The impact of tin immersion in PCB surface finish on solder mask stability

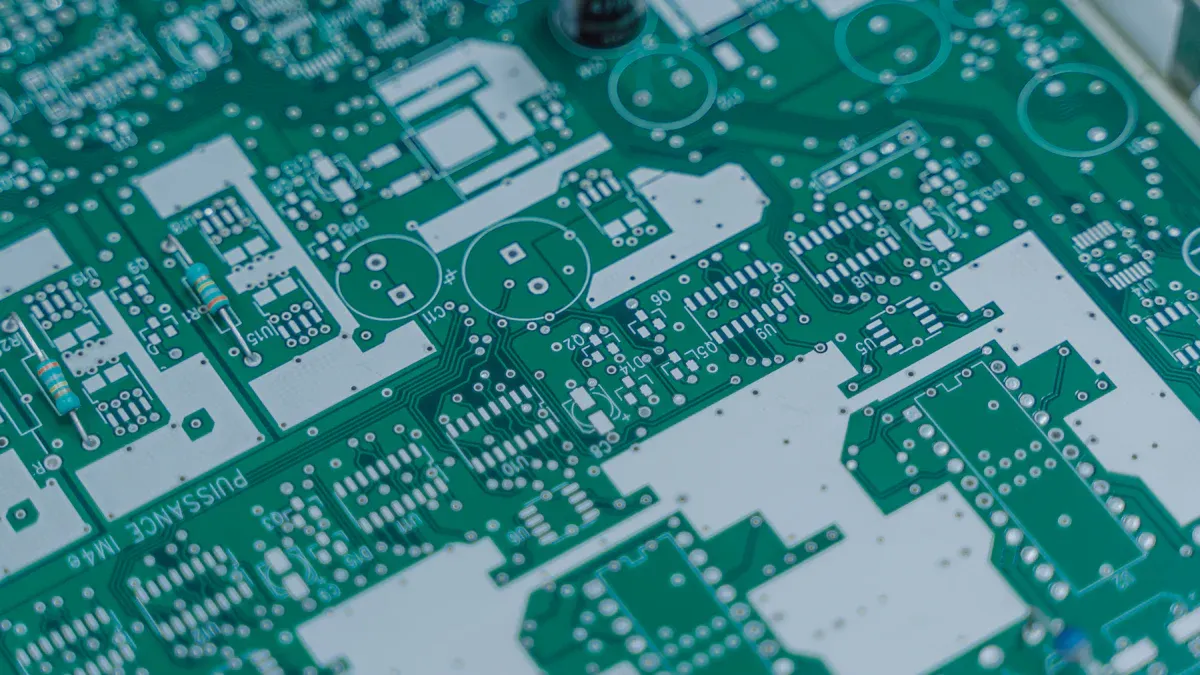

The tin immersion in PCB process significantly impacts the strength of the solder mask. The solder mask serves to protect the board and enhance its functionality. If the solder mask becomes weak, the PCB may experience failure. Addressing this issue is crucial for producing reliable PCBs. LT CIRCUIT is dedicated to developing innovative solutions to enhance this vital component.

Key Takeaways

Tin immersion adds a thin tin layer to PCBs. This stops rust and helps with better soldering.

Solder masks must be cured properly. If not, they can peel or break down, causing PCB problems.

Cleaning well during production removes residues. This makes solder masks stronger and PCBs more reliable.

Understanding Tin Immersion in PCB and Solder Mask Stability

Tin immersion in PCB: Purpose and benefits in surface finishing

Tin immersion is an important step in making PCBs. It uses a chemical process to replace copper with a thin tin layer. This helps protect the board from rust and keeps costs low. For instance, it works well in cars and high-frequency devices. It creates strong copper-tin bonds during soldering. The even tin layer improves electrical performance. Plus, it is lead-free, which is better for the environment.

Benefit/Characteristic | Description |

|---|---|

Tin immersion helps protect against rust. | |

Application Suitability | Used in cars and high-frequency electronics. |

Cost | Cheaper than other surface finishes. |

Joint Formation | Makes strong copper-tin bonds when soldered. |

Whisker Growth Precautions | Needs careful control to avoid whisker growth. |

Deposition Process | Replaces copper with tin using chemicals. |

Ionic Contamination Precautions | Rinsing is needed to avoid contamination. |

The role of solder masks in PCB protection and performance

Solder masks protect PCBs and improve their performance. They stop copper from rusting and prevent solder from connecting wrong parts. Solder masks also lower the chance of circuit failure by increasing insulation. However, the mask's thickness is important. A thick mask protects better but makes soldering small parts harder.

Evidence Type | Description |

|---|---|

Surface Insulation Resistance | Helps stop circuit failure by reducing migration. |

Insertion Loss | Can affect signals by increasing insertion loss. |

Microstrip Evaluation | Impacts trace performance by raising insertion loss. |

Interaction between tin immersion and solder masks during manufacturing

Tin immersion and solder masks affect each other during production. Tin plating can leave solder mask bits on copper, making soldering harder. If the mask isn’t fully cured, it may not stick well. Chemicals in tin baths can dissolve uncured masks, causing copper damage. Proper curing and cleaning help masks stick better and avoid these problems.

Solder mask parts can mix with tin during plating, causing issues.

Mask leftovers can move to the tin layer, weakening solder joints.

Tests show that cleaning the surface improves mask sticking.

By learning about these effects, you can make better PCBs.

Challenges in Solder Mask Stability During Tin Immersion

Chemical interactions affecting solder mask integrity

The chemicals used in tin immersion can harm solder masks. These strong chemicals might damage the mask, causing it to peel or weaken. When this happens, the copper underneath can get exposed and damaged. This can hurt how well the PCB works.

Using good-quality solder masks can lower these risks. Strong solder masks can handle chemical exposure better, keeping the PCB safe. But even with great materials, careful control of the process is still very important.

Problems with undercured solder masks

Undercured solder masks are another problem during tin immersion. If the mask isn’t fully cured, it won’t stick well to the PCB. This weak bond can make the mask peel off or dissolve in the chemicals. When this happens, the copper underneath can rust or get damaged.

To fix this, make sure the solder mask is fully cured before tin immersion. Use the right heat and time to make the mask stick well. Proper curing makes the mask stronger and better at resisting chemicals.

Residue formation and its effects on solder masks

Residues from tin immersion can harm solder masks. These residues often come from poor cleaning during production. They can cause problems like:

Pinholes or voids: Tiny holes in the mask can expose copper, leading to rust.

Damage to copper parts: Moisture and chemicals can get into these holes, harming the copper.

Lower production success: Residues can weaken solder joints, raising costs and lowering quality.

To avoid these issues, clean and rinse thoroughly during tin immersion. This reduces residues, keeps the solder mask strong, and improves PCB performance.

Problem | Explanation |

|---|---|

Sensitive to handling | Tin immersion needs careful handling to protect solder masks. |

Tin immersion has a short shelf life, with risks of whiskers forming. | |

Harsh on solder masks | Tin immersion can damage solder masks, making them less stable. |

Not for peelable masks | Peelable masks don’t work well with tin immersion. |

Special testing needed | Electrical testing requires special settings due to handling challenges. |

By knowing these problems and using smart methods, you can make solder masks last longer and improve PCB reliability.

Effects of Solder Mask Instability on PCB Performance

Soldering problems: De-wetting and non-wetting

Unstable solder masks can cause soldering problems like de-wetting. This happens when solder doesn’t stick well to the PCB. Weak or incomplete joints may form. Residues on copper or tin during tin immersion often cause these issues. For example, residues can block soldering during heating or cause melting problems.

Type of Contamination | Effect on Soldering Problems |

|---|---|

Residues on Copper | Stops solder from sticking, causing de-wetting during heating. |

Contamination on Tin | Leads to melting problems and shows under UV light. |

Re-condensation of Volatiles | Releases gases during heating, weakening the solder mask. |

To avoid these problems, clean and cure solder masks well before tin immersion. This lowers contamination and makes solder joints stronger.

Long-term PCB reliability issues

Solder mask instability can also harm PCB reliability over time. Poor adhesion or tiny holes in the mask let chemicals in. These chemicals damage copper and shorten the PCB’s life. Moisture makes this worse, leading to failures in tough environments.

Tests show how important strong solder masks are. Tests like the Dissolution Test check if masks resist harsh chemicals. Heat Stress Tests ensure PCBs survive extreme temperatures without peeling. These tests prove that bad curing or prep can hurt PCB performance.

Tiny holes in masks let chemicals in, causing damage.

Moisture and other factors lead to failures over time.

Uneven mask thickness changes signals in high-frequency designs.

By following solder mask rules and improving production steps, you can make PCBs last longer and work better.

Solutions and Best Practices by LT CIRCUIT

Process control for better tin immersion results

Controlling the tin immersion process helps solder masks stay strong. It also improves how well PCBs work. You can do this by managing things like heat, time, and chemicals. A good process lowers problems like tin whiskers or uneven tin layers.

Feature | Explanation |

|---|---|

Immersion Tin |

When you control these steps, you get many benefits:

Flat surfaces make soldering easier.

The process avoids lead, helping the environment.

It works well for fixing mistakes and press-fit pins.

But challenges like damage, whiskers, and rust need care. You should check the tin layer thickness, which is hard to measure. Fixing these issues makes PCBs more reliable.

Cleaning and post-treatment for stronger solder masks

Cleaning and post-treatment are key to keeping solder masks stable. Leftover materials after tin immersion can weaken masks and cause problems later. Use cleaning methods that match your PCB needs.

Cleaning Type | Important Points | Helps Solder Mask Stability? |

|---|---|---|

Blocks holes; easy residue removal | Works if residues aren’t over-cured. | |

Aggressive Cleaning | Needed for over-cured masks | Removes leftover materials effectively. |

Low-Residue Soldering | Needs reliability tests | Lowers early failures in the field. |

Cleaning Media | Think about cost and safety | Impacts cleaning success. |

For example, soluble masks make cleaning simpler. Strong cleaning works better for tough residues. Picking the right cleaning tools affects how well the process works. Balance cost, safety, and eco-friendliness when choosing cleaners. Good cleaning keeps solder masks strong and working well.

Picking good solder masks and matching chemicals

Choosing strong solder masks and matching chemicals is important. High-quality masks handle chemicals better and stick firmly to PCBs. This stops peeling, holes, and other problems.

LT CIRCUIT uses smart material choices for reliable PCBs. For example:

Proper trace spacing stops signal problems and handles current safely.

Heat sinks and pads prevent parts from overheating.

Using these ideas with good materials makes better PCBs. Always check that tin immersion chemicals work well with the solder mask. This avoids bad reactions and makes PCBs last longer and work better.

Tin immersion is key to keeping solder masks strong. Strong solder masks help PCBs work well and last longer. Using better materials and improving production steps makes PCBs more reliable. New ideas like nanotechnology and AI will improve accuracy and strength. LT CIRCUIT leads these changes, offering top solutions for industry needs.

FAQ

What does tin immersion do in PCB making?

Tin immersion stops copper from rusting and helps with soldering. It adds a smooth tin layer, making the PCB last longer and work better.

How can you keep solder masks stable during tin immersion?

To keep masks stable, cure them completely and use good materials. Clean off any leftover residues during production to avoid problems.

Why does solder mask thickness matter for PCBs?

Thicker masks protect against rust and short circuits better. But very thick masks can make soldering tiny parts harder.

See Also

How LDI Technology Reduces Solder Mask Bridges in PCBs

Impact of VCP on Copper Thickness Consistency in PCB Manufacturing

How LDI Enhances Overall Quality of PCB Products

Utilizing Horizontal Copper Sinking Technology in PCB Manufacturing

Importance of Vacuum Two-Fluid Etching in Precision PCB Production