Top Factors to Consider When Choosing a Multilayer PCB Supplier

When you pick a multilayer PCB supplier, you should look for good quality and trust. Reports say that bad suppliers can cause many problems, like:

Manufacturing mistakes such as layers not lining up or bad via plating

Soldering problems like cold joints or pads that lift up

Damage from things like water or dust

Burnt parts and mistakes made by people

You want to stay away from these risks to keep your multilayer PCB projects safe and working well. Good testing and strong quality checks help you stop expensive problems and keep your good name.

Key Takeaways

Pick a multilayer PCB supplier that checks quality well and has key certifications. This helps you avoid expensive errors and get products you can trust.

Find suppliers who use advanced manufacturing and talk clearly. They should deliver fast to help your projects stay on time and meet special needs.

Think about value, not only price. Look at the supplier’s experience, clear prices, and great customer support for long-term success.

Manufacturing Capabilities

Technical Expertise

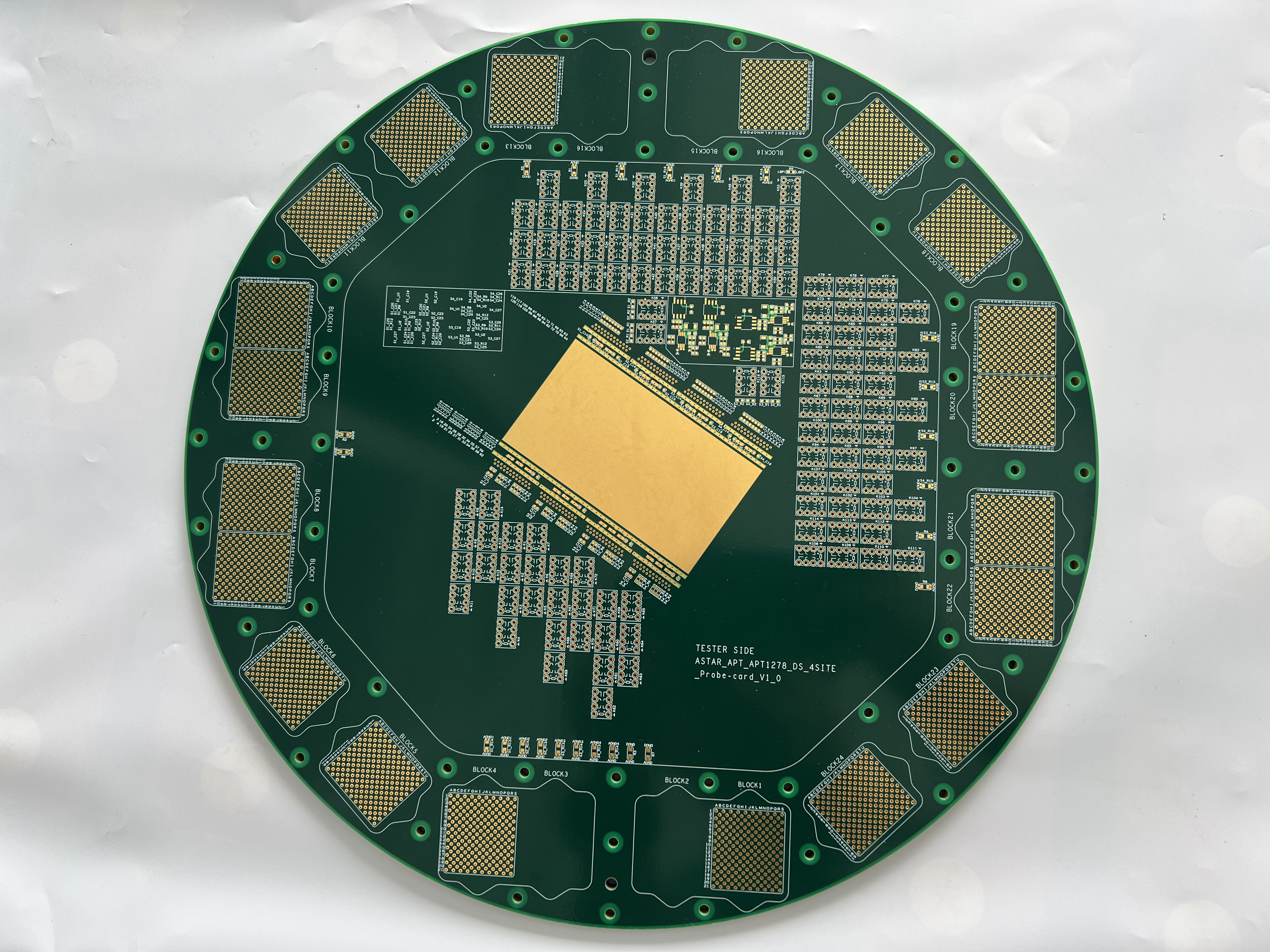

You need a pcb manufacturer who knows a lot. The best ones can make very complex multilayer pcb structures. Some can build up to 40 layers. They use special steps like photo-imaging, etching, and careful drilling. These skills help them work with high-density and high-speed designs. This is important for things like aerospace and medical devices. Working with a manufacturer directly gives you more control. You can also fix problems faster.

High-Layer Count PCBs

A good pcb manufacturer should make boards with many layers. Many can build multilayer pcb boards with 8, 12, or 16 layers. Some can even do more with special methods. Boards with more layers let you fit more connections in less space. This is important for new electronics. Picking a great pcb manufacturer helps your complex designs work right.

Advanced Technology

Modern pcb manufacturers use new technology to make boards better.

Laser drilled microvias (HDI)

Automated Optical Inspection (AOI)

Fine trace/space down to .00275"

Advanced surface finishes like ENIG

These tools help make boards that are exact and work well for tough jobs.

Customization

Every project is not the same. A good pcb manufacturer lets you change size, shape, layer stack-up, and routing. They help you meet special needs for medical, automotive, or industrial uses. Custom multilayer PCBs work better and save space. This helps when regular boards do not fit what you need.

Tip: Talk about your needs with the manufacturer early. This helps you avoid delays and get the best results.

Quality Assurance

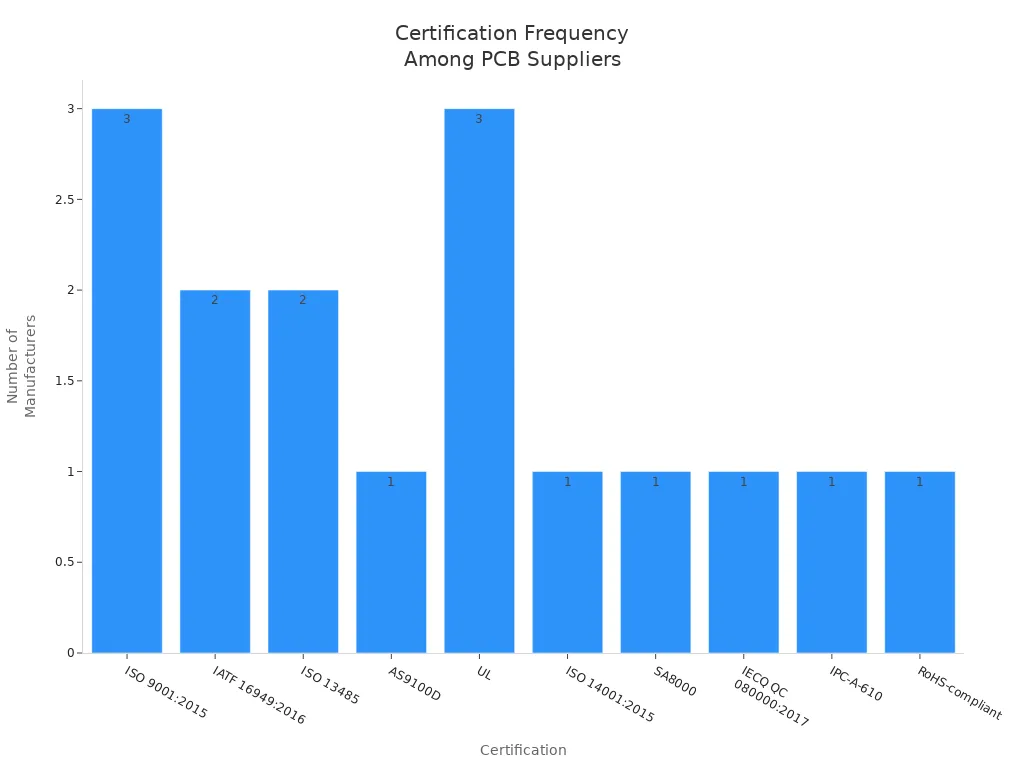

Certifications

When you pick a multilayer PCB supplier, check their certifications. These certificates show the supplier follows important industry rules. Here are some main certifications and what they mean:

ISO 9001: This is for quality in all industries.

IATF 16949: This is for making car parts.

ISO 13485: This is for medical device factories.

AS9100D: This is for making aerospace products.

Suppliers with these certificates can give you better quality. They help you avoid problems when making your products. Many top suppliers also use IPC-6012, which sets levels for PCB quality. For example, aerospace and defense need AS9100D and IPC Class 3. Medical and car companies want ISO 13485 and IATF 16949. These certificates help you trust the supplier’s work.

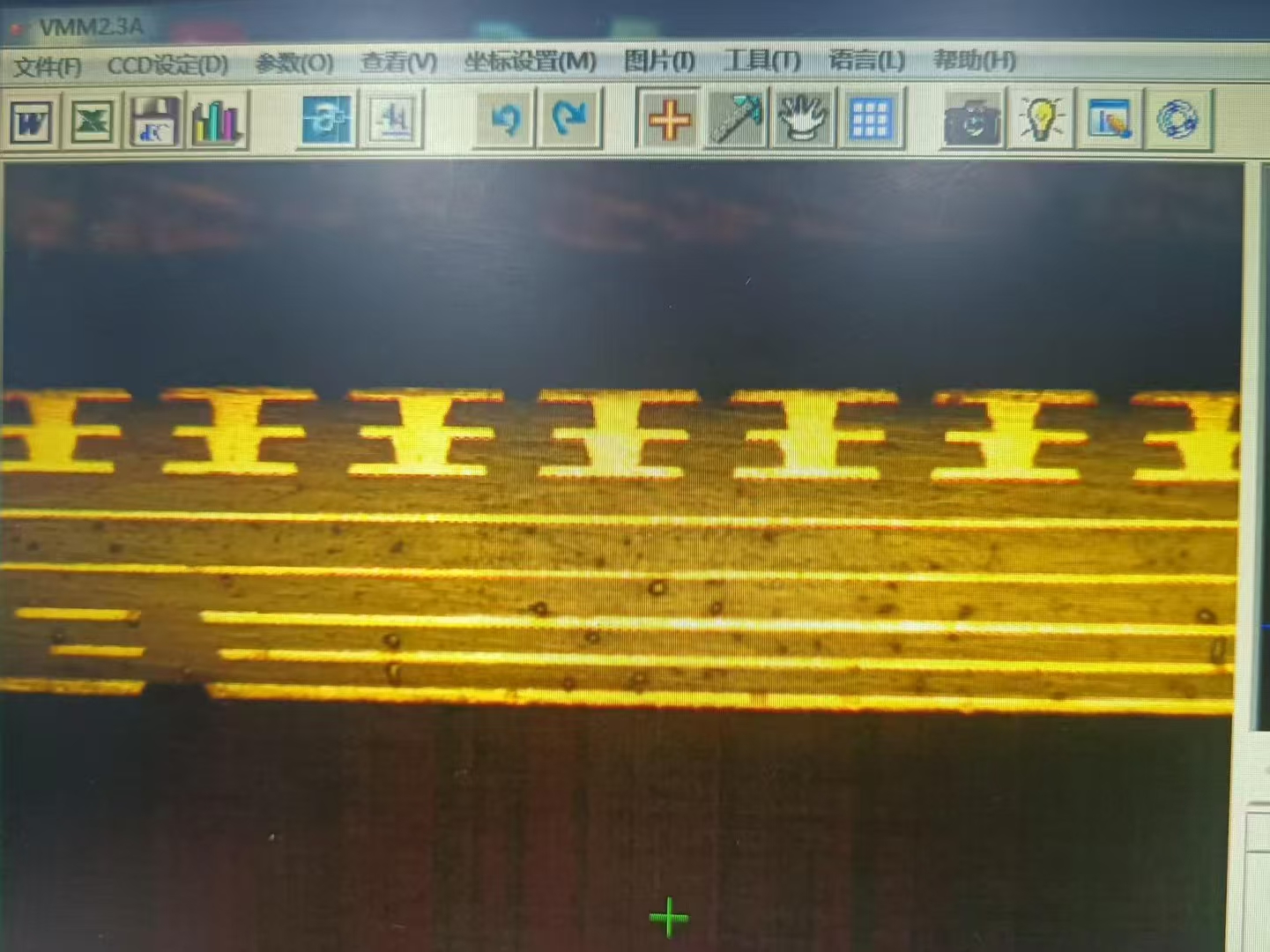

Quality Control

You want your PCBs to work every time you use them. Good quality control keeps your products working and stops mistakes. Good suppliers use many steps to check quality:

They make clear design rules and keep files up to date.

They write down every step and have trained people check.

They use special tools like 3D AOI and X-ray.

They do audits and train workers often.

They work with trusted partners and watch things in real time.

These steps help you get the same good quality every time. You will see fewer mistakes and better results.

Testing Standards

Testing helps make sure your PCBs last and work well. Suppliers use many rules to check if PCBs are strong:

Standard Name | Role in PCB Reliability Testing | Typical Test Items | Key Reliability Aspects |

|---|---|---|---|

Test methods for PCB reliability | Thermal cycling, SIR, peel strength, thermal shock | Thermal and electrical stress, insulation | |

IPC-6012 / IPC-A-600 | Manufacturing acceptance and inspection | Delamination, hole wall, surface defects, pad size | Consistency, material integrity, defect control |

MIL-STD-202 / MIL-STD-883 | Military/aerospace reliability | Vibration, shock, thermal shock, aging, life tests | Extreme environment, long-term stability |

JEDEC | System-level reliability | HAST, moisture, temp cycling, solder joint reliability | Moisture, solder fatigue, package compatibility |

ISO 9001 / IATF 16949 / ISO 13485 | Quality management systems | Process capability, traceability, preventive measures | Full-process reliability, quality consistency |

Suppliers test for heat, shaking, chemicals, and more. They follow these rules to make sure your PCBs work well every time.

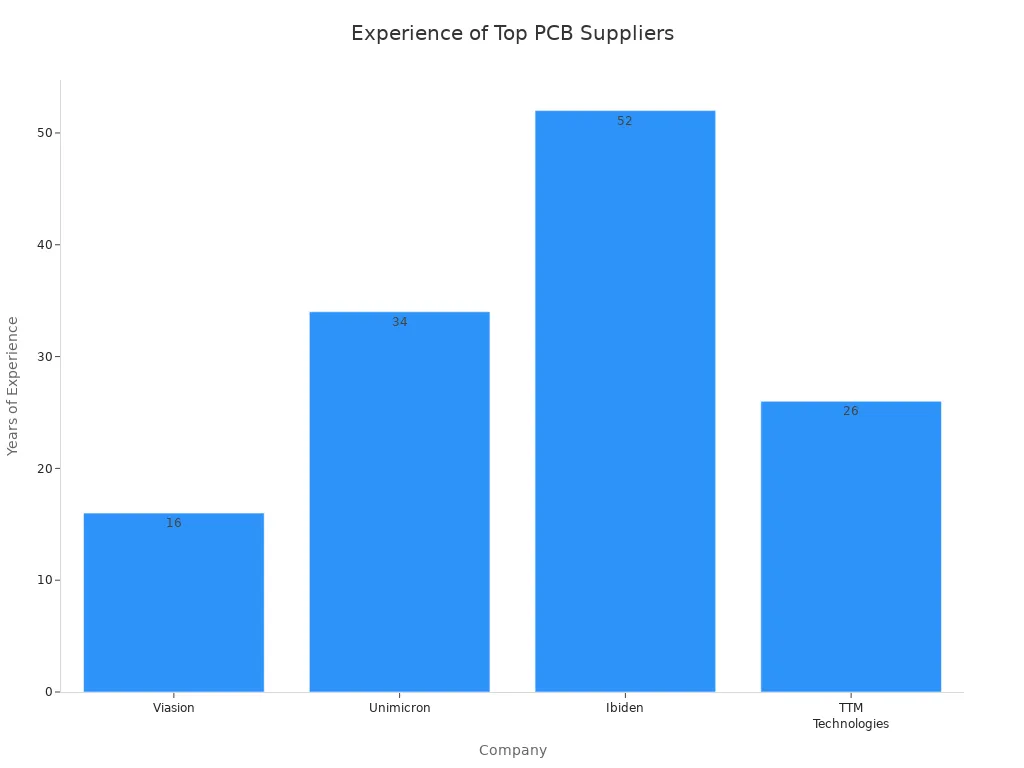

Experience & Reputation

Supplier History

When you pick a multilayer pcb supplier, learn about their past. If a company has been around for many years, they likely have strong skills. They also know how to make good products. Many top pcb manufacturers have worked in this field for a long time. This helps them avoid problems and make high quality boards. The table below shows how experience can help with quality and reliability:

Company | Years of Experience | Impact on Reliability and Quality |

|---|---|---|

Bay Area Circuits | Optimized processes for timely delivery and high product integrity. | |

Viasion | Delivers high-quality PCBs with global certifications and minimal errors. | |

Unimicron | 34+ years | Advanced R&D and high standards keep them as market leaders. |

Ibiden | 52+ years | Premium quality, cost-effective manufacturing, and rigorous testing. |

TTM Technologies | 26+ years | Reliable innovation for aerospace and medical industries. |

It is also smart to find manufacturers who help early in your project. They can check your design and see if it is easy to make. This help lowers risk and makes your boards work better for a long time.

Client Feedback

Client feedback helps you see if a pcb manufacturer does a good job. You can read stories and reviews from other customers. These stories tell you if the company finishes work on time and meets high standards. Good reviews mean you can trust the company. You can also ask for names of past clients to check if they are reliable.

Client reviews show if products are good and arrive on time.

Stories from real projects show if standards are met.

References help you trust the company.

Tip: Always ask for new stories or client names before you decide.

Online Reputation

You can learn a lot about a multilayer pcb supplier by looking at their online reputation. Start by checking industry websites like Find My Manufacturer. These sites show company details, certificates, and customer reviews. You can also visit forums and talk to other people in the field. Trade shows and online events let you meet suppliers and see what they do.

Look at online lists for company facts and reviews.

Read forums to see what others say.

Go to trade shows to compare companies.

Check certificates for more trust.

A good online reputation means the company follows rules and keeps customers happy.

Delivery & Support

On-Time Delivery

You want your multilayer PCB orders to show up on time. Good suppliers use different ways to ship and watch each package. They deliver most orders on time, even if you need them fast. Some can send your order the same day if it is urgent. This helps you keep making products without waiting. Picking a supplier who delivers on time lets you plan better.

Tip: Before you order, ask how fast they deliver and how often they are on time.

Customer Support

Great customer support makes your work easier. You need a team that answers fast and helps with problems. Many electronics makers want these things:

A strong team to answer questions

Fast and clear price quotes by email or phone

Help with tricky designs and moving from samples to big orders

24/7 help from skilled workers for any questions

One person to help you from start to finish

You should get help from your first question until after you get your boards. This support helps you fix problems quickly and keeps your work going.

Communication

Clear communication helps you trust your supplier. You need easy ways to ask questions and get special help. Talking openly helps you avoid mistakes and know what is happening with your order. Good suppliers tell you what is going on at every step. When you can talk to experts any time, you feel sure your project will go well.

Pricing & Value

Cost Transparency

You need to see exactly what you pay for when you order multilayer PCBs. The best suppliers use detailed cost calculations. This model breaks down every part of the price, so you know where your money goes. You can see costs for raw materials, layer count, drilling, setup, labor, and profit. This helps you plan your budget and make smart choices.

Detailed cost breakdowns help you understand each charge.

You can compare quotes and negotiate better deals.

This model works well for big orders or complex projects.

Area-based pricing is simple and fast for small runs or prototypes.

Using design software and panelization tools can lower waste and save money.

When you see a clear cost breakdown, you can spot ways to save and avoid hidden fees. This makes your project easier to manage.

Value vs. Price

You want a good deal, but you also want quality. The lowest price does not always mean the best value. You should look at the total cost of ownership. This means thinking about more than just the first price. You need to consider things like rework, downtime, and support.

Check if the supplier offers competitive prices without cutting quality.

Look at their technical skills and experience.

Ask about volume discounts and payment options.

Review lead times and if they meet industry standards.

Read client reviews and check supplier audits.

A good supplier gives you strong support, reliable products, and fair prices. You get more value when you choose a partner who helps you avoid problems and keeps your project on track.

Compliance & Sustainability

Industry Standards

You need to make sure your multilayer PCB supplier follows the right rules. These rules and certificates show if the supplier makes safe and good products. Some industries, like cars, planes, and hospitals, have very strict rules. Here are some important rules you should check for:

IATF 16949: This rule is for car part quality.

ISO 9001: This checks how well the company controls quality.

AEC-Q100 & AEC-Q200: These rules are for car electronic parts.

RoHS Compliance: This keeps dangerous stuff out of your products.

ISO 13485: This rule is for medical devices and safety.

IPC Class 3 / IPC-6012 Class 3A: These are for strong PCBs in important jobs.

FDA Regulations (21 CFR Part 820): These rules are for medical device quality.

REACH: This rule makes sure chemicals are safe and clear.

Standard | Description |

|---|---|

Sets quality rules for strong multilayer PCBs. | |

IPC-6012EA | Adds more checks for car PCBs. |

IPC-6013E | Covers flexible and bendy PCBs, used in new cars. |

IATF 16949 | Makes sure all parts of the supply chain follow car rules. |

AEC-Q100 | Tests and checks electronic parts for cars. |

Tip: Always ask your supplier to show proof of these rules before you buy.

Environmental Responsibility

You want your supplier to care about the earth. Many multilayer PCB suppliers now use green materials like boards that break down and solder without lead. They also track where their materials come from using special tags or computer systems. This helps make sure they use safe and fair sources. Suppliers often share reports about how much energy they use, how much waste they make, and how safe their workers are. Sometimes, outside groups check them to make sure they follow green rules.

Suppliers use tracking systems to watch materials.

They share reports about energy, waste, and safety.

Many use green materials to help the earth.

Checks and public reports show they follow green rules.

Suppliers who care about the earth get more customers. People like to buy from companies that help the planet. Studies show people may pay more for green products. When you pick a supplier who cares about the earth, you help the planet and make your customers trust you.

Design Tools & Resources

PCB Design Software

You need the right tools to design multilayer PCBs. Most suppliers work with many popular software programs. These programs help you make layouts that are correct. They also help you find mistakes before you build the board. Here are some common choices:

Altium Designer is good for hard boards and tricky routing. Many people like it because it has strong features.

Eagle is simple to use and works for new and skilled users. It lets people work together online.

KiCad is free and open-source. It has good layout tools and a 3D viewer. Many people use it for cheap projects.

OrCAD is known for checking designs and running tests. It helps you spot mistakes early in fast designs.

PADS helps with automation and making boards easy to build. It is used a lot for boards ready for production.

Mentor Graphics Xpedition can handle big and hard designs. It checks rules to make sure things are right.

DipTrace has a simple look and 3D modeling. It works well for small and medium jobs.

EasyEDA is on the web and lets teams work together fast. It is good for quick test boards.

Fritzing is easy for beginners and is open-source. It is best for simple layouts.

Tip: Pick a tool that fits your project and what you know. Many suppliers can help you choose the best one.

Tutorials & Support

You do not have to design by yourself. The best multilayer PCB suppliers give you lots of help:

Step-by-step guides show you each part, from drawing to making files.

Videos and built-in guides in free tools teach you important things and how to fix problems.

Design rule checks and test tools help you find mistakes before you build.

Online groups and forums let you ask questions and share ideas.

Online classes on sites like Coursera and Udemy teach harder topics.

Suppliers can give you direct help with stack-up, materials, and how to build.

Free tools like KiCad and DesignSpark PCB have lots of guides and lessons.

You get a full support system when you use these resources. This makes designing easier and helps you avoid big mistakes.

To pick the best multilayer pcb supplier, you need to do a few things. First, look up each manufacturer’s skills and certificates. Check if they deliver orders on time. Next, ask for samples and see if they are good quality. Make a checklist to look at support, prices, and shipping. Try to work with the same supplier for a long time. This can help you get better results and have fewer problems.

If you choose carefully, you can stop delays, save money, and get PCBs you can trust.

FAQ

What is the main benefit of using a certified multilayer PCB supplier?

You get better quality and fewer mistakes. Certified suppliers follow strict rules. This helps your products work well and last longer.

How do you check if a PCB supplier is reliable?

You can read customer reviews. You can ask for client references. You can also check their certifications and years in business.

Can you get custom multilayer PCBs for special projects?

Yes, you can. Many suppliers offer custom shapes, sizes, and layer counts. You should share your needs early for the best results.