What Is a Copper Base PCB and How Does It Work

You choose a copper base pcb for its superior heat dissipation, excellent electrical conductivity, and dependable mechanical strength in your printed circuit board designs. LT CIRCUIT’s advanced copper base pcb technology guarantees that each copper layer is precisely uniform, delivering consistent performance. Explore the main functions below:

Function | Description |

|---|---|

Electrical Conductivity | A copper base pcb offers a low-resistance conductive layer, supporting high-speed signal transmission and stable power distribution. |

Mechanical Strength | The electroplated copper layer in a copper base pcb boosts structural stability, making the board resistant to external shocks and temperature fluctuations. |

Thermal Management | Copper base pcbs efficiently conduct heat, preventing overheating and ensuring reliable operation in high-power applications. |

Corrosion Resistance | The protective layer formed during copper plating on a copper base pcb prevents oxidation and corrosion, extending the board’s service life. |

Copper base pcbs are essential as modern electronics require smaller, more powerful, and energy-efficient solutions.

Key Takeaways

Copper base PCBs provide excellent heat dissipation, making them ideal for high-power applications. This helps prevent overheating and extends the life of electronic devices.

The high electrical conductivity of copper ensures faster signal transmission and stable power distribution. This is crucial for high-frequency circuits.

Copper base PCBs are more durable than aluminum alternatives, offering better mechanical strength and resistance to temperature fluctuations.

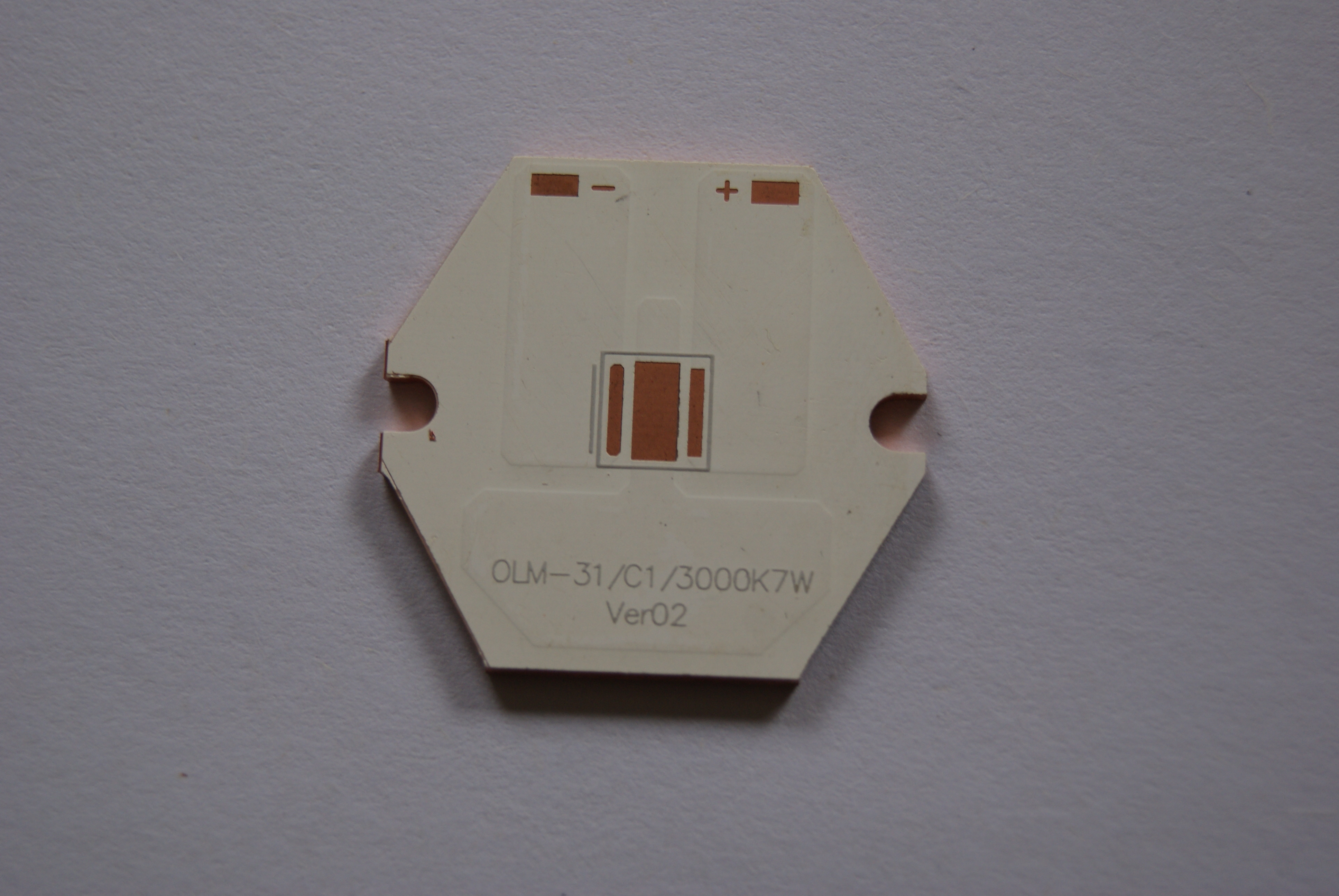

Copper Base PCB Structure

Copper-base pcb designs use a layered structure to deliver excellent performance in demanding applications. Each layer in a copper printed circuit board plays a unique role in supporting both electrical and thermal functions.

Copper Substrate

You will find the copper substrate at the base of every copper-base pcb. This layer uses pure copper, which offers the highest thermal conductivity among metal substrates. Copper substrate pcb types handle high-frequency circuits and large temperature changes with ease. The copper layer in a copper clad pcb can reach thermal conductivity values from 1W/mK up to 9W/mK, and some advanced designs approach 398W/mK. This makes copper circuit board solutions ideal for heat dissipation in power electronics. LT CIRCUIT uses precise copper base pcb fabrication methods to ensure strong adhesion and uniform thickness in every copper layer.

Insulation Layer

Above the copper substrate, you see the insulation layer. This layer separates the copper from the circuit traces and prevents electrical shorts. High-performance copper-base pcb fabrication often uses materials like polyimide, high-Tg FR-4, or PTFE. These materials withstand high temperatures and provide excellent electrical insulation. The insulation layer also helps manage heat flow, which is critical in multilayer copper pcb designs. LT CIRCUIT selects advanced prepreg and laminate materials to improve both signal integrity and thermal management.

Circuit Layer

The top layer is the circuit layer, where you find the copper traces that form the electrical pathways. Thicker copper in this layer reduces resistance and supports stable signal transmission. It also lowers thermal noise and minimizes crosstalk between traces. During copper base pcb fabrication, LT CIRCUIT uses photolithography and precise etching to create accurate circuit patterns. The solder mask protects these traces, ensuring long-term reliability. When you choose copper base pcb assembly from LT CIRCUIT, you get a product that meets strict quality standards at every step.

Tip: The combination of copper, advanced insulation, and precise circuit design makes copper-base pcb solutions stand out in high-power and high-frequency applications.

How Copper Base PCBs Work

Thermal Conductivity of Copper Base PCBs

When you use a copper base pcb, you get the advantage of high thermal conductivity. Copper has a thermal conductivity of about 400 W/m·K, which is much higher than most other materials used in pcb manufacturing. This means copper moves heat away from hot components very quickly. In comparison, FR4 materials only offer a thermal conductivity between 0.25 and 0.3 W/m·K. The high thermal conductivity of copper base pcbs lets you manage heat in high-power devices with ease.

Copper core pcbs provide better thermal conductivity than aluminum pcbs.

IMS pcbs also have better thermal conductivity than FR-4 pcbs.

Copper’s high thermal conductivity allows for more effective heat transfer away from sensitive parts.

You will notice that the thick copper layer in a copper-base pcb acts as a direct path for heat dissipation. This keeps your circuit cool and stable, even when you push it to handle large amounts of power. The thermal conductivity and heat dissipation properties of copper circuit board designs make them ideal for applications where overheating can cause failure. LT CIRCUIT uses advanced manufacturing to ensure each copper layer is uniform, which improves both heat dissipation and overall performance.

Note: The high thermal conductivity of copper base pcbs is essential for keeping your devices safe and reliable, especially in compact or high-power electronics.

Electrical Performance

You benefit from excellent electrical performance when you choose a copper-base pcb. Copper has a conductivity of 5.96 x 10^7 S/m, which is much higher than aluminum’s 3.77 x 10^7 S/m. This high conductivity means your circuit can transmit signals faster and with less resistance. In high-frequency circuits, copper’s superior conductivity results in a smaller skin depth, which reduces resistance and power loss. This is important for stable signal transmission and efficient power delivery.

The stability of dielectric constant (Dk) and dissipation factor (Df) at different frequencies helps you judge pcb material quality.

In high-speed designs, a low dissipation factor (Df) is more important than the dielectric constant (Dk) for minimizing signal loss.

The roughness of copper foil and the skin effect impact insertion loss, which matters for high-frequency circuit performance.

Copper base pcbs show higher electrical conductivity than aluminum pcbs, making them better for high-frequency and high-power uses.

The thick copper layer in heavy copper pcbs provides a low-resistance path for electric current, which is essential for applications like motor controllers and solar panels.

You will see that copper’s high thermal conductivity also helps prevent overheating, which keeps your circuit stable and extends the life of your device. LT CIRCUIT uses strict quality control and advanced materials to ensure every pcb meets high standards for electrical performance and reliability.

Copper Base PCB vs Aluminum PCB

When you compare copper base pcbs to aluminum pcbs, you find several key differences that affect performance, durability, and cost. Copper base pcbs offer higher thermal conductivity and better heat dissipation, which makes them suitable for extremely high-power applications. Aluminum pcbs are lighter and often more cost-effective, but they do not match the high thermal conductivity or durability of copper.

Aspect | Aluminum Core PCB | |

|---|---|---|

Cost | More cost-effective due to lower material costs, but higher manufacturing costs from processing challenges. | Lower manufacturing costs, suitable for small-scale production. |

Durability | Lighter, less wear-resistant, good for low-weight needs. | More durable and wear-resistant, ideal for high-current applications. |

Evidence Description | Findings |

|---|---|

Thermal cycling impact | Repeated temperature changes can cause cracks or solder joint fatigue. |

Failure mechanism | Thermal expansion-induced fatigue, with barrel cracking after life cycles. |

Material selection impact | Material choice affects plated through hole (PTH) life more than copper wrap. |

Stress concentration | Higher stresses near the center of holes can lead to failure in wear-out environments. |

Manufacturing variability | Defects in copper bonding can create weak points, so quality control is vital. |

Copper base pcbs have higher thermal conductivity than aluminum pcbs.

Copper base pcbs are more durable and wear-resistant, making them ideal for high-current and high-power uses.

Aluminum pcbs are lighter and may be chosen for applications where weight matters more than heat dissipation.

You will find that copper base pcbs are the best choice when you need high thermal conductivity, excellent heat dissipation, and long-term reliability. LT CIRCUIT’s commitment to quality and innovation ensures that every copper-base pcb delivers top performance, even in the most demanding environments.

Applications of Copper Core PCBs

Industrial and Power Electronics

You see copper core pcbs used in many industrial and power electronics systems. These boards handle high-power applications where heat management and reliability matter most. Copper core circuit boards appear in:

Lighting systems, including street lights and camping lanterns

Automotive electronics, such as headlights and power controllers

Telecommunications equipment, like high-frequency amplifiers

Audio devices, including power amplifiers

Computer hardware, such as CPU boards and power devices

Power supply units, including solid-state relays and converters

Medical tools, like surgical lighting and high-power scanning technology

Copper core pcbs offer superior thermal conductivity and mechanical stability. You benefit from cooler components under heavy loads, which improves efficiency and extends device life. These advantages make copper core circuit boards ideal for demanding environments.

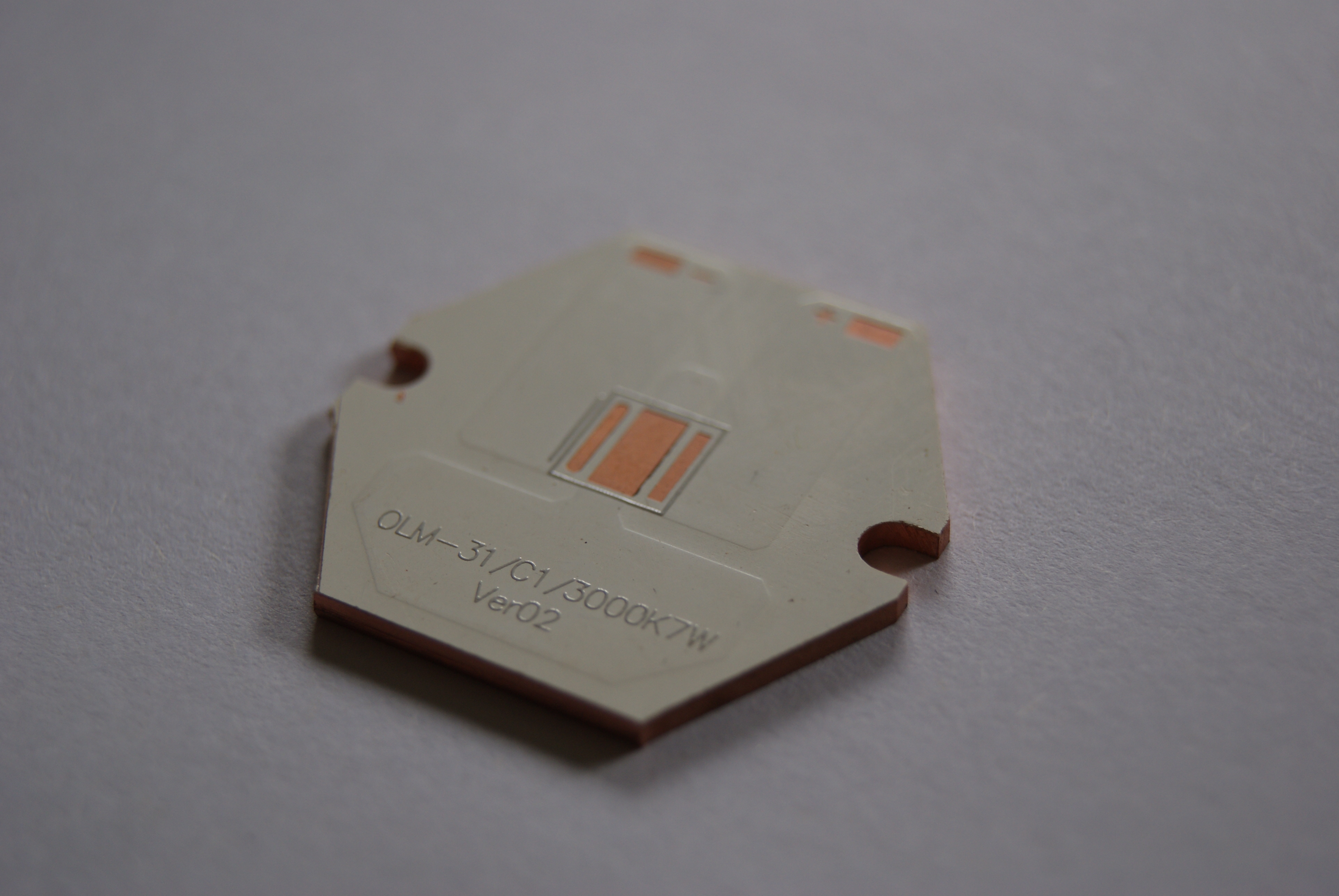

LED and Lighting Solutions

You rely on copper core pcbs for LED and lighting solutions. Copper base pcb fabrication creates boards that act as effective heat sinks. The copper layer draws heat away from LED chips and spreads it across the circuit. This process keeps operating temperatures low and prevents premature failure. You notice that copper core circuit boards help maintain stable light output and color consistency.

Material Type | |

|---|---|

Copper | > 380 |

Aluminum | Lower than Copper |

Copper core pcbs reduce temperatures by 15-20℃ compared to aluminum substrates. You see LED lifespan increase by more than 30%. These advantages make copper-base pcb solutions perfect for automotive and architectural lighting.

LT CIRCUIT Copper Core PCBs in High-Performance Devices

You choose LT CIRCUIT for advanced copper core pcb solutions in high-performance devices. LT CIRCUIT offers a wide range of customization options:

Customization Aspect | Description |

|---|---|

Layer Count | Specify the number of layers for your copper core circuit boards. |

Surface Finish | Select finishes that match your application needs. |

Solder Mask Color | Pick custom colors for functional or aesthetic purposes. |

Testing Services | Request tailored tests to ensure your pcb meets performance standards. |

LT CIRCUIT uses precise copper base pcb fabrication methods to deliver reliable copper-base pcb products. You get circuit boards with exceptional thermal management and electrical performance. These boards support high-power applications and meet strict quality requirements.

Tip: Copper core pcbs provide 5 to 15 times better thermal management than aluminum-based boards. You gain stability and reliability in every circuit.

You gain superior thermal management with copper base PCBs, thanks to thick copper layers that dissipate heat and extend component life. LT CIRCUIT’s advanced designs, including thermal vias and wide copper traces, keep temperatures low and performance high. Choose copper base PCBs for automotive, LED lighting, and power electronics.

LT CIRCUIT maintains LED temperatures below 85°C, ensuring longer lifespans.

Over half of electronic failures result from excessive heat, so effective thermal management is essential.

FAQ

What makes copper base PCBs better for heat management?

You get faster heat dissipation with copper base PCBs. Copper moves heat away from components quickly, which keeps your devices cool and safe.

Can you use copper base PCBs in high-frequency circuits?

You can use copper base PCBs in high-frequency circuits. These boards support stable signal transmission and reduce power loss.

How do you choose the right PCB for your application?

Application Type | Recommended PCB |

|---|---|

High-power devices | Copper base PCB |

Lightweight devices | Aluminum PCB |

See Also

Utilizing Horizontal Copper Sinking Technology in PCB Manufacturing

Incorporating Panasonic Copper-Clad Laminates in PCB Production

Understanding PCB Printed Circuit Boards and Their Key Principles

Key Guidelines for Creating Heavy Copper PCBs for High Currents

Comprehensive Technology Guide for Heavy Copper Multilayer PCBs