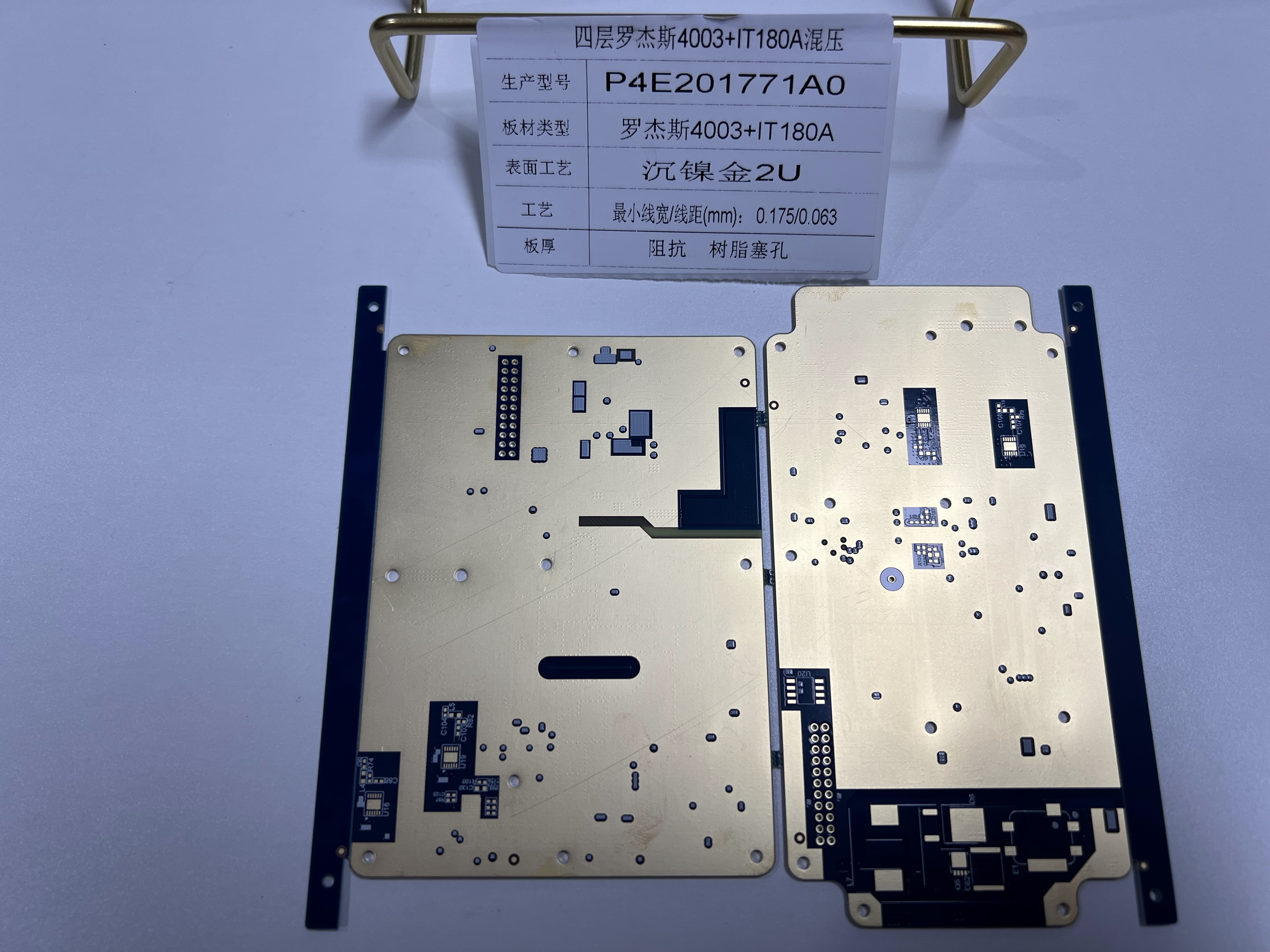

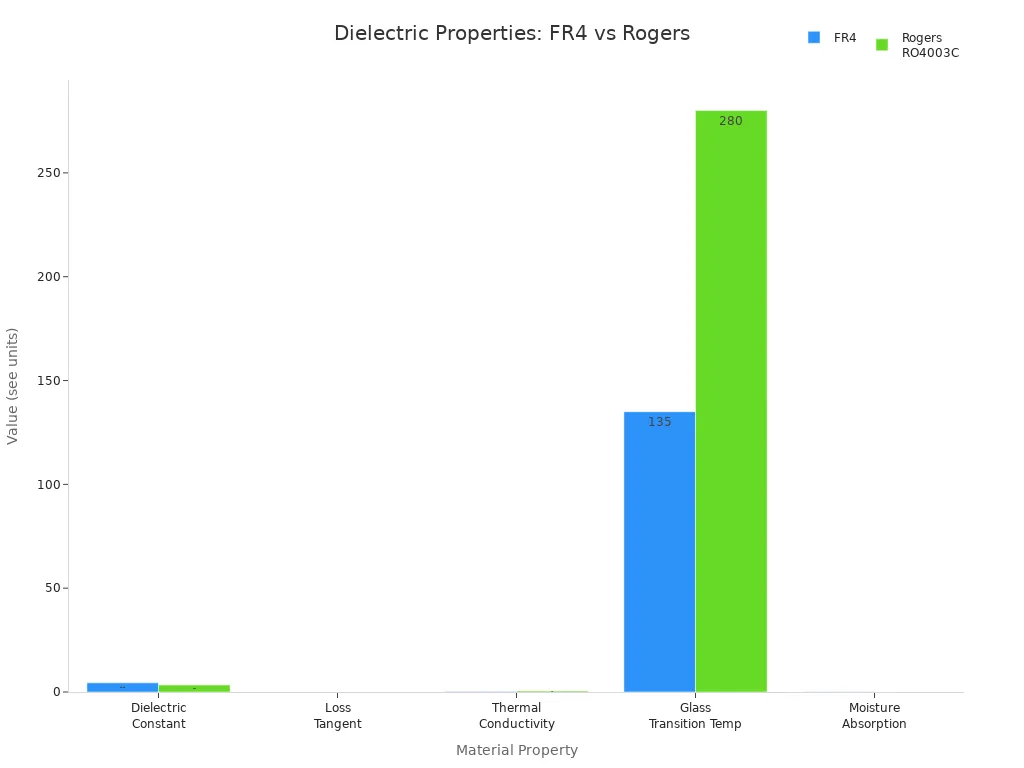

You need materials that deliver consistent electrical performance at high frequencies. Rogers materials stand out because they offer low dielectric constants and low dielectric losses, which are essential for reliable signal transmission. When you compare Rogers RO4003C to standard FR-4, you see a clear advantage in every critical property.

Property | FR4 | Rogers RO4003C |

|---|---|---|

Dielectric Constant (Dk) | ~4.4 (variable) | 3.38 (stable up to 10+ GHz) |

Loss Tangent (Df) | 0.020–0.025 | 0.0027 |

Thermal Conductivity | ~0.25 W/m·K | ~0.50 W/m·K |

Glass Transition Temp | ~135°C | >280°C |

Moisture Absorption | 0.10% – 0.20% | ~0.06% |

Frequency Range | Up to ~1 GHz | 500 MHz to 20+ GHz |

Impedance Stability | Moderate | Excellent |

You benefit from stable electrical performance because Rogers materials maintain a consistent dielectric constant across GHz frequencies. For example, you can rely on a dielectric constant value between 2.5 and 3.7, depending on the product line. This stability ensures your designs perform predictably, even in demanding RF applications like 5G antennas or radar modules.

LT CIRCUIT uses advanced Rogers materials to achieve low dielectric losses and high thermal conductivity. You gain improved signal integrity and reduced signal loss, which are critical for high-frequency circuits. LT CIRCUIT’s commitment to quality means every special Rogers HDI PCB board meets strict standards for impedance stability and moisture resistance. You can trust these boards to deliver reliable electrical performance in harsh environments.

Tip: When you choose special Rogers HDI PCB boards from LT CIRCUIT, you ensure your project benefits from industry-leading material properties and robust quality control.

High Circuit Density and Microvias

You need compact designs with high functionality. Special Rogers HDI PCB boards allow you to pack more active components into a smaller space. HDI technology supports line widths and spacing down to 75μm (3 mil), and advanced processes can achieve 50μm (2 mil) or even below. This capability gives you the flexibility to create dense track layouts and intricate routing.

HDI PCBs use microvias, which are much smaller than traditional through-hole vias.

Microvias connect different layers efficiently, improving signal routing and electrical performance.

You can achieve greater design freedom and precision with microvias, blind vias, and buried vias.

The finer lines and higher layer counts in HDI PCBs enhance the functionality of compact devices.

Microvias are essential for high-speed applications, supporting stable electrical performance and signal integrity.

Rogers HDI PCBs from LT CIRCUIT feature microvias that maximize circuit density and routing efficiency. You can design products with more features without increasing the size. Microvias also help maintain low dielectric losses, which is vital for high-frequency signal transmission.

LT CIRCUIT implements rigorous quality control standards to ensure every special Rogers HDI PCB board meets your requirements. You benefit from vector network analysis, X-ray inspection, thermal cycling, impedance testing, and moisture resistance tests. These methods guarantee stable electrical performance and reliability.

Test Method | Purpose | Acceptance Criteria |

|---|---|---|

Vector Network Analysis | <0.3dB/inch loss at 60GHz; return loss >20dB. | |

X-Ray Inspection | Verifies microvia integrity in stacked vias. | Voids <5% of via volume; no cracks in barrel plating. |

Thermal Cycling | Tests performance through 1,000 cycles to simulate field conditions. | No delamination; resistance change <5%. |

Impedance Testing | Ensures 50Ω ±5% tolerance for RF traces. | Impedance within ±5% of target; no discontinuities. |

Moisture Resistance | Tests insulation resistance under high humidity and temperature. | Insulation resistance >10¹⁴ Ω·cm. |

You get the benefit of LT CIRCUIT’s innovation, which uses low-loss dielectrics and embedded components to reduce noise and delays. This approach improves electrical performance and efficiency, making your devices faster and more reliable.

Note: Microvias are the key to unlocking higher circuit density and better electrical performance in your next high-frequency design.

Benefits and Applications

Signal Integrity and Reliability

You demand reliable performance in every high-frequency application. A special rogers hdi pcb board delivers measurable improvements in signal integrity and reliability, setting a new standard for advanced circuit boards. You benefit from thinner layers and smaller controlled impedance traces, which allow ground planes to sit closer to signal paths. This design reduces noise and crosstalk, giving you improved signal integrity even in dense, high-density circuit applications.

Thinner layers in HDI boards create smaller, more precise impedance traces.

Ground planes positioned closer to traces enhance signal integrity.

Fine-pitch BGAs enable tighter trace routing, boosting performance.

Material choices, such as low dielectric constant substrates, optimize signal integrity metrics.

When you use a special rogers hdi pcb board, you reduce dielectric losses. Lower dielectric constant materials shift the focus to copper losses, which are easier to manage at high frequencies. For example, switching from FR4 to advanced materials like Megtron 7(G) or Rogers laminates significantly reduces dielectric loss, resulting in improved signal integrity for high-frequency performance.

HDI technology also uses smaller vias, which shorten signal paths and minimize signal loss. This construction enhances overall signal integrity, making these boards ideal for high-speed communication devices and high-frequency applications. You see fewer signal reflections and less interference, which is critical for reliable data transmission.

You also gain enhanced thermal management. Special rogers hdi pcb boards dissipate heat efficiently, keeping your devices cool and reliable in high-power environments. This feature, combined with low loss factors and excellent mechanical strength, ensures your printed circuit boards maintain performance under demanding conditions.

LT CIRCUIT ensures consistent high-frequency performance by using advanced material selection, controlled impedance routing, and rigorous quality assurance processes. The table below highlights these strategies:

Strategy | Description |

|---|---|

Material Selection | Use of low dielectric constant materials like Megtron 6 and Panasonic R5775 to maintain signal integrity. |

Stackup Strategies | Controlled impedance routing and special via designs to reduce signal loss. |

Quality Assurance Processes | Flying Probe Test and Automated Optical Inspection to ensure performance. |

You experience measurable improvements in product reliability when you choose a special rogers hdi pcb board. These improvements include reduced electrical signal and dielectric losses, better controlled impedance, enhanced plated through hole reliability, and improved dimensional stability. The table below summarizes these benefits:

Measurable Improvement | Description |

|---|---|

Reduced electrical signal and dielectric losses | Enhances overall performance in electronic applications. |

Improved controlled impedance | Ensures consistent performance across various conditions. |

Enhanced plated through hole (PTH) reliability | Increases durability and reliability of connections. |

Better dimensional stability | Maintains integrity under varying environmental conditions. |

Low CTE values | Ideal for applications in space and radar, reducing thermal stress. |

Tip: You can rely on LT CIRCUIT’s special rogers hdi pcb boards for consistent, high-frequency performance and long-term reliability in your most demanding projects.

Real-World Uses of Special Rogers HDI PCB Boards

You see the impact of special rogers hdi pcb boards across a wide range of industries. In consumer electronics, these boards power the latest smartphones, wearable medical devices, and advanced communication systems. You benefit from miniaturization and space efficiency, which allow you to integrate amplifiers, microcontrollers, memory, and RF chips into compact designs.

HDI technology is essential for wearable medical devices, enabling the integration of multiple components in a small form factor.

Special rogers hdi pcb boards are at the core of modern smartphones and advanced communication systems.

These boards support rapid design refreshes and new feature integration in consumer electronics.

In medical devices like wearable ECG monitors, you achieve thin, flexible designs with reliable high-frequency performance.

In telecom infrastructure, you rely on special rogers hdi pcb boards for 5G stations, cellular base station antennas, power amplifiers, automotive radar, microwave links, and RFID tags. These applications demand exceptional dielectric properties and low signal loss. You benefit from improved signal integrity and enhanced thermal management, which keep your systems running smoothly in high-power environments.

Special rogers hdi pcb boards offer exceptional dielectric properties, ensuring better signal integrity and low signal loss for high-frequency applications.

Industrial devices also depend on these advanced circuit boards. You find them in telecommunications and 5G technology, aerospace and defense radar systems, satellite communication devices, MRI machines, wireless monitoring systems, automotive radar, and ADAS. These boards maintain strong signals, accurate diagnostics, and consistent performance under extreme conditions.

The table below highlights how special rogers hdi pcb boards contribute to increased efficiency in electronic product design and manufacturing:

Property | Benefit |

|---|---|

Low dielectric constant | Faster signal transmission with lower latency, essential for high-speed applications. |

Low loss factor | Reduces energy loss during signal transmission, improving overall system efficiency. |

Excellent thermal stability | Maintains performance at high temperatures, suitable for long-duration applications. |

Good mechanical strength | Ensures reliability in harsh environments, extending product lifespan. |

Chemical resistance | Stability in various chemical environments, suitable for specialized electronic devices. |

Consistency and repeatability | High production consistency improves product quality and manufacturing efficiency. |

You also extend product longevity by choosing special rogers hdi pcb boards. Compared to conventional materials, these boards offer very low dielectric loss, high thermal conductivity, low coefficient of thermal expansion, high glass transition temperature, and excellent mechanical stress resistance.

Property | Rogers HDI PCB Boards | Conventional Materials (e.g., FR4) |

|---|---|---|

Dielectric Loss | Very Low | Higher |

Thermal Conductivity | High | Lower |

Coefficient of Thermal Expansion | Low | Higher |

Glass Transition Temperature | High | Lower |

Mechanical Stress Resistance | Excellent | Moderate |

Industry reports confirm the advantages of special rogers hdi pcb boards. You see increasing use of advanced materials, adoption of Any-Layer HDI for compact designs, and integration of embedded passive and active components for high-speed communication devices. Finer lines, microvias, and design flexibility support a wide range of high-density circuit applications.

LT CIRCUIT’s special rogers hdi pcb boards stand out in high-frequency applications. You can route signals freely across all layers, reducing signal path length by 30% in 5G units. AI-based quality control ensures a defect rate of less than 1%, which is critical for high-reliability and high-performance pcb needs.

Engineers and designers appreciate the practical advantages of these boards. You achieve significant miniaturization, enhanced functionality, and reduced footprint—up to 40% smaller than traditional printed circuit boards. Blind vias, buried vias, and via-in-pad technology help you minimize board space and shorten signal paths, which boosts signal quality and space efficiency.

Note: When you choose LT CIRCUIT, you gain a partner committed to delivering special rogers hdi pcb boards that meet the highest standards for high-frequency performance, reliability, and innovation.

You achieve measurable improvements in high-frequency performance with special Rogers HDI PCB boards from LT CIRCUIT. These boards deliver reliability, efficiency, and extended product life.

Description | |

|---|---|

IPC-A-600 Class 3 | Highest quality for critical systems where failure is not acceptable. |

AS9100D | Aerospace quality management system certification for aviation and space. |

Choose LT CIRCUIT for your next high-frequency PCB project and experience industry-leading innovation.

FAQ

What makes special Rogers HDI PCBs different from standard PCBs?

You get advanced materials and HDI technology. These pcbs offer stable electrical performance, low signal loss, and high reliability for demanding high-frequency applications.

Can you use special Rogers HDI PCBs in consumer electronics?

You can use these pcbs in smartphones, wearables, and communication devices. The compact design and high performance make these pcbs ideal for modern consumer electronics.

How does LT CIRCUIT ensure the quality of its special Rogers HDI PCBs?

You benefit from strict testing methods. LT CIRCUIT uses flying probe tests, impedance checks, and X-ray inspections to guarantee every batch of pcbs meets industry standards.

Tip: You should choose LT CIRCUIT’s pcbs for consistent high-frequency performance and long-term reliability.

Feature | Benefit |

|---|---|

Advanced materials | Stable performance in all pcbs |

Rigorous testing | Reliable pcbs for every project |

See Also

Essential Design Factors for Reliable HDI PCB Production

Understanding High-Speed PCBs and Their Importance

Design and Manufacturing Insights for High Frequency PCBs