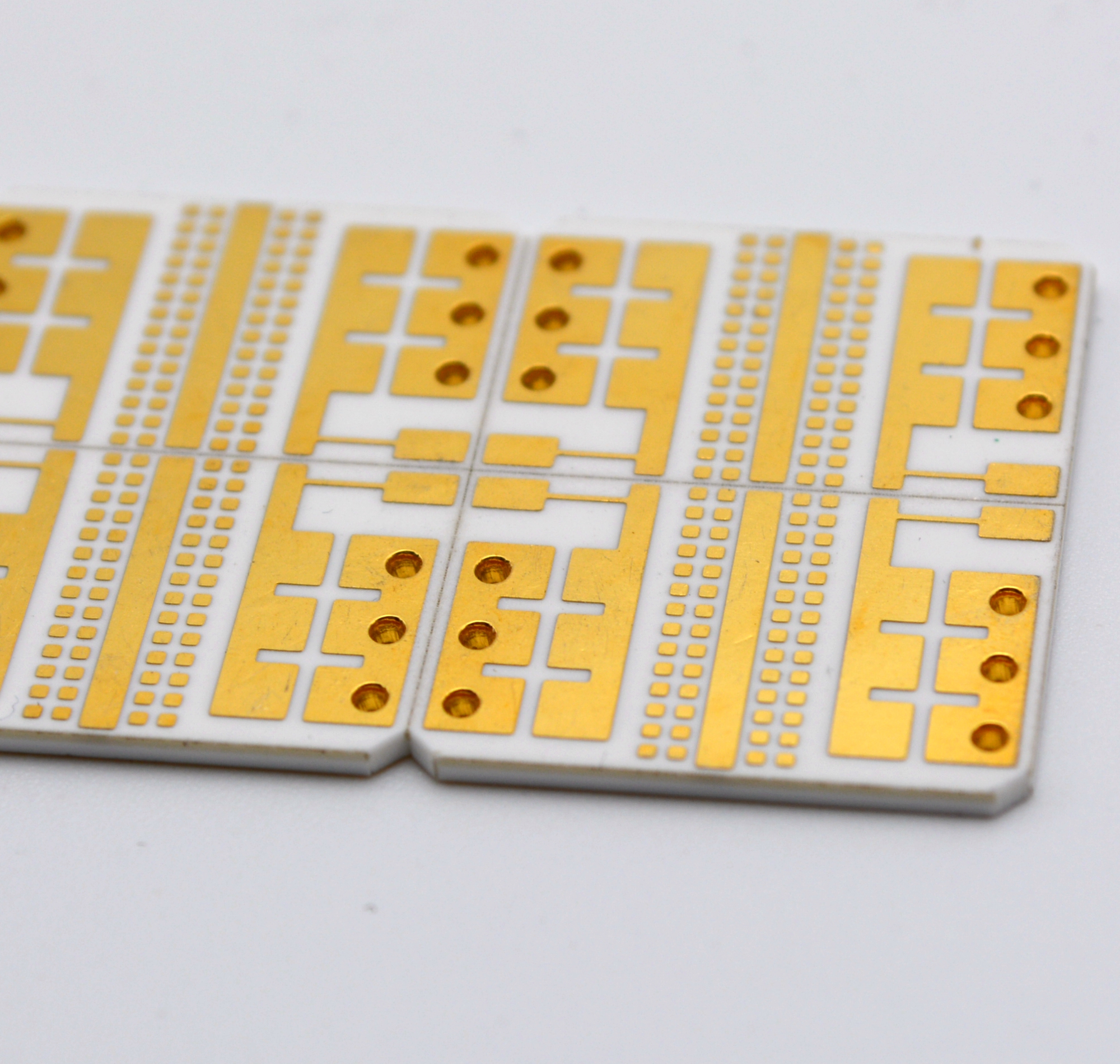

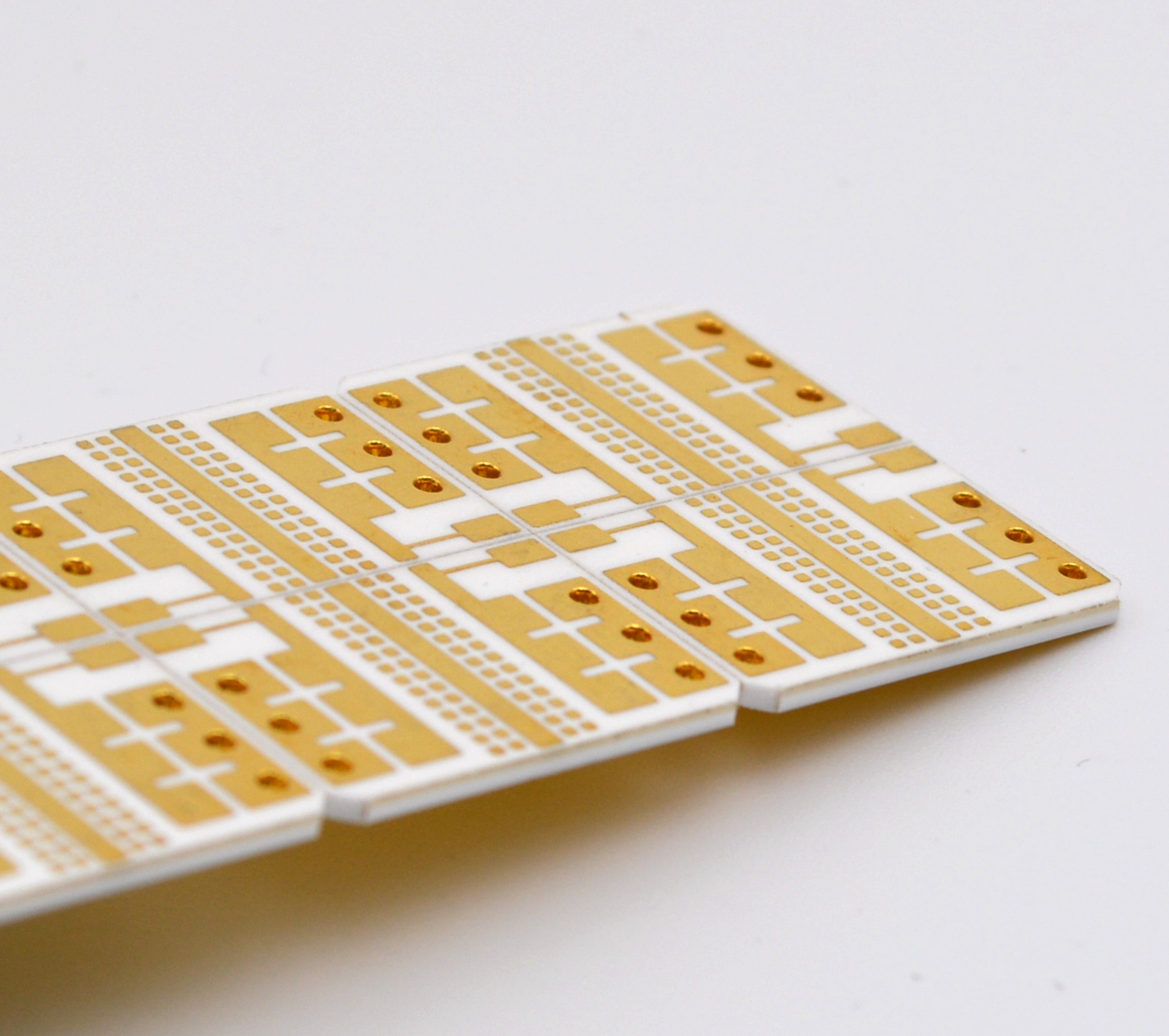

Best Ceramic Multilayer PCB Makers for High-Performance Applications

Leading ceramic multilayer PCB makers for high-performance use in 2025 are Zhen Ding Tech. Group, Unimicron, Viasion Technology, Suzhou Dongshan Precision, Compeq, Nippon Mektron, TTM Technologies, Tripod Technology, GlobalWellPCBA, Best Technology Co., Ltd., PCBONLINE, and BSTCeramicPCB. These ceramic pcb makers are special because:

They use advanced ways to make PCBs, like laser drilling, microvias, and thermal management.

They have important certificates, such as ISO 9001:2015 and IPC-6012 Class 3.

They are known for making reliable ceramic PCBs for tough jobs.

Picking a trusted ceramic multilayer pcb maker helps make sure your project works well, lasts long, and stays safe for important uses.

Key Takeaways

The best ceramic multilayer PCB makers use new technology. They also use strict checks to make strong boards. These boards work well for hard jobs like aerospace, medical, and car uses.

Picking a trusted maker with the right certificates is important. Good customer help makes sure your project is done well. This helps your project last longer and work well in tough places.

Ceramic multilayer PCBs are great at moving heat. They do not break easily and can be made in special ways. This makes them good for fast electronics, defense, and medical tools.

Top Ceramic Multilayer PCB Manufacturers

Zhen Ding Tech. Group

Zhen Ding Tech. Group is a top company for ceramic multilayer PCBs. They make products for jobs that need strong and advanced PCBs. Zhen Ding works with high-frequency and special PCB types. Their PCBs are used in 5G, cars, computers, radar, planes, and electronics for people. Zhen Ding’s PCBs follow strict rules. Their products help in places where quality and performance matter most.

Unimicron Technology Corporation

Unimicron Technology Corporation is one of the best ceramic PCB makers. They are good at making HDI substrates, flip-chip substrates, and rigid-flex PCBs. Unimicron uses new ways to make PCBs, like tiny lines and small holes.

Aspect | Details |

|---|---|

Core Products | HDI PCBs, Flexible Printed Circuits, Rigid-Flex PCBs, IC Substrates, Multilayer PCBs |

Applications | Consumer Electronics, Telecommunications (5G), High-speed Communication, Data Centers, Automotive |

Factory Locations | Taoyuan (Taiwan), Shenzhen (China), Suzhou (China) |

Advantages | Advanced packaging, green materials, high-speed and high-density PCBs for IoT and 5G |

Unimicron’s PCBs are used in tough jobs like telecom and cars.

Viasion Technology Co., Ltd.

Viasion Technology Co., Ltd. makes ceramic multilayer PCBs for many industries.

Main industries they help:

Electronics for people

Car solutions

Medical machines

Defense and space

Factory automation

Application areas:

Power PCB

LED PCB

Inverter PCB

Control PCB

Sensor PCB

Amplifier PCB

Radar PCB

Medical PCB

Automotive PCB

Capacitive PCB

HVAC circuit board

UPS circuit board

Energy meter PCB

Viasion’s skill in making ceramic multilayer PCBs means their products work well in both normal and important jobs.

Suzhou Dongshan Precision Manufacturing

Suzhou Dongshan Precision Manufacturing, called DSBJ, is known for being careful and making quality PCBs. They help with telecom, cars, and factory electronics. DSBJ uses new tech and checks quality closely. This makes them a good pick for hard jobs.

Compeq Manufacturing Co., Ltd.

Compeq Manufacturing Co., Ltd. is known for new ideas in ceramic multilayer PCBs. They make PCBs for telecom, cars, and electronics for people. Compeq works hard on research. This helps them make PCBs for fast and reliable needs.

Nippon Mektron, Ltd.

Nippon Mektron, Ltd. is a big Japanese company for flexible and multilayer PCBs. Their ceramic multilayer PCBs are used in cars, medical, and factory jobs. Nippon Mektron cares about quality and new ideas. This makes their PCBs work well in hard places.

TTM Technologies Inc.

TTM Technologies Inc. is special for making PCBs for jobs that must not fail. They use new PCB tech, like substrate-like PCBs and special packages. Their PCBs are used in planes, defense, space, medical, telecom, and military. TTM’s PCBs are fast, strong, and small. CoreEZ® packages help in space jobs that need to handle radiation. This makes TTM a trusted company for important jobs.

Tripod Technology Corporation

Tripod Technology Corporation is a big name in ceramic multilayer PCBs. Their PCBs are used in cars, electronics for people, and factories. Tripod uses new ways to make PCBs and checks quality. This helps their PCBs work well for hard jobs.

GlobalWellPCBA

GlobalWellPCBA is in Guangzhou, China. They make ceramic multilayer PCBs with alumina and aluminum nitride.

Feature | Details |

|---|---|

Certifications | ISO 9001, UL, RoHS, IATF 16949 |

Industries Served | Medical, Automotive, Aerospace, Military, Telecom |

Distinguishing Features | High thermal conductivity, durability, customization, high-quality standards |

GlobalWellPCBA is good at making custom PCBs and cares about quality. This makes them a good choice for projects that need strong ceramic PCBs.

Best Technology Co., Ltd.

Best Technology Co., Ltd. has more than 18 years of experience with ceramic multilayer PCBs.

Special things about them:

They do everything from start to finish

They answer fast (in 12 hours)

They use military-level quality

Certifications: ISO13485, IATF16949, AS9100D

No minimum order size

5 years quality promise

Free tech help

They make PCBs in their own factory

All PCBs are tested before shipping

They can make samples fast and also do big orders

Custom designs for any industry

Friendly and helpful team

New ways to make PCBs and strict checks

Many products like Aluminum Nitride PCB, Alumina, and multilayer ceramic PCBs

Best Technology stands out because they care about quality and helping customers.

PCBONLINE

PCBONLINE is a trusted company for ceramic multilayer PCBs.

They use an ISO quality system.

Certifications: ISO 9001, IATF 16949, RoHS, REACH, UL, and IPC.

Ceramic is a main material in their PCBs.

PCBONLINE’s focus on quality and rules means their PCBs are good for tough jobs.

BSTCeramicPCB Co., LTD

BSTCeramicPCB Co., LTD has many types of advanced ceramic PCBs.

Layers | Temperature Range | Conductor Thickness | Line Spacing/Width (LS/LW) | Typical Applications / Industries | |

|---|---|---|---|---|---|

Thick Film Ceramic PCB | Up to 10 | -50 to 500°C | 5µm - 13µm | 6/8 mil (0.15/0.20 mm) | Medical, automotive, aerospace, laser equipment, solar cells, high-power semiconductor modules |

Thin Film Ceramic PCB | Up to 10 | -40 to 200°C | 1-3 µm | 20µm / 20µm | Satellite communications, defense equipment, sensor systems |

DPC Ceramic PCB | 2 | -40 to 200°C | 2µm - 200µm | 3/3 mil (0.075/0.075 mm) | LED lighting, electronic products, laser equipment, aerospace, automotive electronics |

DBC/DCB Ceramic PCB | 2 | -40 to 200°C | 3.90 oz - 8.60 oz | 12/12 mil (0.30/0.30 mm) | High-speed rail, automotive electronics, industrial electronics, communications, military, aerospace |

AMB Ceramic PCB | 2 | -40 to 200°C | 80 oz - 22.90 oz | 20/20 mil (0.50/0.50 mm) | High-power semiconductor modules, high-frequency switches, wind power, solar energy, automotive, aerospace, 5G, medical |

LTCC Ceramic PCB | 2 | -40 to 300°C | 2µm - 200µm | 6/8 mil (0.15/0.20 mm) | Communication equipment, power base stations, automotive electronics, solar applications, radar, aerospace |

HTCC Ceramic PCB | 6-30 | -40 to 300°C | 2µm - 12µm | 150µm (surface layer can be refined to 50µm) | Aerospace, military, national defense, high-temperature equipment, medical equipment |

BSTCeramicPCB has 17 years of experience, custom options, and quick service.

They help customers all over the world with ceramic PCB and PCBA needs.

Other Notable Ceramic PCB Manufacturers

Some new ceramic multilayer PCB makers are getting noticed for new ideas and quality.

Location | Key Materials Used | Certifications | Industries Served | Distinguishing Features / USPs | |

|---|---|---|---|---|---|

GlobalWellPCBA | Guangzhou, China | Alumina (Al2O3), Aluminum Nitride (AlN) | ISO 9001, UL, RoHS, IATF 16949 | Medical, Automotive, Aerospace, Military, Telecom | High thermal conductivity, durability, customization, high-quality standards |

Millennium Circuits Limited | Harrisburg, USA | Aluminum Nitride, Alumina, Boron Nitride | ISO 9001, RoHS | Aerospace, Automotive, Medical, Heavy Machinery | High thermal conductivity, chemical erosion resistance, cost-effective, custom solutions |

Sierra Assembly Technology | Chino, California, USA | Alumina, Aluminum Nitride, Beryllium Oxide | ISO 9001 | Aerospace, Automotive, Medical, Telecom, Industrial | Superior heat management, high-frequency performance, durability, customization |

Andwin Circuits | Irvine, California, USA | Alumina, Aluminum Nitride, Silicon Nitride | UL, TS16949 | Consumer Electronics, Automotive, Communications | High thermal conductivity (up to 320 W/m.K), mechanical strength, chemical resistance, customization |

Absolute Electronics | Illinois, USA | Alumina, Aluminum Nitride | ISO 9001:2015, ISO 14001 | LED Lighting, Automotive, Aerospace, Military | High thermal conductivity, mechanical strength, reliability, advanced manufacturing technology |

Rush PCB Inc. | Milpitas, California, USA | Alumina, Aluminum Nitride | ISO 9001, UL, RoHS, IPC | Solar Panels, Automotive, Aerospace, Military | High stability, high thermal conductivity, low dielectric loss, high dielectric strength |

TTM Technologies | Costa Mesa, California, USA | LTCC and thick-film ceramics | N/A | Medical Devices, Aerospace | Specializes in LTCC and thick-film tech for high-reliability applications |

These companies keep making better ceramic multilayer PCBs. They help industries that need strong and advanced PCBs.

Key Features of Leading Manufacturers

Advanced Capabilities

Top ceramic multilayer PCB makers use new technology for better PCBs. They use laser drilling and patterning for exact holes and lines. Ultrasonic and epoxy bonding keep the layers together and strong. They control heating steps to stop cracks or bending. This makes the PCBs last longer. Machines check for problems with cameras, X-rays, and tests. Makers use process control to keep every batch the same. Laser micromachining and ultrasonic bonding help make tiny, strong parts. Makers work with suppliers to get better materials and tools. They use special checks like XRD and SEM to pick the best ceramic. Robots and machines help make PCBs with fewer mistakes and lower costs. Makers test PCBs with heat and shaking to make sure they work in hard places.

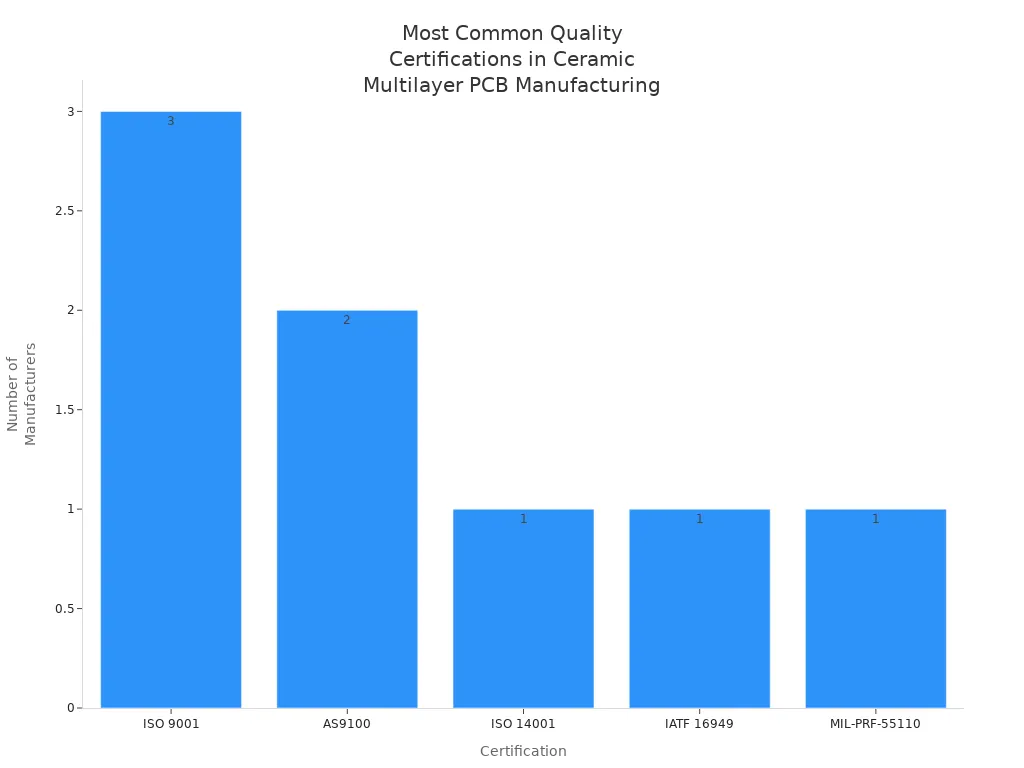

Quality and Certifications

Quality is very important for top ceramic PCB makers. They follow strict rules to make sure PCBs are safe and work well. Common certifications are ISO 9001, AS9100, IATF 16949, and MIL-PRF-55110. These rules help track parts, protect the environment, and control bad chemicals. Makers test PCBs with heat, electricity, and machines to check if they last and work right.

Certification | Focus Area | Industry Application |

|---|---|---|

ISO 9001 | Quality Management | All Industries |

AS9100 | Aerospace Quality | Aerospace, Defense |

IATF 16949 | Automotive Quality | Automotive |

MIL-PRF-55110 | Defense Reliability | Defense, Aerospace |

Customer Support

Good ceramic PCB makers give strong customer support. They answer questions fast and keep talking with customers. Design help lets customers get PCBs that fit their needs. Custom choices mean each project gets the right answer. Engineers give tips to make PCBs work better and last longer. Makers plan their work to match customer deadlines, so projects finish on time. Certifications like ISO 9001 and IATF 16949 show they care about quality. These steps help customers trust the maker and do well in hard jobs.

High-Performance Applications

Ceramic multilayer PCBs are very important in many top industries. The table below shows where these special boards are most useful:

Application Sector | Relevance to Ceramic Multilayer PCBs in High-Performance Applications |

|---|---|

Consumer Electronics | Used in things like smartphones because they are small, strong, and reliable. |

Telecommunication | Used in network tools, GPS, and transmitters for steady work. |

Medical Devices | Needed in laser tools, CAT scans, and heart monitors that must work right every time. |

Military and Defense | Needed for jobs that need tough, light, small, and fast boards. |

Automotive and Aerospace | Used in car computers, sensors, and systems that face heat and rough places. |

Industrial | Used in factories, home gadgets, and IoT where space and speed matter a lot. |

Aerospace & Defense

Aerospace and defense need the best PCBs for safety and performance. Ceramic multilayer PCBs must handle very hot and cold, shaking, and strong signals. These boards are used in planes, radar, and missile systems. They follow military rules like MIL-PRF and IPC-6012 to work well in hard places. Engineers use heat sinks and thermal vias to stop them from getting too hot. Extra safety parts and backup systems keep important things safe. Making these PCBs is hard and takes more time, but they last longer and work better.

Automotive Electronics

Cars use ceramic multilayer PCBs in engine controls, brakes, and sensors. These boards can take high heat and power in cars. Ceramic gives good heat flow, keeps electricity safe, and is very strong. The low thermal expansion matches silicon, so it does not break when hot or cold. These things help the boards last in tough car places, like in electric cars and smart driving systems.

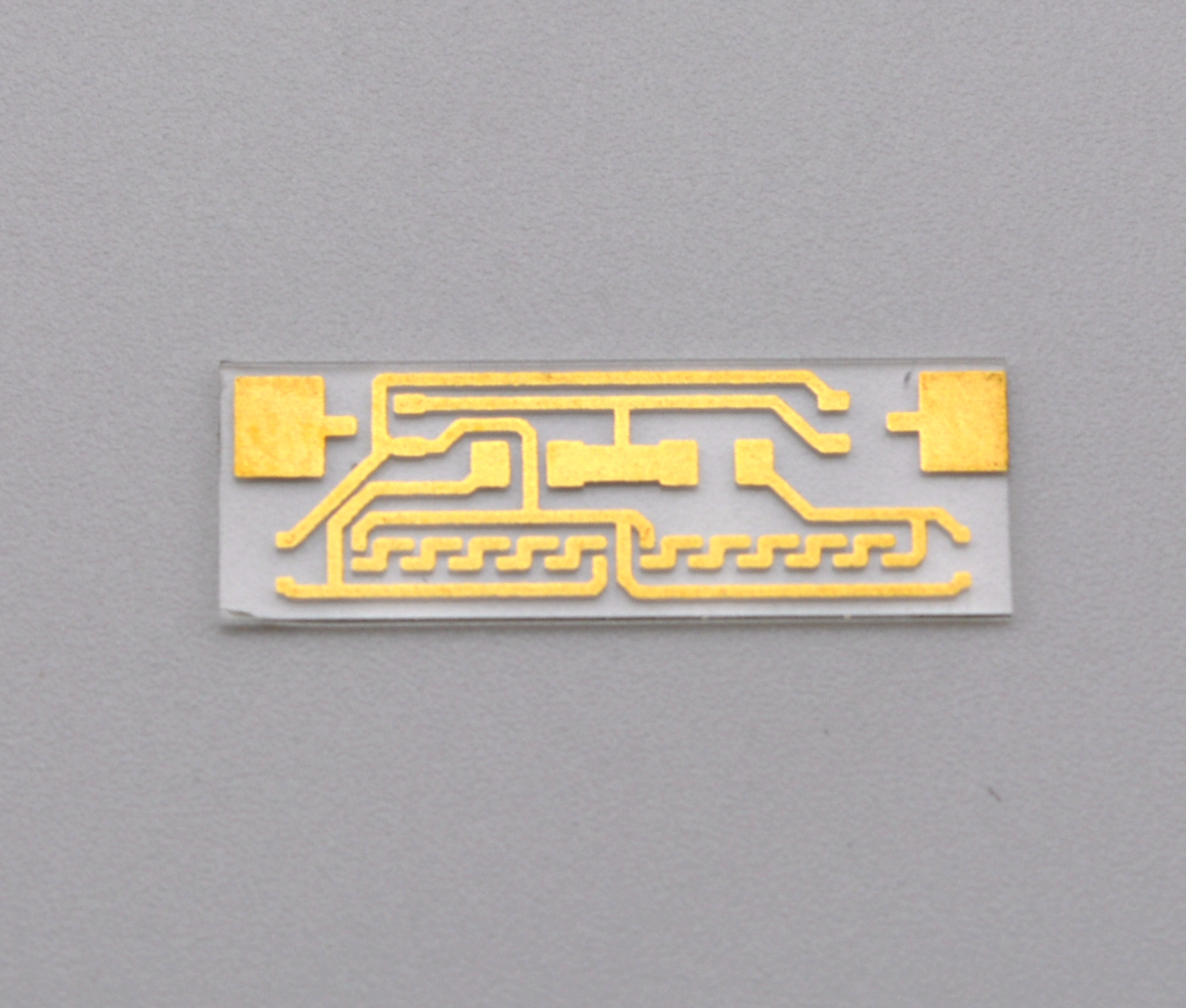

RF & Microwave

RF and microwave jobs need ceramic PCBs to keep signals clear at high speeds. Engineers pick ceramic to stop signal loss and crosstalk. Careful trace spacing and steady dielectric constants help keep signals strong. These boards do not get hurt by water or radiation, so they work in satellites and radar. Many layers help match impedance and move heat away, so the boards work well in hard RF jobs.

Medical Devices

Medical devices need ceramic multilayer PCBs to be safe and work every time. These boards are in heart monitors, CAT scans, and laser tools. Makers follow strict rules like IPC-6012 Class 3, ISO 13485, and IEC 60601. They test with heat and stress to make sure the boards last. Ceramic stands up to heat, wetness, and chemicals. Special coatings and smart designs make them stronger and stop problems. These things help medical devices stay safe and work well for people.

Choosing Ceramic PCB Manufacturers

Technical Requirements

When picking a ceramic PCB maker, you must know your needs. Makers should have experience with alumina, aluminum nitride, and glass ceramics. These materials change how heat moves and how strong the board is. You must pick thick film or thin film technology. Thick film is good for power electronics and sensors. Thin film is better for high-frequency circuits. It is important to be very exact for advanced uses. The table below shows what you should look for:

Technical Requirement | Description |

|---|---|

Material Capabilities | Experience with alumina, aluminum nitride, glass ceramics |

Manufacturing Processes | Thick film or thin film, metallization methods |

Precision and Tolerances | Ability to meet strict controls |

Production Volume Capacity | Support for prototypes to large-scale production |

Quality Control Measures | Robust inspection and testing |

Certifications and Standards | Compliance with ISO, IPC, and industry-specific standards |

Quality Standards

Quality is very important when making ceramic PCBs. Top makers test boards for electricity, heat, and strength. They pick ceramic PCBs that are strong and work well. Rules like IPC-TM-650 and ISO 9001 help check copper peel strength and soldering. Makers keep holes and lines the right size. They use special finishes and test every batch to make sure it is good.

Lead Times & Scalability

Makers can finish boards fast or take more time if needed. Some can make a prototype in just one day. Normal orders may take up to four weeks. They can make just a few boards or many at once. There is no minimum order, so anyone can order what they need. This helps new companies and big companies get the right amount of boards quickly.

Value-Added Services

Good ceramic PCB makers do more than just make boards. They let you customize and use new ways to make PCBs. They help design PCBs and test them with in-circuit and X-ray checks. They can make prototypes quickly. Makers offer different finishes and help many industries, like aerospace, cars, and medical devices. These extra services make products better, stronger, and faster to sell.

Picking a trusted ceramic multilayer PCB maker helps your project work well. The best companies use new technology and have important certificates. They also know a lot about how to use PCBs in different jobs.

People who buy PCBs should look at how reliable the maker is, if they give good help, and if they check quality.

It is smart to pick a maker that is reliable and helpful. This helps your project do well in hard jobs.

FAQ

What are the main benefits of ceramic multilayer PCBs?

Ceramic multilayer PCBs move heat away fast. They stop electricity from leaking. These boards are very strong and last a long time.

Engineers use them in places like planes, cars, and hospitals.

How do manufacturers ensure quality in ceramic multilayer PCBs?

Makers check their boards many times. They use special tests and follow world rules.

ISO 9001

IATF 16949

AS9100

Can ceramic multilayer PCBs support custom designs?

Yes, most top makers let you pick your own design. You can choose the materials and get samples quickly.

Service | Availability |

|---|---|

Custom Layout | ✅ |

Material Choice | ✅ |

Fast Prototyping | ✅ |

See Also

A Comprehensive Overview Of Manufacturing Multilayer Ceramic PCBs

Diverse Uses Of Multilayer PCBs In Various Industries

Understanding Ceramic PCB Applications In Today’s Industrial Sectors

Advanced Production Techniques For Heavy Copper Multilayer PCBs