Why Choose 20 oz Copper Thickness in Heavy Copper PCBs

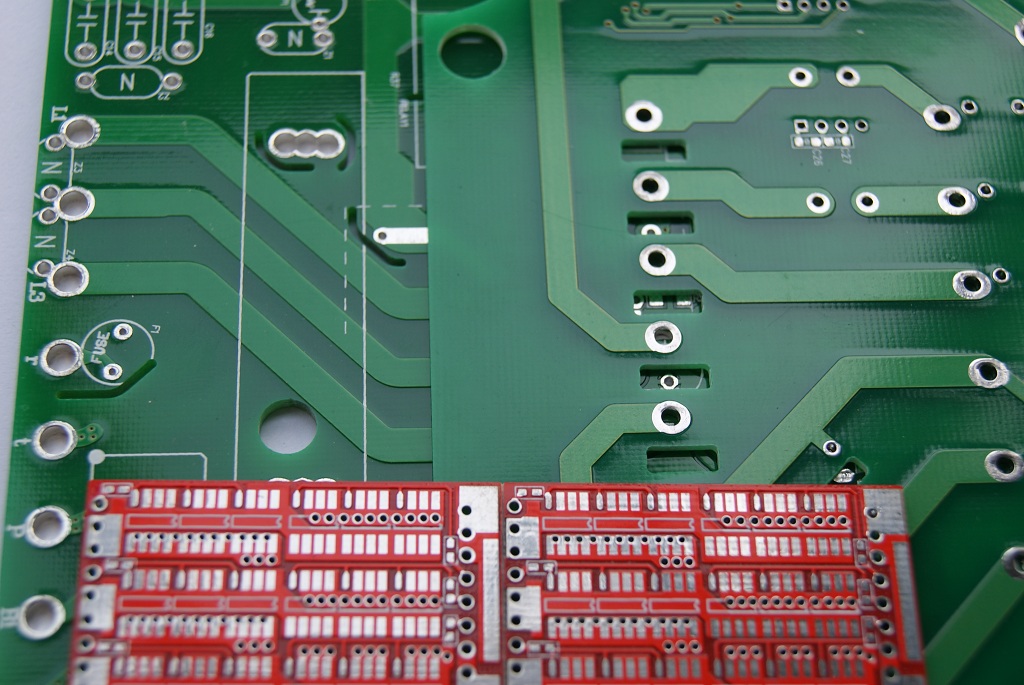

If you need a solution that can manage extreme power and heat, selecting 20 oz copper thickness in heavy copper pcb delivers exceptional durability for high-power distribution, efficient heat dissipation, and challenging applications. This specification is trusted across various industries, such as:

Planar transformers

Power converters

Radar system power supplies

Safety and signal systems

Welding equipment

Automotive

Solar panel manufacturing

Nuclear power

Key Takeaways

20 oz copper thickness significantly increases current carrying capacity, allowing heavy copper PCBs to handle up to 150A continuously. This is essential for high-power applications.

Enhanced thermal management in heavy copper PCBs improves heat dissipation, reducing the risk of overheating and component failure in demanding environments.

Heavy copper PCBs offer superior durability and reliability, making them ideal for harsh conditions. They resist physical stress and thermal cycling, ensuring long-term performance.

Benefits of 20 oz Copper Thickness in Heavy Copper PCBs

Increased Current Carrying Capacity

When you choose 20 oz copper thickness in heavy copper pcb, you unlock a much higher current carrying capacity for your designs. Standard PCBs can only handle about 5-10 amps, but heavy copper pcbs with 20 oz copper thickness can safely carry up to 150A continuously. This makes them ideal for high current circuits and power distribution systems where reliability is critical.

Copper Thickness | Maximum Current Rating |

|---|---|

20 oz | 150A continuous |

You get a significant boost in high current capability, which is essential for demanding applications like motor drives, power converters, and industrial equipment. The thicker copper layer creates low-resistance pathways, reducing voltage drops and power loss. This means your heavy copper pcbs deliver more efficient electrical performance and help prevent circuit burnout.

Enhanced Thermal Management

Heavy copper pcbs with 20 oz copper thickness offer increased thermal management, which is vital for high-power electronic systems. Thicker copper layers improve heat dissipation, allowing your board to spread heat more evenly and protect sensitive components from overheating. This is especially important in high current circuits, where large amounts of energy can generate significant heat.

Heavy copper increases thermal conductivity, moving heat away from hot spots.

The thicker copper layer allows your board to carry more current without overheating.

You reduce the risk of component failure and maintain safe operation.

Tip: Increased thermal management in heavy copper pcbs helps you achieve stable performance even in the most demanding environments.

Compared to standard PCBs, heavy copper pcbs dissipate heat 3-5 times faster. This makes them a better choice than alternatives like busbars for many applications, as you get both electrical and thermal benefits in a single board.

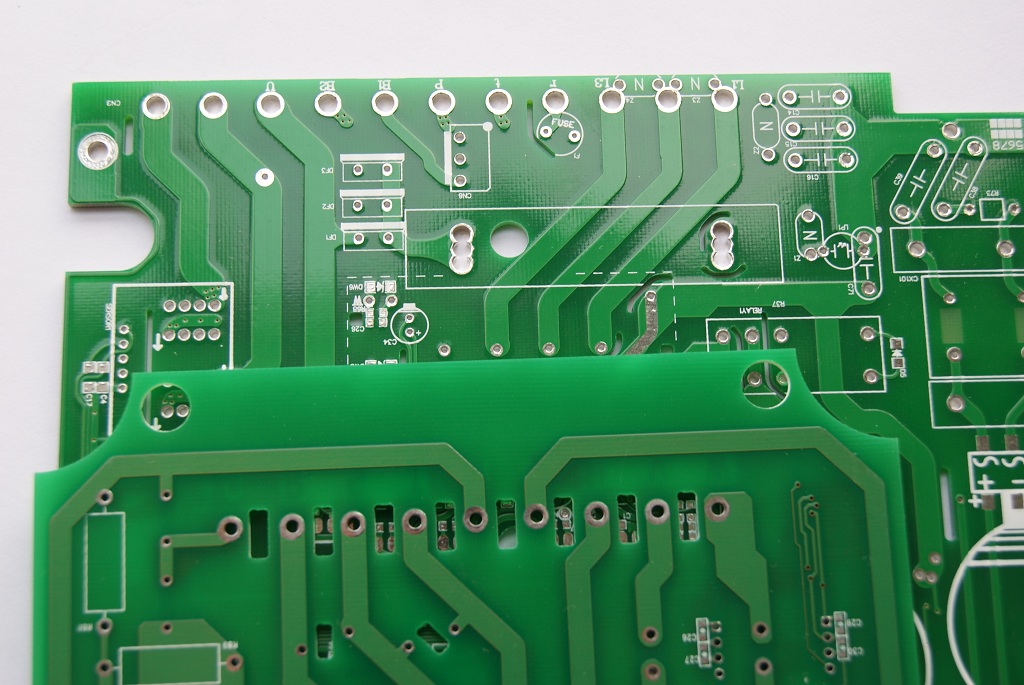

Superior Durability and Reliability

You can count on heavy copper pcbs for enhanced durability and long-term reliability. The thick copper layers provide strong mechanical support, making your board more resistant to physical stress, vibration, and harsh environmental conditions. This is crucial for high current circuits used in automotive, industrial, and power generation systems.

Heavy copper pcbs withstand thermal cycling, reducing the risk of cracks or delamination.

The design supports higher power density without sacrificing performance.

Thicker copper layers resist corrosion, heat, and cold, extending the lifespan of your board.

You also benefit from increased efficiency, as heavy copper pcbs create low-resistance pathways for high currents. This reduces the risk of burnout and improves the overall reliability of your circuit. The enhanced durability ensures your system keeps running, even in tough conditions.

Note: Enhanced durability in heavy copper pcbs means fewer failures and less maintenance, saving you time and money over the life of your equipment.

Design Considerations for Heavy Copper PCBs

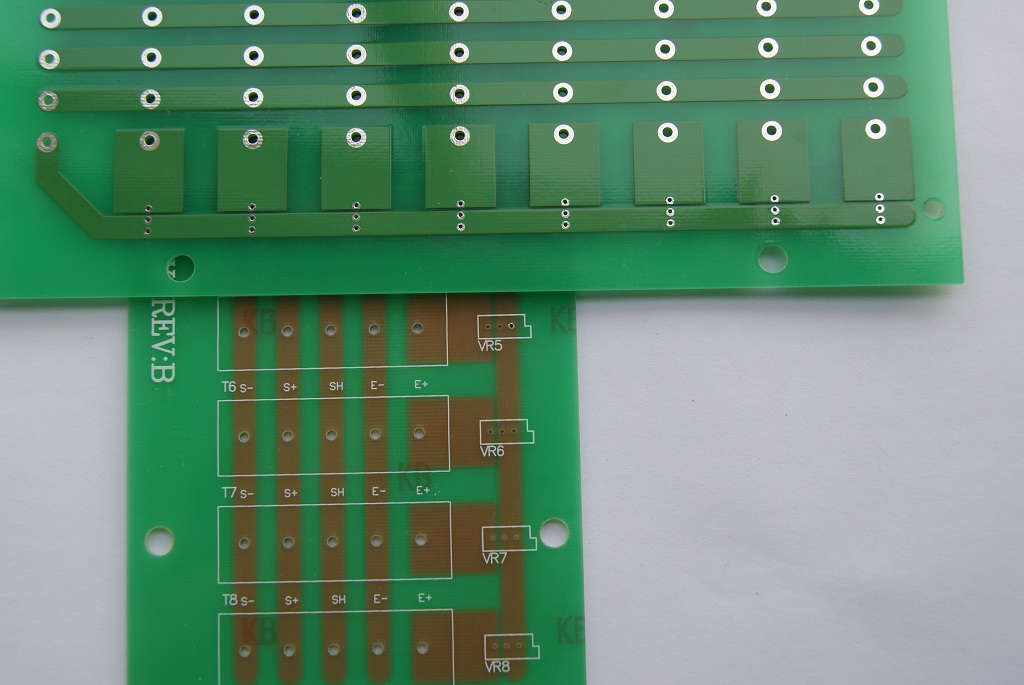

Impact on PCB Thickness and Layout

When you use 20 oz copper thickness in heavy copper pcb, you change the way your board looks and works. The extra copper adds to the total thickness, making your board stronger and more resistant to bending or vibration. This strength is important for industrial and automotive uses, where mechanical reliability matters.

Copper Weight | Mechanical Strength | Durability in Harsh Conditions |

|---|---|---|

Standard | Moderate | Limited |

Heavy Copper | High | Enhanced |

You must also adjust your design. Thicker copper needs a thicker solder mask and more clearance around pads and traces. You should balance copper across the board to prevent warping. Fine-pitch designs become harder because etching thick copper takes longer.

Use a solder mask layer of 1.5-2 mil (38-50 μm)

Increase solder mask clearance to 4-6 mil (0.1-0.15 mm)

Add dummy copper fills for balance

Application Scenarios for 20 oz Copper

You will find heavy copper pcbs with 20 oz copper thickness in heavy copper pcb in places where high current and heat dissipation are critical. Power supplies, electric vehicles, and industrial controls all need boards that can handle high currents and repeated thermal cycles. These boards also work well in radar systems, welding equipment, and solar panel manufacturing. You get enhanced durability and reliability in every use.

Cost and Manufacturing Factors

Choosing heavy copper means you face higher costs and more complex manufacturing steps. The raw copper costs more, and the process takes longer. You need special steps for etching, plating, and drilling. Fabrication expenses can rise by 20-30% compared to standard boards.

Performance Benefits | Cost Implications |

|---|---|

Higher current-carrying capacity | Increased material costs for heavier copper weights |

Superior heat dissipation | Fabrication costs rise due to complexity |

Enhanced mechanical strength and integrity | Overall expenses can increase by 20-30% |

Improved signal integrity | Manufacturing hurdles with greater copper thickness |

Tip: Use heavy copper only where you need it most. This helps you manage costs while still getting the benefits of high current and thermal management.

You gain superior current capacity, thermal control, and durability with 20 oz copper in heavy copper PCBs. Review your application’s needs and consult PCB experts. Many experts suggest using thick copper only in high-current areas for efficiency:

Use selective heavy copper or embedded copper coins.

Maintain standard copper elsewhere.

Copper Thickness | Current-Carrying Capacity | Temperature Rise | Service Life |

|---|---|---|---|

1 oz → 3 oz | +50–70% | -15–30°C | +20–40% |

3 oz → 6 oz | +40–50% | -10–20°C | +15–30% |

FAQ

What makes 20 oz copper PCBs better for high-power devices?

You get higher current capacity and better heat control. These boards handle tough jobs in power supplies, automotive, and industrial systems.

Can you use 20 oz copper PCBs for small electronics?

You should avoid them for small gadgets. The thick copper adds size and cost. Standard PCBs work better for low-power devices.

How does 20 oz copper affect PCB design?

You must plan for thicker traces and larger clearances. The board becomes stronger, but you need careful layout to avoid design issues.

See Also

Key Strategies for Creating High-Current Copper PCBs

Comprehensive Guide to Heavy Copper Multilayer PCB Production

Impact of Vertical Continuous Plating on Copper Thickness Uniformity

Grasping Vertical Continuous Plating for Copper Thickness Precision