Thermal Management Solutions for PCBs in LED Lighting Systems to Extend Product Lifespan

You need good thermal management for your LED lighting. If you do not have it, high heat can hurt your PCB and make LED lights not last as long. Advanced materials like aluminum and copper make the PCB better and keep LEDs safe.

The LED lighting market is growing, so better thermal management is needed.

Better PCB design helps LED systems work well.

Key Takeaways

Use metal-core PCBs like aluminum or copper. These help move heat away fast. This keeps LED lights cool. It also helps them last longer.

Apply thermal interface materials (TIMs) to fill air gaps. TIMs help heat move better. This lowers the LED temperature. It also makes LEDs last longer.

Protect PCBs with coatings and encapsulation. This blocks dust, water, and heat damage. It helps LEDs work well for a long time.

Thermal Management in LED PCBs

Heat Sources and Effects

It is important to know where heat comes from in your LED PCB. Most heat starts at the p-n junction inside the LED chip. Over half of the energy used by the LED becomes heat, not light. This heat moves into the PCB and other parts. If you do not control the heat, it can hurt the LED and other parts, like capacitors and lenses. If the LED gets 20°C hotter, it will not last as long. High heat also makes it harder for heat to leave the system. You can use aluminum or copper in your PCB to help heat move away faster. These materials help keep the LED safe by moving heat away quickly.

Aspect | Evidence Summary |

|---|---|

Main heat source in LED PCBs | Heat comes from the p-n junction; over half of energy turns into heat. |

Effect on component longevity | Higher temperature makes LED lights not last as long. |

Thermal management strategies | Use aluminum PCBs, heat sinks, and good layout to help heat leave. |

Impact on other components | High heat can hurt capacitors and lenses. |

Importance for Lifespan and Reliability

Good thermal management helps your LED lights last longer and work better. Studies show that better PCB thermal management can make the LED cooler by 56%. This can make the light 24% brighter. Every time the temperature goes up by 10°C, the chance of parts failing doubles. More than half of electronic failures happen because of too much heat. If you use good PCBs that move heat well and do not hold it in, your LED lights will last longer and work well. Using smart designs and materials, like thermal vias and heat sinks, helps heat leave faster and saves energy. LT CIRCUIT uses these ideas to help your LED systems work their best. When you control heat, you protect your lights and make them last for years.

Solutions for High-Quality PCBs

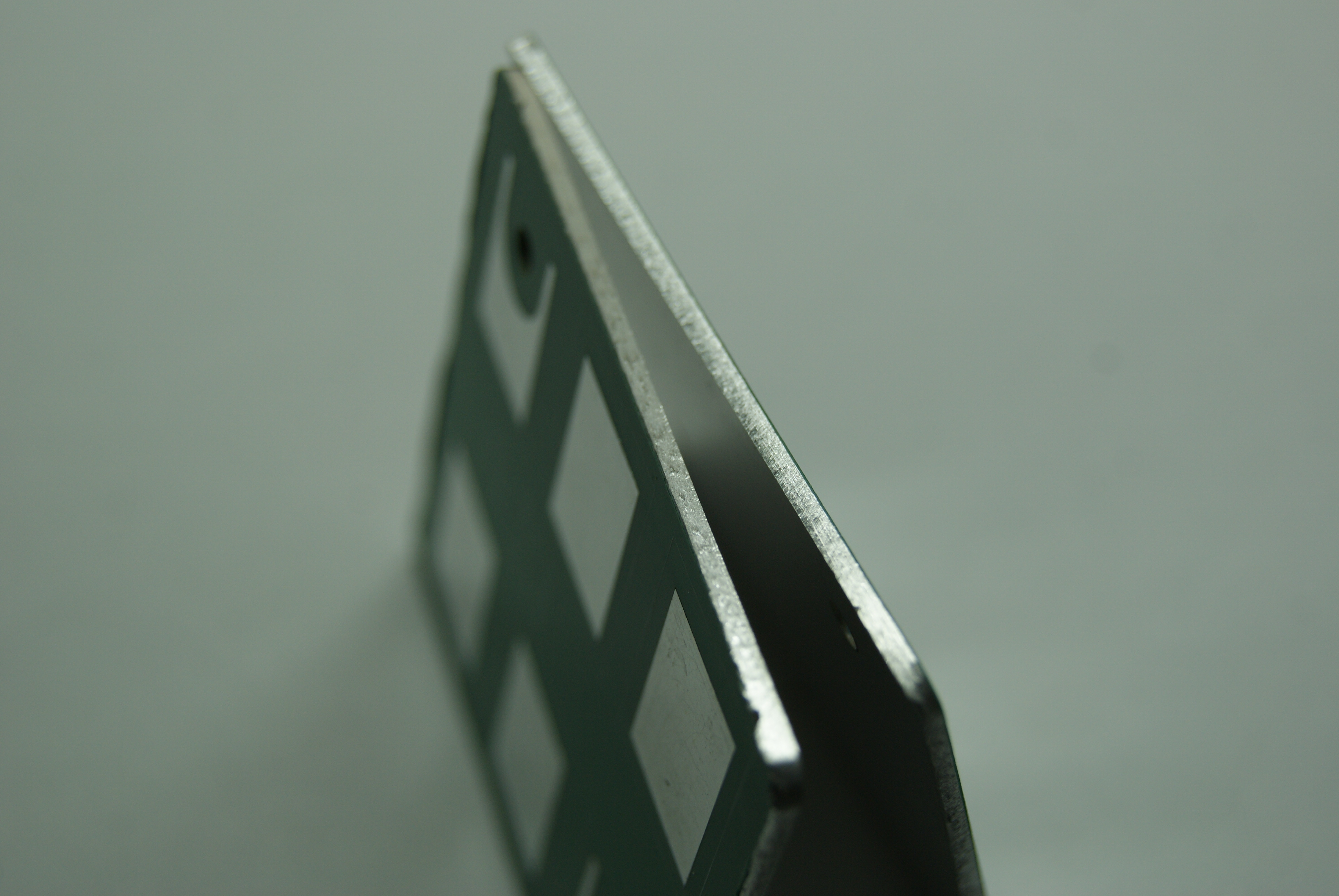

Metal-Core and Aluminum PCBs

LED lights need good thermal management. Metal-core PCBs and aluminum PCBs help move heat away fast. These PCBs use a metal base, like aluminum or copper. Aluminum core PCBs move heat well, between 1 and 10 W/mK. Copper core PCBs move heat even better, at 20 W/mK or more. Copper is faster but costs more and is heavier. Aluminum is lighter and costs less, so many people use it for LED systems.

Property | Copper Core PCB | Aluminum Core PCB |

|---|---|---|

Thermal Conductivity | ~200–230 W/m·K | |

Electrical Performance | High | Good |

Durability | High | Good |

Cost | Higher | Lower |

Both materials help with heat, but copper is the best. Using these PCBs keeps LEDs cool and helps them last longer. LT CIRCUIT uses strong materials and smart designs to make LED products work better. Wide copper traces, thermal vias, and heat sinks help move heat away. This keeps things cool and saves energy.

Tip: Pick the right metal core for your project. Aluminum works for most LED lights. Use copper if you need the best heat movement for special jobs.

Thermal Interface Materials

Thermal interface materials, or TIMs, help manage heat on your PCB. TIMs fill tiny air spaces between the LED and heat sink. Air does not move heat well, but TIMs do. This helps heat move from the LED to the metal core or heat sink. You can use pastes, pads, or special phase change materials as TIMs. They lower resistance and keep the LED temperature safe.

TIMs make it easier for heat to leave the LED.

Less resistance means better heat flow and longer life.

Some TIMs, like those with nanoparticles, move heat even better.

The right TIM can lower the LED temperature and help it last.

When you use good PCB designs and the best TIMs, your LED lights last longer. LT CIRCUIT says to use TIMs in all high-power LED projects to protect your lights.

Encapsulation and Coatings

Encapsulation and coatings keep your PCB safe from tough conditions. Encapsulation covers parts with a thick layer that spreads heat and blocks dust, water, and chemicals. This layer uses materials that move heat well and keep things cool. Thinner layers help heat move out and lower the temperature. Coatings, like waterproof and UV-resistant ones, add more protection. They stop water and sunlight from hurting your LED system.

Encapsulation Thickness | Operating Temperature Change | Thermal Resistance Change | Electrical Insulation (Breakdown Voltage) |

|---|---|---|---|

1mm | Baseline | Baseline | N/A |

2mm | Decreased temperature | Improved heat dissipation | Meets insulation requirements |

4mm | N/A | N/A | +500V |

5mm | +15°C | +0.5°C/W | Good insulation but higher temperature |

These coatings and encapsulation help your PCBs last longer and stay strong. LT CIRCUIT uses special finishes and coatings to make sure LED products work well anywhere.

Enhancing Reliability with LT CIRCUIT

You want your LED lights to last a long time. LT CIRCUIT helps by using great PCBs and smart designs. LT CIRCUIT uses metal-core PCBs, thermal vias, and strong materials to move heat away. In real projects, LT CIRCUIT keeps LED temperatures below 85°C. This helps LEDs last longer and work better. For example, a street light with an aluminum PCB and thermal pads stayed cooler and lasted longer.

Metric / Technique | Description |

|---|---|

Heat Dissipation Improvement | Metal core PCBs move 300% more heat than FR-4 boards |

Thermal Vias | Holes filled with copper or solder help heat move up and down |

Thermal Resistance Reduction | Thermal vias lower resistance by 40–60% compared to just using traces |

Implementation Best Practices | Put thermal vias under hot parts; use silver-filled pastes or copper for better heat flow |

LT CIRCUIT also tests and checks every PCB to make sure it is good. You get PCBs that work well, last long, and are safe. With LT CIRCUIT, your LED lights will work well even in tough places.

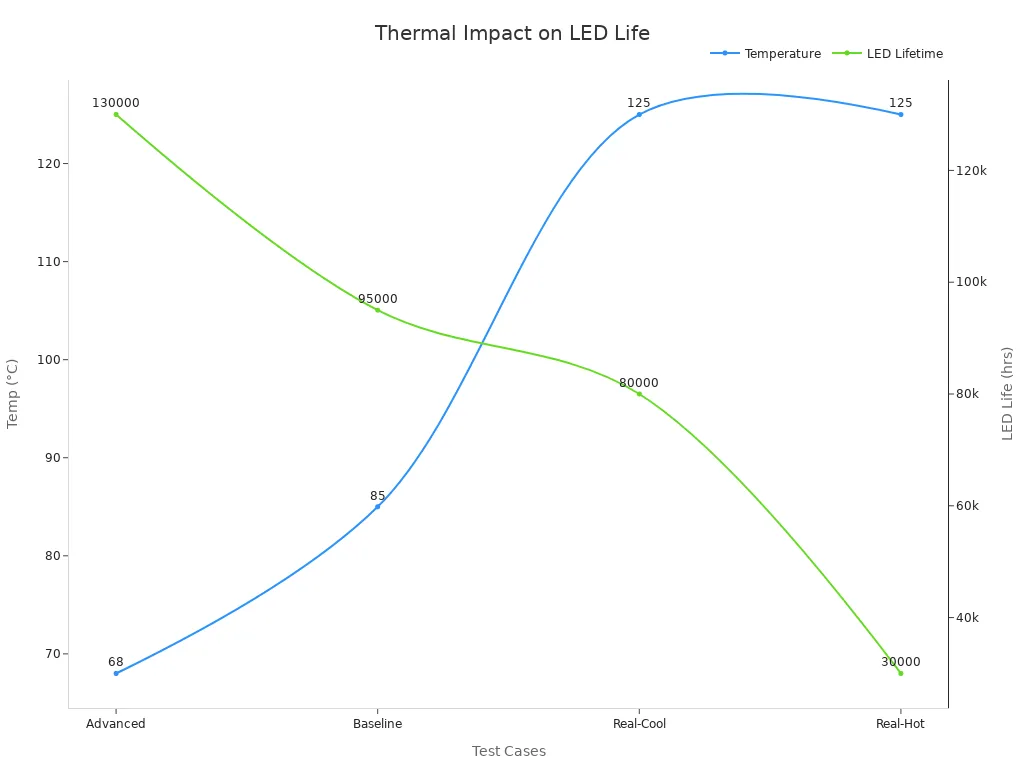

You can help your LED lights last longer by using good thermal management and strong PCBs. LT CIRCUIT gives you smart ways to control heat better. Look at the table below. It shows how picking the right materials and design helps LEDs work well and last longer.

Aspect | Description / Data |

|---|---|

Temperature Reduction Example | The right thermal interface material can make LED temperature drop by 20-30%. It can go from 85°C down to 68°C. |

Lifetime Improvement Example | Good thermal management can make LED lifetime go from 95,000 hours up to 140,000 hours. |

Tip: Check your PCB design for hot spots. Test it and use better materials to help your LED lights last longer.

FAQ

What is the best PCB material for LED thermal management?

Aluminum core PCBs work well for most LED lights. You get good heat movement, light weight, and lower cost compared to copper.

How do you know if your LED PCB has good thermal management?

You can check for hot spots with a thermal camera. If the board stays cool and LEDs last longer, your thermal management works.

Why does LT CIRCUIT recommend using thermal interface materials (TIMs)?

TIMs fill air gaps between parts. You get better heat flow, lower temperatures, and longer LED life when you use them.

See Also

Creating Efficient PCBs Specifically For LED Technology Use

Boosting LED And Power Electronics With Aluminum PCB Production

High Temperature FR4 PCBs Delivering Outstanding Performance Results

Key Factors In Producing PCBs For Tough Industrial Conditions

Overcoming Production Issues With High TG FR4 PCBs In Industry