The technical difficulties in processing a 2-layer aluminum base PCB

You face complex technical difficulties when processing 2-layer aluminum base PCBs. These challenges can affect both manufacturing efficiency and product reliability. LT CIRCUIT focuses on quality and innovation to help you overcome these issues. You must address each problem with care to ensure consistent results and long-term performance.

Key Takeaways

Monitor temperature and pressure during lamination to ensure strong bonding and prevent delamination.

Select high-quality resins with good thermal conductivity to avoid defects like bubbling and cracking during thermal cycles.

Use precise surface treatment and high-quality solder mask materials to prevent peeling and ensure even coverage.

Key Technical Difficulties

When you process a 2-layer aluminum base PCB, you face several technical difficulties that can impact the final product. Each stage of manufacturing brings its own set of challenges. You need to understand these issues to ensure high-quality results.

Bonding and Dielectric Layer Issues

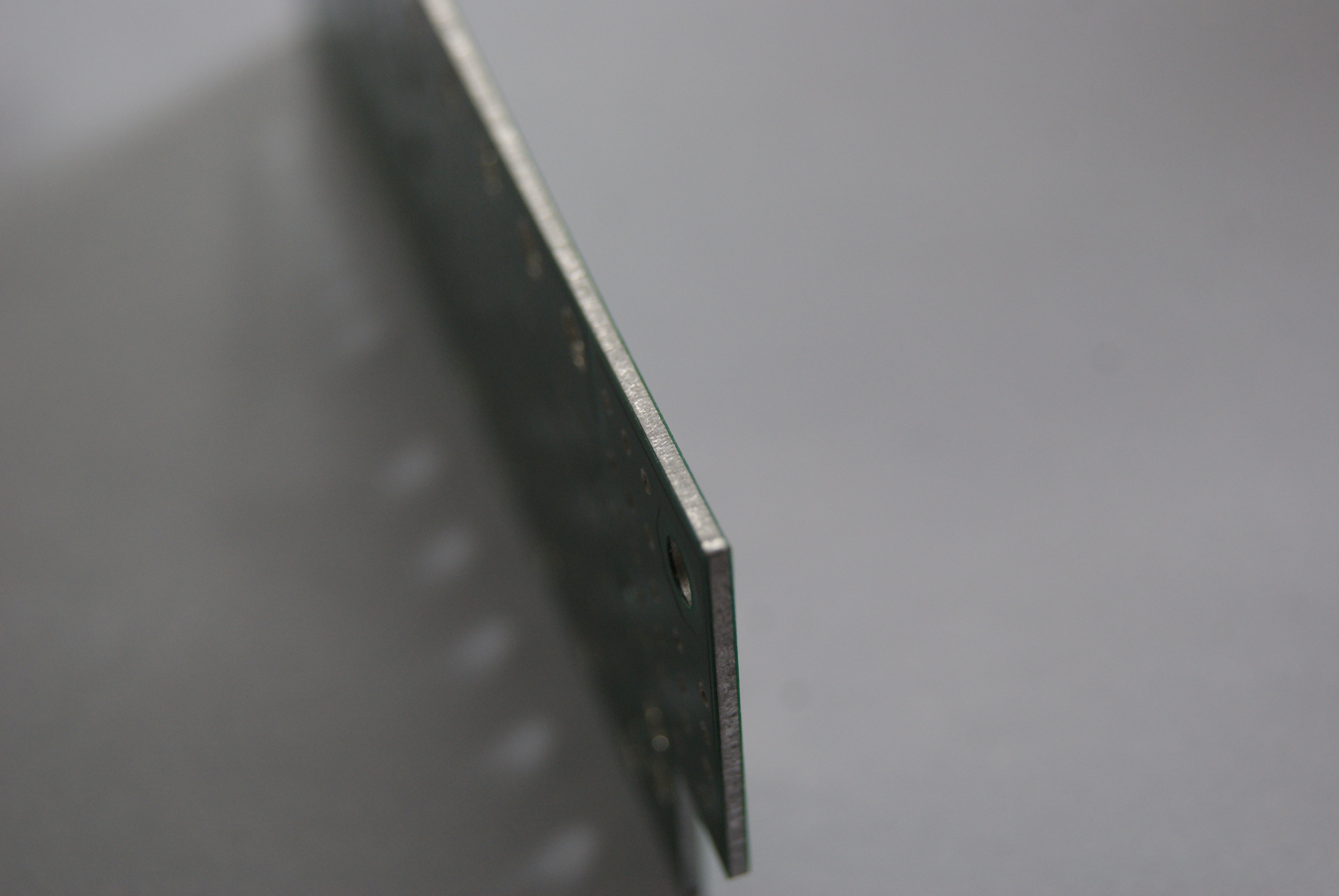

You must pay close attention to the bonding between the aluminum base and the dielectric layer. Weak bonding can cause delamination, which leads to circuit failure. The dielectric layer must have uniform thickness and strong adhesion. If you do not control the lamination process, you may see air gaps or uneven surfaces. These problems can reduce electrical insulation and mechanical strength.

Tip: Always monitor temperature and pressure during lamination. This helps you avoid weak bonds and ensures a stable dielectric layer.

LT CIRCUIT uses advanced bonding techniques to achieve strong adhesion and consistent dielectric thickness. Their process reduces the risk of delamination and improves the reliability of your PCBs.

Resin and Thermal Conductivity Challenges

Resin quality plays a big role in the performance of your aluminum base PCB. Poor resin can lead to bubbling or cracking during thermal cycles. These defects often appear when you expose the board to high temperatures. If you do not address these technical difficulties, you may see reduced heat dissipation and lower product lifespan.

You need to select resins with high thermal conductivity and good mechanical properties. This helps your PCB handle heat from power components. LT CIRCUIT selects premium resins and controls the curing process. This approach prevents bubbling and cracking, so your boards stay reliable even in demanding environments.

Common resin issues you may face:

Bubbling during curing

Cracking under thermal stress

Poor heat transfer

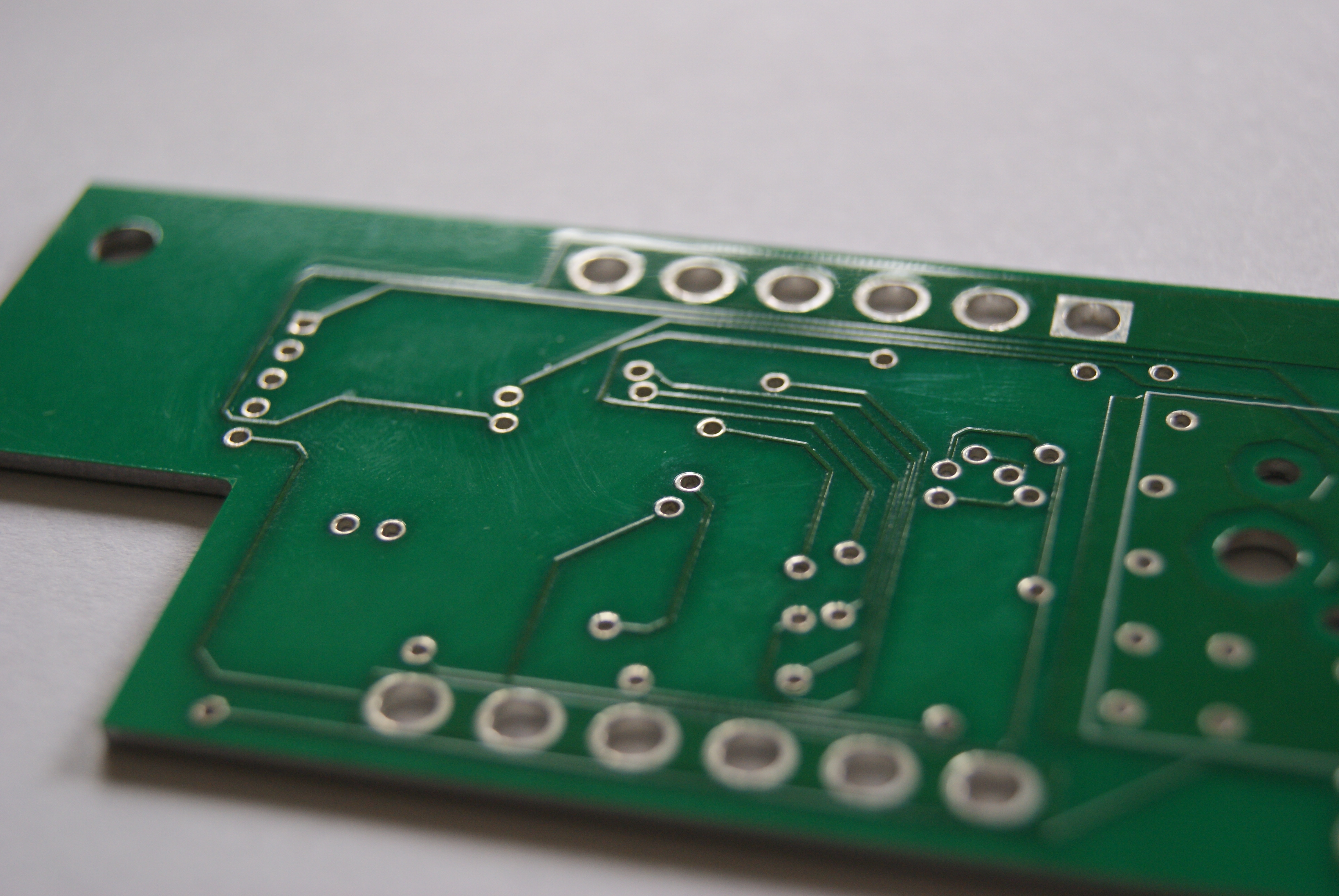

Solder Mask and Surface Integrity

Applying the solder mask on a 2-layer aluminum base PCB brings its own technical difficulties. The aluminum base can make it hard for the solder mask to stick. If you do not prepare the surface well, you may see peeling, pinholes, or uneven coverage. These defects can cause short circuits or corrosion.

You should use precise surface treatment and high-quality solder mask materials. LT CIRCUIT uses advanced surface cleaning and optimized printing methods. This ensures smooth, even coverage and strong adhesion. Your finished PCB will have better protection and a longer service life.

Note: Always inspect the solder mask for defects before moving to the next production step. Early detection saves time and reduces waste.

By understanding and addressing these technical difficulties, you can improve your manufacturing process and deliver reliable 2-layer aluminum base PCBs.

LT CIRCUIT Solutions and Best Practices

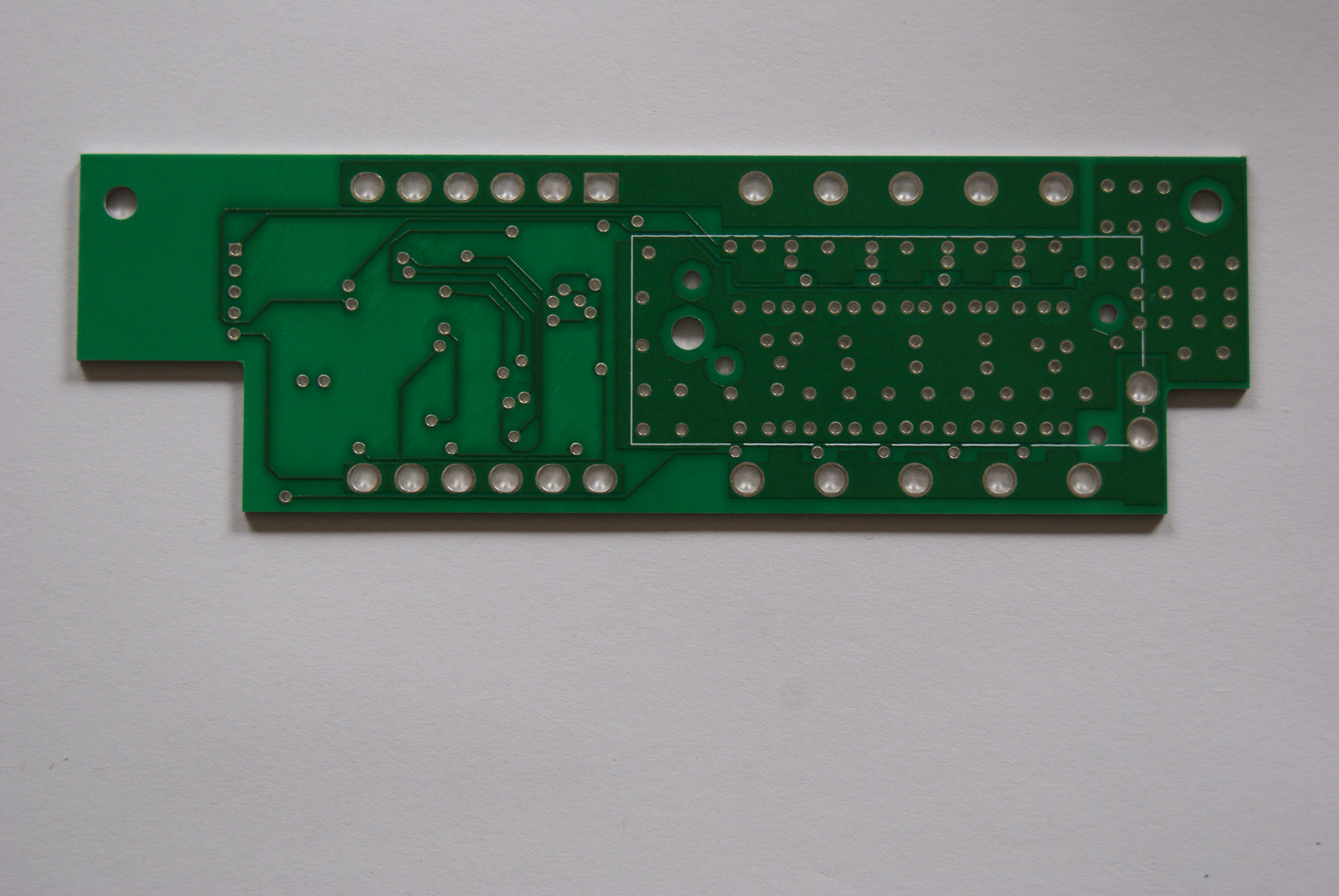

Precision Machining and Layer Alignment

You need precise machining to create high-quality 2-layer aluminum base PCBs. LT CIRCUIT uses advanced CNC equipment to cut and drill each board. This equipment keeps the layers perfectly aligned. You get tight tolerances and smooth edges. Proper alignment helps you avoid shorts and open circuits. LT CIRCUIT’s process ensures that each layer matches exactly, even for complex designs.

Reliable Via Formation and Testing

You rely on strong vias to connect the layers in your PCB. LT CIRCUIT uses controlled drilling and plating methods to form reliable vias. These methods prevent cracks and voids. You can trust that each via will carry current without failure. After forming the vias, LT CIRCUIT tests every board using flying probe and E-test systems. These tests catch any defects before the boards reach you.

Tip: Fast turnaround is possible with LT CIRCUIT. For standard 2-layer fast turn PCBs, you can expect delivery in 24 to 48 hours. This speed helps you resolve technical difficulties quickly and keep your projects on schedule.

Quality Control and Yield Optimization

You want every PCB to meet strict quality standards. LT CIRCUIT uses automated optical inspection and surface treatment to check for defects. These steps catch issues like poor solder mask adhesion or uneven surfaces. The team also monitors heat dissipation by testing thermal performance. You benefit from high yields and fewer returns. LT CIRCUIT’s best practices help you avoid common technical difficulties and deliver reliable products to your customers.

You face several technical difficulties when processing 2-layer aluminum base PCBs. Solving these problems helps you achieve high-quality, reliable boards. LT CIRCUIT gives you proven solutions and expert support.

For more details or help, visit LT CIRCUIT’s official website.

FAQ

What makes 2-layer aluminum base PCBs harder to process than standard PCBs?

You must handle extra steps like bonding and thermal management. Aluminum base PCBs need special care to avoid delamination and heat issues.

Tip: Always check for proper bonding and resin quality.

How do you prevent solder mask defects on aluminum base PCBs?

You should clean the surface thoroughly and use high-quality solder mask materials. This helps you avoid peeling, pinholes, and uneven coverage.

Why is thermal conductivity important in these PCBs?

You need good thermal conductivity to keep your components cool. This prevents overheating and extends the life of your electronic devices.

See Also

Challenges In Prototyping Multi-Layer Circuit Board Manufacturing

Comprehensive Guide To Heavy Copper Multilayer PCB Production

Understanding The Production Steps For Rigid-Flex Multilayer PCBs

Essential Knowledge For Designing PCB Multi-Layer Layouts

The Manufacturing Process Of Aluminum-Based PCBs With Insulation