Why Are Copper Core PCBs More Expensive Than Others

You notice that a copper core pcb costs more than many alternatives. The price reflects higher material expenses, advanced manufacturing, and top-tier performance. LT CIRCUIT delivers these premium solutions by using advanced techniques and materials. You receive quality and reliability that set your projects apart from the rest.

Key Takeaways

Copper core PCBs cost more due to expensive raw materials and advanced manufacturing processes. Investing in these boards ensures better performance and reliability for your projects.

Thicker copper layers in copper core PCBs enhance thermal management, making them ideal for high-power applications. This leads to longer device life and reduced cooling needs.

Choosing copper core PCBs can save you money over time through lower maintenance costs and improved system efficiency. The initial investment pays off in demanding industries.

Copper Core PCB Price Factors

Material Cost

You pay more for a copper core pcb because copper is much more expensive than other materials like aluminum or fiberglass. The high raw material cost starts with the price of copper itself. Copper mining and refining require a lot of energy, which adds to the expense. The thicker copper base in these pcbs means you need more copper, and that drives up the price even further.

Copper costs up to three times more than aluminum, making copper core pcb production much pricier.

The thicker copper layers and heavier base need more energy and effort to process, which increases manufacturing costs.

High raw material cost affects every step, from sourcing to final production.

LT CIRCUIT uses only premium copper and other top-grade materials for its copper core pcb products. You benefit from this commitment to quality because your pcbs deliver better performance and reliability.

The market price of copper changes over time. You can see how copper prices have trended in recent years:

Time Period | Price (USD/KG) | Change (%) |

|---|---|---|

Current Price | 9.75 | +0.3% |

Last Month | 9,770.58 | -1.03% |

One Year Ago | 8,971.96 | +7.78% |

Average Growth (5 years) | N/A | +6.54% |

You notice that copper prices have increased steadily, which impacts the overall price of copper core pcb products.

Premium materials also play a big role in the cost. The table below compares the price of different pcb materials over time:

Material Type | 2020 Price ($/sq inch) | 2022 Price ($/sq inch) | 2025 Price ($/sq inch) |

|---|---|---|---|

FR-4 (Standard PCB material) | $0.08 – $0.30 | $0.10 – $0.40 | $0.10 – $0.50 |

High-Frequency (Rogers, Teflon-based) | $1.50 – $3.50 | $1.80 – $4.50 | $2.00 – $5.00 |

Metal Core PCB (Aluminum, Copper) | $1.20 – $3.00 | $1.40 – $3.50 | $1.50 – $4.00 |

You see that metal core pcbs, including copper core pcb, cost much more than standard FR-4 pcbs. This price difference comes from the high raw material cost and the need for thicker copper layers.

Copper Thickness and Price

You find that copper core pcb products use much thicker copper than standard pcbs. Regular pcbs usually have copper layers that are about 1oz thick. Copper core pcbs need layers between 2oz and 10oz. This extra thickness means you need more copper, which increases the price.

Thicker copper layers also make manufacturing harder. You need special equipment and skilled workers to handle the extra material. This adds to the cost and makes copper core pcb production more complex.

LT CIRCUIT invests in advanced technology and skilled labor to make sure your copper core pcb meets the highest standards. You get a product that performs better and lasts longer, even though the price is higher.

Tip: When you choose a copper core pcb, you invest in quality and durability. The higher price reflects the superior materials and advanced manufacturing that go into every board.

Costlier and Harder to Process

Manufacturing Complexity

You face more challenges when you choose a copper core pcb. The manufacturing process involves extra steps and advanced techniques that make these boards costlier and harder to process. Unlike standard pcb production, you need to handle thicker copper foil, special insulating layers, and more complex designs.

Here is a table that shows some unique steps in copper core pcb manufacturing:

Evidence Description | Details |

|---|---|

Thicker Copper Foil | The circuit layer uses copper foil between 35μm and 280μm for high current. |

Specialized Materials | The core includes thermally conductive layers made from aluminum oxide and silicon powder. |

Complexity of Designs | Multiple layers, such as circuit, solder mask, and silkscreen, add to the process. |

You often see that copper core pcb designs stray from standard pcb technology. This leads to more complex configurations and higher costs. You may need more holes and extra layers, which take more time to manufacture. Thicker copper and extra materials also mean longer production times.

You need to process more holes, which increases the time and cost.

You must use additional layers or thicker copper, which requires more energy and effort.

You deal with thermoelectric separation technology, which adds complexity.

The energy requirements for copper core pcb production are much higher than for standard boards. Thicker copper layers and heavier bases need more power and advanced processing. This extra energy use adds to the overall cost.

You also need to meet strict quality standards. Certifications like ISO 9001 ensure that every copper core pcb meets high standards for copper purity and thickness. IPC standards help you maintain product quality and safety.

Note: LT CIRCUIT uses advanced manufacturing methods and strict quality controls. You get copper core pcb products that meet the highest industry standards for reliability and performance.

Specialized Equipment

You cannot make a copper core pcb with basic tools. You need specialized equipment to handle the thick copper layers and complex structures. This equipment requires a large investment and skilled operators.

Here is a table showing the types of equipment needed and their estimated costs:

Equipment Type | Estimated Investment |

|---|---|

Advanced drilling systems | |

High-speed plating lines | $5-8M |

Advanced testing equipment | $1-3M |

Total Capital Expenditure | Substantial |

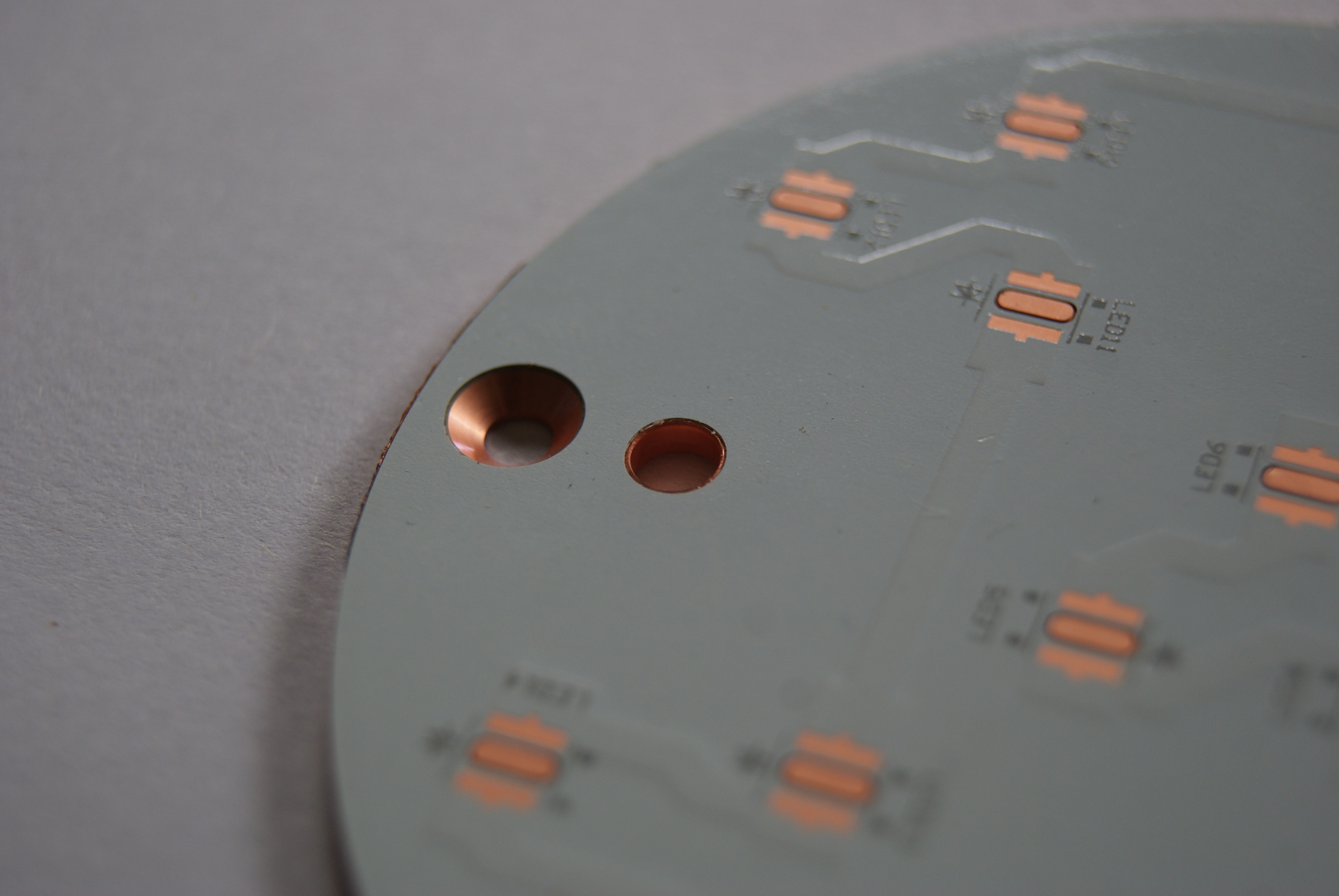

You need advanced drilling systems to create precise holes in thick copper. High-speed plating lines help you apply copper layers evenly. You also use advanced testing equipment, such as X-ray diagnostics, to check for defects and ensure quality.

Recent advancements in copper core pcb manufacturing have made the process more efficient. You now see 3D printing, microvias in HDI pcbs, and built-in passive or active elements. These technologies allow you to create more complex and compact designs. Lead-free and green production methods help you meet environmental standards. AI and machine learning tools help you optimize designs and predict maintenance needs.

Tip: LT CIRCUIT invests in the latest equipment and technology. You benefit from their expertise and commitment to producing high-quality copper core pcb products, even when the process is costlier and harder to process.

Copper Base PCB Performance & Applications

Superior Thermal Management

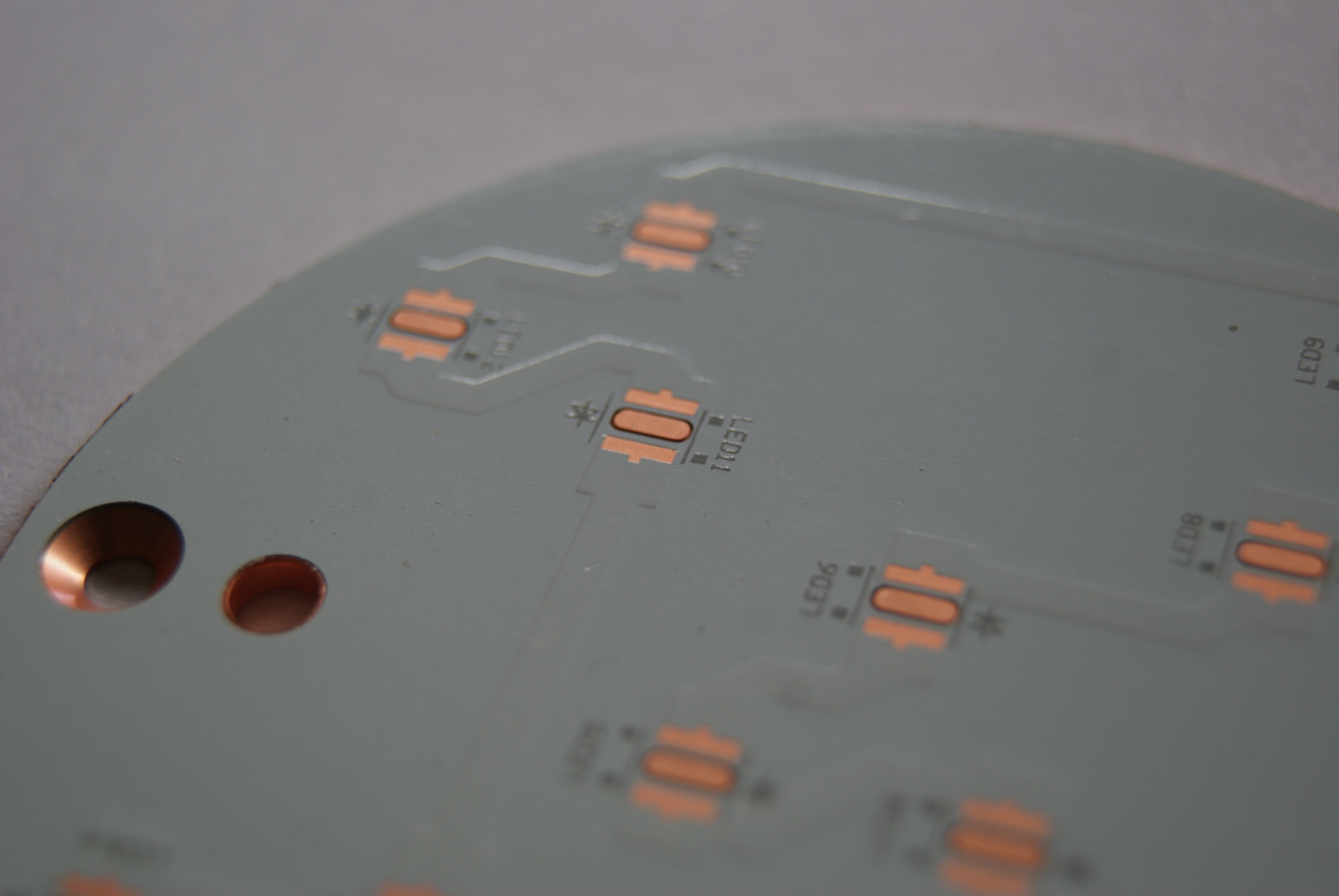

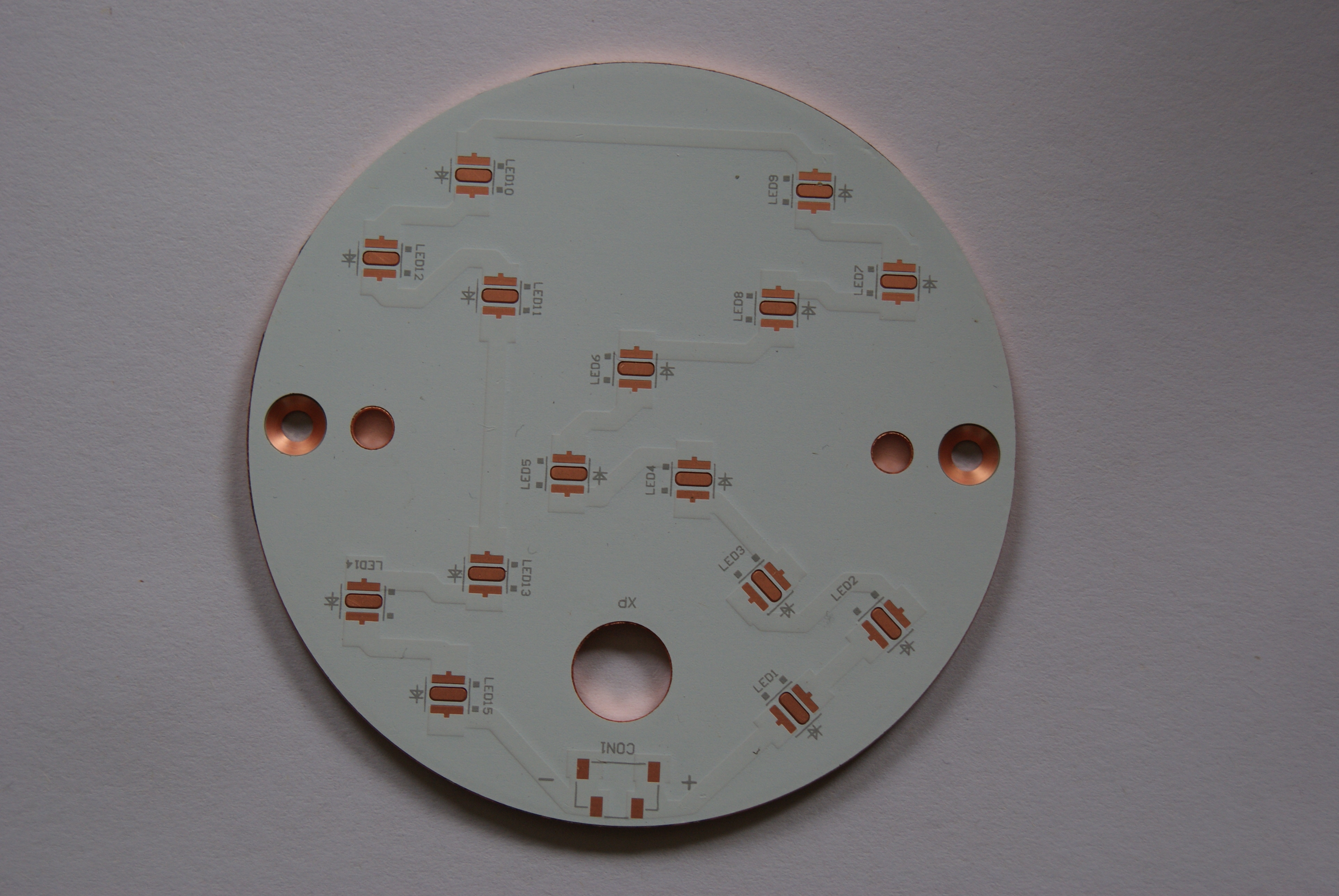

You choose a copper base pcb when you need the best thermal performance. Copper has a thermal conductivity of 400 W/mK, which is much higher than aluminum or FR4. This means your copper base pcb can move heat away from hot components quickly. In high-power LED lighting, copper base pcb designs keep temperatures low and prevent damage. You see this advantage in the table below:

Material | Thermal Conductivity (W/mK) |

|---|---|

Copper | 400 |

Aluminum | ~200 |

FR4 | 1 to 2 |

Copper base pcb solutions handle more heat, so your devices last longer and work better. You also get less risk of overheating, which protects sensitive parts. When you use copper pcb prototyping, you can test and confirm these thermal benefits before full production.

Where the Cost Pays Off

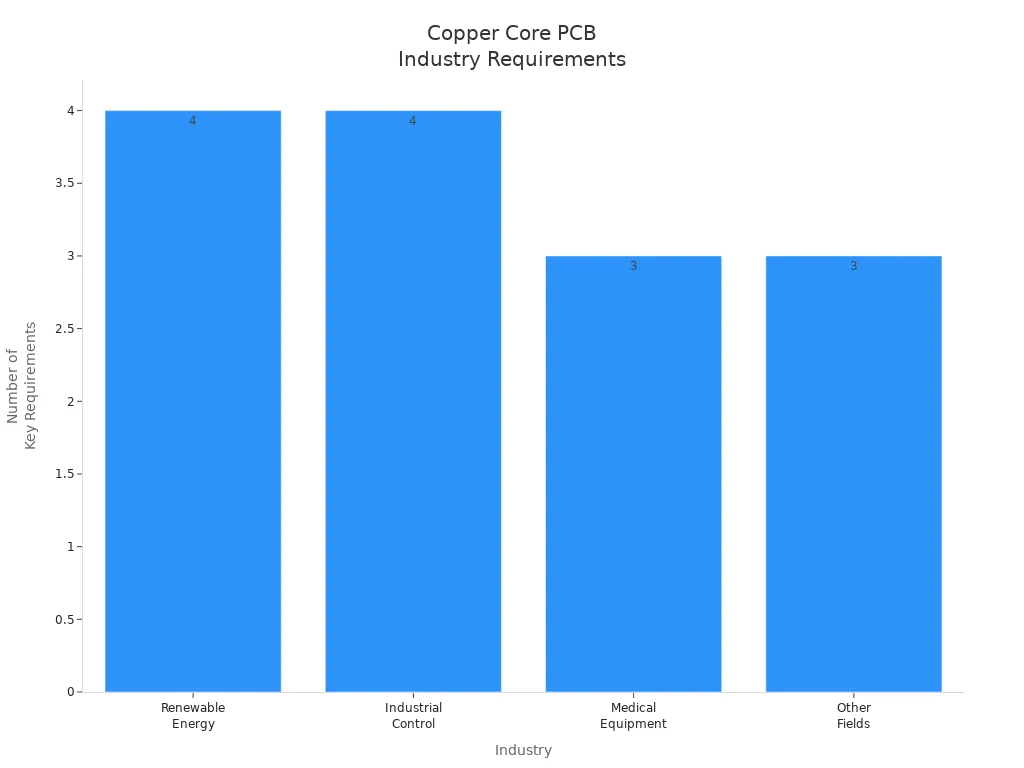

You invest in a copper base pcb because you want reliability and top performance. Copper base pcb products offer superior electrical conductivity, strong mechanical strength, and excellent corrosion resistance. These features make them the first choice for demanding industries. You find copper base pcb designs in renewable energy, industrial control, and medical equipment. The chart below shows how different industries rely on copper base pcb solutions:

You see that copper base pcb products meet strict requirements for high current, heat dissipation, and durability. LT CIRCUIT has delivered copper pcb prototyping for projects that need 50A+ current, stable power, and resistance to vibration. You benefit from lower maintenance costs and longer device life. Copper base pcb designs reduce cooling needs, which saves you money over time. When you use copper pcb prototyping, you ensure your final product meets all performance goals.

Tip: Choose copper base pcb solutions for applications where thermal, electrical, and mechanical performance matter most. LT CIRCUIT’s experience in copper pcb prototyping helps you achieve the best results in every project.

You pay more for copper core PCBs because of premium materials, advanced processing, and top performance. Industry experts highlight these benefits:

Benefit | |

|---|---|

Thermal Conductivity | Excellent heat dissipation |

Design Flexibility | Stable, versatile structures |

Smaller Warpage | Less deformation than aluminum PCBs |

You also save money over time:

Lower maintenance costs

Better system efficiency

Choose LT CIRCUIT for reliable copper core PCB solutions.

FAQ

What makes the cost of copper core PCBs higher than other types?

You see the cost rise because copper is expensive. The cost of raw materials, the cost of thicker copper, and the cost of advanced processing all add up. The cost also reflects the need for specialized equipment. You pay a higher cost for better performance. The cost of energy and the cost of skilled labor increase the total cost. You notice the cost difference when you compare to standard boards. The cost of meeting strict quality standards also matters. The cost of testing and the cost of certifications add to the final cost. You invest in a higher cost for reliability. The cost of maintenance drops over time. The cost of cooling systems goes down. The cost of repairs is lower. The cost of downtime decreases. The cost of ownership becomes more manageable. The cost of using a metal core printed circuit board is worth it for demanding projects.

How does the cost of copper core PCBs compare to aluminum core PCBs?

You pay a higher cost for copper core PCBs. The cost of copper is greater than aluminum. The cost of manufacturing and the cost of processing also increase with copper.

When should you accept the higher cost of copper core PCBs?

You accept the higher cost when your project needs top thermal management. The cost pays off in high-power, high-reliability, or mission-critical applications.

See Also

Comprehensive Guide to Heavy Copper Multilayer PCB Production

Key Strategies for Designing High-Current Heavy Copper PCBs

Utilizing Panasonic Copper-Clad Laminates in PCB Fabrication

Ten Strategies to Reduce Expenses in Custom PCB Manufacturing

Using Horizontal Copper Sinking Technology in PCB Manufacturing