Exploring the Thermal and Electrical Efficiency of Aluminum PCBs

Aluminum PCBs are great for heat and electricity use. They are popular in modern electronics because they manage heat well. Their thermal resistance is 1–2 degrees per watt (at 1.5mm thick). FR-4 PCBs have 20–22 degrees per watt, so aluminum PCBs handle heat much better. With thermal conductivity over 0.8 ω/m-k, they work well in powerful devices.

Key Takeaways

Aluminum PCBs are great at handling heat. They work well in powerful devices like LED lights and car electronics.

They carry electricity better, which saves energy and boosts performance in many uses.

Aluminum PCBs can be customized. This helps industries create designs that fit their needs and work reliably.

Thermal Properties of Aluminum PCBs

Aluminum PCBs are great at managing heat. This makes them a top choice for devices needing good heat control. Their special design and materials help them handle high temperatures well. This keeps them working properly in tough conditions.

High Thermal Conductivity in Aluminum PCBs

Aluminum's ability to conduct heat is very important. Aluminum PCBs spread heat much faster than regular materials like FR4. This helps stop hot spots and keeps the board's temperature steady.

Aluminum PCBs work well in high-power devices like LED lights.

Their strong heat-handling ability makes them useful for industries needing good heat control.

This fast heat transfer helps aluminum PCBs meet the needs of modern electronics. Better heat control means devices last longer and work more reliably.

Efficient Heat Dissipation Mechanisms

Aluminum PCBs have layers that help spread heat. The aluminum base acts like a heat sink, pulling heat away from important parts. This design spreads heat evenly and stops overheating.

Aluminum's heat conductivity keeps these PCBs cooler, even when working hard. This is helpful in cars and power devices where steady heat control is needed.

By spreading heat well, aluminum PCBs improve how devices work and last longer. This makes them a smart and cost-saving choice for industries needing durable electronics.

Understanding the Thermal Resistance of Aluminum PCB

Thermal resistance shows how well a material blocks heat flow. Lower resistance means better heat control.

Thermal resistance is found using this formula:Rθ = t / (λ * A)

Where:

t= material thicknessλ= heat conductivityA= material area

For example, a 2 cm² soldermask with 20 µm thickness has 0.5 °C/W resistance. This low resistance shows how well aluminum PCBs manage heat.

Other measures, like junction-to-ambient (θJA) and junction-to-case (θJC) resistance, also matter. These help designers make aluminum PCBs better for specific uses. This ensures good heat control and reliable performance.

Electrical Properties of Aluminum PCBs

Aluminum PCBs are good at handling heat and electricity. Their special design and materials make them great for carrying current. They also provide strong insulation to keep devices safe.

Better Electrical Conductivity

Aluminum PCBs conduct electricity better than regular boards like FR-4. This makes them perfect for devices needing lots of power. Aluminum reduces energy loss, even when working hard.

Aluminum PCBs carry more current than FR-4 boards.

They are used in cars and LED lights for power efficiency.

The table below compares how well aluminum PCBs conduct electricity:

Material | Electrical Conductivity Level | Comparison to FR-4 |

|---|---|---|

Aluminum | Handles more power |

This great conductivity helps aluminum PCBs support powerful parts. They manage both heat and electricity, making them useful for many devices.

Strong Insulation and Dielectric Strength

Good insulation keeps devices safe and working well. Aluminum PCBs have a special layer that stops electricity from leaking. This helps devices stay stable and reliable.

The comparative tracking index (CTI) measures how well materials resist forming tracks. A higher CTI means better insulation. Things like air pressure can affect insulation too. For example, low pressure makes tracking easier, which can change performance.

With strong insulation and high dielectric strength, aluminum PCBs keep devices safe. These features make them a smart choice for electronics needing steady performance.

Advantages of Aluminum PCBs Over Other Materials

Aluminum PCBs vs. FR4 PCBs

Aluminum PCBs are better at handling heat than FR4 PCBs. They spread heat quickly, stopping devices from overheating. This makes them great for high-power uses like LED lights. FR4 PCBs have higher thermal resistance, which can cause heat buildup. This may lower their reliability.

Aluminum PCBs also carry electricity more efficiently. They are perfect for devices needing lots of power. Their lightweight design helps make gadgets easier to carry. FR4 PCBs are cheaper but lack the strength and heat control of aluminum PCBs.

Aluminum PCBs vs. Ceramic PCBs

Aluminum PCBs transfer heat better than ceramic PCBs. They keep parts cooler and work well in tough conditions. Their strong build resists bending and vibrations, making them ideal for cars and planes.

Ceramic PCBs handle heat but are less durable and cost more. Aluminum PCBs manage higher power levels and protect parts from overheating. They are a smarter choice for industries needing reliable electronics.

Metric | Aluminum PCBs | Ceramic PCBs |

|---|---|---|

Transfers heat faster | Transfers heat slower | |

Mechanical Strength | Resists bending and vibrations | Less sturdy |

Durability | Lasts longer in tough conditions | Wears out faster |

Operating Temperatures | Keeps parts cooler | Parts get hotter |

Power Density | Handles more power | Handles less power |

Vibration Resistance | Strong against vibrations | Weak against vibrations |

Cost-Effectiveness | Saves money over time | Costs more long-term |

Performance and Cost Benefits of Aluminum PCBs

Aluminum PCBs are both powerful and affordable. They lower device temperatures, helping gadgets last longer. This makes them perfect for high-power uses.

These PCBs save energy by staying cooler, cutting costs. Industries like cars and telecoms use them for their power-handling ability. Their recyclable material is also better for the environment.

The aluminum PCB market is growing fast. It was worth $1.1 billion in 2022 and is expected to grow 6.5% yearly until 2030. This shows how popular they are for lightweight and efficient electronics.

Aluminum PCBs are strong, affordable, and great at managing heat. They are a smart pick for modern devices.

Practical Uses of Aluminum PCBs

Aluminum PCBs are important in many industries. They handle heat well and work reliably, making them key for modern electronics.

Aluminum PCBs in LED Lights

Aluminum PCBs are common in powerful LED lights. They stop LEDs from overheating and help them last longer. The aluminum base spreads heat quickly, keeping LEDs cool and working well.

Benefit/Use | Details |

|---|---|

Spreads heat to keep LEDs at safe temperatures. | |

Strong and Long-Lasting | Tough design resists damage, ensuring LEDs work for a long time. |

Lightweight | Easy to install and reduces the weight of light fixtures. |

Budget-Friendly | Offers good heat control at a lower cost than copper materials. |

Street Lights | Used for durability and long-lasting performance in outdoor lighting. |

Panel Lights | Allows slim designs with bright light and long life. |

Downlights | Perfect for small designs needing good heat control. |

Car Lights | Works well in headlights, tail lights, and inside car lighting. |

Aluminum PCBs keep LED lights running smoothly, even when they use a lot of power.

Aluminum PCBs in Cars

Cars use aluminum PCBs to manage heat in electronics. They are found in headlights, tail lights, and air-conditioner systems. The aluminum layer spreads heat, keeping parts cool and safe.

These PCBs are tough and resist shaking, making them great for cars. Their lightweight design helps save fuel. They also handle heat well, ensuring parts work in tough conditions.

Aluminum PCBs in Telecom and Power Devices

Telecom and power devices need aluminum PCBs for heat control. These PCBs handle high power and run for long periods. They are used in phone cameras, speakers, and TV backlights.

Aluminum PCBs are strong and resist damage. This makes them useful in airplanes and medical tools, where reliability is key. The aluminum layer keeps them working well, even in hot conditions.

Aluminum PCBs are vital for modern devices. They manage heat and electricity better than other materials.

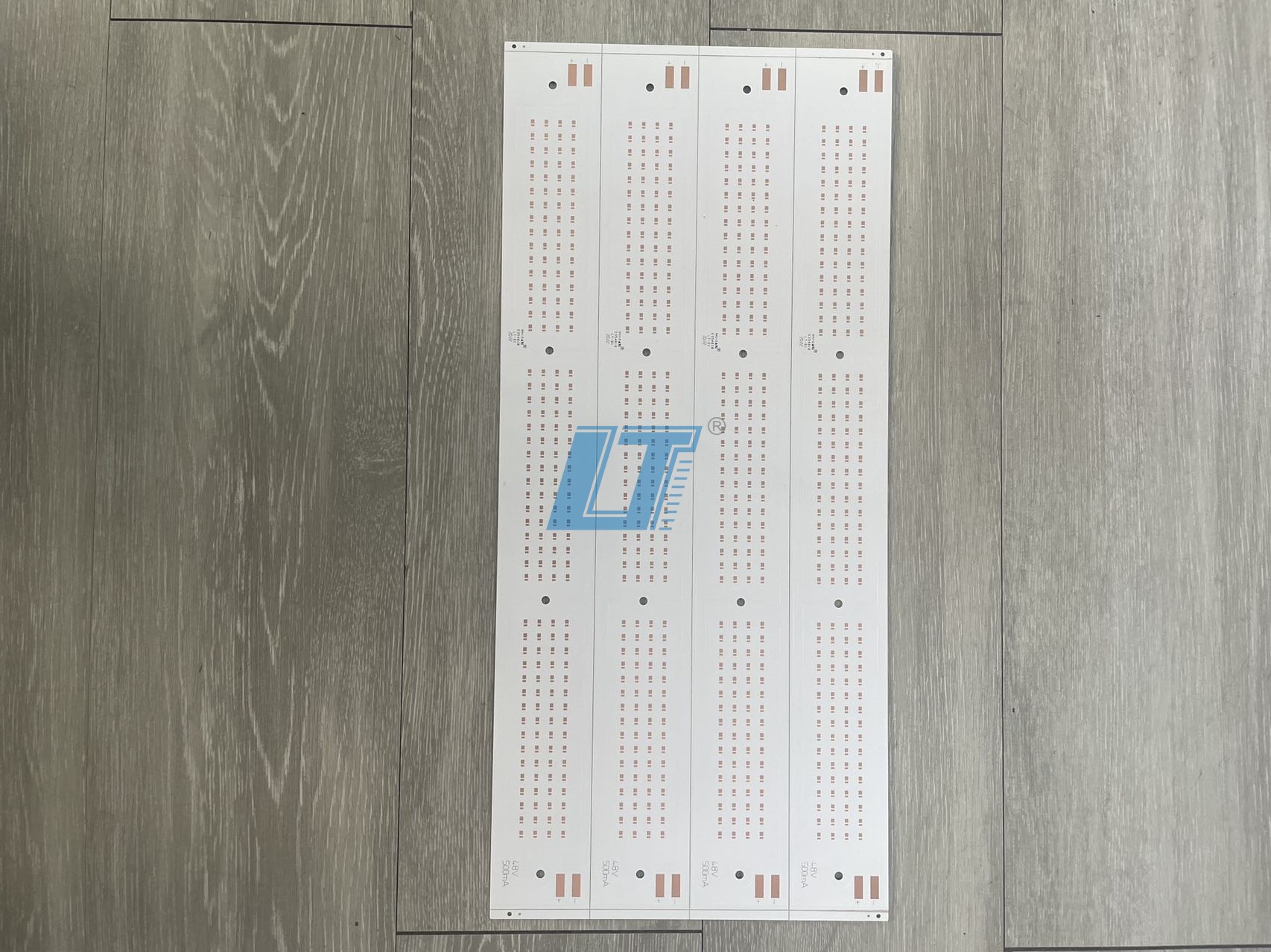

LT CIRCUIT: Leading the Way in Aluminum PCB Solutions

LT CIRCUIT’s Skill in Managing Heat

LT CIRCUIT is great at handling heat in aluminum PCBs. Their advanced methods make PCBs with up to 220 W/m·K conductivity. This keeps temperature changes below 15°C/mm, perfect for high-power devices. LT CIRCUIT ensures your devices stay cool and work well, even in tough conditions.

The company focuses on precision and quality. They have a first-pass success rate over 98%. Their micro-component placement is 99.5% accurate. This shows their dedication to making reliable and high-performing PCBs.

Custom Aluminum PCBs by LT CIRCUIT

LT CIRCUIT offers many ways to customize aluminum PCBs. You can choose double-sided designs for complex circuits. They also provide unique solder mask colors to match your brand. PCB thickness ranges from 0.6 to 6.0mm, and copper thickness from 0.5 to 6.0oz. This flexibility suits many needs.

Customization Option | Details |

|---|---|

Minimum Line Width/Spacing | 0.075/0.075mm |

Copper Thickness | 0.5 to 6.0oz |

ISO Certification | ISO 9001:2015, ISO 14001:2015, ISO 13485:2016 |

Number of Layers | Double-sided Printed Circuit Boards |

These features make LT CIRCUIT a great choice for industries needing strong aluminum PCBs.

Why Pick LT CIRCUIT for Aluminum PCBs?

Choosing LT CIRCUIT means picking a company that values quality. They have certifications like ISO 9001:2015 and UL, meeting global standards. Their aluminum PCBs are RoHS-compliant, making them eco-friendly.

LT CIRCUIT stands out for its heat and electricity management. With <15°C/mm temperature changes and high conductivity, their PCBs beat competitors. They are trusted in industries like cars, telecom, and LED lighting.

By choosing LT CIRCUIT, you get advanced technology, great customization, and reliable performance for your devices.

Aluminum PCBs are great at handling heat and electricity. They cut heat resistance by half, spreading heat better. This makes them useful in cars and LED lights. Special tools like ANSYS Icepak check their designs for strength. These qualities show why they are so valuable today.

FAQ

Why are aluminum PCBs better for managing heat?

Aluminum PCBs move heat away quickly. Their aluminum base helps keep devices cool. This makes them work well, even with high power.

Can aluminum PCBs be made for special uses?

Yes, aluminum PCBs can be customized in many ways. You can pick the thickness, copper amount, and mask colors to fit your needs.

Why is aluminum used in making these PCBs?

Aluminum moves heat well and is very strong. It helps aluminum PCBs work better in powerful devices like LED lights and car electronics.

See Also

The Superior Heat Dissipation Properties of Ceramic PCBs

Utilizing Aluminum Nitride Ceramic PCBs Across Various Industries

Investigating Al₂O₃ Ceramic PCB Uses in Today's Industries

Comprehensive Guide to Heavy Copper Multilayer PCB Production