How to balance heat dissipation and performance in 400 watt copper base PCBs

When you choose a 400 watt copper base pcb, you’re addressing the critical challenges of heat dissipation and electrical performance. The 400 watt copper base pcb from LT CIRCUIT leverages copper’s exceptional thermal conductivity to reduce failure rates in high-power systems. LT CIRCUIT’s advanced selection of materials for their 400 watt copper base pcb meets rigorous certifications such as ISO 9001 and UL, ensuring enhanced reliability and superior signal integrity.

Key Takeaways

Choose thick copper layers for better heat dissipation and electrical performance. This helps prevent overheating and enhances the lifespan of your PCB.

Optimize your layout by placing heat-generating components away from each other. This reduces hot spots and improves overall thermal management.

Consult with experts at LT CIRCUIT to select the right materials and design strategies. This ensures your PCB meets specific application needs for reliability and performance.

Key factors for 400 watt copper base pcb

Material selection and copper thickness

When you design a 400 watt copper base pcb, you must focus on the materials and copper thickness. The right choices help you achieve better heat dissipation and electrical performance. Copper stands out because it offers high thermal conductivity and excellent electrical properties. You can see how copper compares to other materials in the table below:

Property | Description |

|---|---|

Thermal Conductivity | Copper effectively dissipates heat, preventing overheating in high-power applications. |

Electrical Conductivity | Copper minimizes signal loss and resistance, enhancing overall electrical performance. |

Heavy copper PCBs usually range from 3 oz to 20 oz copper weight. These boards can handle over 100 amps per layer. This makes them ideal for high-power applications like a 400 watt copper base pcb. Thicker copper layers provide a lower resistance path for current. You get higher current carrying capacity and improved heat dissipation. Here are some benefits of increased copper thickness:

A thicker copper layer offers a greater surface area for heat dissipation, which is crucial for high-power applications.

Heavy copper PCBs efficiently dissipate heat, reducing the chance of overheating and enhancing longevity.

Thicker copper layers reduce resistance, allowing more current to flow efficiently.

You can see the current carrying capacity for different copper thicknesses in the table below:

Copper Thickness | Current Carrying Capacity |

|---|---|

1oz | ~3A |

4oz | 8–10A |

10oz | >20A |

LT CIRCUIT uses advanced materials and heavy copper to improve the reliability of your copper base pcb. More copper helps spread heat and keeps your components safe. The board also becomes stronger and more resistant to damage.

Thermal management in copper core pcb

Thermal management plays a key role in the performance of your 400 watt copper base pcb. You need to use materials with high thermal conductivity to move heat away from critical components. Copper has a thermal conductivity of about 400 W/m·K, which is much higher than other common PCB materials. The table below shows how copper compares to aluminum and FR-4:

Material | Thermal Conductivity (W/m·K) |

|---|---|

Copper | 400 |

Aluminum | 205 |

FR-4 | 0.2 |

You can improve thermal management by using thick copper layers, thermal vias, and metal backing. Here are some factors that influence heat dissipation efficiency in a 400 watt copper base pcb:

High thermal conductivity materials reduce thermal resistance.

Thick copper layers improve heat spreading and current carrying capacity.

Thermal vias provide vertical heat transfer paths.

Metal backing enhances thermal mass and spreading.

Embedded metal layers and coins quickly conduct heat away from hot spots.

Optimized layout helps distribute heat evenly.

Copper substrates are the most effective for thermal performance. They offer better thermal conductivity than aluminum or iron. You should use copper substrates for high-frequency circuits and applications with large temperature changes. IMS PCBs use a metal core substrate, usually copper, which allows for superior thermal management in high-power applications.

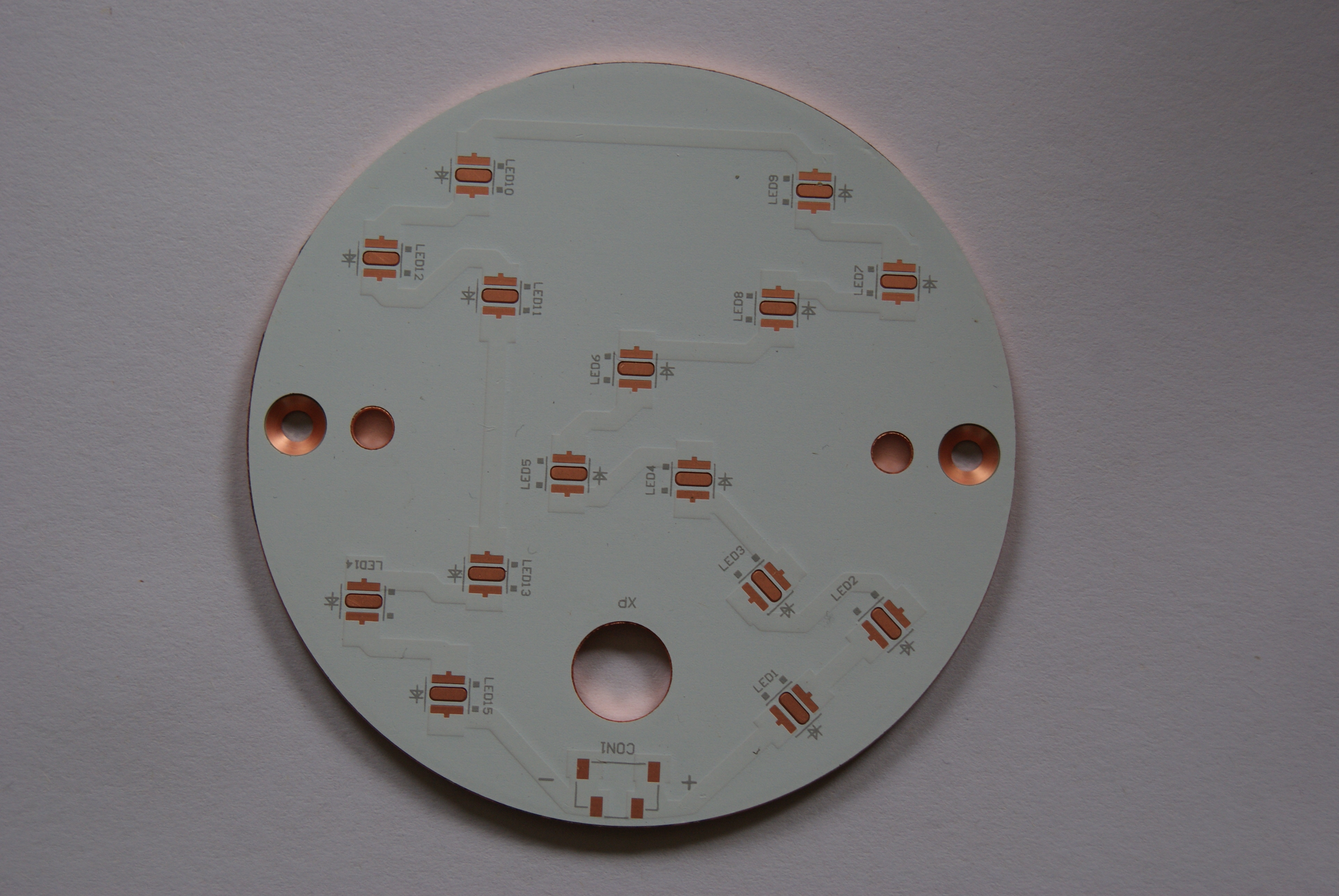

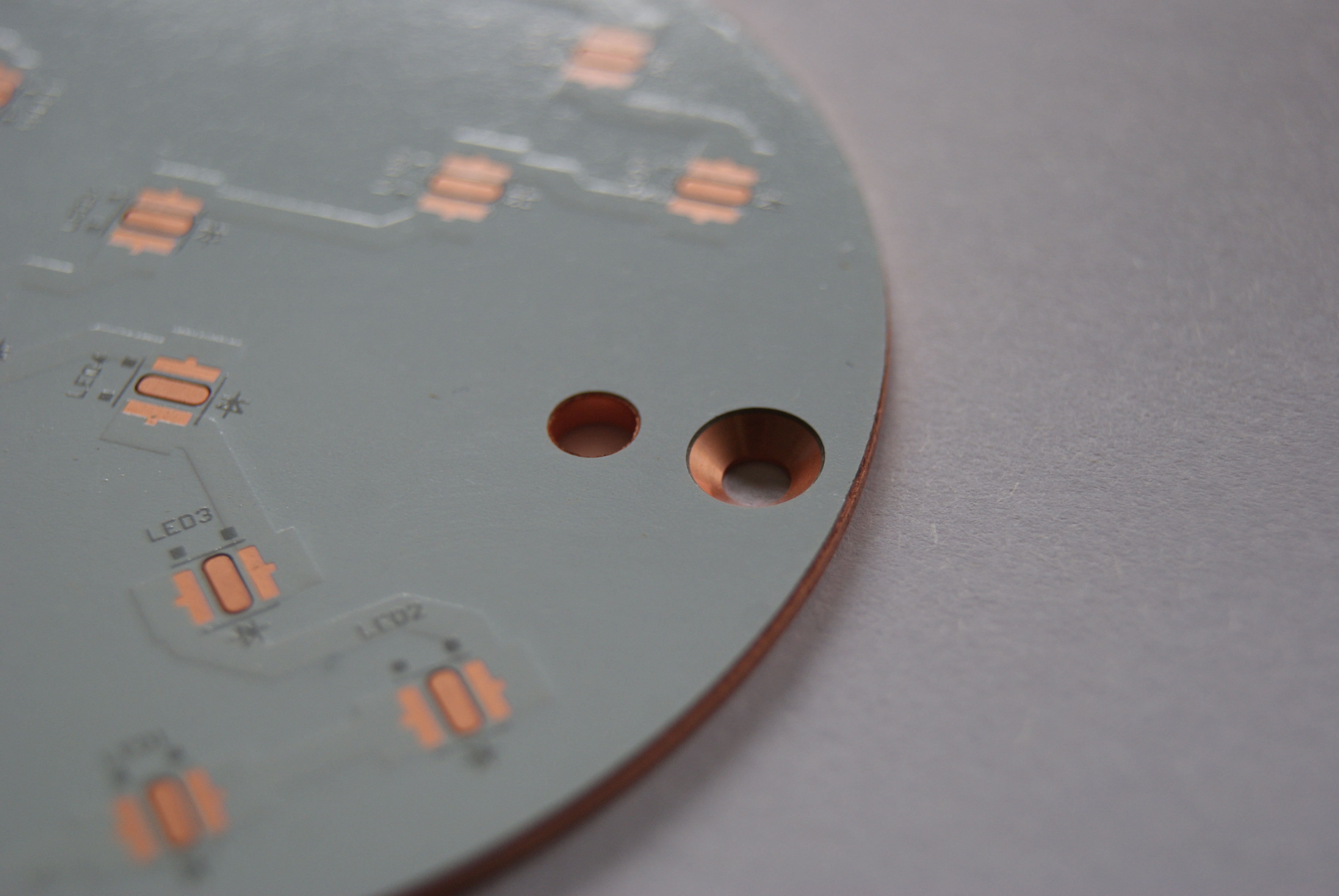

Metal core pcb structure

The structure of a metal core PCB sets it apart from standard FR4 boards. In a 400 watt copper base pcb, you get a copper layer combined with a metal backing. This design improves thermal conductivity and heat dissipation. The table below highlights the differences:

Feature | FR4 PCB | Metal Core PCB (MCPCB) |

|---|---|---|

Thermal Conductivity | Low (around 0.3W) | High (1.0W-4.0W, avg. 2.0W) |

Heat Dissipation | Via-based thermal relief | Built-in thermal relief |

Material Structure | Standard dielectric | Copper layer + metal backing |

Application Suitability | General use | High-power LED applications |

You benefit from built-in thermal relief in a metal core PCB. The copper layer and metal backing work together to spread heat quickly. This structure makes your 400 watt copper base pcb suitable for demanding environments, such as high-power LED lighting and industrial controls.

LT CIRCUIT specializes in advanced copper base pcb designs. You can rely on their expertise to select the right materials and structure for your application. Their solutions help you achieve better thermal management and higher reliability.

Design strategies with LT CIRCUIT

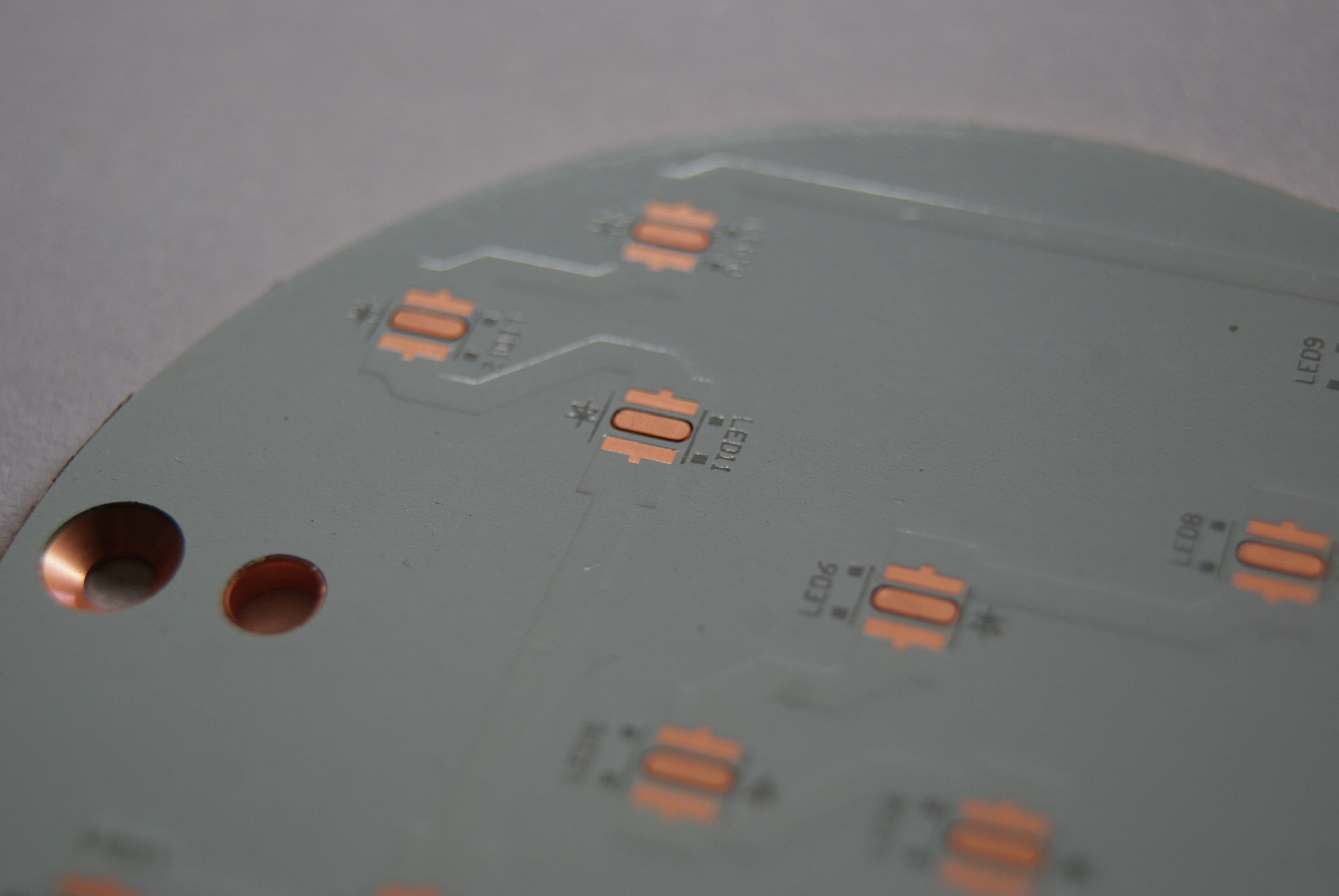

Layout and dielectric optimization

You can achieve excellent heat dissipation and electrical performance in copper core pcb designs by focusing on layout and dielectric optimization. Start with careful component placement. Place heat-generating parts away from each other to minimize hot spots. Use thermal interface materials, such as thermal greases or pads, to improve contact between components and the copper core pcb surface. This step reduces thermal resistance and helps transfer heat efficiently.

Thermal vias play a major role in high power applications. Place thermal vias directly under hot components. Use arrays of thermal vias to move heat from the surface to the inner copper layers. Add thermal vias around embedded parts and beneath power ICs. This creates efficient heat dissipation paths and helps distribute heat evenly across the copper core pcb.

The thickness of the dielectric layer affects both thermal and electrical performance. Thicker substrates improve mechanical strength and thermal management. They work well for power modules and high power applications that generate a lot of heat. Thinner substrates help reduce weight and size, which is important for compact applications. However, thinner dielectrics may increase signal loss in high-frequency designs. You need to balance these factors based on your application.

LT CIRCUIT offers a wide range of customization options for copper core pcb designs. You can choose copper layers from 1 to 3oz, dielectric thickness from 50 to 200μm, and surface finishes like ENIG or HASL. For complex applications, you can select up to 20 layers, copper weights up to 6oz, and large board sizes for demanding power modules. These options help you match the copper core pcb to your specific application needs.

Tip: Always consult with LT CIRCUIT’s experts to select the right dielectric thickness and copper weight for your application. This ensures optimal performance and long-term reliability.

Balancing thermal management and performance

You need to balance thermal management and performance when designing copper core pcb for high power applications. Copper core pcb offers excellent heat dissipation, which is essential for high-power electronics. However, increasing copper thickness can make the design more complex and affect electrical conductivity.

Here are some strategies to help you achieve the right balance:

Design the central layer with maximum copper thickness and balance the outer layers to prevent warping.

Use grid patterns for wide copper areas to avoid density mismatches and minimize bow and twist.

Place power planes symmetrically within the layer stackup to reduce electromagnetic interference and maintain signal integrity.

Maintain uniform copper distribution in core and prepreg layers to enhance thermal conductivity and stability.

Couple high-frequency signal layers tightly with adjacent ground planes to minimize EMI.

Add copper isolation zones around power devices for EMI shielding and to balance local thermal density.

Use a composite structure of surface copper, thermal vias, and backside copper blocks for high-heat sources.

Adjust dielectric thickness based on layer adjacency to maintain impedance and reduce capacitive coupling.

Copper’s high thermal conductivity, about 385 W/mK, makes it ideal for dissipating heat in high power applications. You must consider the trade-offs between thermal management and electrical performance. Increasing copper thickness improves thermal performance but may complicate manufacturing. Always aim for symmetry in your layer stackup and keep power planes balanced to preserve signal integrity.

LT CIRCUIT’s high TG copper core pcb products offer superior heat resistance and mechanical strength. These features prevent warping or cracking under stress, making them suitable for demanding applications like power modules and high-power electronics. You can rely on LT CIRCUIT to deliver copper core pcb solutions that meet the highest standards for reliability and performance.

Real-world copper base pcb examples

You can see the benefits of copper core pcb in real-world applications. Many industries use copper core pcb for power modules, LED lighting, and high power applications. These boards deliver strong performance and reliability.

Performance Aspect | Improvement Description |

|---|---|

Thermal Management | Copper core pcb dissipates heat more efficiently, reducing the need for extra cooling. |

Electrical Conductivity | Thick copper layers provide low-resistance paths, improving efficiency and reducing power loss. |

Mechanical Strength | Copper core pcb adds structural integrity, making boards resistant to bending and warping. |

Reliability | Better thermal management and strength lead to longer lifespan and less maintenance. |

Corrosion Resistance | Copper’s natural resistance to corrosion increases durability in tough environments. |

For example, a customer in the automotive industry needed a copper core pcb for a power module in electric vehicles. LT CIRCUIT provided a custom solution with 4oz copper layers and optimized dielectric thickness. The result was improved thermal performance, higher efficiency, and long-term reliability. Another case involved high-power LED lighting, where the copper core pcb reduced hot spots and extended the product’s lifespan.

LT CIRCUIT’s copper core pcb products meet or exceed industry standards for high power applications. You get improved heat resistance, strong mechanical strength, and reliable performance in demanding environments. These advantages make copper core pcb the preferred choice for applications that require both high performance and durability.

Application-based advice: Always match your copper core pcb design to the specific needs of your application. Consider factors like current load, operating temperature, and required board size to achieve the best results.

To balance heat dissipation and performance, you should use thick copper traces, thermal via arrays, and the right board materials. Optimize your layout for better airflow. Partnering with LT CIRCUIT gives you high-frequency performance, support for dense layouts, and durability in harsh environments.

Benefit | Description |

|---|---|

High-Frequency Performance | Maintains signal integrity above 60GHz for modern applications. |

Dense Component Layouts | Supports complex, compact high-power designs. |

Durability | Withstands extreme automotive and aerospace conditions. |

FAQ

What makes a metal core pcb better for power applications than an aluminum pcb?

You get higher thermal conductivity with a metal core pcb using copper. This helps your circuit board handle more power and heat than an aluminum pcb in demanding environments.

How do you choose the right supplier for copper mcpcb and metal core pcb?

You should look for a supplier with proven experience in copper mcpcb and metal core pcb production. LT CIRCUIT offers advanced pcb solutions for power and reliability.

Can you use metal core pcb for high-frequency power circuits?

You can use metal core pcb for high-frequency power circuits. Copper layers in the pcb help maintain signal integrity and manage heat, making your circuit board more efficient.

Tip: Always check the supplier’s certifications before ordering any copper mcpcb or metal core pcb for your power project.

See Also

Key Strategies for Creating High Current Copper PCBs

The Advantages of Ceramic PCBs in Heat Management

Investigating Thermal and Electrical Performance of Aluminum PCBs

Comprehensive Guide to Manufacturing Heavy Copper Multilayer PCBs

Seven Essential Quality Control Measures for Heavy Copper PCB Assembly