Understanding Rigid-Flex PCBs and Their Structure

Rigid-flex printed circuit boards combine durable rigid layers with adaptable flexible circuits. This innovative design enables compact and robust layouts that traditional PCBs cannot achieve. Their unique construction eliminates the need for connectors, simplifies assembly, and enhances performance in dynamic environments.

The adoption of rigid-flex printed circuit boards is increasing across industries every year. By 2034, the market is projected to reach $77.7 billion, driven by advancements in 5G technology and the demand for smaller devices. In 2024, the Asia-Pacific region is expected to dominate with over 35% of the market share, generating $9 billion. These trends highlight the growing significance of rigid-flex printed circuit boards in modern electronics.

Key Takeaways

Rigid-flex PCBs mix stiff and bendable layers. This helps make small, lightweight designs for modern gadgets.

These PCBs are strong and dependable, perfect for tough places like airplanes, medical tools, and cars.

Using fewer parts in rigid-flex PCBs makes building easier. It also costs less and works better by avoiding problems.

Rigid-flex PCBs give better signals with direct links. This cuts down on signal problems and makes devices work well.

Even though they cost more to make, rigid-flex PCBs save money later. They are cheaper to put together and last longer.

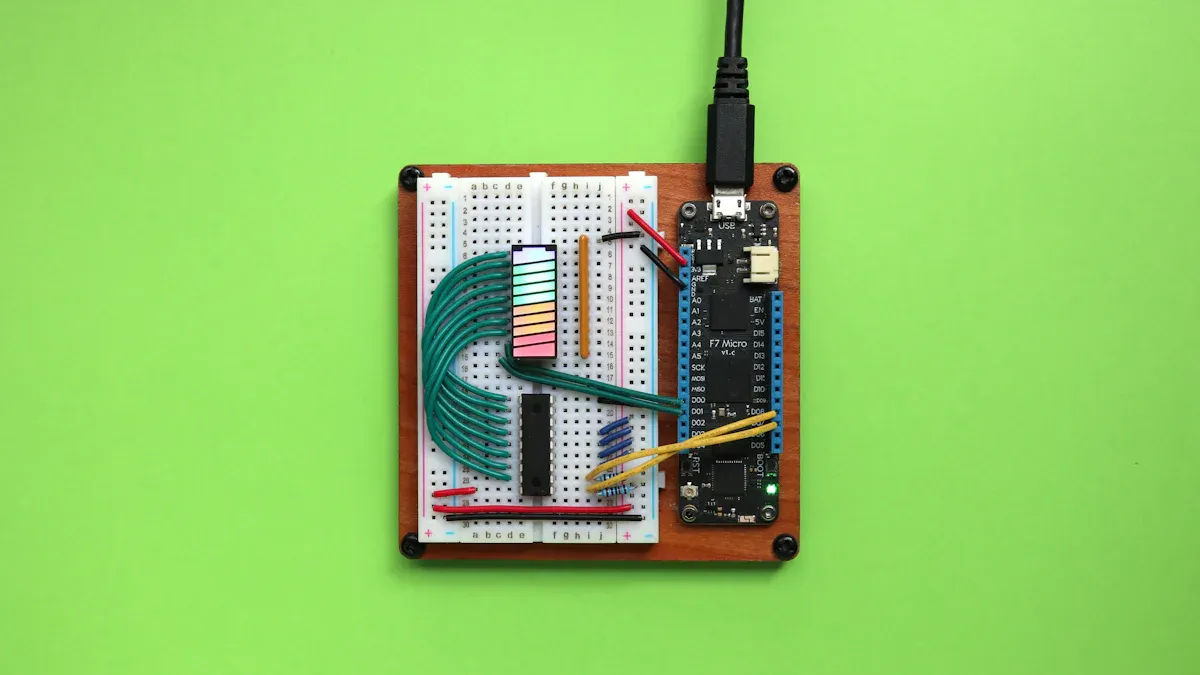

What Are Rigid-Flex Printed Circuit Boards?

Definition and Key Features

A rigid-flex PCB combines stiff and bendable parts in one board. This mix makes it strong but also flexible. It works well in small spaces or where bending is needed. The stiff parts give support, while the flexible parts allow movement and folding.

Here are some key features of rigid-flex PCBs:

Feature | Description |

|---|---|

Structure | Mix of stiff and bendable parts for folding and flexing. |

Materials | Stiff parts use FR-4 or Teflon; flexible parts use polyimide. |

Manufacturing Process | Made by layering, drilling, plating, and etching patterns. |

Rigid-flex PCBs save space and are very reliable. They don’t need connectors, which reduces parts and fits into small designs. Their strong build handles stress and heat, making them good for tough conditions. Fewer parts also mean lower assembly costs, even though making them is complex.

Differences from Traditional PCBs

Rigid-flex PCBs are different from regular PCBs in design and use. Regular PCBs are only stiff, but rigid-flex PCBs can bend and fit into tight spaces. This makes them better for small or moving devices.

Here’s a comparison of rigid-flex and regular PCBs:

Aspect | Rigid-Flex PCBs | Traditional PCBs |

|---|---|---|

Manufacturing Costs | Higher due to design but uses fewer parts | Lower cost but needs more components |

Assembly Costs | Fewer parts make it cheaper to assemble | More parts make it harder and costlier to build |

Maintenance and Reliability | Stronger and lasts longer with less upkeep | More likely to have connection problems over time |

Long-Term Savings | Costs more upfront but saves money later | Cheaper at first but costs more in the long run |

Rigid-flex PCBs also improve how electricity flows. They connect everything directly, reducing weak spots. Regular PCBs use cables and connectors, which can wear out and need fixing.

Why Rigid-Flex PCBs Are Essential in Modern Electronics

Rigid-flex PCBs are important because they are versatile and work well. They are used in fields like aerospace, medicine, and cars, where small size and reliability matter. For example, in pacemakers, they are safe for the body and last a long time. In space, they are light and stable, perfect for satellites.

Here’s how rigid-flex PCBs are used in different industries:

Industry | Applications | Key Features |

|---|---|---|

Medical Devices | Pacemakers, imaging tools, diagnostic machines | Small, reliable |

Aerospace Systems | Satellites, planes, military communication | Light, stable |

Automotive | Car sensors, infotainment systems, control units | Handles heat and shaking |

Military Systems | Communication tools, navigation, weapons | Strong and works in tough conditions |

Rigid-flex PCBs help make smaller and better devices. They combine stiff and flexible parts to save space and weight. This is great for wearables, phones, and other small gadgets. By connecting everything in one board, they work better and last longer, meeting today’s tech needs.

Structure of Rigid-Flex PCBs

Rigid Layers and Their Role

Rigid layers give rigid-flex PCBs their strong structure. These layers use materials like FR-4 or Teflon, which are tough and handle heat well. They are placed where parts like chips or connectors need solid support.

These layers help the board keep its shape and resist damage. For example, they protect the board from shaking or impacts, making them great for cars or airplanes.

Here are some details about rigid layers:

Feature | Description |

|---|---|

Number of layers | |

Materials used | FR-4, Teflon, and copper foil |

PCB thickness | Between 0.4mm and 3mm |

Surface finishes | ENIG, OSP, Immersion tin, or Immersion silver |

Minimum mechanical drill | 0.20mm |

Rigid layers also improve how electricity flows. They provide a steady base, which helps control signals better. This is important for devices that need to work fast and reliably.

Flexible Layers and Their Role

Flexible layers make rigid-flex PCBs special. These layers are made from polyimide (PI) and copper foil, which are bendable but strong. They are used where the board needs to fold or fit into small spaces.

These layers allow movement, making them great for wearables, medical tools, or foldable gadgets. They also remove the need for extra cables, making the design simpler and more reliable.

Key features of flexible layers include:

Bending performance: Can bend 90° or even 360° many times.

Bend radius: Thinner materials allow tighter bends.

Thickness: Usually between 0.05mm and 0.8mm, depending on use.

Flexible layers also help cool the device. They use materials that spread heat well, keeping devices from overheating.

Layer Configurations in Rigid-Flex PCBs

The way layers are arranged affects how the PCB works. Rigid and flexible parts are combined into one board, allowing creative designs. This is useful for small, complex devices.

Here’s how the layers are arranged:

Rigid sections: These are fixed and hold important parts.

Flexible sections: These connect rigid parts and allow bending.

Interconnections: Layers are joined using bonding or vias to keep signals steady.

To make them last, manufacturers test bending and add strain relief. They also use heat-spreading methods like thermal vias to improve performance.

By mixing rigid and flexible layers, these PCBs save space, last longer, and allow for creative designs in modern gadgets.

Interconnections Between Rigid and Flexible Sections

The link between rigid and flexible parts is key in a rigid-flex PCB. These connections let signals move smoothly while keeping the board strong. Knowing how these links work shows the smart design behind these PCBs.

How Rigid and Flexible Sections Are Joined

Special methods join rigid and flexible parts. Makers use glue, bonding layers, or mechanical ways to make strong links. These methods help the board handle stress without breaking or failing.

Here are some common ways to join them:

Adhesive Bonding: Glue holds the flexible part to the rigid part. This creates a smooth and secure connection.

Staggered Vias: Tiny holes filled with conductive material connect layers. Staggering them lowers stress and makes them last longer.

Reinforcement Layers: Extra layers, like stiffeners, add strength to the connection points.

The method depends on the board's design and where it will be used.

Challenges in Interconnecting Sections

Joining rigid and flexible parts isn’t easy. The materials in each part act differently, like bending or expanding with heat. These differences can cause stress, especially in hot or shaky places.

To fix this, makers:

Add strain relief to lower stress.

Pick materials that handle heat the same way.

Test the board in real-life conditions to ensure it works well.

Tip: Plan for stress points when designing a rigid-flex PCB. Good planning makes the board last longer.

Benefits of Seamless Interconnections

Good connections make rigid-flex PCBs work better and last longer. They let signals move without stopping, which is important for fast devices. These links also remove the need for extra cables, saving space and weight.

Why seamless connections are important:

Benefit | Description |

|---|---|

Improved Signal Flow | Direct links lower resistance and stop interference. |

Enhanced Durability | Strong links handle bending and tough conditions. |

Compact Design | No bulky connectors, making the board smaller and lighter. |

Strong connections help devices work better and stay reliable.

Real-World Applications of Interconnections

How rigid and flexible parts connect matters in many fields. For example:

In medical devices, these links keep pacemakers and imaging tools working during movement.

In aerospace systems, they handle shaking and big temperature changes.

In consumer electronics, they make foldable phones and small wearables work smoothly.

These examples show why good connections are so important. A well-made rigid-flex PCB can improve a product’s performance.

Note: Work with skilled makers when designing rigid-flex PCBs. Their knowledge ensures the connections fit your device’s needs.

By learning about interconnections, you can design better PCBs. These links are not just small details—they are the base of strong and efficient devices.

Advantages of Rigid-Flex PCBs

Space and Weight Efficiency

Rigid-flex PCBs save space and reduce weight. This makes them perfect for small, modern devices. They combine stiff and bendable layers, removing the need for big connectors or cables. This design helps create smaller and lighter gadgets without losing functionality.

These PCBs replace multiple boards and wires with one unit. This cuts down on size and weight.

They can bend or twist to fit tight spaces, which is useful for things like airplanes and wearable tech.

Using flex circuits instead of cables saves space and improves reliability. They also carry more current.

For example, rigid-flex PCBs make smartphones and laptops thinner. In cars, they help create compact dashboards and sensor systems. This boosts both performance and design options.

Enhanced Durability and Reliability

Rigid-flex PCBs are very strong and reliable. They are made with tough materials like polyimide, which handle stress and extreme conditions. This keeps devices working well, even in hard environments.

Test Type | Purpose |

|---|---|

ESD/EMP Testing | Checks if the board can handle static electricity and electromagnetic pulses. |

Moisture Resistance Testing | Tests how much water the board can resist without damage. |

Vibration Testing | Simulates shaking to ensure the board works after movement. |

Low Pressure Testing | Mimics high-altitude pressure changes to check durability. |

Thermal Cycling Testing | Measures how well the board handles heat changes without breaking. |

These tests show how durable rigid-flex PCBs are. For instance, in space, they handle shaking and temperature changes. In medical tools, they work well in small, high-stress places like implants.

Simplified Assembly and Reduced Components

Rigid-flex PCBs make assembly easier by needing fewer parts. This speeds up production and lowers mistakes during installation. It also saves time and money.

Their design reduces the need for many connections.

Easy-to-use connectors make setup faster and simpler.

Fewer parts mean fewer errors and better production results.

Benefit | Description |

|---|---|

Reduced packing requirements | Smaller final product size. |

Simplified assembly process | Fewer parts make assembly easier. |

Reduced assembly errors | Flex circuits only fit one way, avoiding mistakes. |

Reduced component assembly requirements | Combines functions into one step for faster assembly. |

By combining many features into one board, rigid-flex PCBs improve efficiency. They are a great choice for industries like electronics, where small and efficient designs are key.

Better Signal Quality

Signal quality is key for making devices work well. Rigid-flex PCBs improve signal quality by cutting down interference and keeping connections steady. Their design removes the need for extra connectors and cables, which can cause noise and weaken signals.

How Rigid-Flex PCBs Improve Signal Flow

Rigid-flex PCBs connect parts directly. This lowers the chance of signal problems. Flexible layers create shorter paths for signals, making them faster and stronger. The rigid parts give a solid base, keeping signals steady and reliable.

Tip: Shorter signal paths make devices like phones and consoles faster.

Advantages of Better Signal Quality

Using rigid-flex PCBs gives you many signal-related benefits:

Less Noise: Direct links reduce electromagnetic interference (EMI).

Faster Signals: Shorter paths speed up signal travel.

More Reliable: Strong connections stop signal breaks.

Feature | Effect on Signal Quality |

|---|---|

Direct Links | Lower resistance and improve signal strength. |

Reduced EMI | Less noise for clearer communication. |

Solid Base | Stops signal issues from movement or shaking. |

Real-Life Uses

Better signal quality makes rigid-flex PCBs great for fast data devices. Examples include:

Medical Tools: Clear signals help imaging machines give accurate results.

Space Systems: Satellites need steady signals for data and navigation.

Everyday Electronics: Phones and tablets get quicker, more stable connections.

Note: Plan signal paths carefully when designing rigid-flex PCBs for top performance.

By boosting signal quality, rigid-flex PCBs help devices work better and stay reliable, even in tough conditions.

Challenges of Rigid-Flex PCBs

Higher Costs of Manufacturing

Making rigid-flex PCBs costs more than regular PCBs. Materials like copper and laminates are pricey and their costs can change. These materials directly raise the production cost. The process also needs advanced tools and skilled workers to handle the complex designs and HDI. This makes production even more expensive.

Trade issues and global tensions can disrupt supplies. These problems cause delays and raise material costs, slowing production. To save money, you can design boards for easier manufacturing and produce in larger amounts. Even though the upfront cost is high, rigid-flex PCBs save money later by lowering assembly costs and lasting longer.

Complex Design and Prototyping

Designing rigid-flex PCBs is harder than regular ones. Combining stiff and bendable layers needs careful planning to work well. You must think about bending, signal flow, and heat control. These make designing more complicated than for rigid PCBs.

Prototyping is also tricky. Special materials and methods often lead to more waste during production. But improving the design and checking total costs can help. While prototypes cost more, they reduce mistakes and improve reliability, making them worth it.

Main cost factors in design and prototyping:

Complicated processes

Special materials

More waste during production

Material Availability Issues

Getting materials for rigid-flex PCBs can be tough. Polyimide, used in flexible parts, and copper, used in both sections, are sometimes hard to find. Supply chain problems, often caused by global issues, make these materials rare or costly. This slows down production and raises costs.

To solve this, work with trusted suppliers and plan for delays. You can also use other materials that still meet your needs. By staying prepared, you can reduce the effects of material shortages on your projects.

Tip: Partner with skilled manufacturers to handle material supply challenges better.

Mechanical Stress in Flexible Areas

Stress in flexible parts of rigid-flex PCBs can shorten their life. Bending or folding these parts often puts strain on the materials. Over time, this strain may cause cracks, layer separation, or even circuit failure.

Causes of Mechanical Stress

Many things can create stress in flexible areas:

Frequent Bending: Moving the board too much weakens it.

Tight Bends: Sharp folds put extra pressure on copper and polyimide.

Heat Changes: Heat makes materials expand and shrink, adding strain.

Shaking: Vibrations in cars or planes wear out the board faster.

Tip: Follow the suggested bend radius for your PCB. This helps avoid extra strain and keeps it working longer.

Effects of Stress on Flexible Areas

Stress can damage the board in visible and hidden ways. Cracks in copper lines can stop signals from flowing. Layers may separate, making the board weaker. These problems can cause devices to fail, especially in important tools like medical or space equipment.

Problem | How It Affects the PCB |

|---|---|

Cracks in Lines | Stops signals, leading to device issues. |

Layer Separation | Weakens the board, risking breakdowns. |

Material Weakness | Makes the board less able to handle bending or shaking. |

How to Reduce Mechanical Stress

You can lower stress and make the board last longer:

Add strain relief features like rounded edges at connection points.

Pick materials that are flexible and handle heat well.

Test the board in real-life conditions to find weak spots.

By fixing stress issues early, your rigid-flex PCB will work better in tough situations.

Applications of Rigid-Flex PCBs

Consumer Electronics

Rigid-flex PCBs are key in making small, reliable gadgets. They help create thinner and lighter devices like smartphones, laptops, and wearables. These PCBs can bend and fold, which is perfect for foldable phones. Flexible layers let these phones fold without losing performance.

The consumer electronics market for rigid-flex PCBs is growing fast. This is because people want smaller devices with more features.

By 2031, the market is expected to grow from $3.20 billion in 2024 to $6.04 billion, with a yearly growth rate of 9.50%.

Sector | Benefits of Rigid-Flex PCBs |

|---|---|

Consumer Electronics | Saves space, Can bend to fit tight areas, Improves reliability |

These PCBs also make devices more reliable. They remove the need for extra cables and connectors, which often break. This makes modern gadgets work better and last longer.

Medical Devices

Rigid-flex PCBs are important in healthcare for advanced tools. They are used in imaging machines, monitors, and wearable health devices. Their small size and strength make them great for life-saving tools like pacemakers and portable diagnostic machines.

The need for advanced medical devices is increasing, boosting demand for these PCBs.

Rigid-flex PCBs lower assembly costs and make medical tools more reliable.

Sector | Benefits of Rigid-Flex PCBs |

|---|---|

Medical Devices | Lowers assembly costs, Improves reliability of medical tools |

These PCBs ensure tools work well in critical situations. For example, they help imaging machines give clear results and wearable trackers monitor health accurately.

Tip: Focus on making PCBs small and reliable for medical devices to meet industry needs.

Aerospace and Defense

Rigid-flex PCBs are crucial for aerospace and defense equipment. They handle tough conditions like extreme temperatures, shaking, and impacts. Their lightweight design reduces equipment weight, improving fuel use and carrying capacity.

These PCBs keep signals strong, reducing data loss in important systems.

They meet strict rules and quality standards required by the industry.

Feature | Description |

|---|---|

Lightweight | Cuts down weight, improving fuel use and carrying ability. |

Environmental Resistance | Handles heat, shaking, impacts, and moisture without damage. |

Signal Integrity | Keeps signals strong and clear for critical systems. |

Compliance | Meets strict quality and performance rules. |

Rigid-flex PCBs are used in satellites, military tools, and navigation systems. Their ability to survive harsh conditions ensures they work well in important aerospace and defense tasks.

Automotive Systems

Rigid-flex PCBs are important in today’s cars. They help add advanced electronics to vehicles, improving both safety and performance. These PCBs can handle tough conditions like heat changes, constant shaking, and sudden impacts. Their mix of stiff and bendable layers lets them fit into small spaces, perfect for dashboards and control units.

To keep cars safe, rigid-flex PCBs follow strict rules. For example:

Standard | Description | How It Helps |

|---|---|---|

Safety rules for car systems | Makes systems safer by reducing critical failures. | |

IPC-6012DA | Rules for making and testing PCBs | Ensures strong and reliable boards with fewer failures. |

AEC-Q100 to Q200 | Tests for car parts | Checks parts work well under stress, improving reliability. |

Electromagnetic Compatibility (EMC) is also very important. Rigid-flex PCBs meet EMC rules to stop electronic parts from interfering with each other. This helps sensors and infotainment systems work smoothly together. By keeping signals steady, these PCBs make car systems work better.

These PCBs also save space and weight. They remove the need for big connectors and wires, which is great for electric cars where every bit of space matters.

Tip: Use materials that handle heat and shaking when designing rigid-flex PCBs for cars.

Industrial and Robotic Equipment

Rigid-flex PCBs are great for industrial machines and robots. They are built to handle tough conditions like shaking, impacts, and extreme heat. Their design combines stiff and flexible parts, making them easier to build and more durable.

Here are some ways they improve performance:

Metric | Description |

|---|---|

Strong design makes them last longer and work better. | |

Space Saving | Fits into small or odd shapes, perfect for compact designs. |

Easier Assembly | Fewer parts make building faster and cheaper. |

High Durability | Can handle shaking and impacts without breaking. |

These PCBs save space by bending to fit unusual shapes, like robotic arms or small machines. They also cut down on extra wires, improving signal flow and lowering the chance of breaking.

In robots, precision and reliability are key. Rigid-flex PCBs help sensors and controls work well, even in fast-moving systems. This makes them perfect for things like factory robots or robotic surgery tools.

Note: Work with skilled makers to ensure your rigid-flex PCBs meet the needs of industrial and robotic systems.

Design and Manufacturing of Rigid-Flex PCBs

Picking Materials for Rigid and Flexible Layers

Choosing the right materials is very important for making strong rigid-flex PCBs. You need to think about many things to make sure the board works well. Rigid parts often use FR-4 or Teflon, while flexible parts use polyimide. Each material must meet certain needs.

Electrical Performance: Pick materials that handle heat well and don’t expand much. This keeps signals clear and helps with cooling.

Mechanical Properties: Use materials that are both strong and bendable. Check their thickness and strength.

Environmental Resistance: Choose materials that can handle water, chemicals, and high heat. Look for a UL94 fire safety rating.

Manufacturing Compatibility: Make sure the materials work with production methods and are easy to get.

Regulatory Compliance: Ensure they follow rules like IPC and RoHS for safety and quality.

Balancing cost and quality is key. While better materials may cost more, they last longer and save money over time.

Tips for Designing Flexible and Strong Boards

Designing rigid-flex PCBs needs careful planning to keep them strong and flexible. Avoid uneven designs, as they can bend wrong during production. Symmetrical designs work better and last longer.

Here are some tips for a good design:

Keep at least 8 mil space between drill holes and copper.

Use teardrop shapes for thin traces to make them stronger.

Don’t put vias in flexible parts to avoid cracks.

Leave 50 mil space between vias and stiffener edges.

Keep a 50 mil gap between holes and flexible parts.

Add stiffeners to make the board stronger.

Also, think about how much the flexible part will bend. The bend radius should be 10 times the layer’s thickness to avoid damage. Following these tips helps make boards flexible and strong.

Solving Manufacturing Problems

Making rigid-flex PCBs can be tricky. Joining rigid and flexible parts needs special tools and careful work. One problem is stress on materials during production, which can cause damage.

Here’s how to fix these problems:

Add strain relief to lower stress at connection points.

Use materials that expand the same way when heated to avoid bending.

Test prototypes in real-life conditions to find and fix weak spots.

Another issue is keeping the board’s quality consistent. Advanced tests like heat and vibration checks ensure the board is durable. Working with skilled manufacturers can also help make the process smoother and the boards better.

By knowing these problems and using smart solutions, you can make rigid-flex PCBs that are reliable and work well in many devices.

Testing and Quality Assurance

Testing ensures rigid-flex PCBs work well and last long. These checks confirm the boards meet rules and handle real-world use. Following strict steps helps manufacturers make reliable and high-quality boards.

Key Testing Protocols

Manufacturers use tests to check how rigid-flex PCBs perform. Below are common testing methods:

Description | |

|---|---|

Material Selection | Uses strong materials for heat and electrical stability. |

Electrical Testing | Finds defects with checks like continuity and impedance tests. |

Environmental Testing | Tests boards in heat, shaking, and wet conditions. |

Accelerated Life Testing | Measures how long boards will last over time. |

Compliance with IPC Standards | Makes sure boards follow industry rules for quality. |

Industry Standards for Quality

Rigid-flex PCB makers follow strict rules to ensure quality. Some important IPC standards include:

IPC-A-600: Looks for cracks or layer problems during inspection.

IPC-TM-650: Tests adhesive strength and electrical reliability.

IPC-TM-650 2.6.7: Checks if boards can handle fast temperature changes.

IPC-TM-650 2.5.5.7: Tests signal quality for high-speed applications.

Additional Testing Methods

Extra tests help ensure rigid-flex PCBs are strong and reliable. Electrical tests find broken circuits, while impedance tests check signal flow. Bend tests see if boards can handle movement. Peel tests check how well layers stick together. X-ray or optical tests find hidden flaws. These steps make sure every board works well and lasts long.

With careful testing, rigid-flex PCBs can handle tough jobs and stay dependable.

Rigid-flex PCBs are both strong and bendable, making them vital for today’s gadgets. Their special design helps make small devices, boosts durability, and improves how they work in fields like space, healthcare, and everyday tech. The demand for these boards keeps rising as technology advances and people want smaller, smarter gadgets.

Aspect | Details |

|---|---|

Market Growth | |

Key Segments | Single-sided rigid-flex PCBs are great for Aerospace and Defense. |

Future Outlook | Bright future with new tech and higher demand. |

Use rigid-flex PCBs to build creative devices. Solve issues like high costs and tricky designs by working with expert makers. These boards open up exciting opportunities for the future of technology.

FAQ

How long do rigid-flex PCBs last?

The lifespan depends on how they are made and used. With good materials and careful handling, they can last over 10 years. Regular checks and following bending rules help them stay strong in tough conditions.

Tip: Use strong materials and avoid too much bending to make them last longer.

Can rigid-flex PCBs work in extreme heat or cold?

Yes, they work well in very hot or cold places. Materials like polyimide and FR-4 can handle big temperature changes. These boards are great for planes, cars, and factories where temperatures often change.

Note: Always check the material’s heat limits before using it.

Are rigid-flex PCBs recyclable?

Parts of rigid-flex PCBs can be recycled. Copper and some layers can be reused, but adhesives and polyimide are harder to recycle. Special recycling centers can handle these materials better.

♻️ Eco Tip: Work with certified recyclers to reduce waste and help the planet.

How is the flexibility of a rigid-flex PCB tested?

Bend tests are used to check how flexible they are. These tests bend the board many times to see if it cracks. They also check how well the layers stick together and if the bend radius is correct.

Tip: Make sure the bend radius is at least 10 times the thickness of the material for better results.

Which industries use rigid-flex PCBs the most?

Rigid-flex PCBs are used in planes, medical tools, cars, and gadgets. Their small size and strength make them perfect for places where space is tight and reliability is important.

Industry | Key Benefits |

|---|---|

Aerospace | Light and handles heat well |

Medical Devices | Small and safe for the body |

Automotive | Handles shaking and heat |

Note: Pick rigid-flex PCBs for jobs that need strong and reliable boards in tough conditions.

See Also

Exploring Rogers R4350B, R4003, And R5880 For RFPCB Use

An Overview Of PCB Printed Circuit Boards And Essentials

Defining Multilayer PCBs And Their Role In Electronics

Unveiling Cutting-Edge HDI PCB Prototyping Methods Now

Understanding RF Circuit Boards And Their Functionality Explained