Why Engineers Choose VIPPO for Compact and Complex PCB Layouts

Engineers pick vippo pcb when they have hard pcb design jobs. VIPPO lets them put many parts close together and helps with tricky pcb designs that work well. Many people use vippo pcb for small layouts. VIPPO lets engineers fit more parts and gives them more choices in busy pcb projects. Good pcb design needs vippo pcb to save space and get steady results.

Key Takeaways

VIPPO PCB technology lets engineers save space. Parts and vias can be put very close together. This helps make circuit boards smaller and more compact.

Using VIPPO makes signal quality better. It gives short and clear paths for electricity. This keeps signals strong and steady in fast and tricky circuits.

VIPPO PCBs are more reliable and control heat better. This makes boards stronger and last longer for tough electronic projects.

VIPPO PCB: How It Works and Why It Matters

What is VIPPO and Its Role in High-Density PCB Design

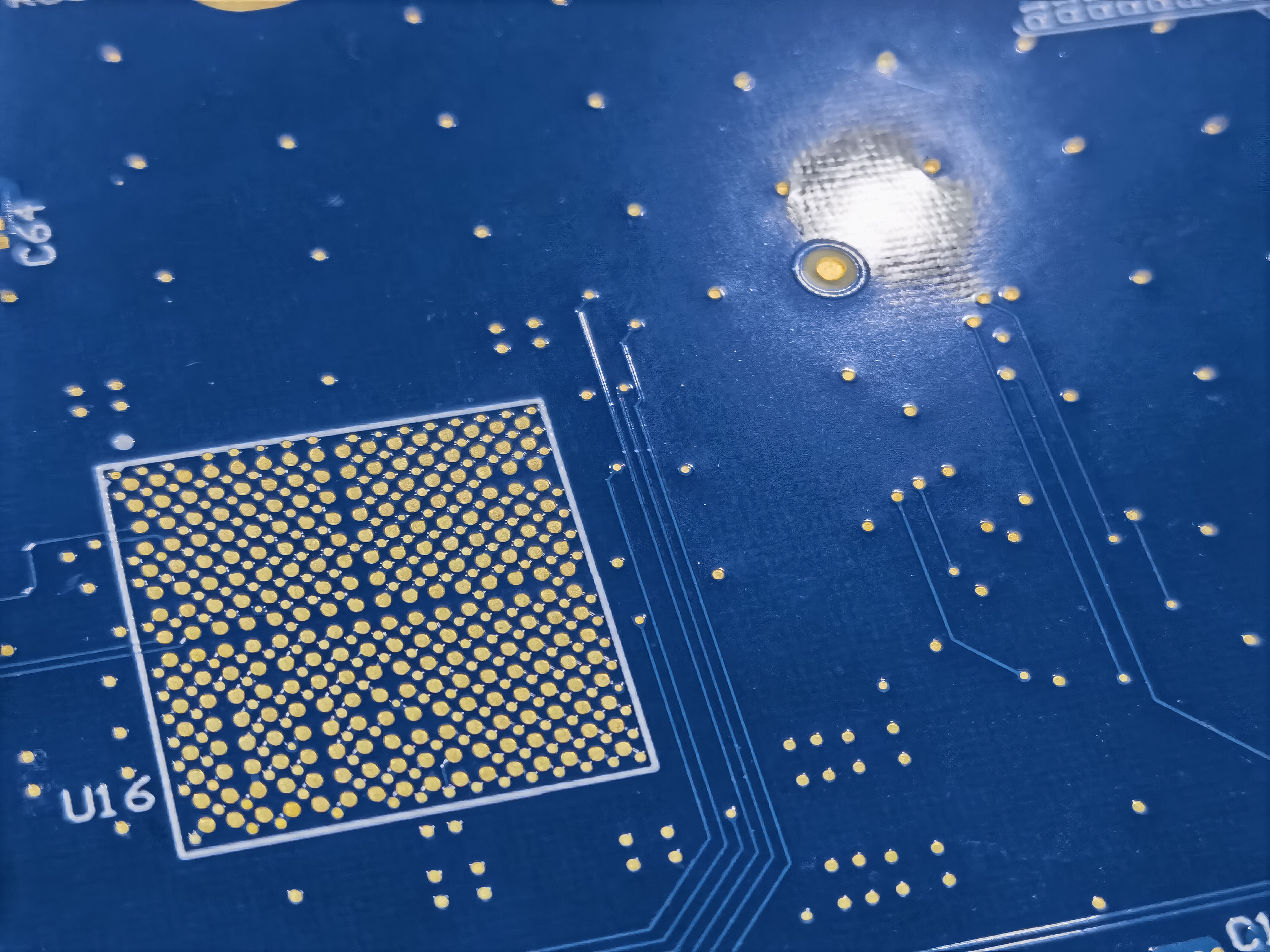

VIPPO PCB helps with tough designs that need many parts close together. Engineers use VIPPO when they want to fit lots of pieces in a small space. VIPPO uses a special way to fill a hole with epoxy or paste, make it flat, and cover it with copper. This stops solder from going down the hole, so parts can sit right on top. This makes it easier to add more wires and keep the board small. VIPPO PCB also helps signals stay strong and lets power move better. With VIPPO, engineers can make boards with more paths and smaller sizes.

Aspect | Explanation |

|---|---|

VIPPO (Via In Pad Plated Over) is a through-hole via filled with epoxy or conductive paste, flattened, and plated over. | |

Purpose | Prevents solder wicking, allows placement under component pads. |

Fabrication Process | Hole filled, flattened, and plated with copper. |

Standard Reference | IPC-4761 type 7 defines this via type. |

Key Features of VIPPO Technology

VIPPO PCB is special because it uses via-in-pad technology. The process uses lasers and chemicals to make strong and lasting holes. Engineers pick materials that help signals and heat move well. The filled hole helps electricity flow and keeps the board strong. VIPPO PCB lets people build smaller and thinner boards for fast devices. The table below shows the main features:

Specification / Parameter | Impact | |

|---|---|---|

Base Material | Low Dk, high thermal conductivity | Maintains signal integrity, improves thermal management |

Via Filling Material | High electrical conductivity, matched CTE | Ensures signal transmission, reduces stress |

Manufacturing Process | Laser drilling, copper plating | Accurate vias, strong interconnect |

Performance Features | Smaller systems, better signal transmission | Supports high-density interconnect, high-speed circuits |

LT CIRCUIT’s Expertise in VIPPO PCB Solutions

LT CIRCUIT is very good at making VIPPO PCBs for busy boards. Their team uses new ways to build and checks quality carefully. They tell the factory exactly what VIPPO PCB needs to look like. LT CIRCUIT picks the best stuff for good signals and heat control. Their engineers test every VIPPO PCB to make sure it works well. People trust LT CIRCUIT for small, strong, and fast PCBs with via-in-pad technology.

Key Benefits of VIPPO in High-Density PCB Layouts

Space Optimization and Layout Flexibility

VIPPO PCB helps engineers use every bit of board space. With via-in-pad, they can put vias right under parts. This means they do not need extra paths for wires. It gives more room for important traces. Engineers can fit more parts without losing quality or making things hard to build.

VIPPO lets engineers make thinner wires and pack them closer.

Designers can plan paths to fit more parts in small spots.

The technology works well with BGA assembly for new packages.

VIPPO PCB makes it easier to design tricky circuits.

Note: VIPPO PCB helps save space and gives more ways to lay out the board. This makes PCB design better and uses the area well.

Improved Signal Integrity and Electrical Performance

Signal quality is very important in fast and busy PCBs. VIPPO PCB uses via-in-pad to make short, straight paths. This helps stop signal loss and keeps signals clear. Engineers use this to keep signals strong, even when they need high trust.

Micro-section and X-ray checks make sure vias have no gaps.

Back-drilling takes away extra via parts to help signals at fast speeds.

VIPPO PCB stops problems from old vias in pads, which is key for fast circuits.

A table below shows how VIPPO helps signal quality and electrical work:

Feature | Benefit for Signal Integrity |

|---|---|

Via-in-pad technology | Shorter signal paths, less distortion |

Void-free via filling | Stable, reliable signal transmission |

Back-drilling | Improved high-speed data performance |

Controlled impedance | Consistent electrical performance |

VIPPO PCB keeps signals strong by lowering problems and making sure electricity flows well. The technology lets engineers make hard paths and supports fast data, so it is needed for new PCBs.

Enhanced Reliability and Manufacturability

Making sure PCBs work well is very important, especially for tough jobs. VIPPO PCB uses smart via-in-pad and careful steps to help with this. Engineers pick materials that move electricity and heat well, so the board lasts longer.

VIPPO stops solder problems by keeping solder from moving.

Fast heat and special tests show VIPPO PCBs are strong.

Better heat control helps the board handle hot parts, which is needed for strong power.

The process makes flat, gap-free vias that make the board stronger and more reliable.

Tip: VIPPO PCB gives better heat control and keeps things working, even when it gets tough.

Companies like LT CIRCUIT use computer tests and real data to plan the board and check how it works. This makes sure every VIPPO PCB is high quality and works the same way each time. Using via-in-pad, good heat control, and strong materials makes VIPPO PCB the best pick for busy, powerful boards.

Engineers pick these PCB solutions for small designs.

They work well for hard projects that need to last.

Good reliability means the board works the same every time.

LT CIRCUIT makes sure their boards are ready for new technology.

These reasons show why vippo is a good pick for busy layouts.

FAQ

What makes VIPPO PCB different from standard via technology?

VIPPO PCB has vias that are filled and covered in pads. This lets engineers put more parts close together. It also helps signals move better than normal through-hole vias.

Can LT CIRCUIT customize VIPPO PCBs for unique project needs?

LT CIRCUIT can make VIPPO PCBs just how you want. Engineers can pick the materials, finishes, and tests to fit their design.

How does VIPPO PCB improve reliability in high-density designs?

VIPPO PCB stops solder from moving where it should not go. It makes pads flat and strong. This helps the board last longer and keeps connections safe for new devices.

See Also

Top Three Advantages Of Using VIPPO In PCB Design

Essential Skills Required For Designing Multi-Layer PCB Layouts

How Multilayer PCBs Are Used In Various Industries

Selecting A Reliable PCB Manufacturer For Your Business Needs

OSP Finish In PCB Production: Advantages, Drawbacks, And Guidelines